Patents

Literature

50results about How to "Unobstructed access" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

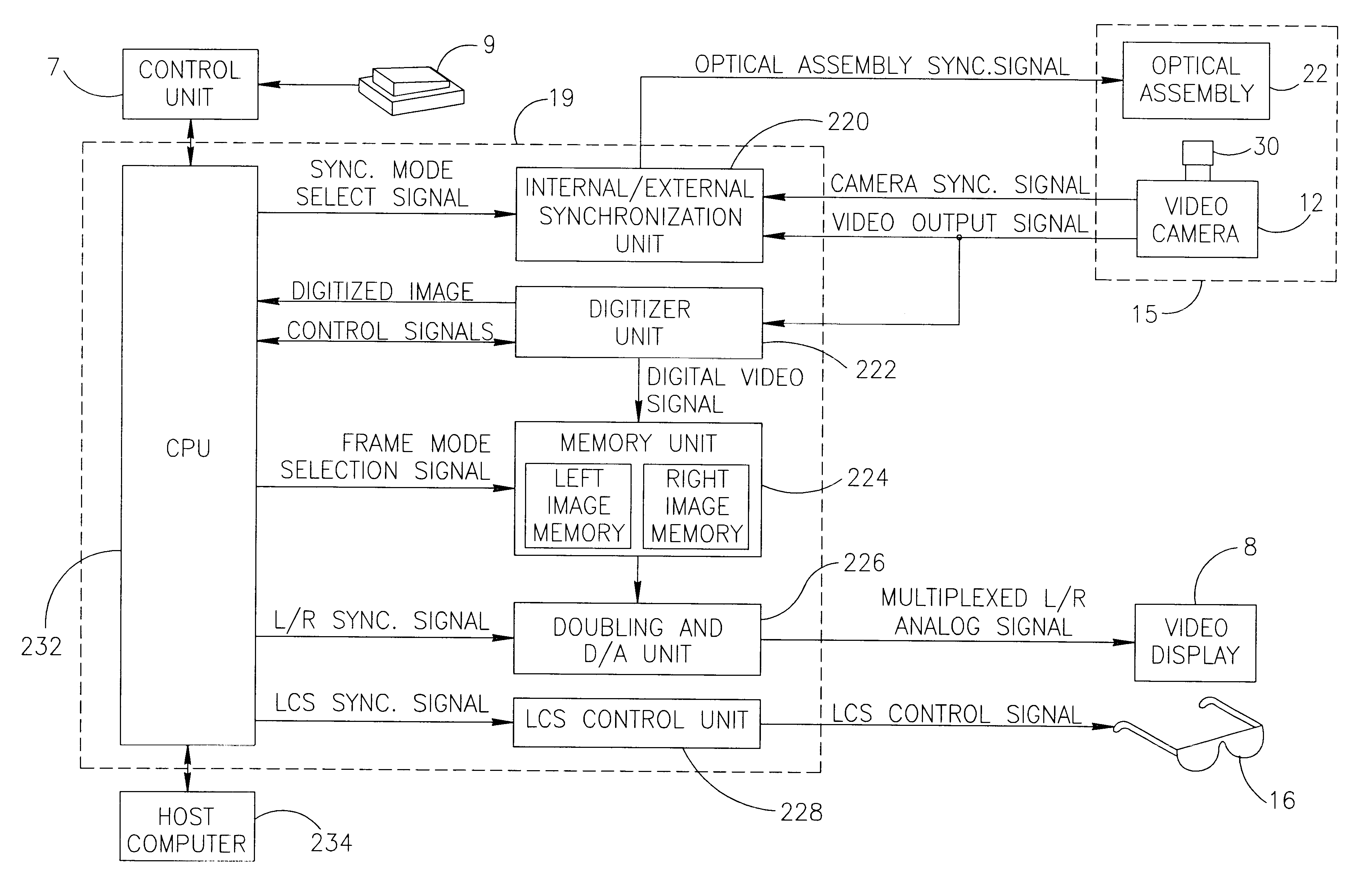

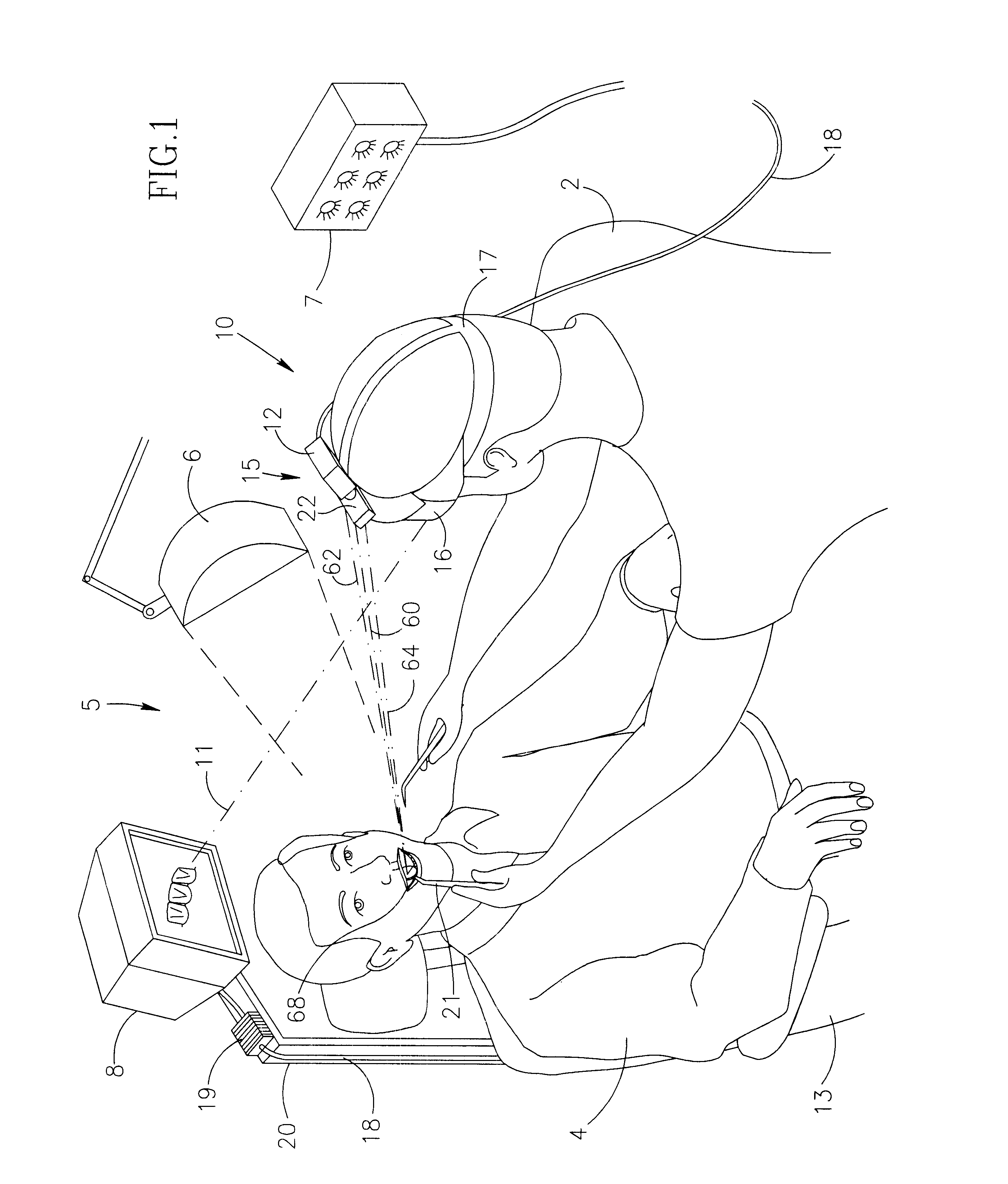

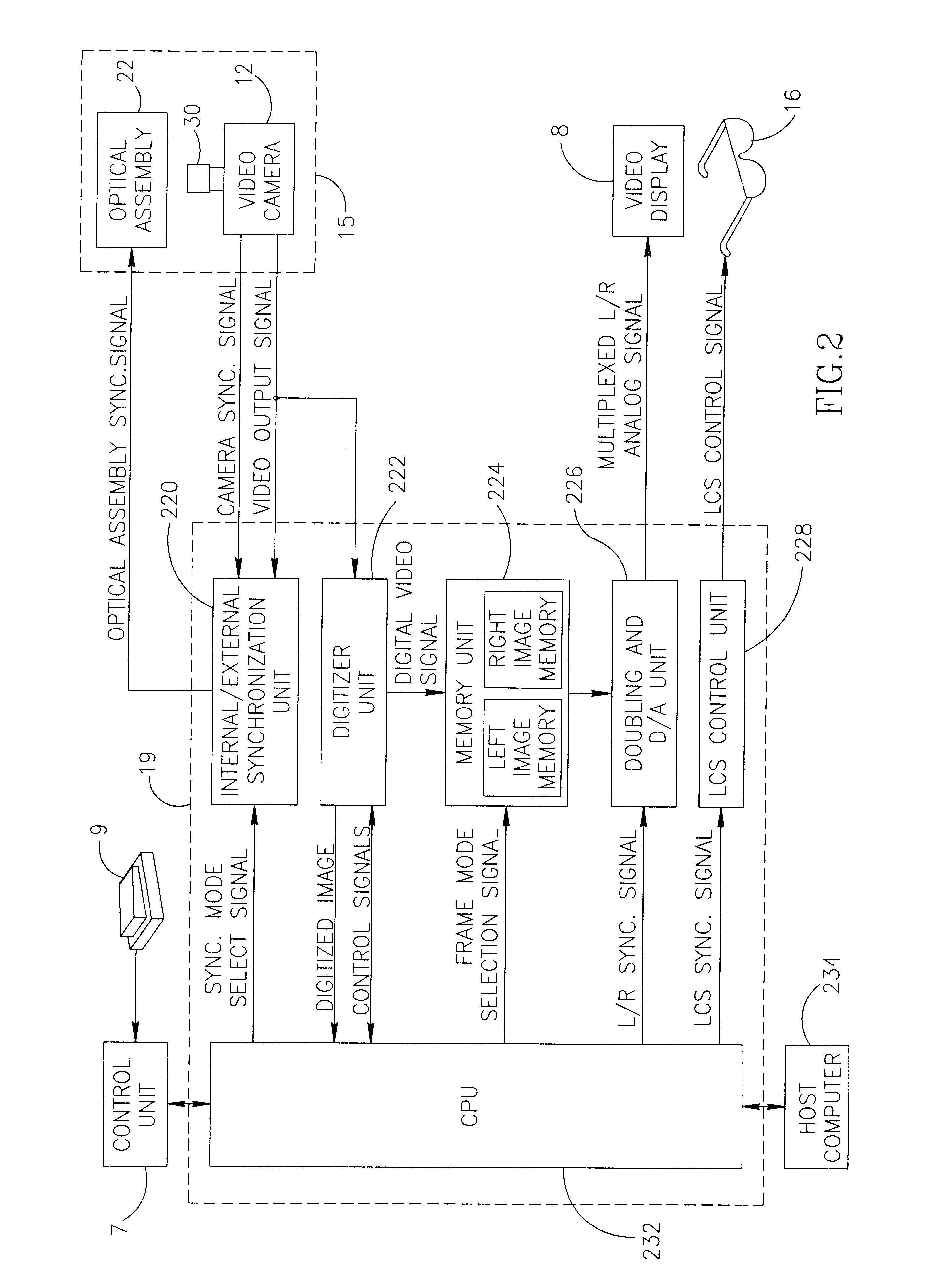

Video system for three dimensional imaging and photogrammetry

InactiveUS6414708B1Eliminate needUnobstructed accessSurgeryEndoscopesStereoscopic videoDisplay device

A video system for providing an operator with a three dimensional stereoscopic image of the oral cavity of a patient is provided. The system includes an imaging unit for providing at least two stereoscopic images of the oral cavity, a pair of switchable shutters for alternatingly blocking the view of the left eye and the right eye of the operator, a synchronizing unit for synchronizing the switching of the pair of switchable shutters with the rate of generation of the two stereoscopic video images by the imaging unit and a video display for displaying the two stereoscopic images.

