Chemical adsorption type heat refrigeration system employing alkaline-earth metal halide

An alkaline earth metal, chemical adsorption technology, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of affecting refrigeration effect, poor effect, unbalance, etc., to improve adsorption refrigeration capacity, high control accuracy , The effect of improving cooling capacity and cooling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

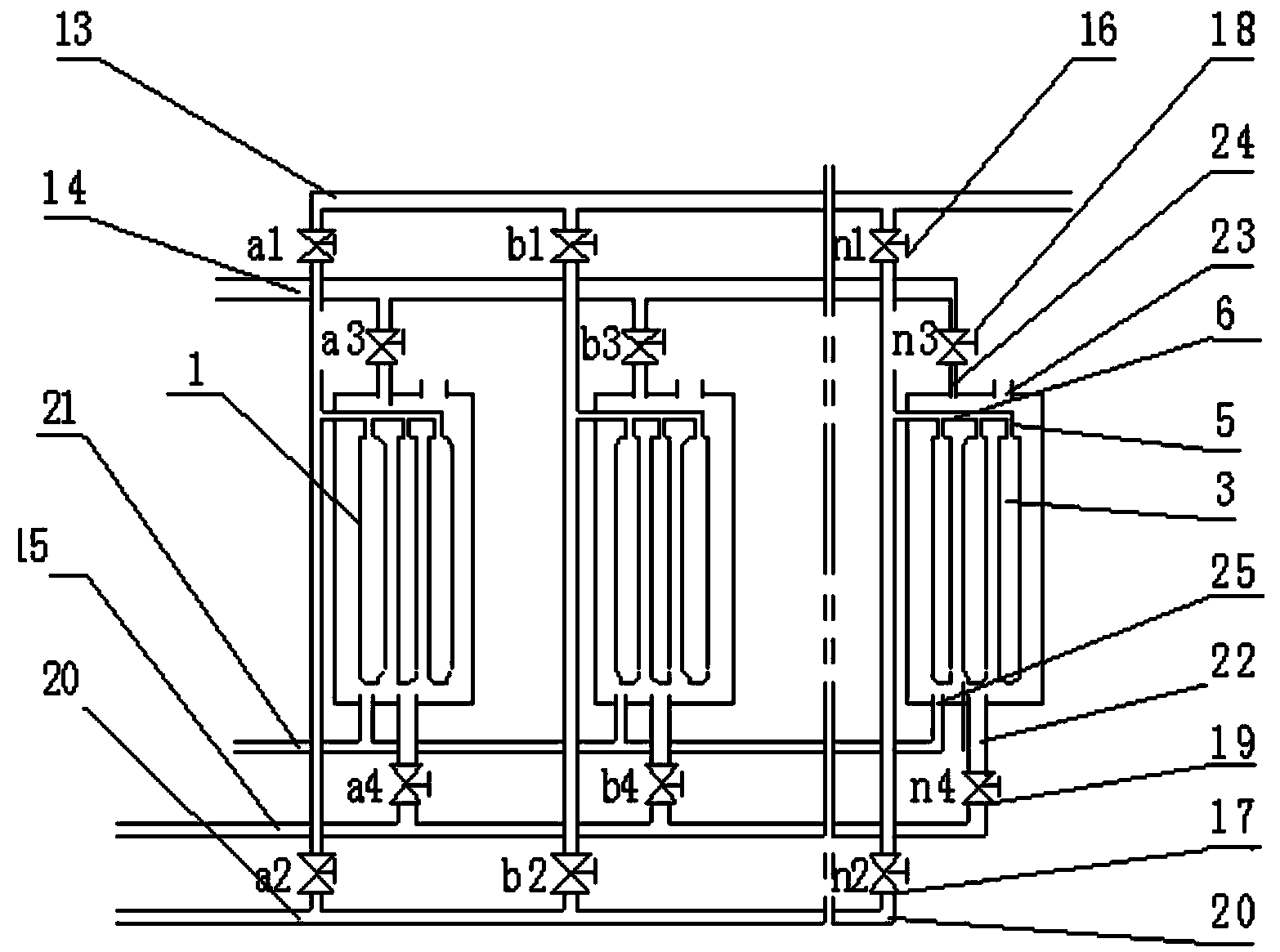

