Heat exchange and heat storage device for biogas power generation high-temperature exhaust air

A biogas power generation and heat device technology, which is applied to household heating, heating methods, household heating and other directions, can solve problems such as corrosion of heat exchange devices, reduce outlet temperature, enhance heat exchange capacity, and stabilize the process of heat absorption and release. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

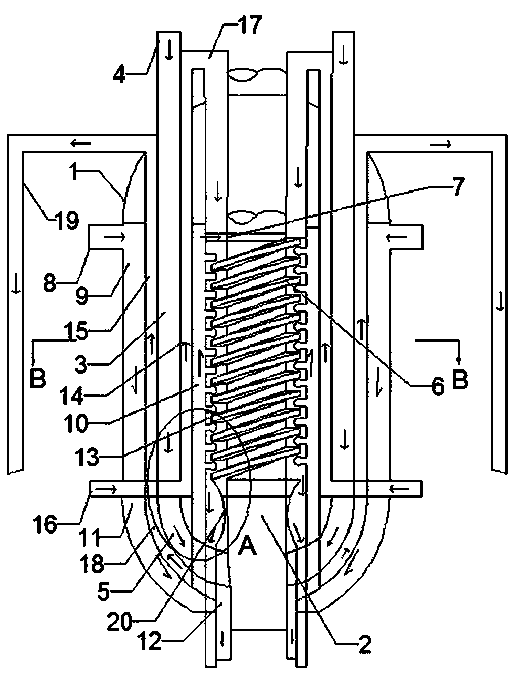

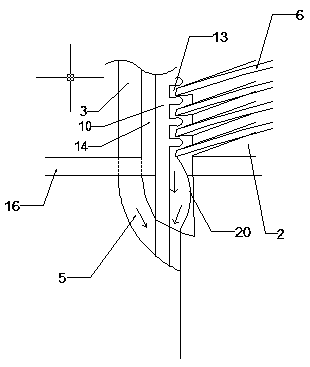

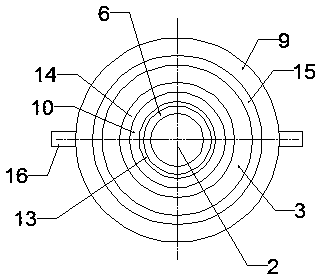

[0031] A heat exchange and heat storage device suitable for high-temperature exhaust gas in biogas power generation, such as Figure 1-3 As shown, it includes a heat exchange tank 1 , a water storage part arranged in the heat exchange tank 1 , and a heat source delivery part and a heat storage part sleeved in the water storage part.

[0032] The high-temperature waste heat and exhaust gas enter the heat exchange and storage device, and exchange heat with the heat storage medium and cold water. The hot flue gas first contacts the heat storage medium, and the heat storage medium first absorbs a large amount of heat, and gradually absorbs the heat through circulation. For storage, the slightly heated heat storage medium first exchanges heat with cold water to perform a further preheating function, and then the heat storage medium exchanges heat with flue gas again, thereby realizing the heat storage and heat exchange functions of the device.

[0033] The high-temperature waste he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com