Owner:DENTOP SYST

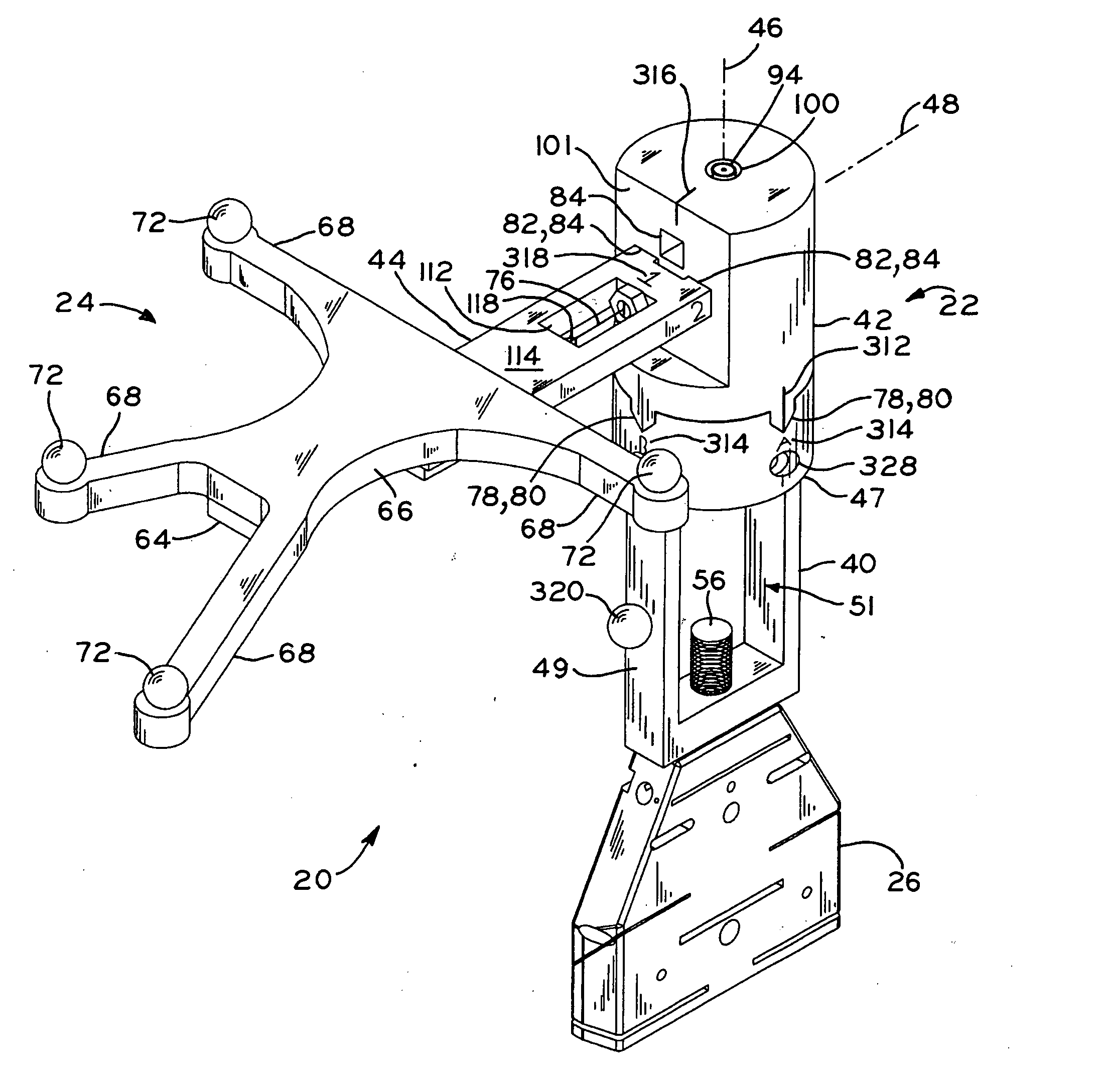

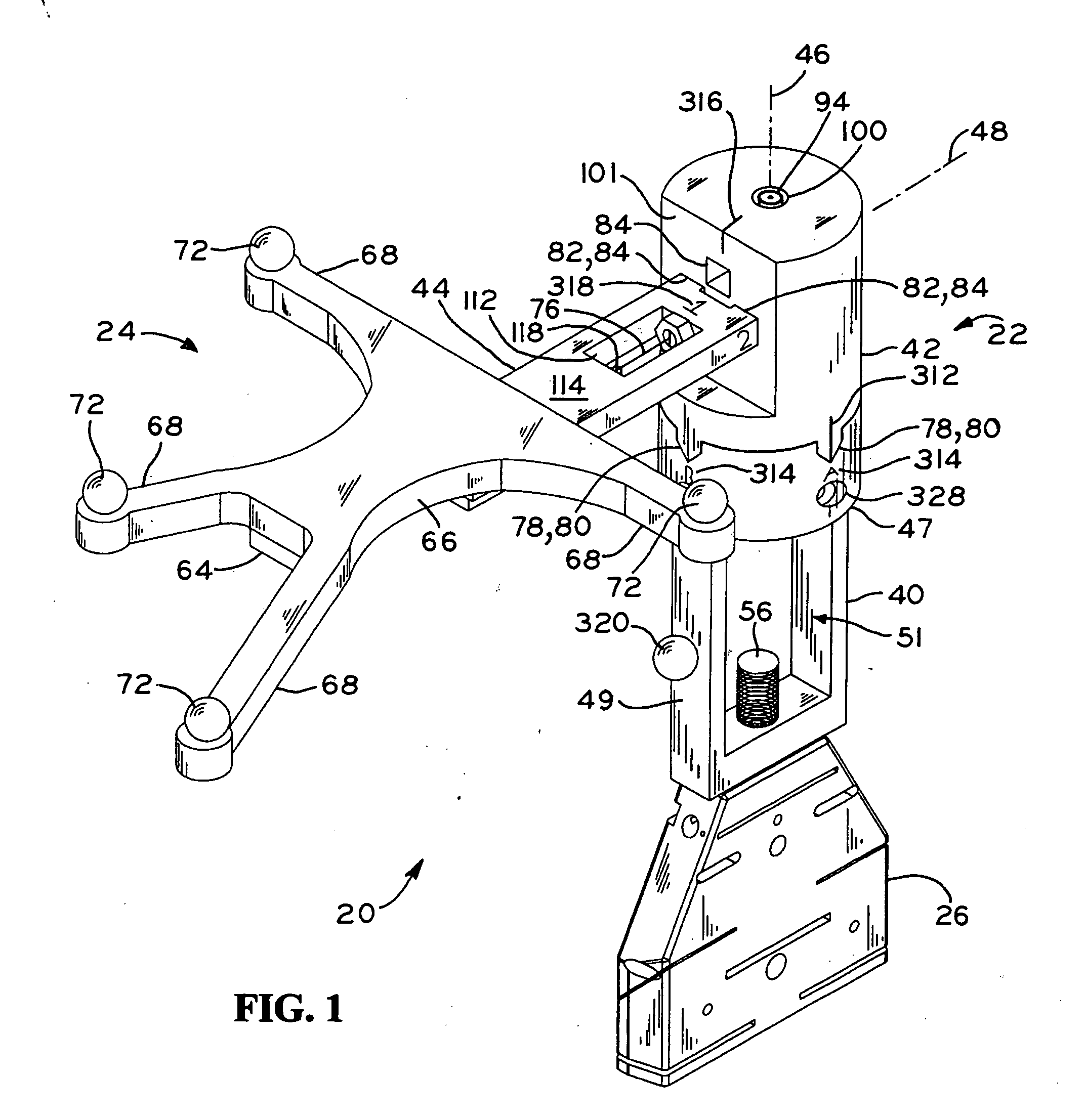

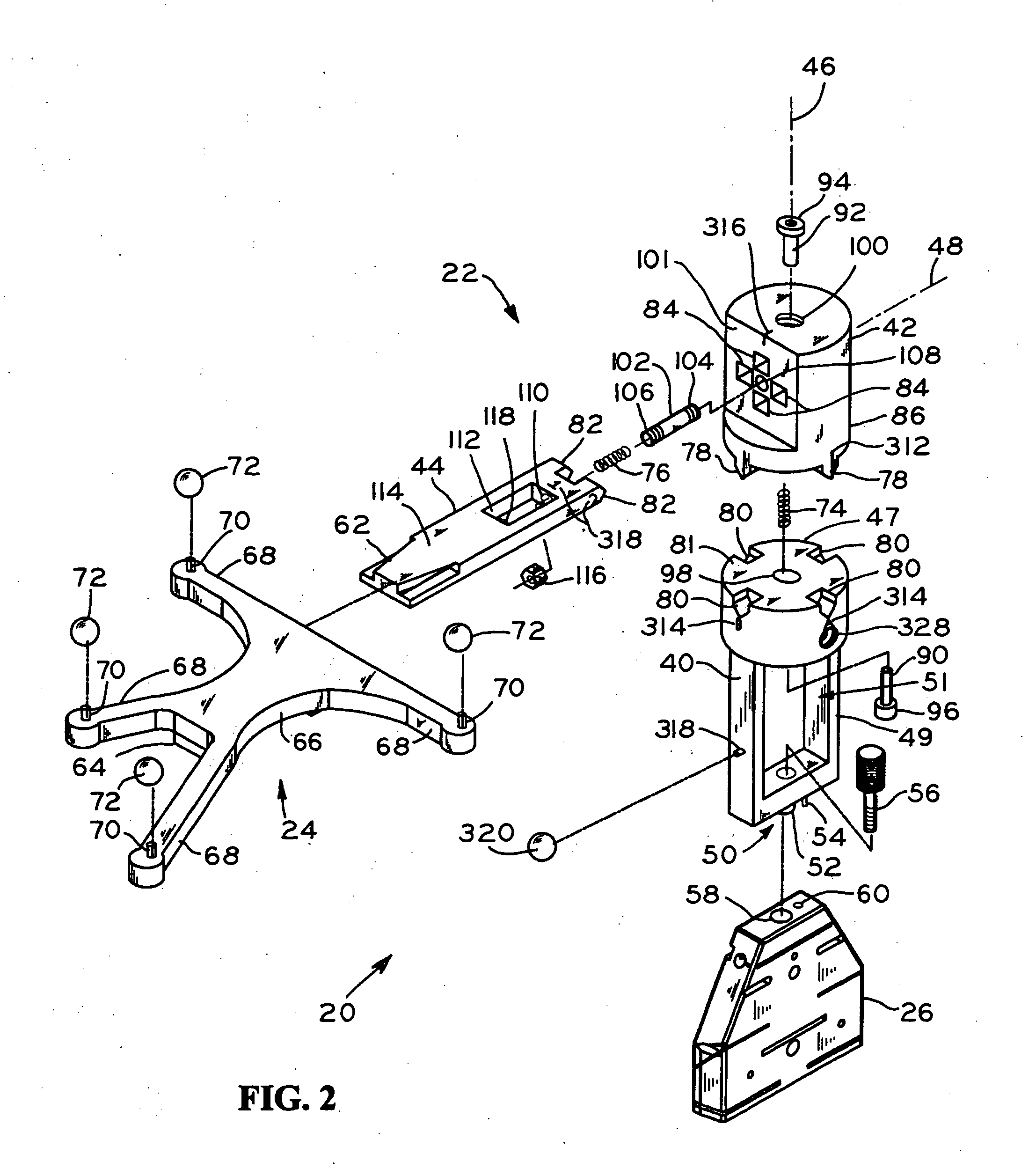

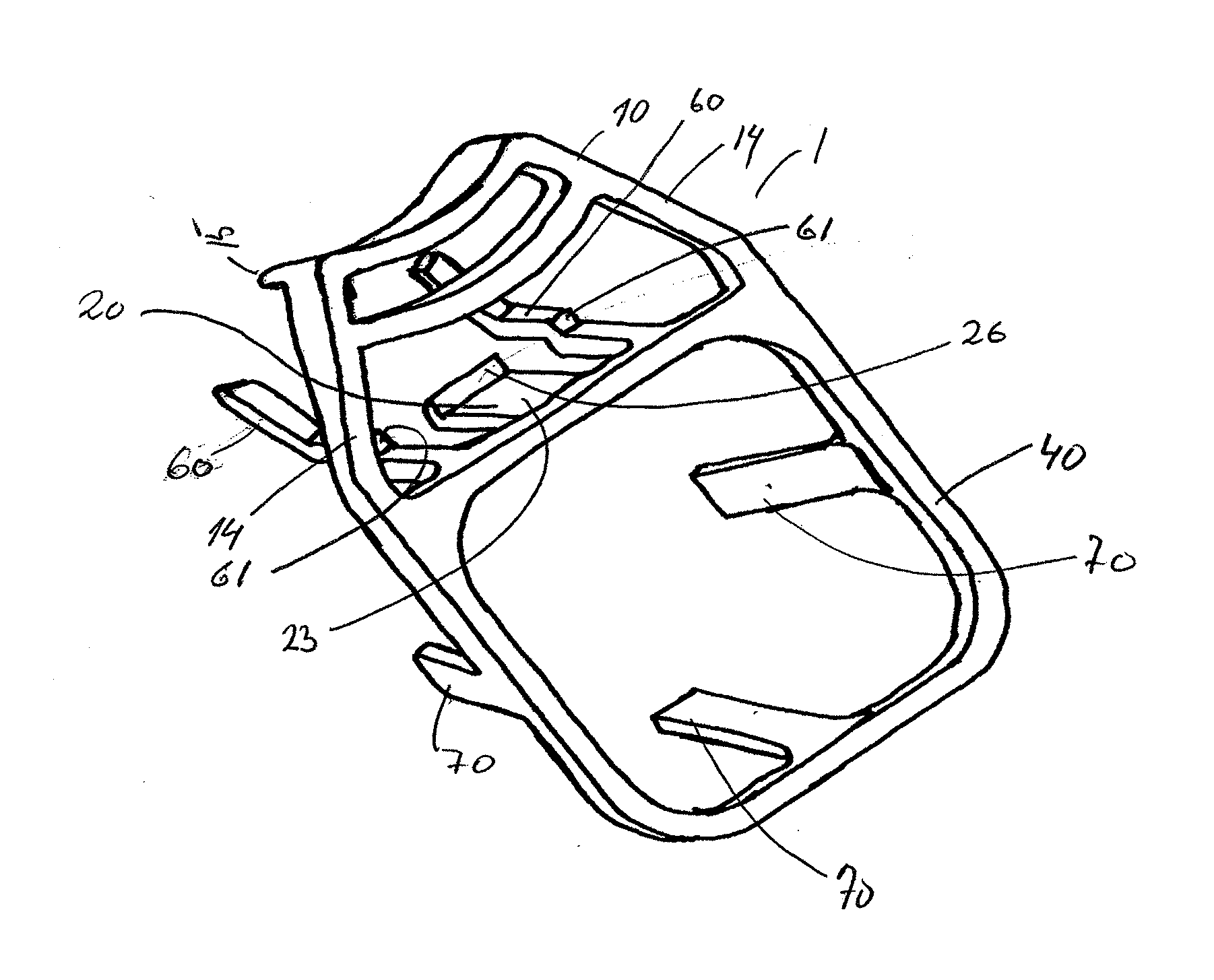

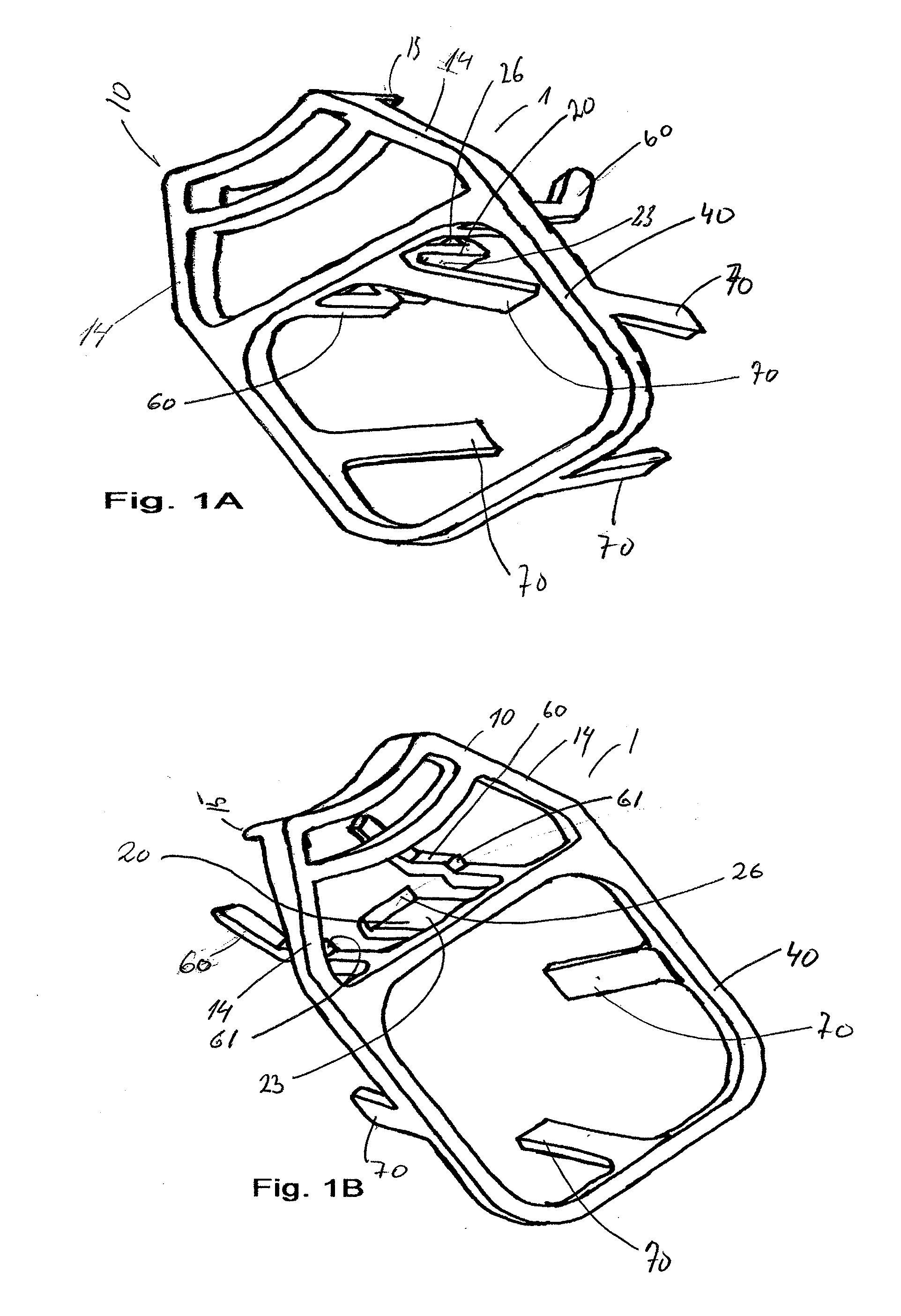

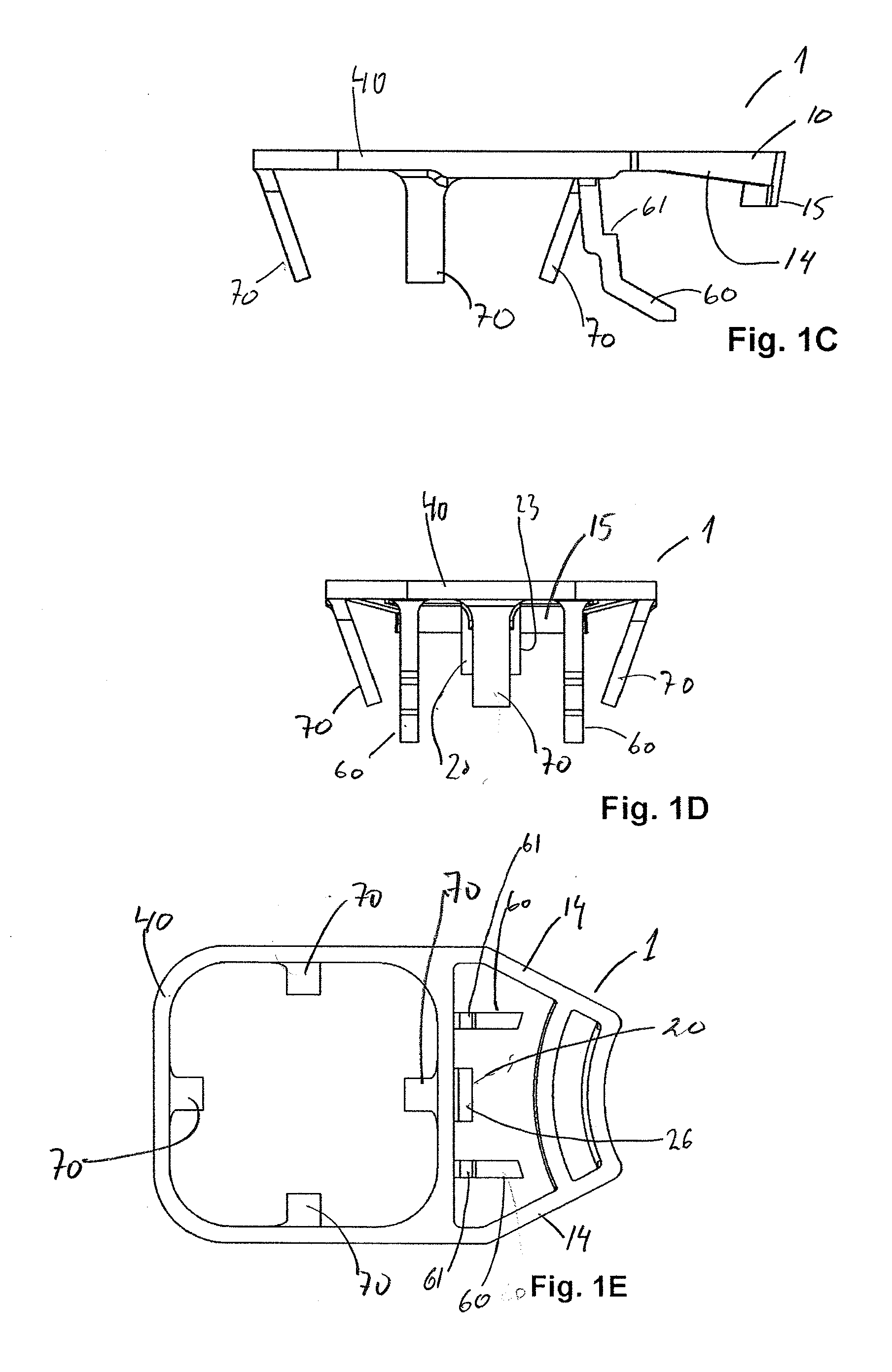

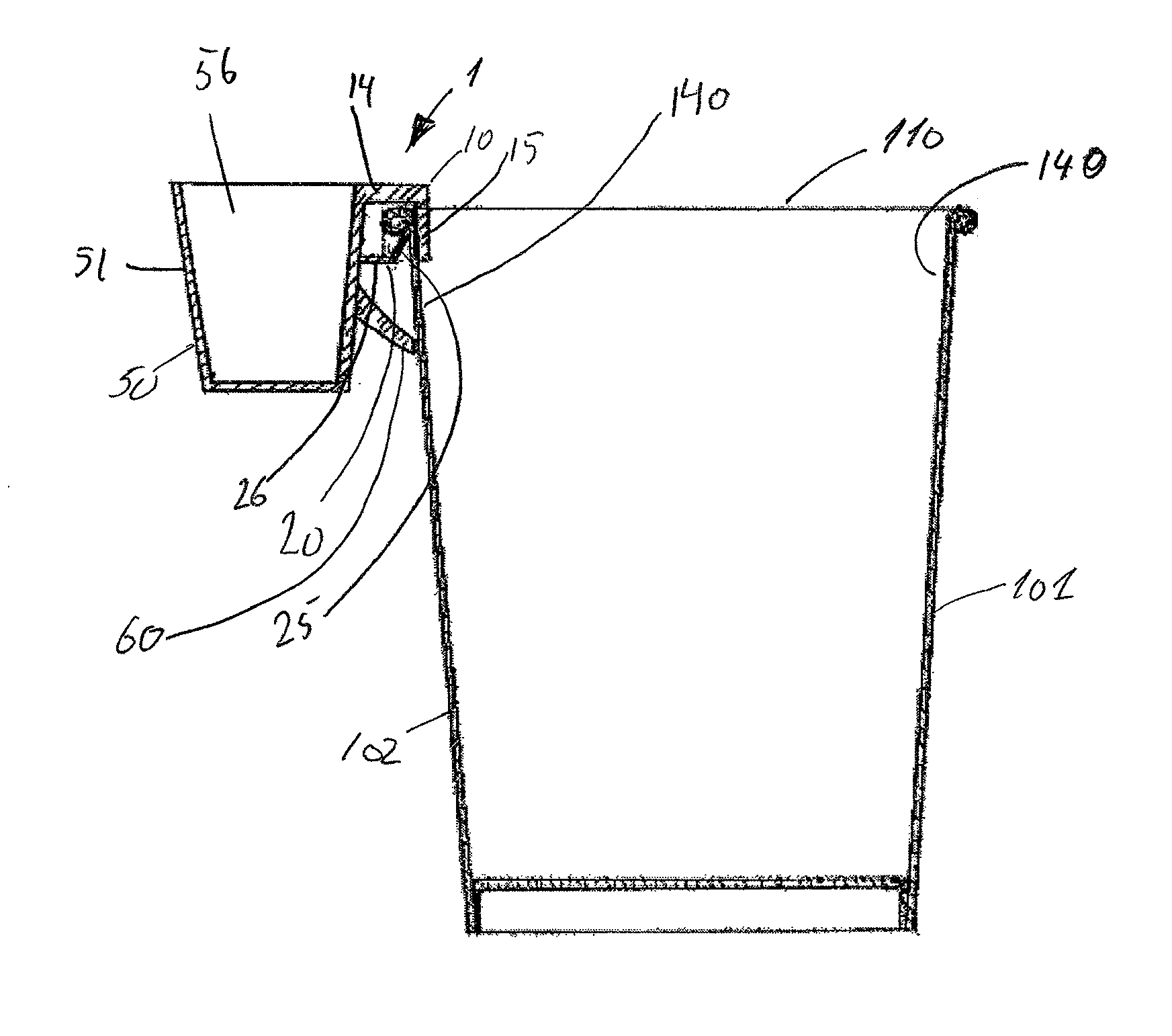

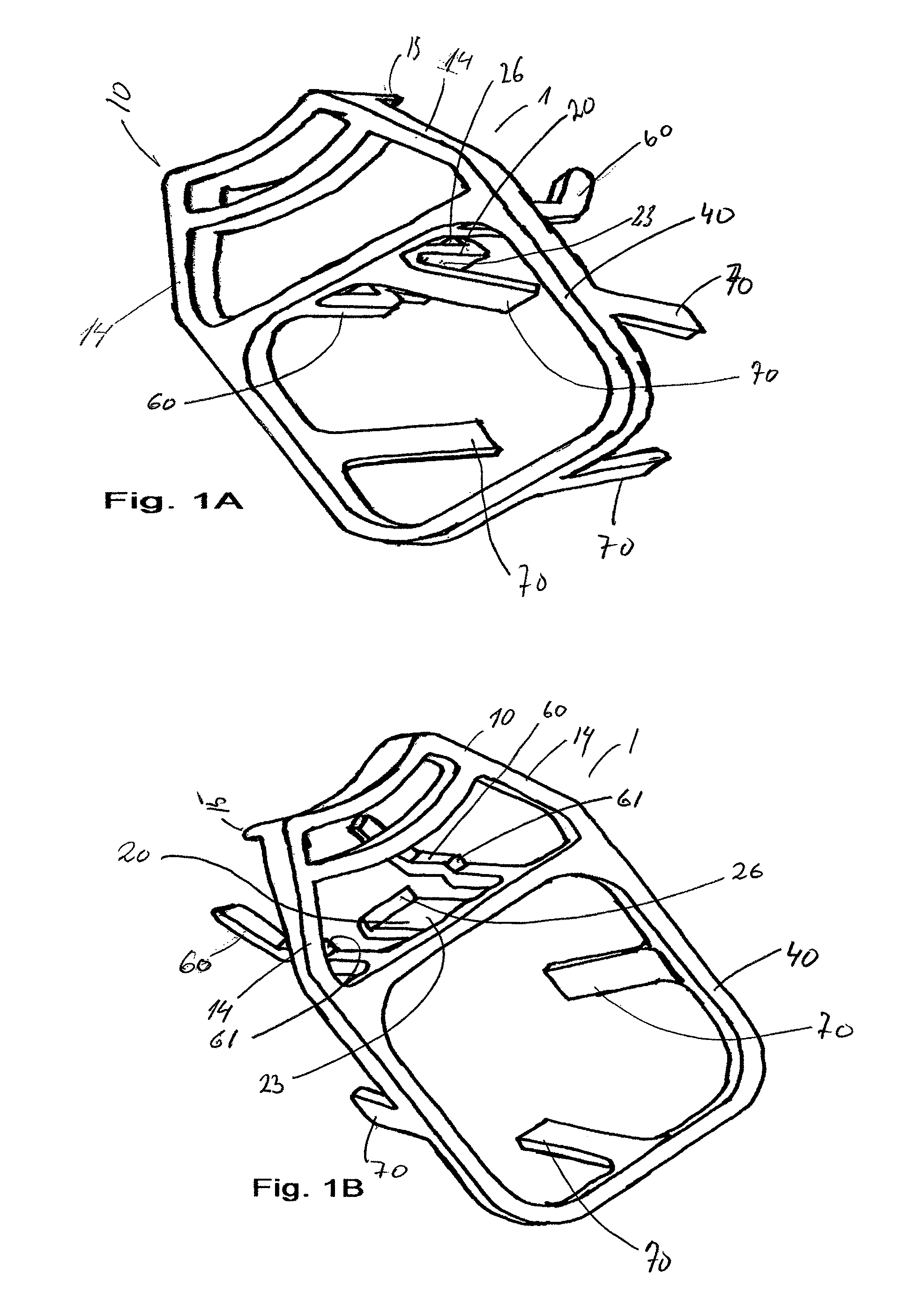

Universal support arm and tracking array

InactiveUS20050215888A1Precise definitionAdjustable positionDiagnostic markersDiagnostic recording/measuringCouplingLocation tracking

A universal tracking apparatus for a surgical instrument, the tracking apparatus including a support arm and tracking array. The support arm allows position adjustment of the tracking array between a number of predefined orientations relative to the instrument which are recognizeable and registerable in the navigation system. The support arm may be coupled with multiple types of surgical instruments and used to accurately define the position of the instrument in an anatomical model generated by the navigation system. The adjustable coupling between the tracking array and the support arm allows the surgeon to determine which orientation is best suited for the surgical application and also allows the surgeon to adjust the position of the tracking array during a surgical procedure without the need to