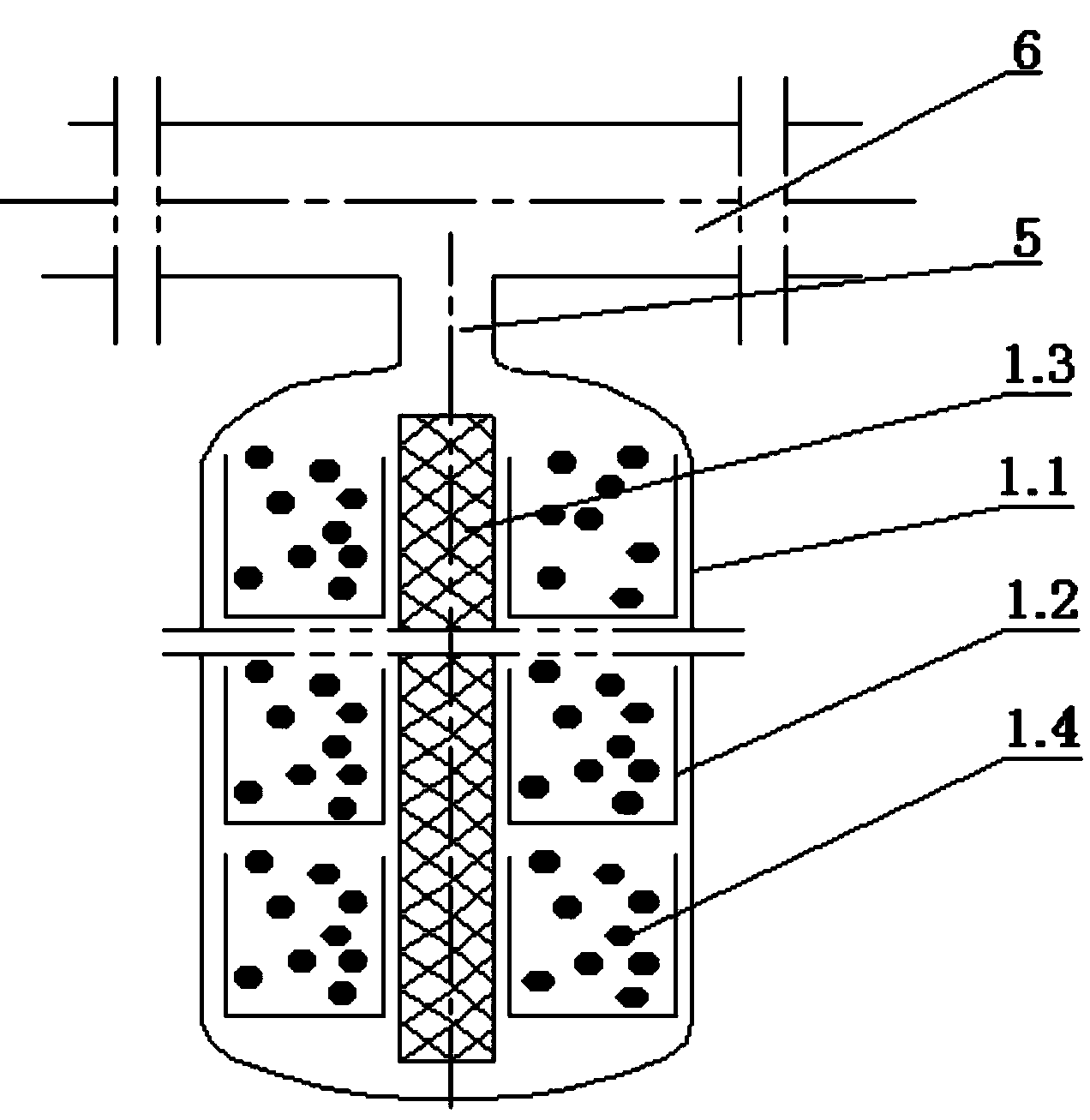

[0031] Such as figure 1 As shown, the adsorption outer tube 1.1 in the unit tube 3 of the adsorption bed is the main material of IG18Ni9Ti stainless steel seamless steel pipe of Φ70×2×500mm, the tray 1.2 is made of a 0.4mm pure aluminum plate into a ring-shaped container, and the tray 1.2 is filled with alkaline earth metal halides The adsorbent is 500 grams, and each group of adsorption beds is composed of four adsorption bed unit tubes 3 .