re-register the tracking apparatus. The tracking array may also include at least one repositionable reference element to allow a single tracking array to be configured for use with a plurality of different instruments, wherein differing geometries defined by the tracking array and corresponding to particular instruments are recognizable and registerable by the navigation system.

Owner:ZIMMER TECH INC

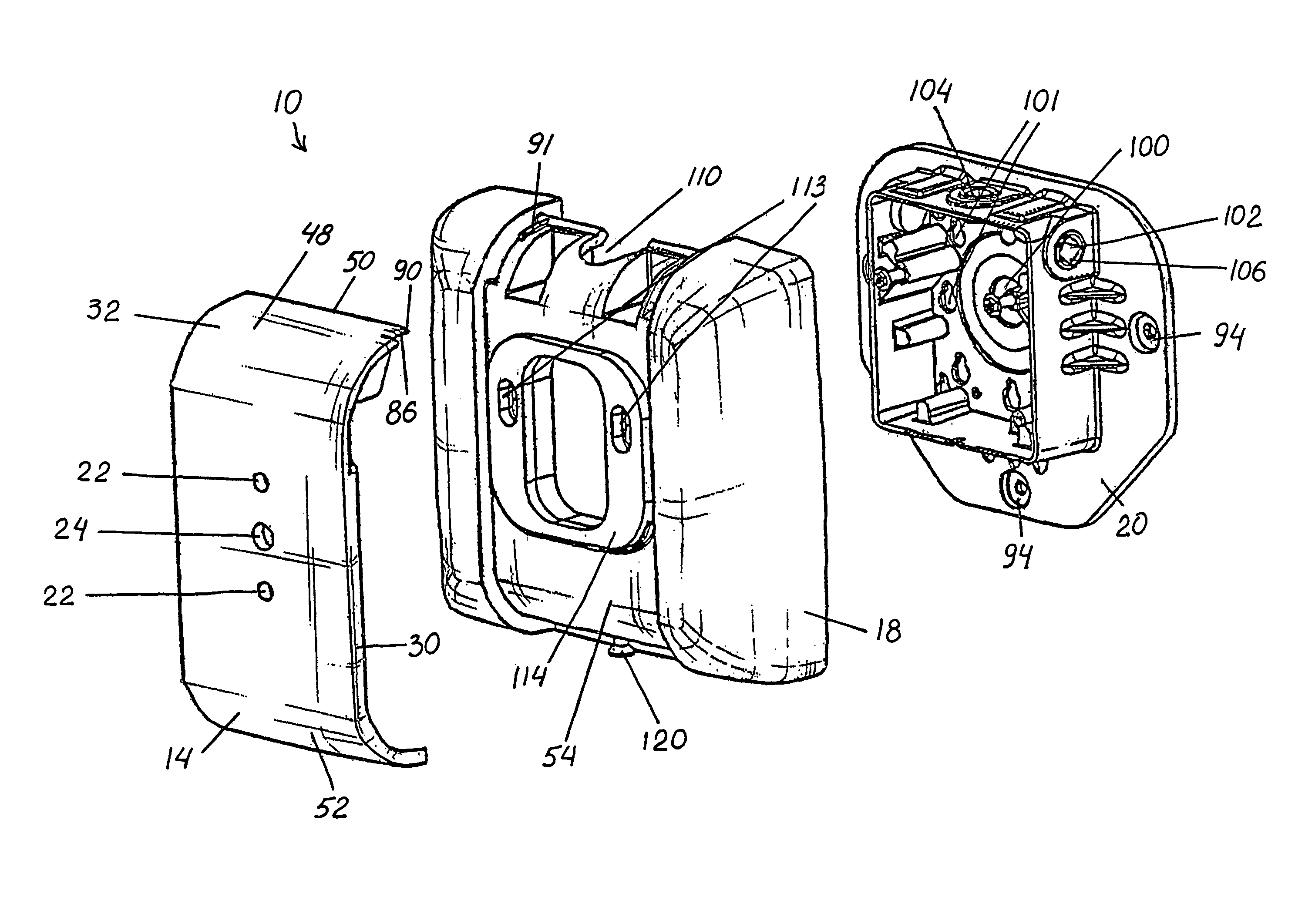

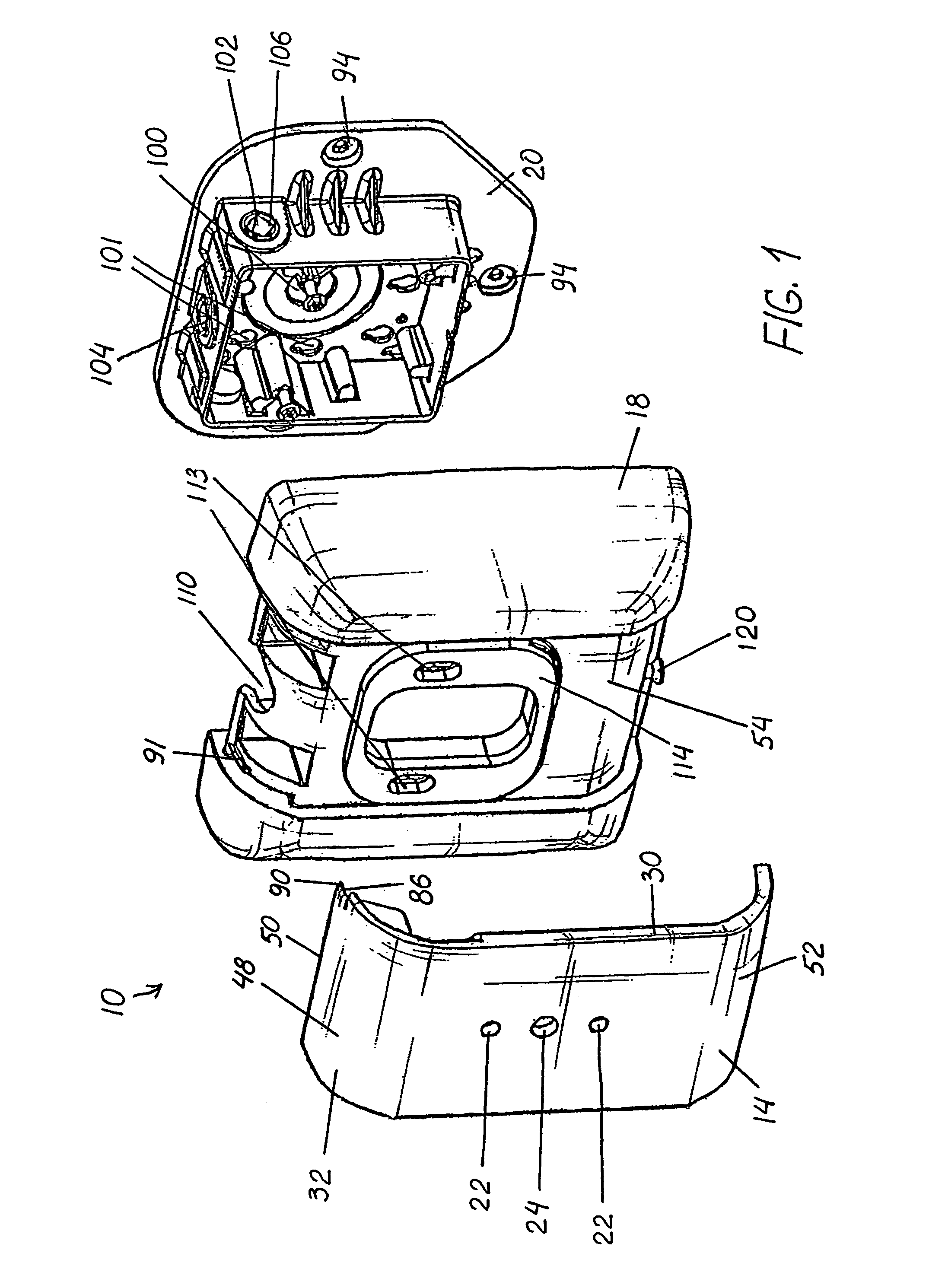

Wall mount with detachable support panel

ActiveUS7401939B2Reliable electrical connectionEasy accessNon-electric lightingLighting support devicesEngineeringWall mount

An apparatus for mounting a lighting fixture is provided having a mount housing with at least one pivot portion and a support panel with at least one hook portion, the support panel being attached to the mount housing in a manner where the hook portion can slide and pivot with respect to the pivot portion. The pivot portion includes a rail, a tab-slot and a tab-rest, the tab-slot and tab-rest being adjacent to the rail and the hook portion has a hook member and a tab-stand adjacent to the hook member. The support panel is free to move between an open and a closed position and, preferably, detachable from the mount housing. A method for mounting a lighting fixture is also disclosed.

Owner:IDEAL IND LIGHTING LLC

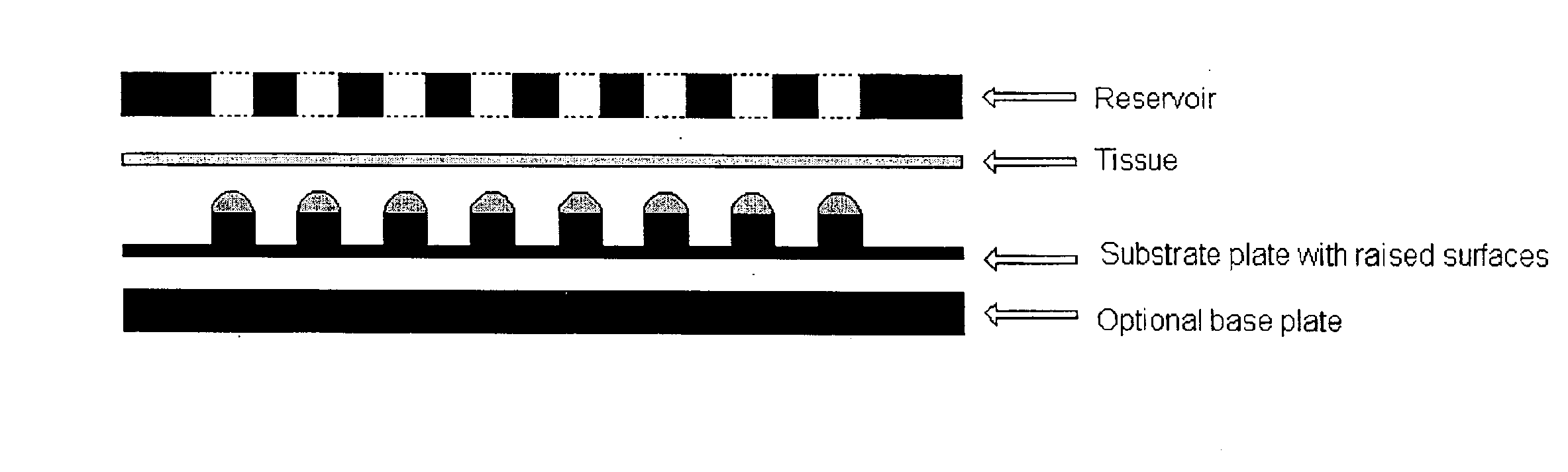

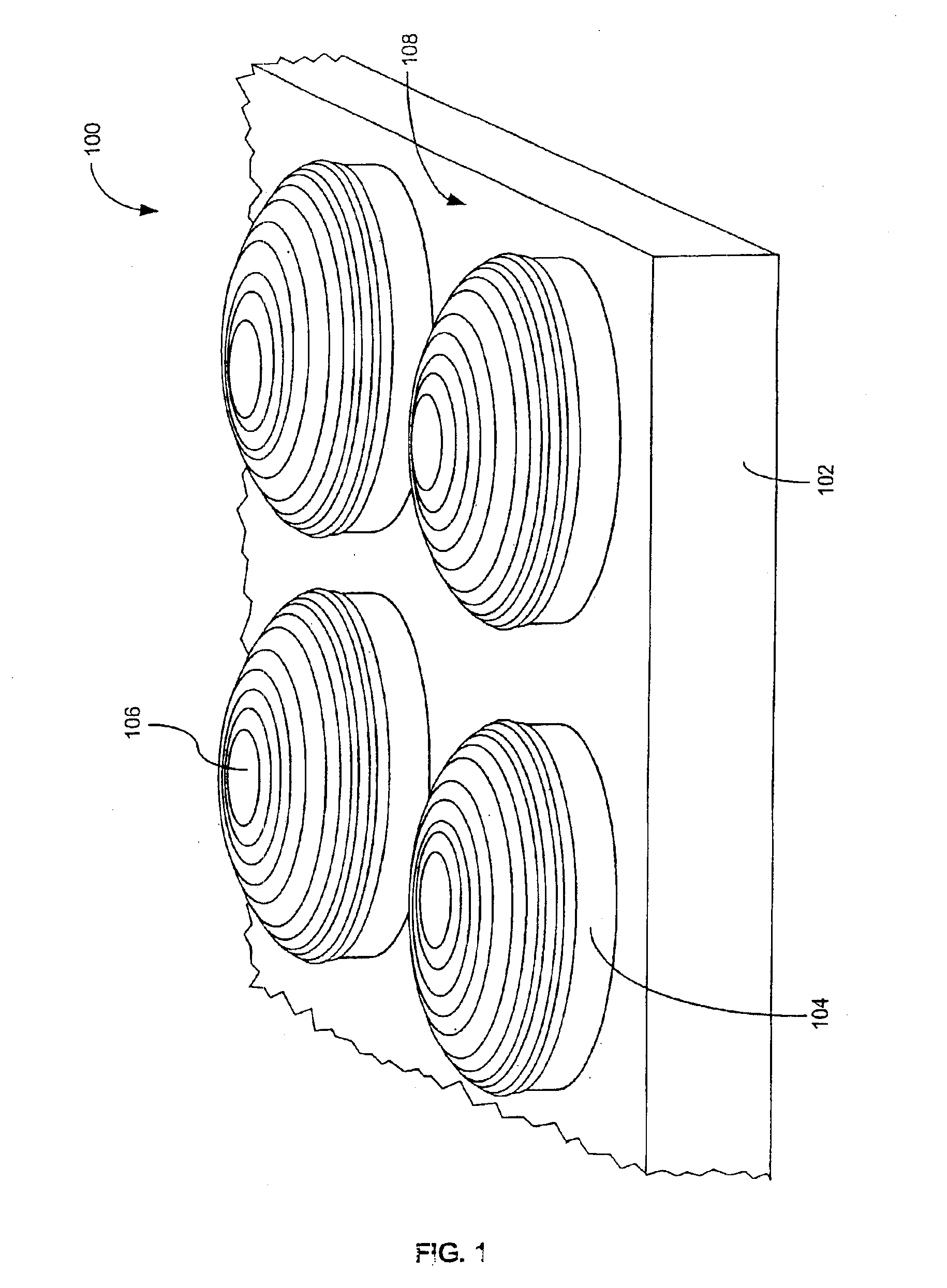

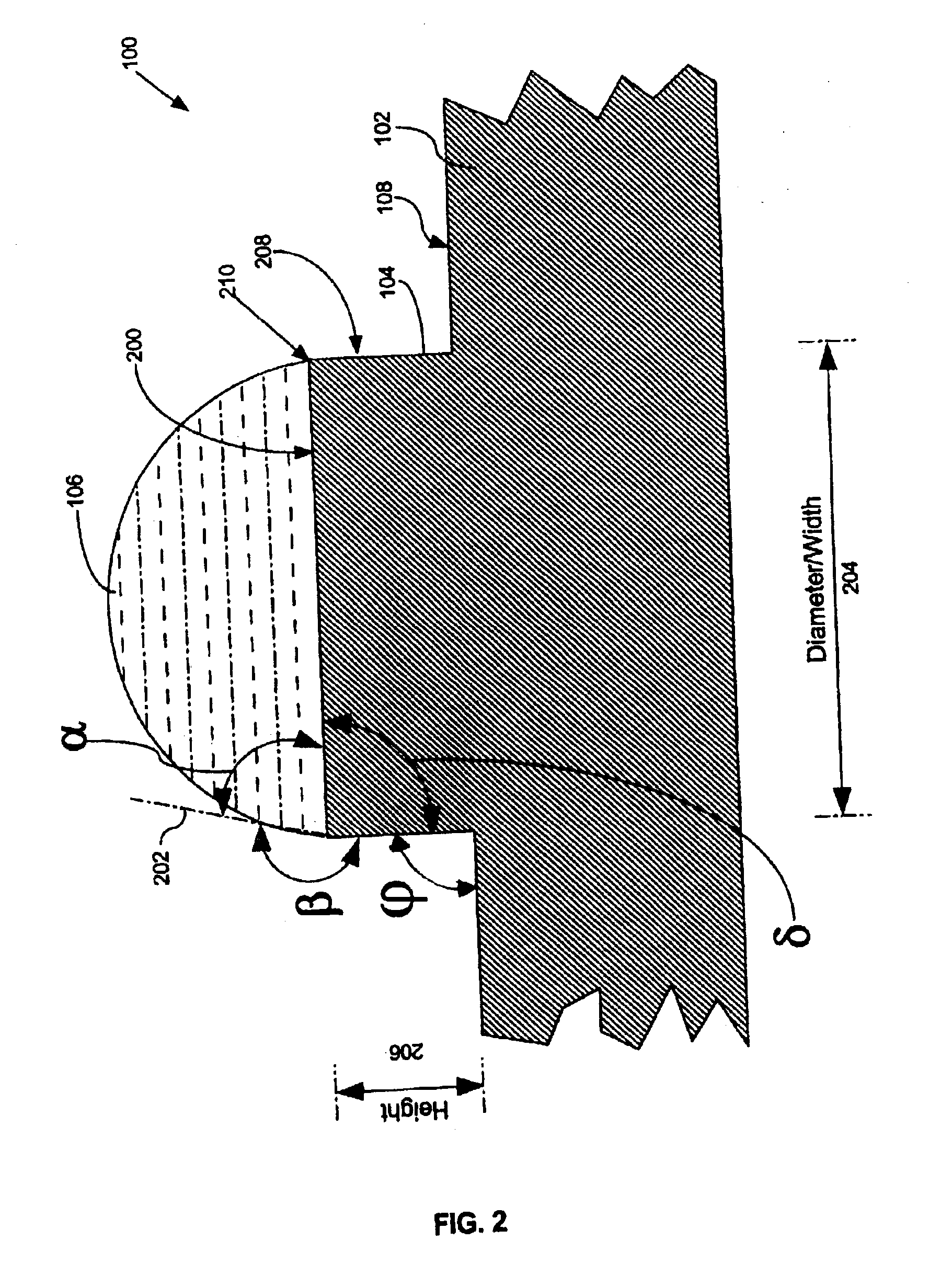

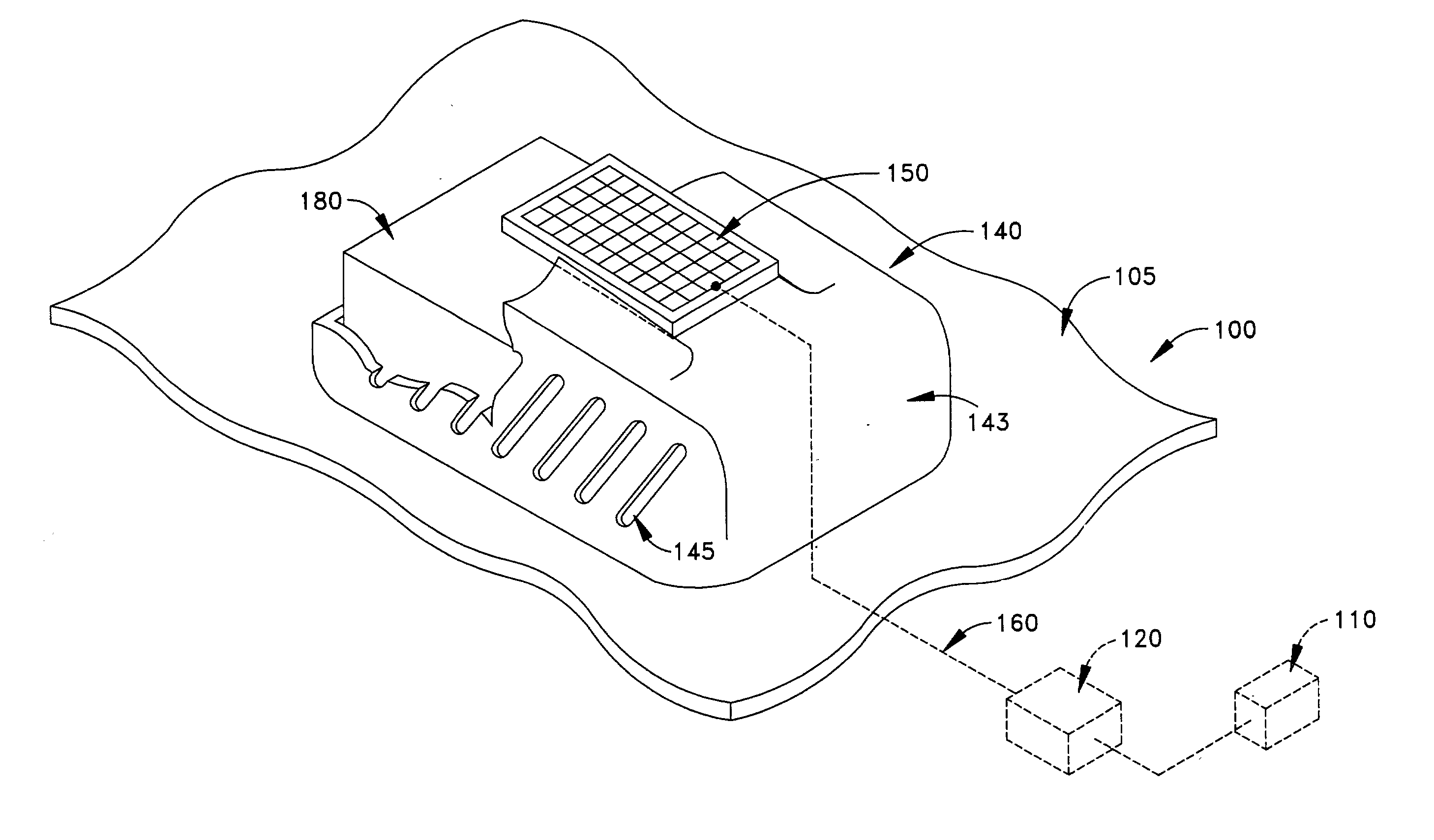

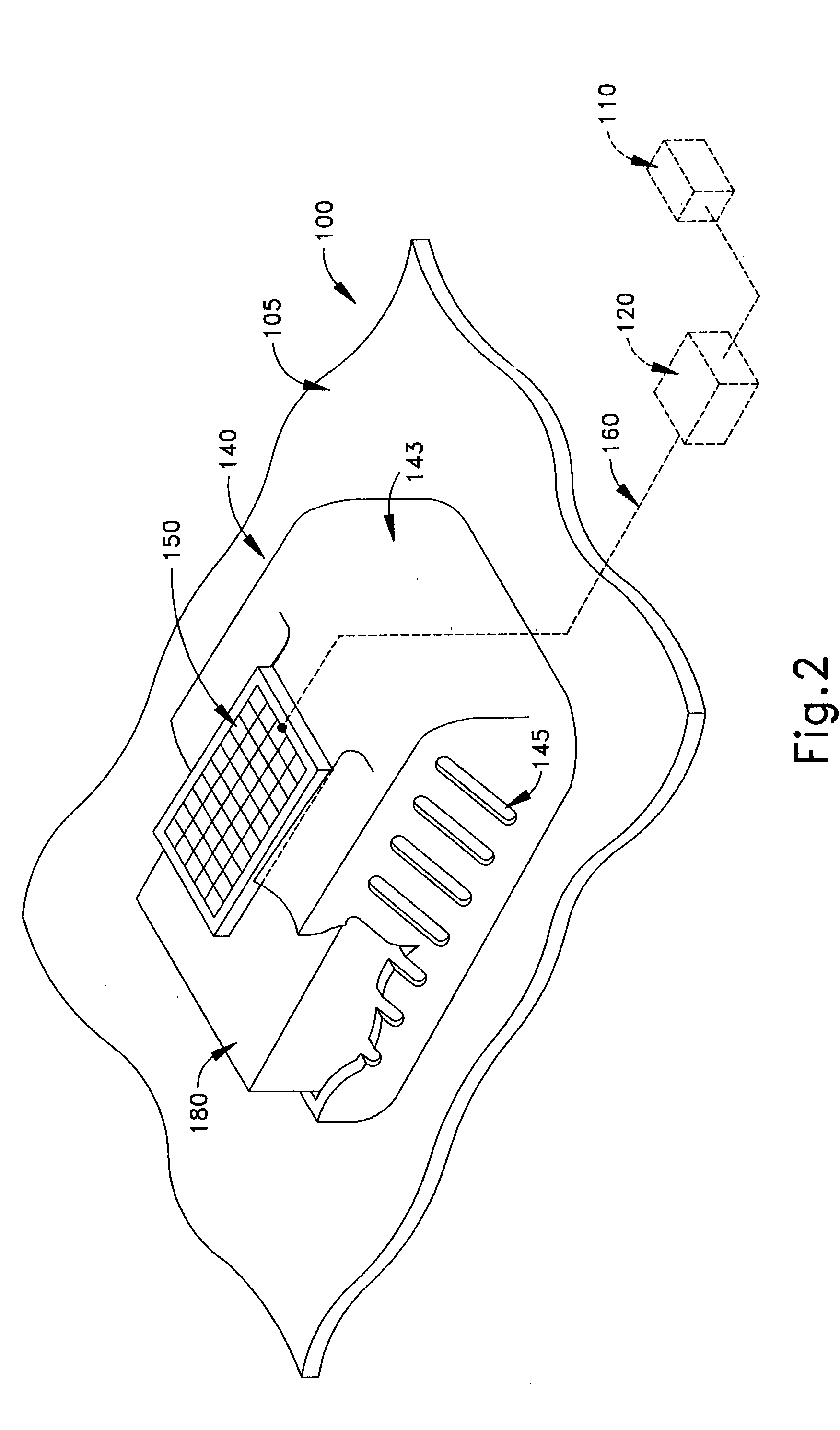

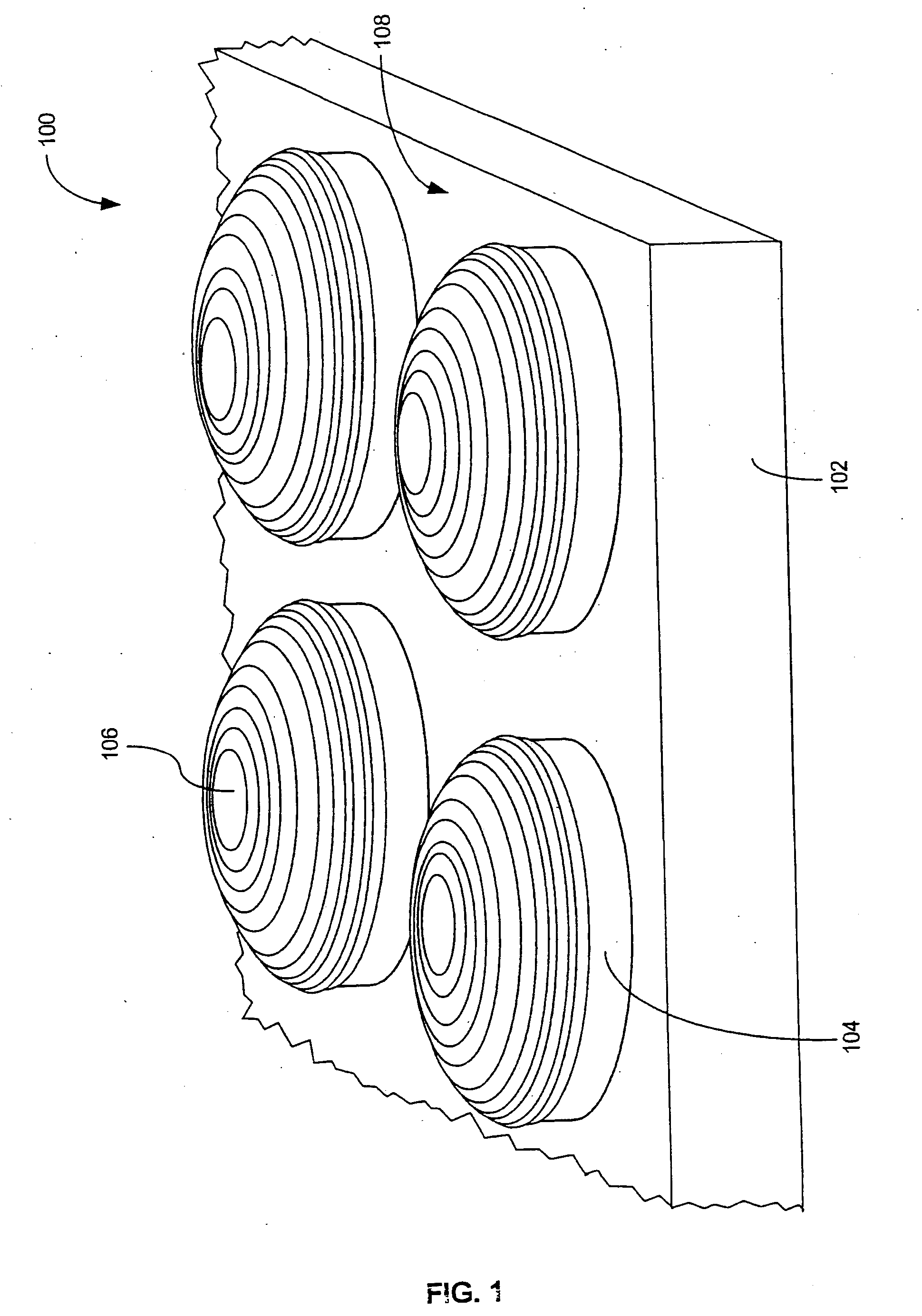

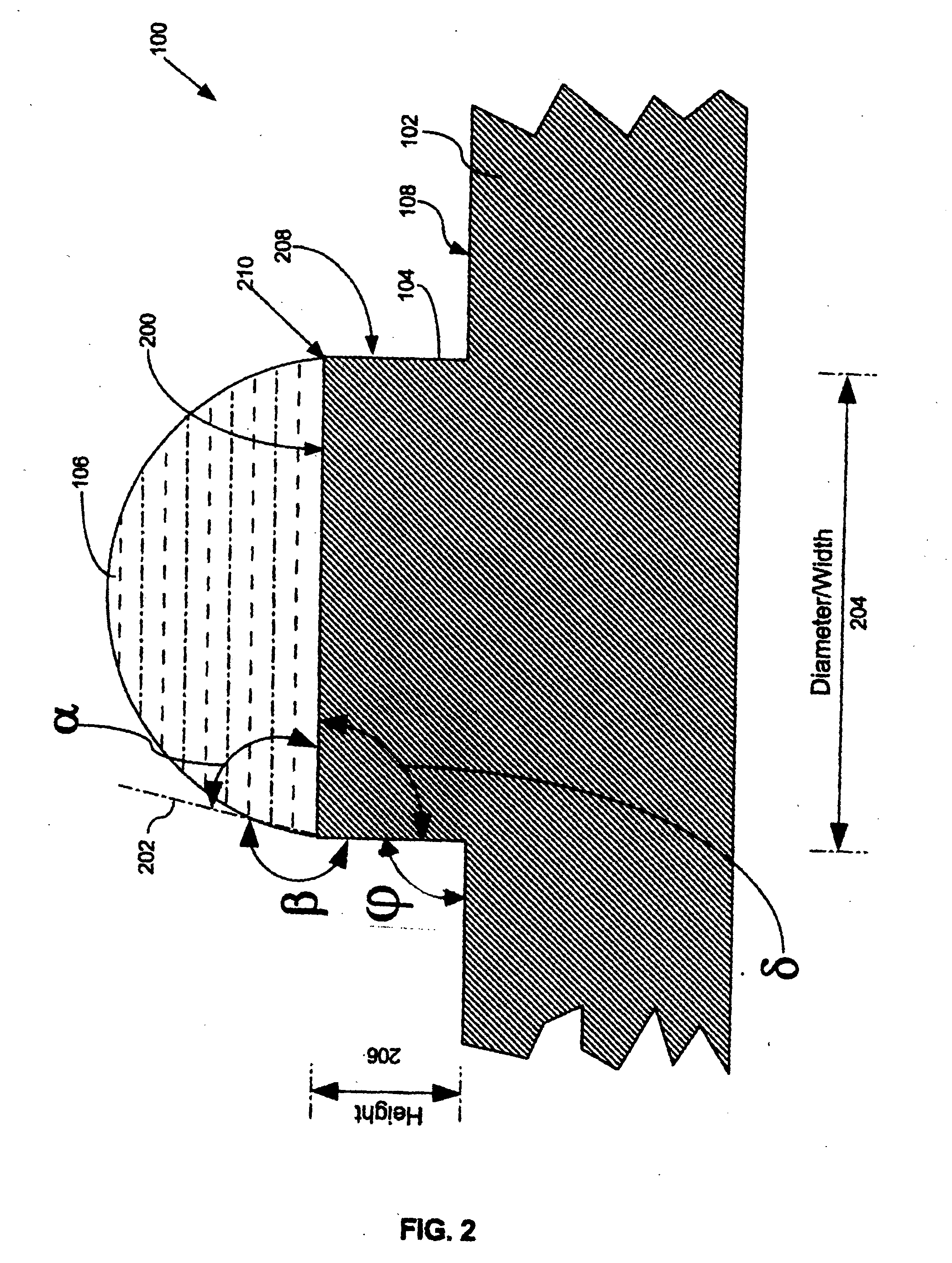

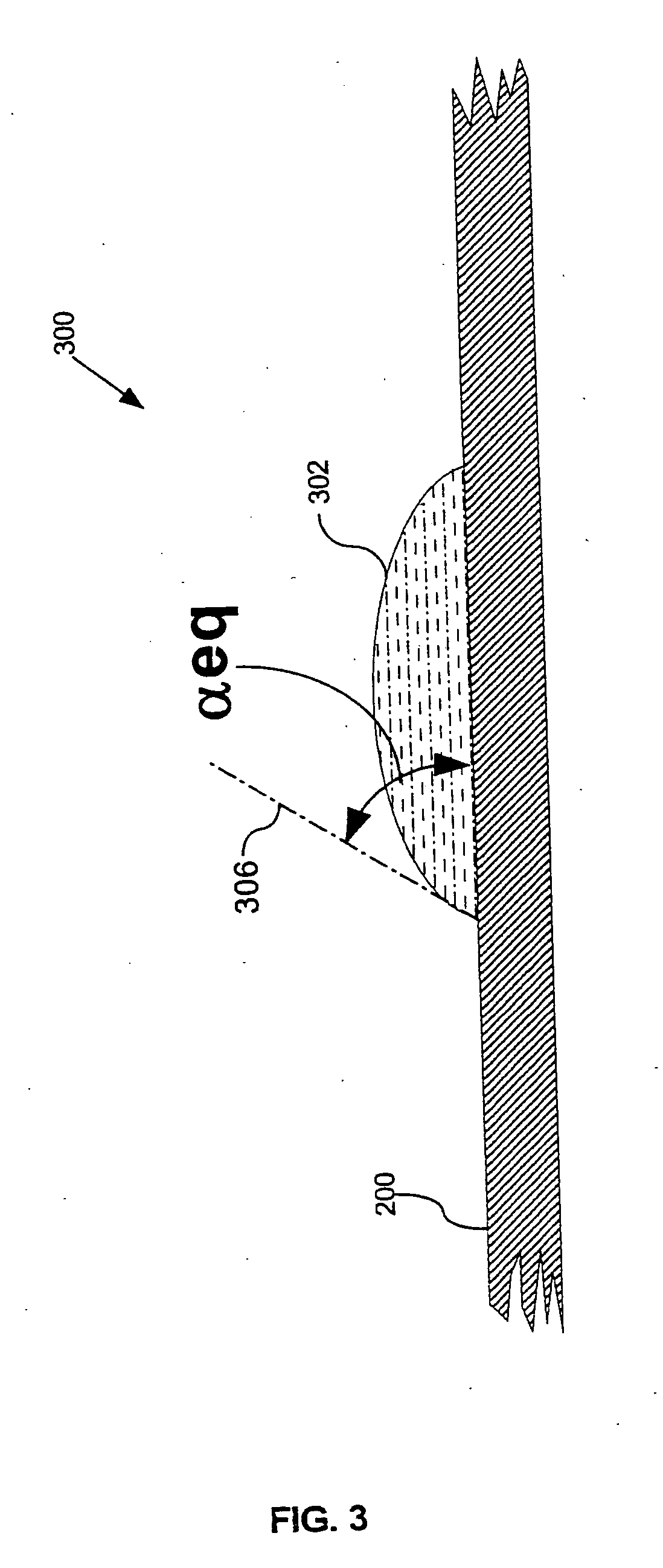

Raised surface assay plate

InactiveUS6908760B2Unobstructed accessBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiomedical engineering

The assay plate includes a substrate having an substrate surface and at least one raised pad extending from the substrate surface. The raised pad includes a substantially planar sample receiving surface configured for holding a sample thereon for in-situ experimentation. The sample receiving surface preferably has at least one sharp edge at the junction between a sidewall coupling the sample receiving surface to the substrate surface. The sample receiving surface is preferably a circle, oval, square, rectangle, triangle, pentagon, hexagon, or octagon shape that is sized to hold a predetermined volume of the sample. A method of using the above described assay plate is also provided. Once a raised pad extending from a substrate is formed, a sample is deposited on the raised pad. Experiments are subsequently performed using the sample on the raised pad.