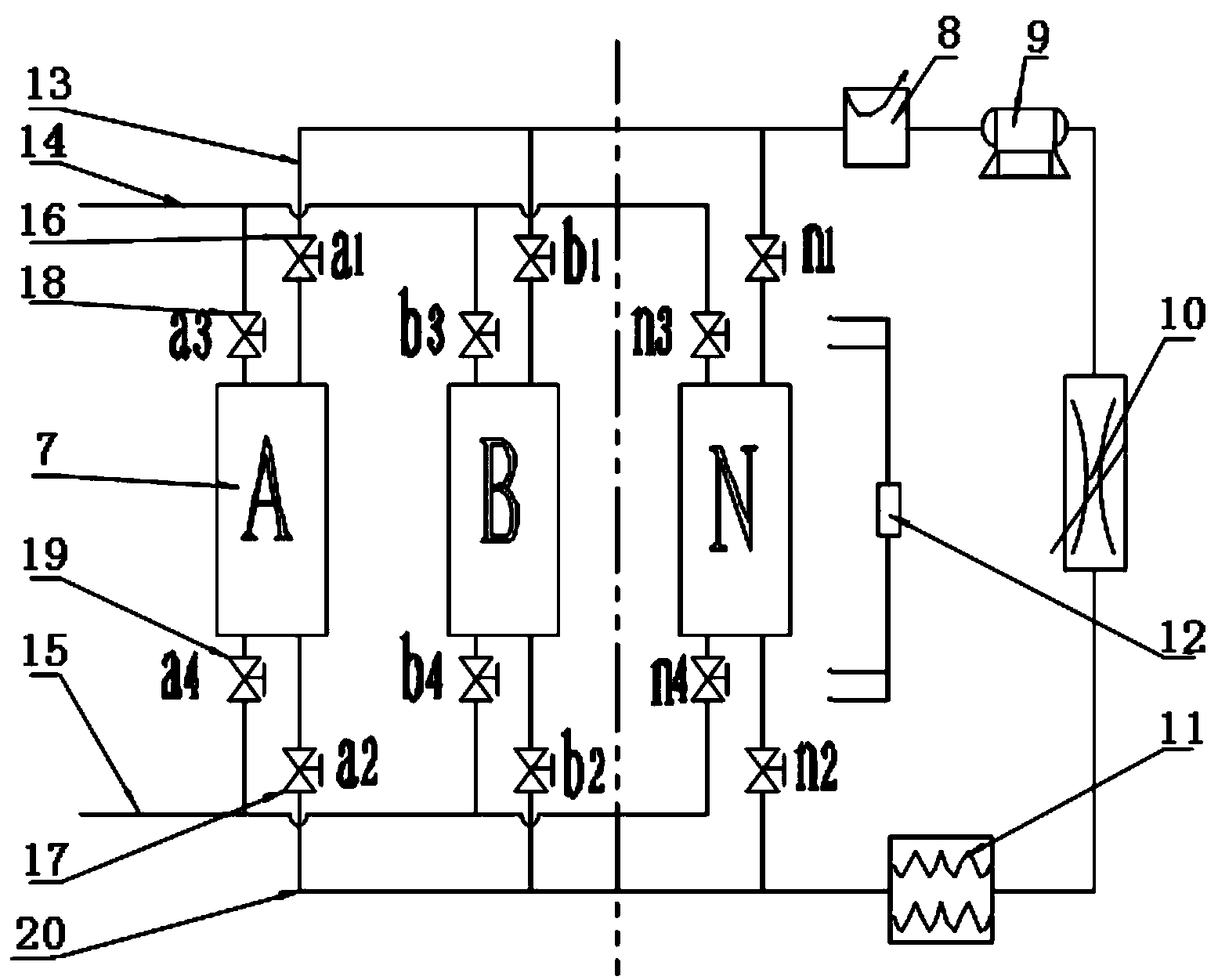

[0032] Such as figure 2 , the heat source is a 7kw×2 electric low-pressure steam generator, which can output 5kg of saturated steam with a pressure of 0.3Mpa per hour. The condenser 8 is an ethylene glycol ice bucket with a coil as an evaporator, with a volume of 20 liters.

[0033] Such as image 3 , using low-pressure steam as the heat source, so the heat source inlet pipeline 15 is placed above the adsorption bed group 7, and the heat source outlet 23 is placed at the bottom of the adsorption bed group 7. The goal of this prototyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com