Owner:TRANSFORM PHARMACEUTICALS INC

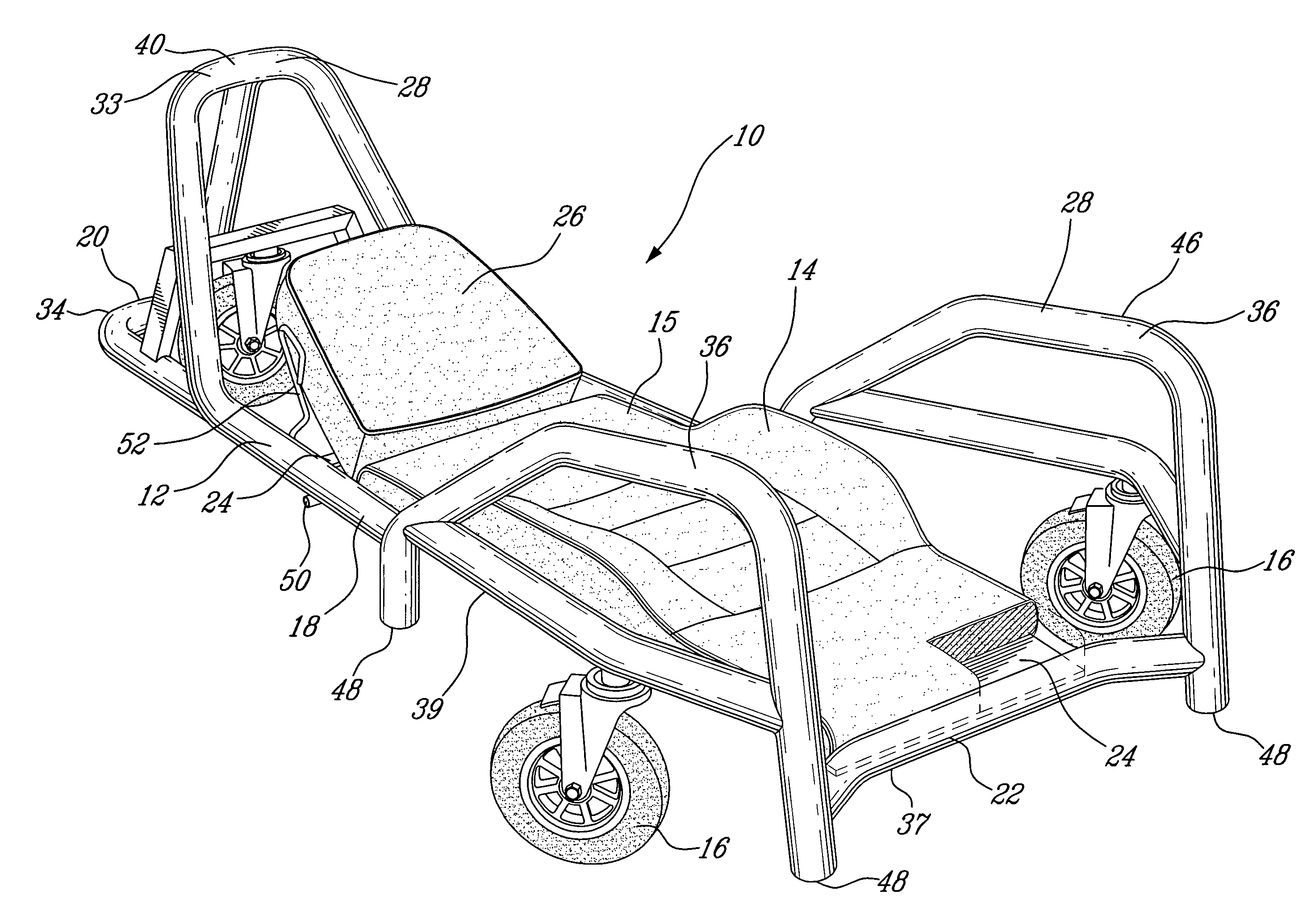

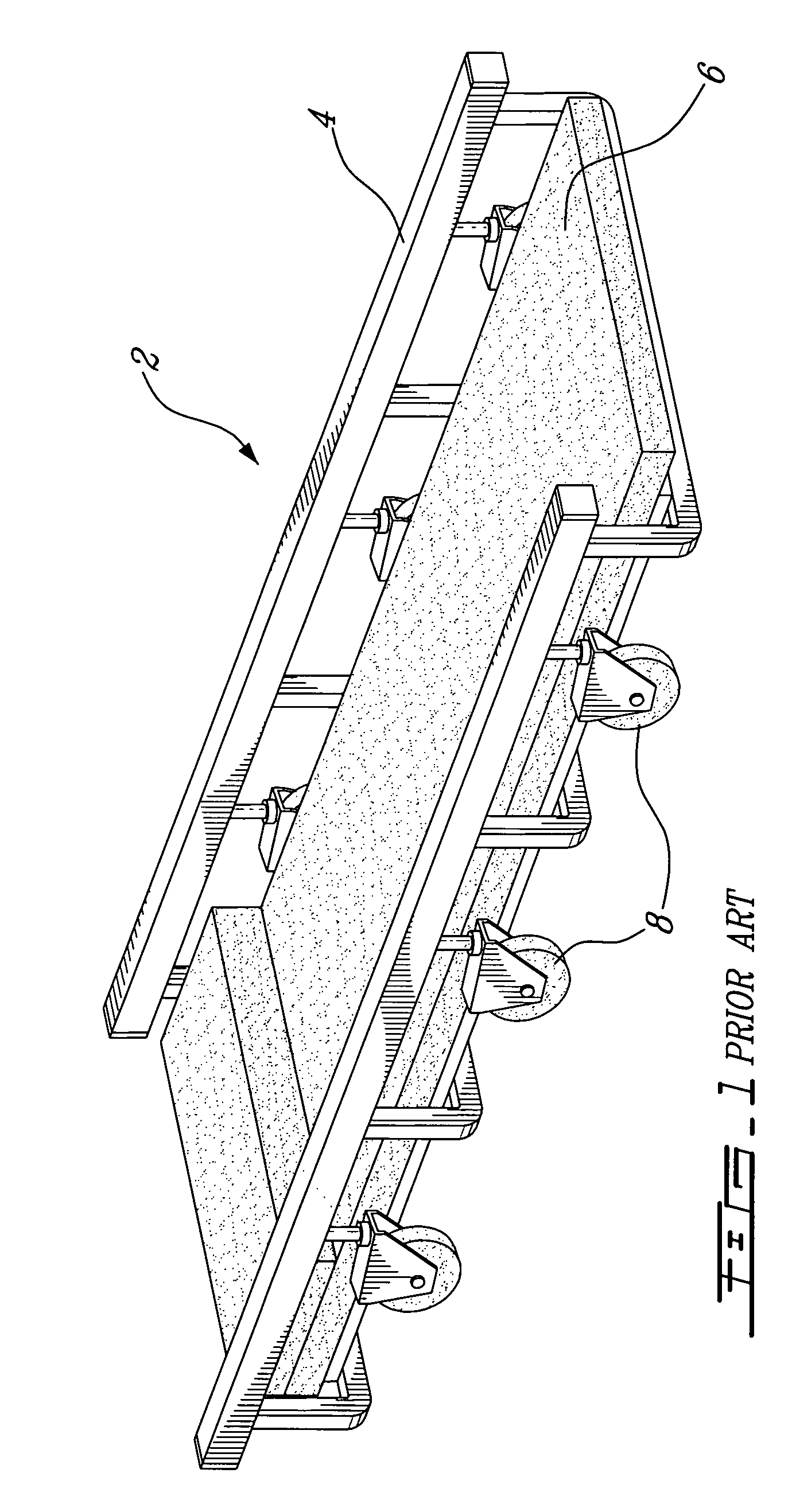

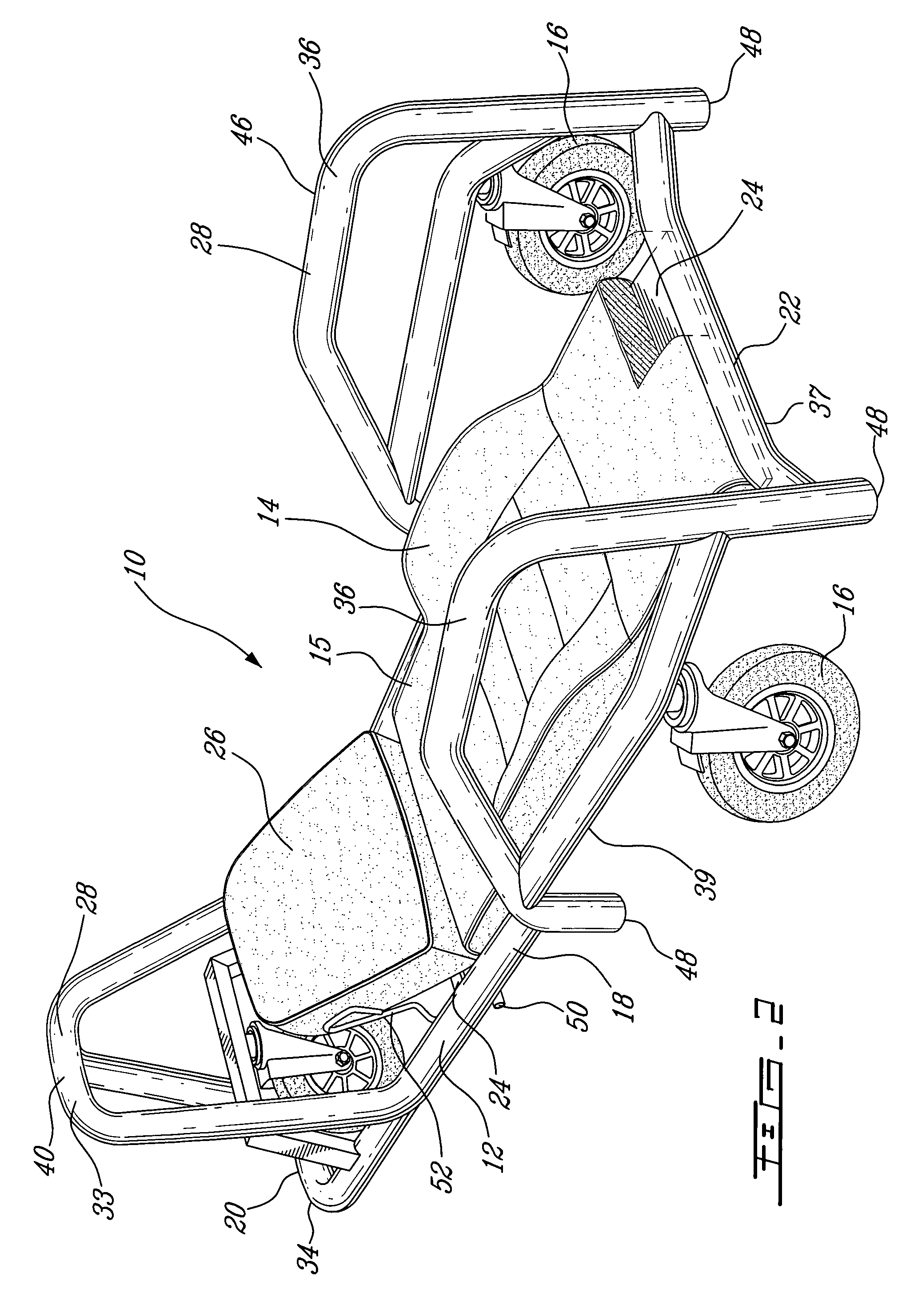

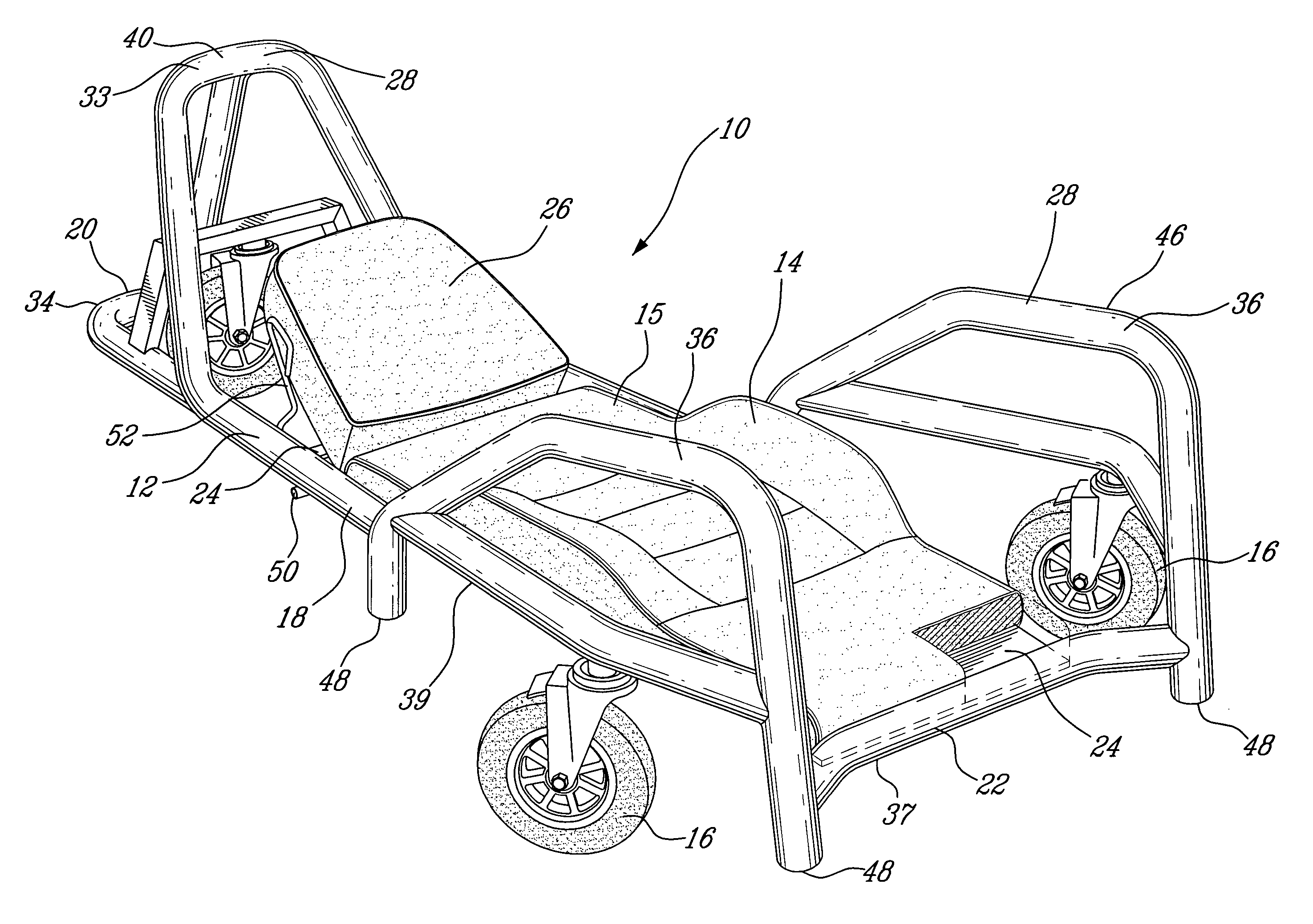

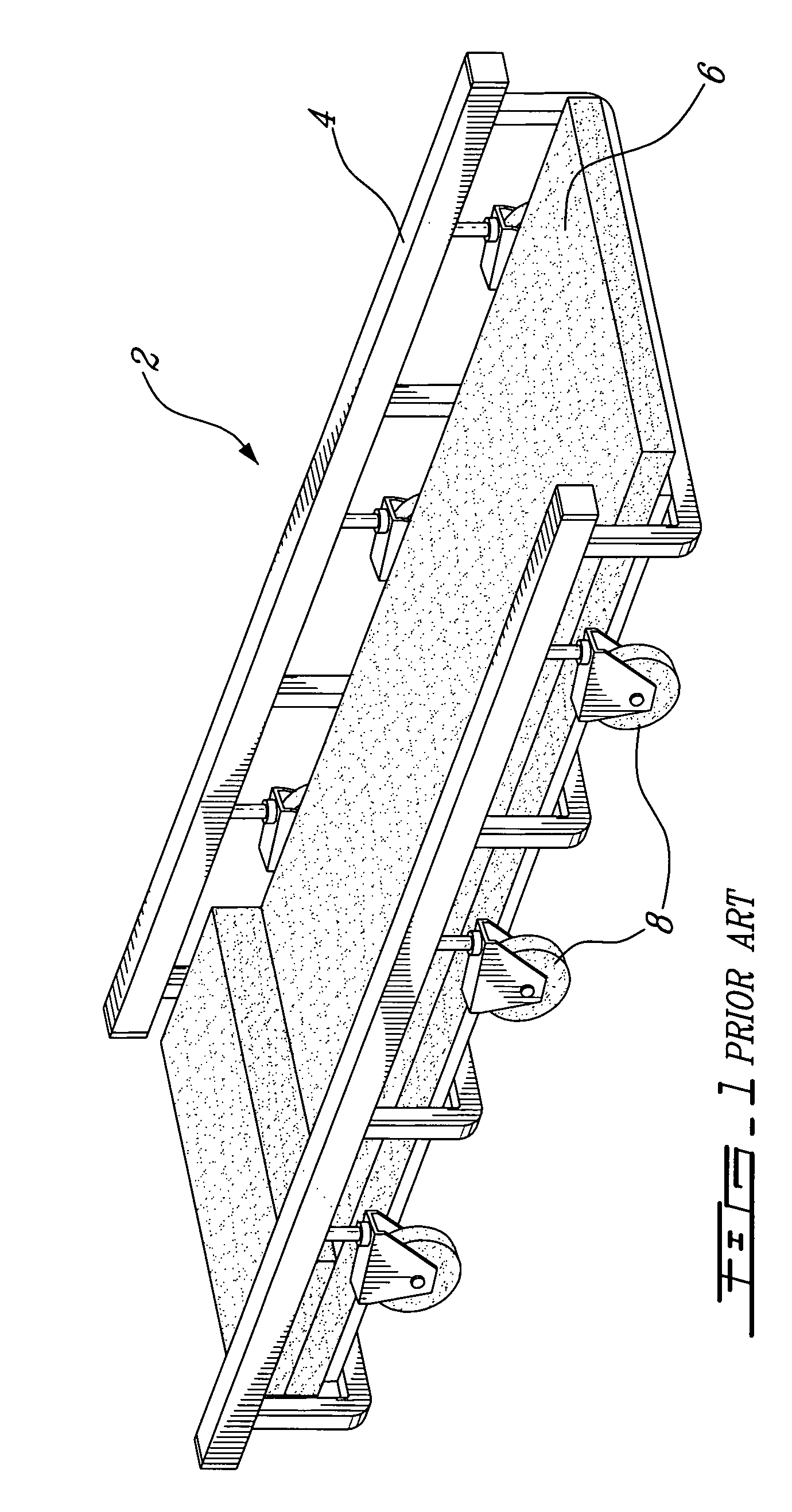

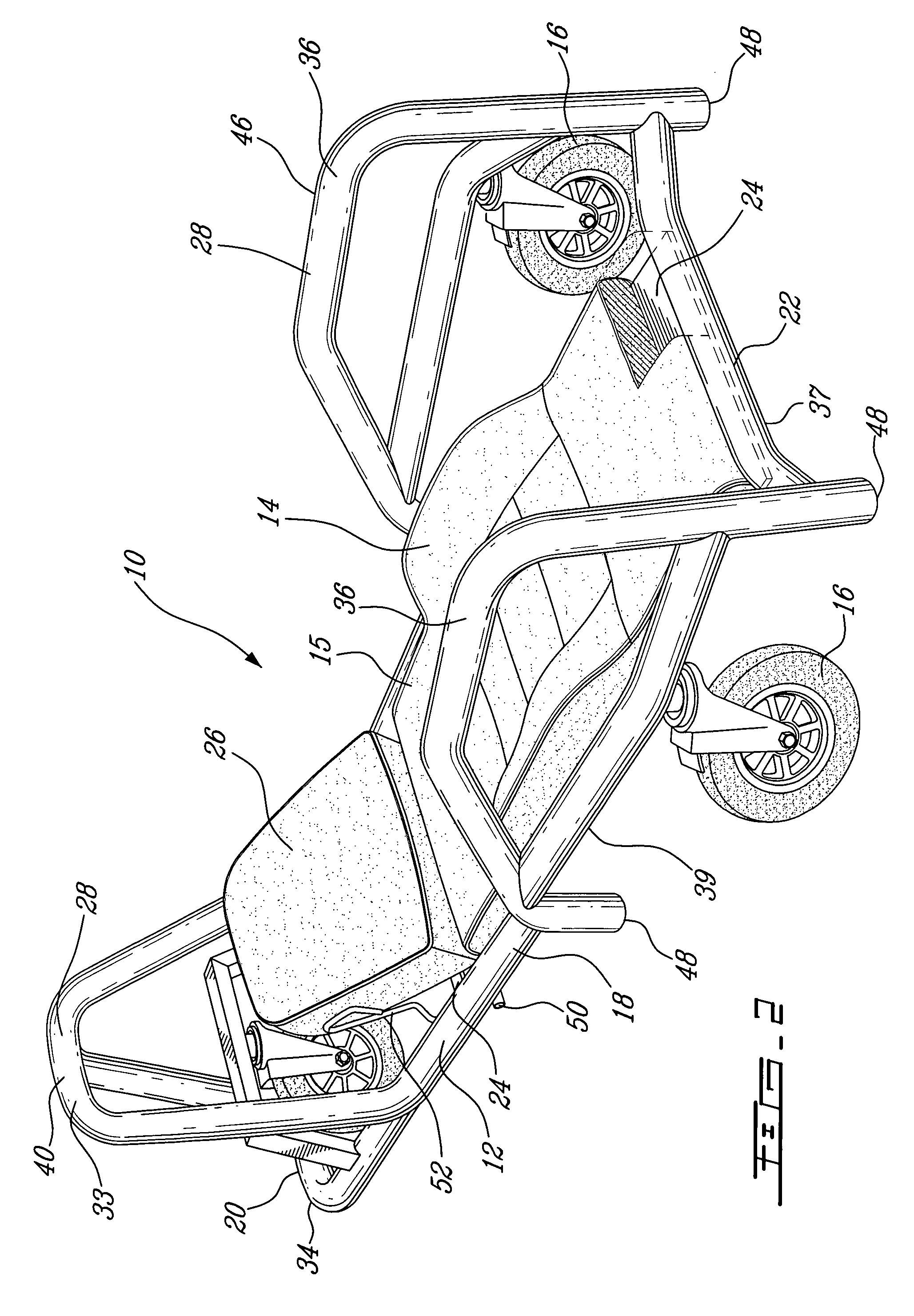

Mechanic's creeper

InactiveUS7726668B2Provide protectionUnobstructed accessCarriage/perambulator accessoriesHand carts with one axisEngineeringSupine position

Owner:SIEB KRISTOPHER +1

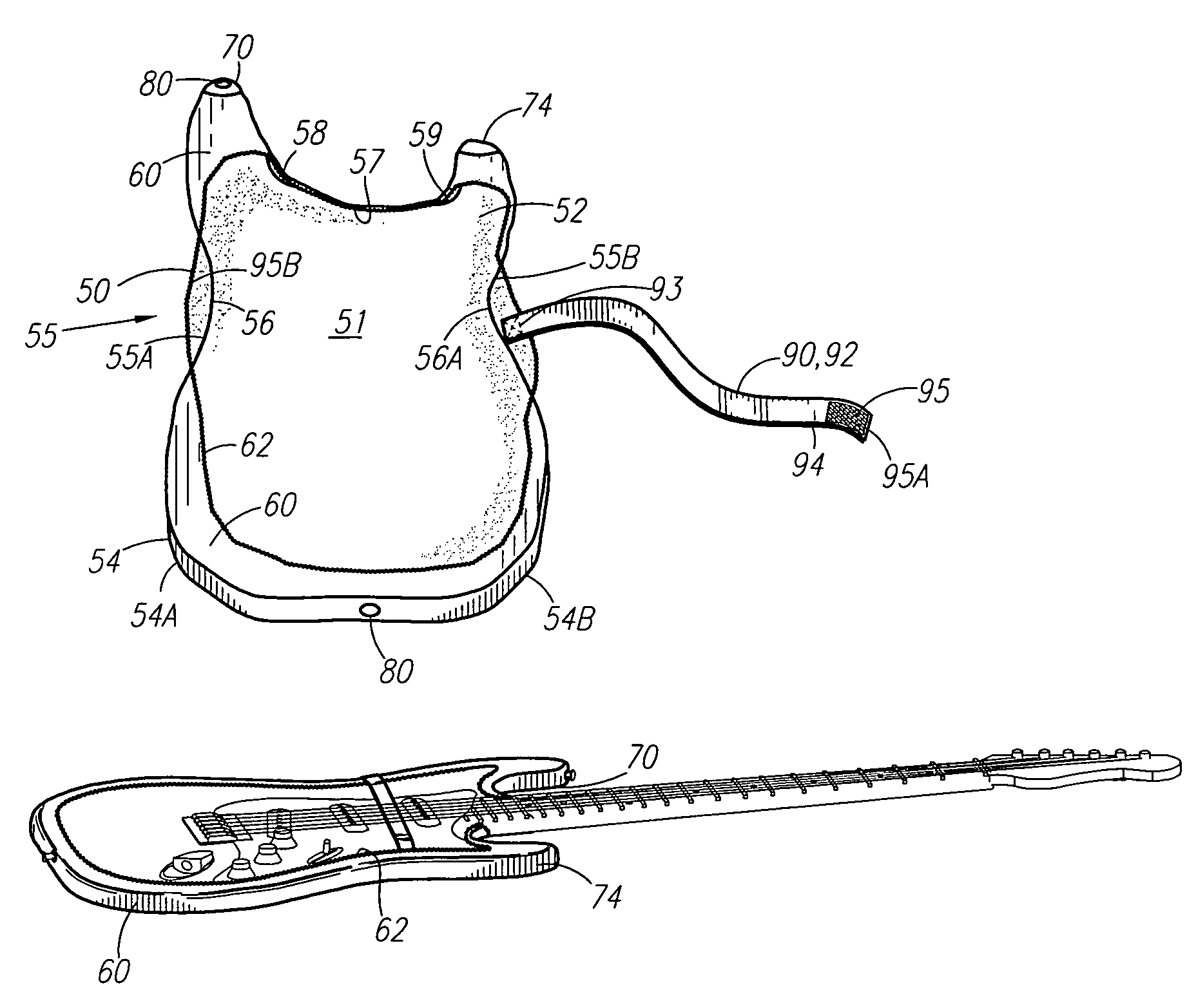

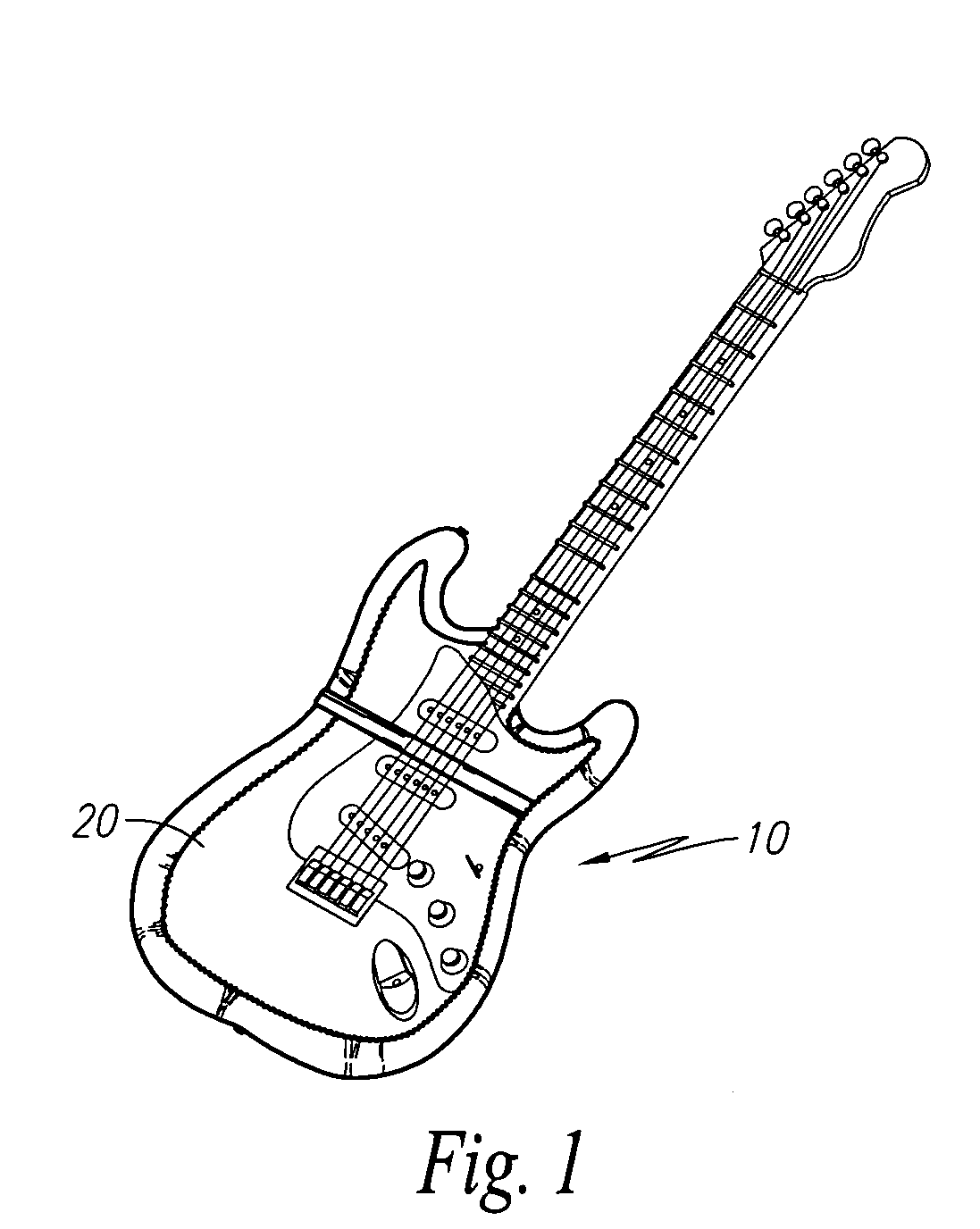

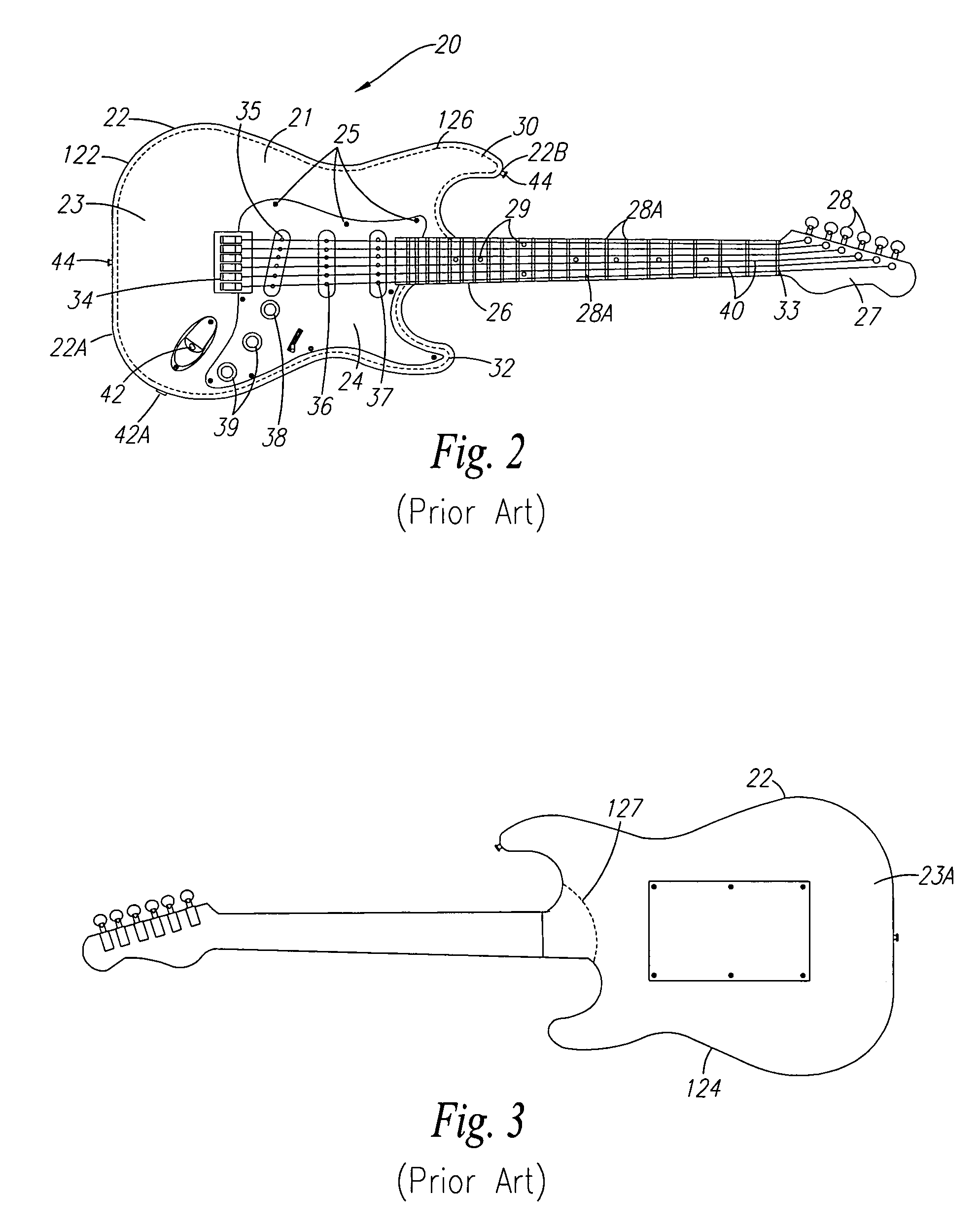

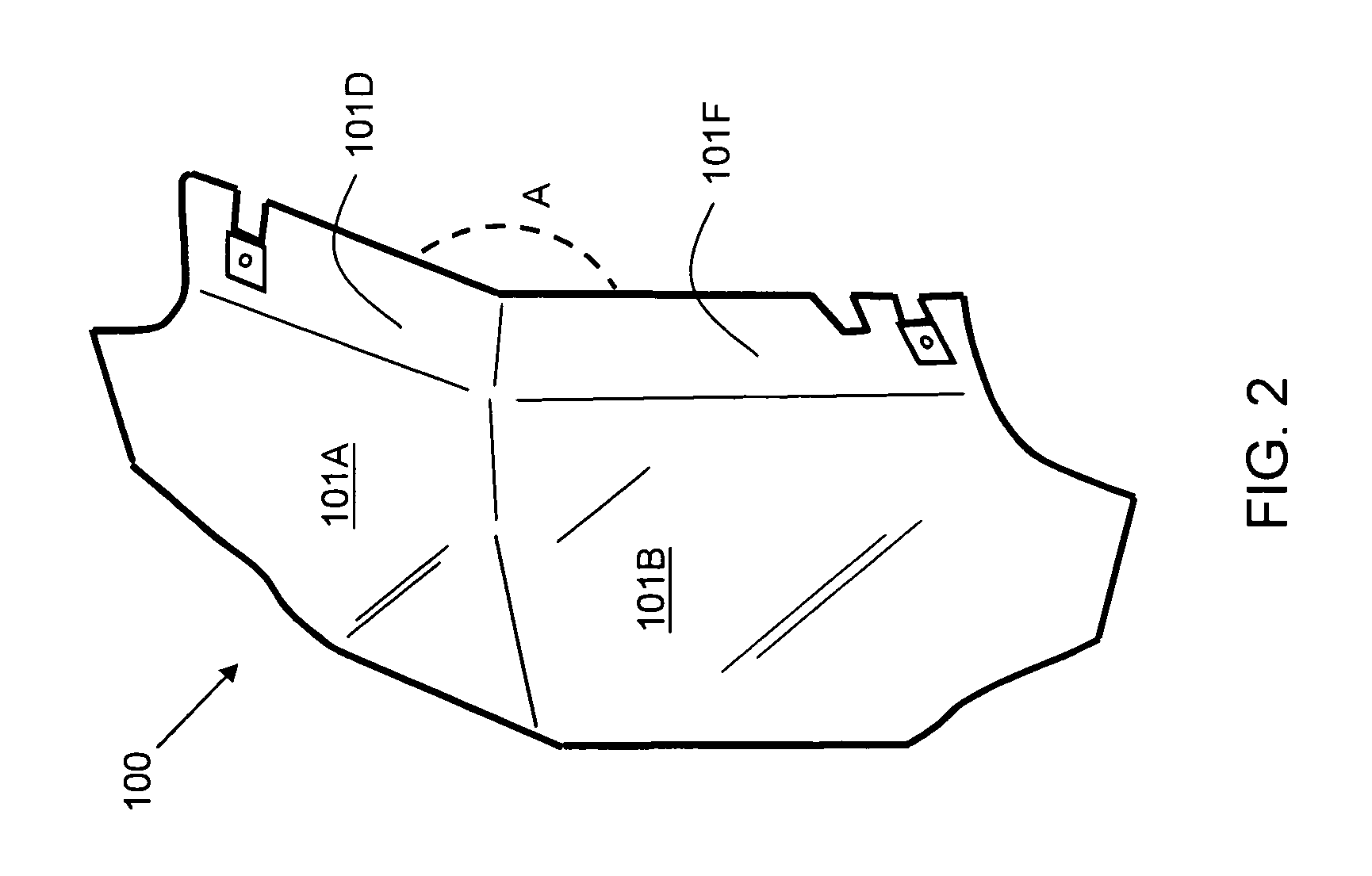

Protective cover for a guitar

InactiveUS7671264B1Securely holdUnobstructed accessStringed musical instrumentsFlushing devicesEngineeringMechanical engineering

Owner:HEDA HOWARD J

Mechanic's creeper

InactiveUS20060186619A1Provide protectionUnobstructed accessCarriage/perambulator accessoriesHand carts with one axisEngineeringSupine position

A creeper is disclosed for protecting a user in a supine position when manoeuvring under a raised object. The creeper comprises a user support surface and a safety structure. The safety structure comprises at least one upwardly projecting rigid element defining a protective space above at least a portion of the support surface. A foldable creeper which folds into a work bench and comprises a similar safety structure is also disclosed.

Owner:SIEB KRISTOPHER +1

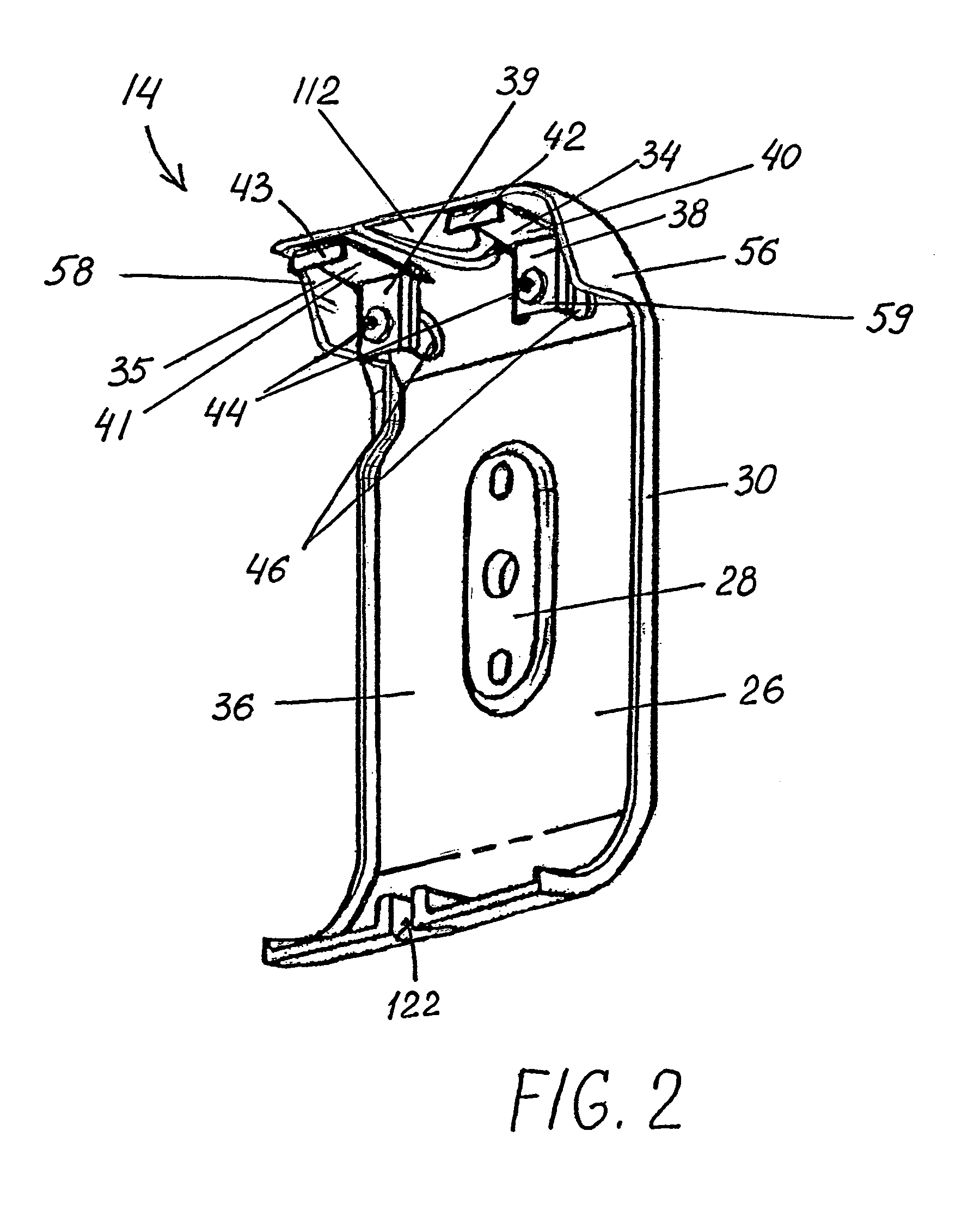

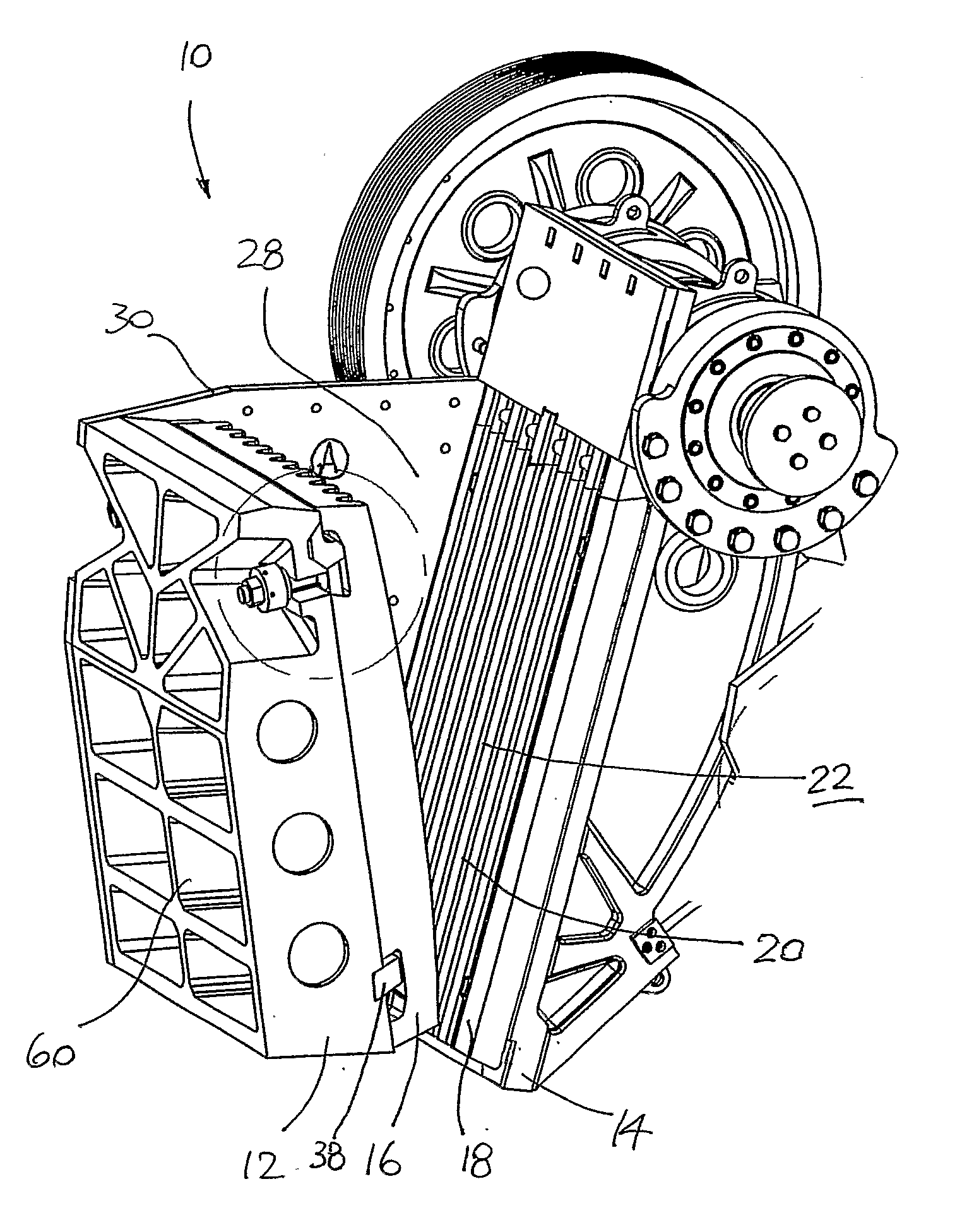

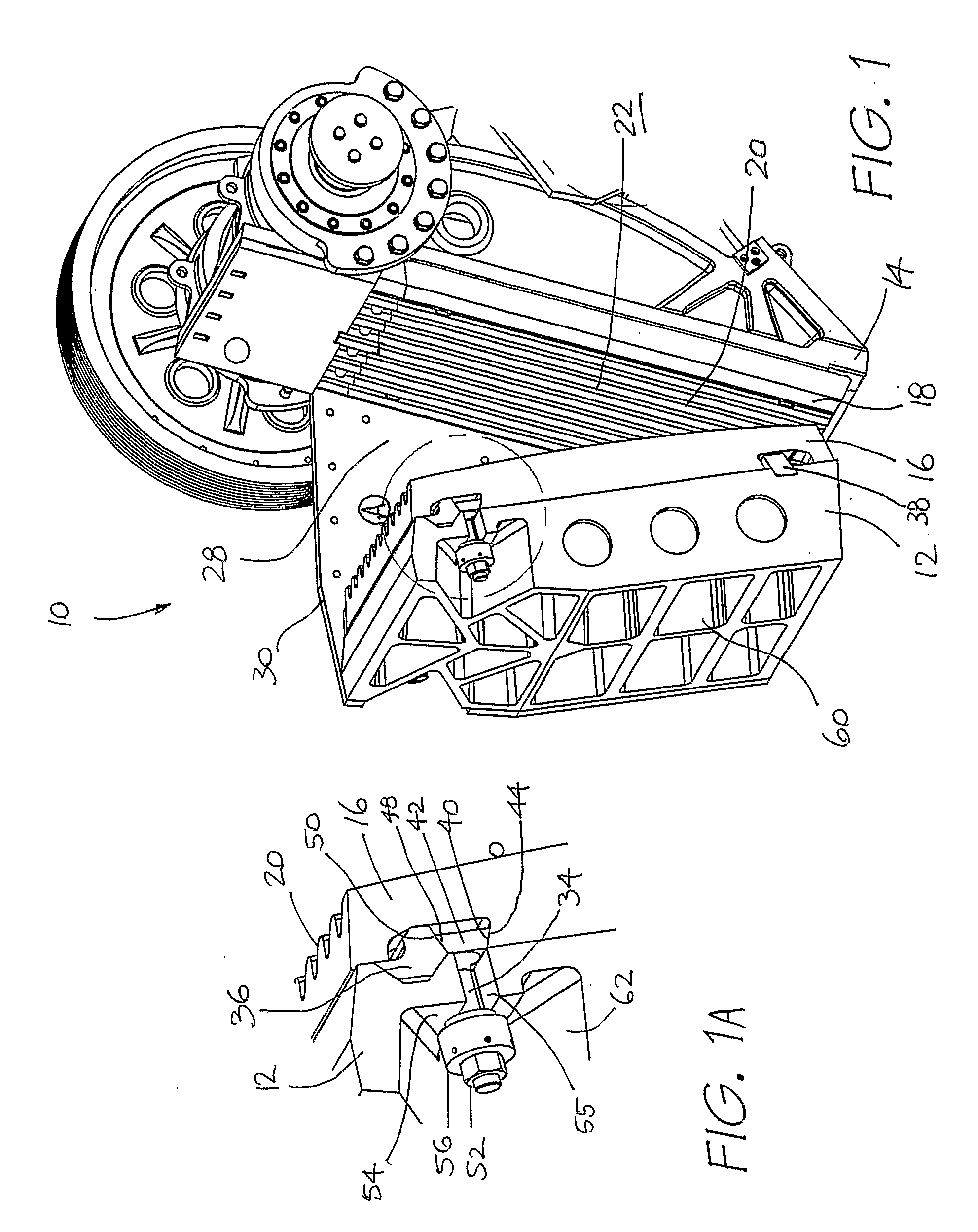

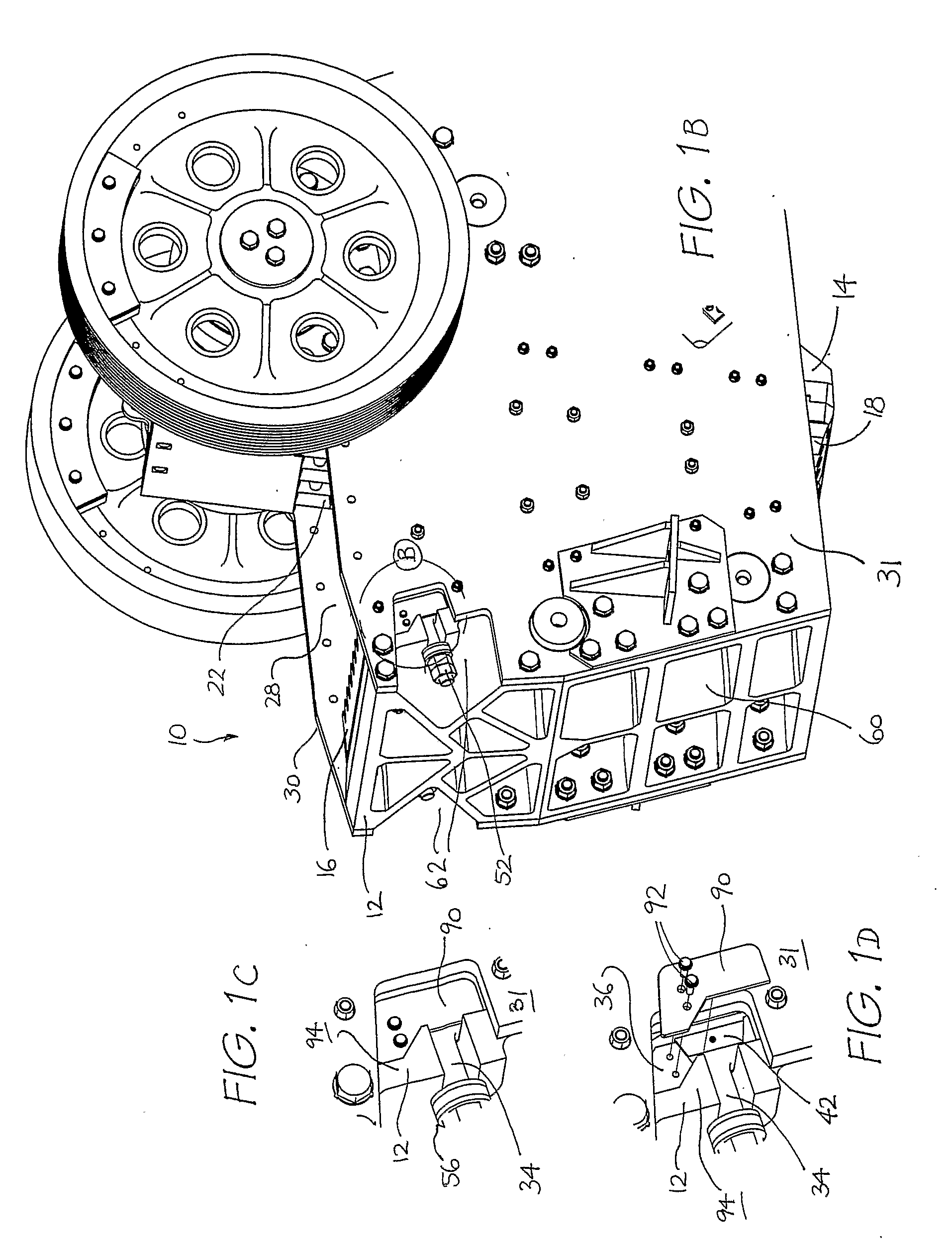

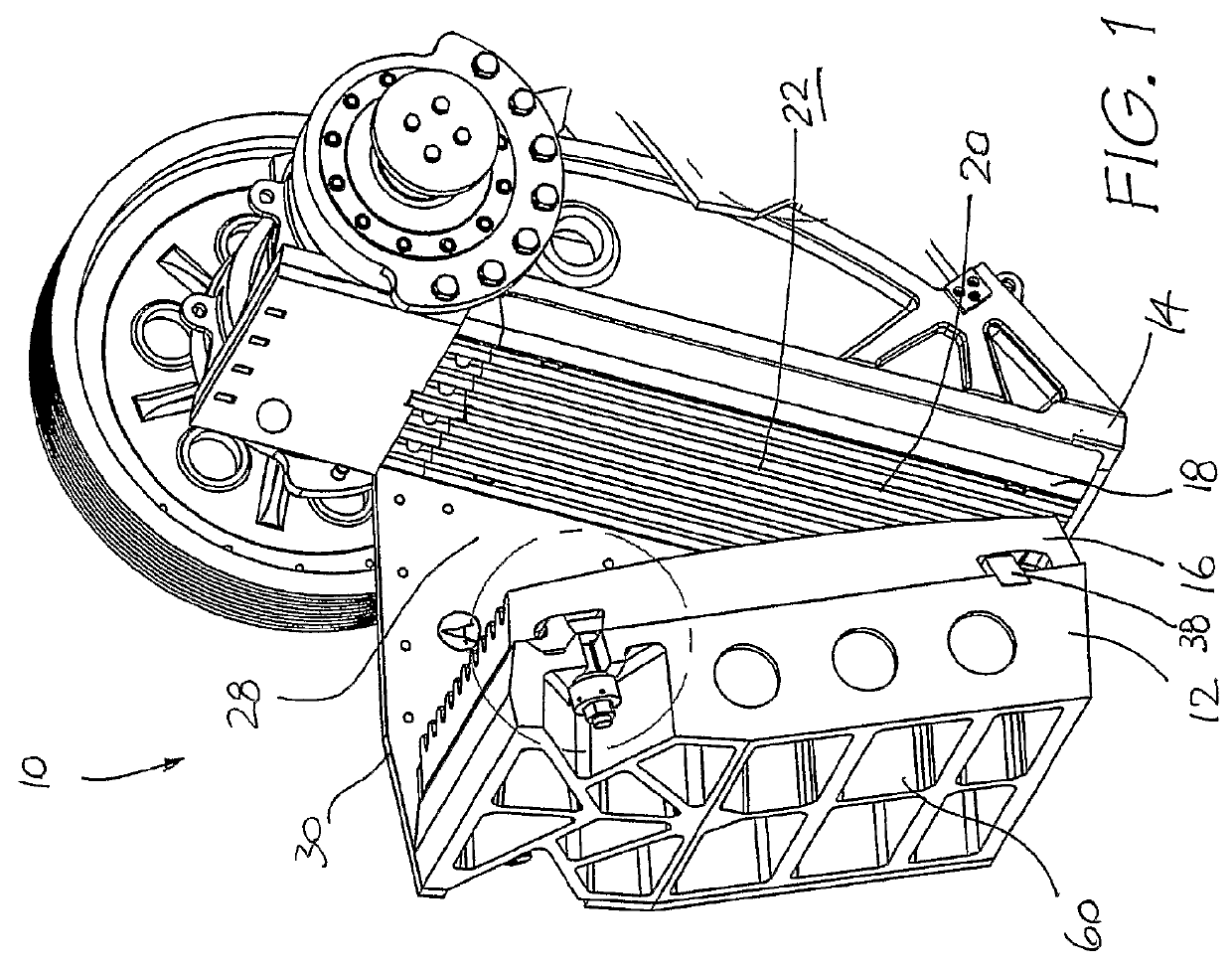

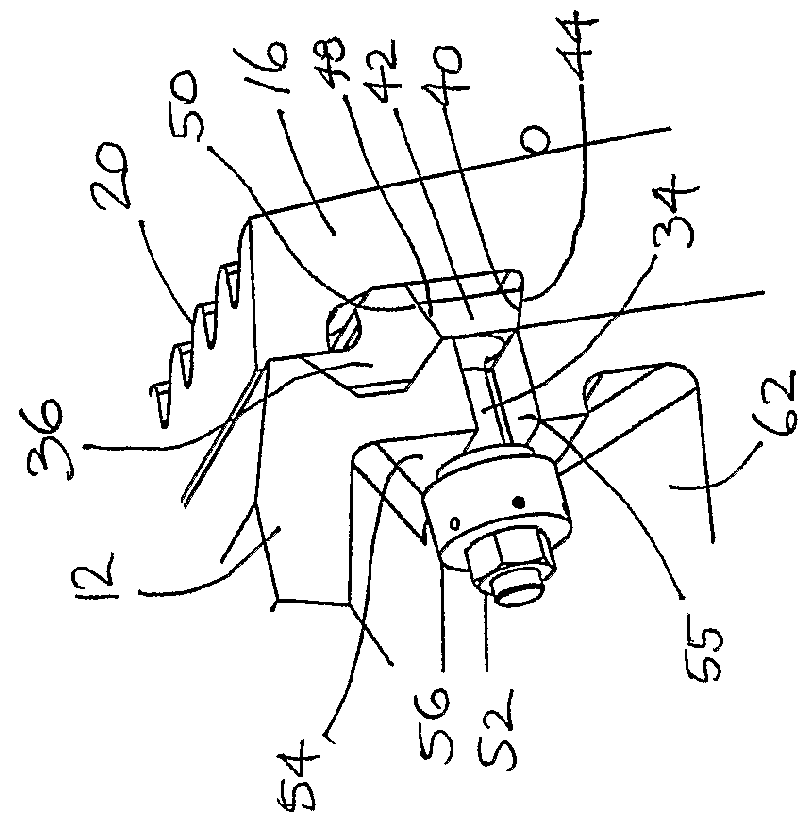

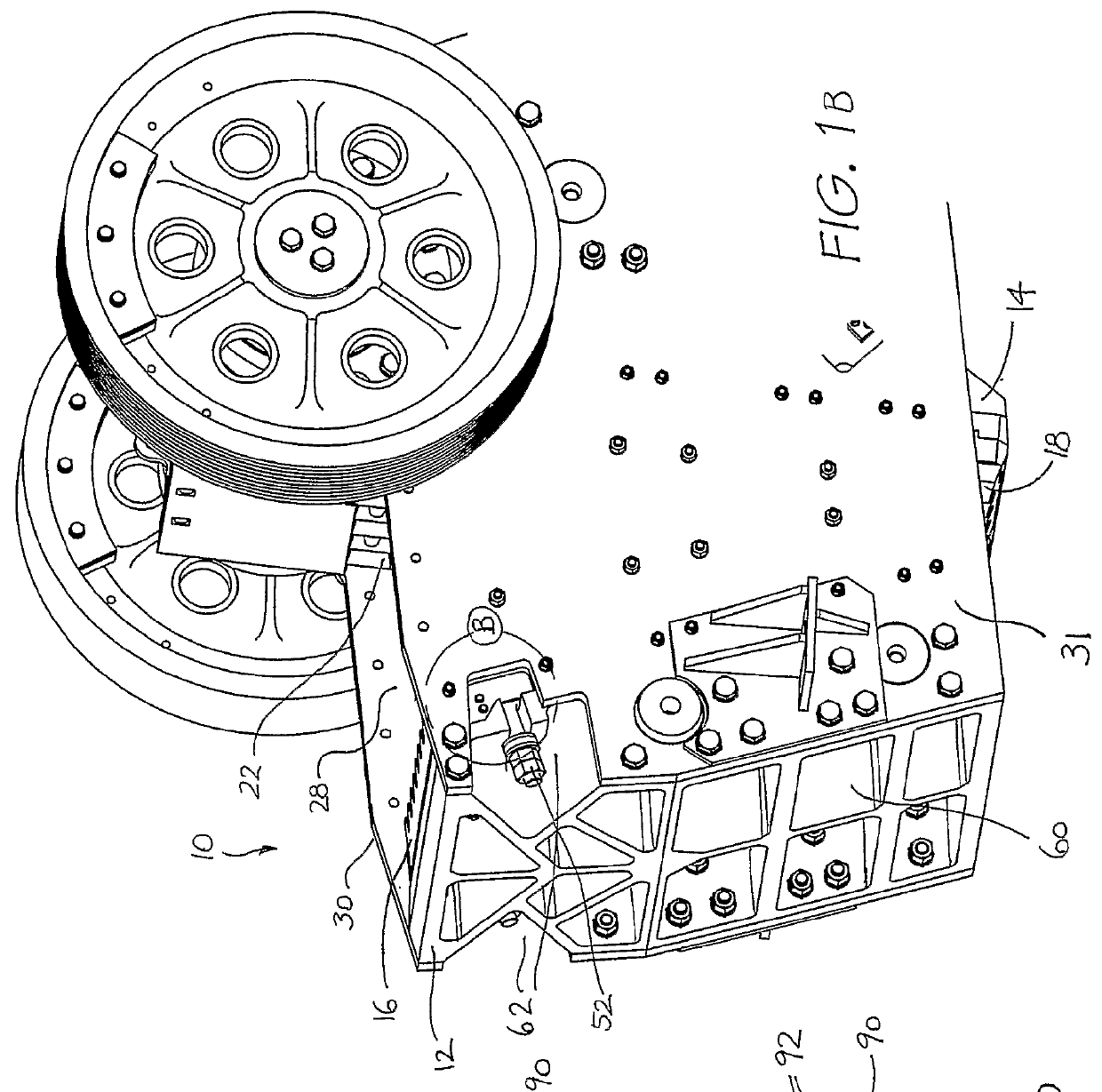

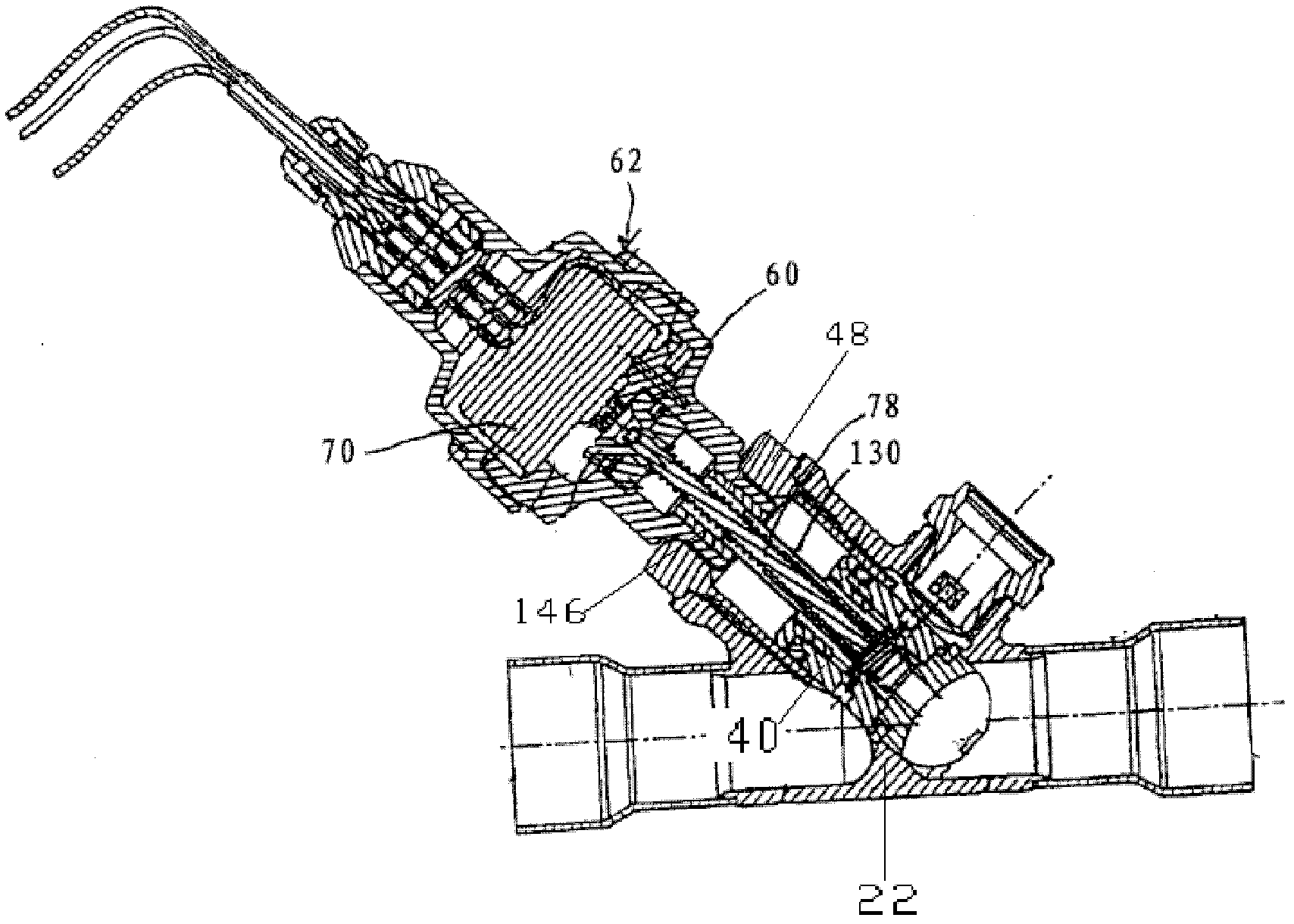

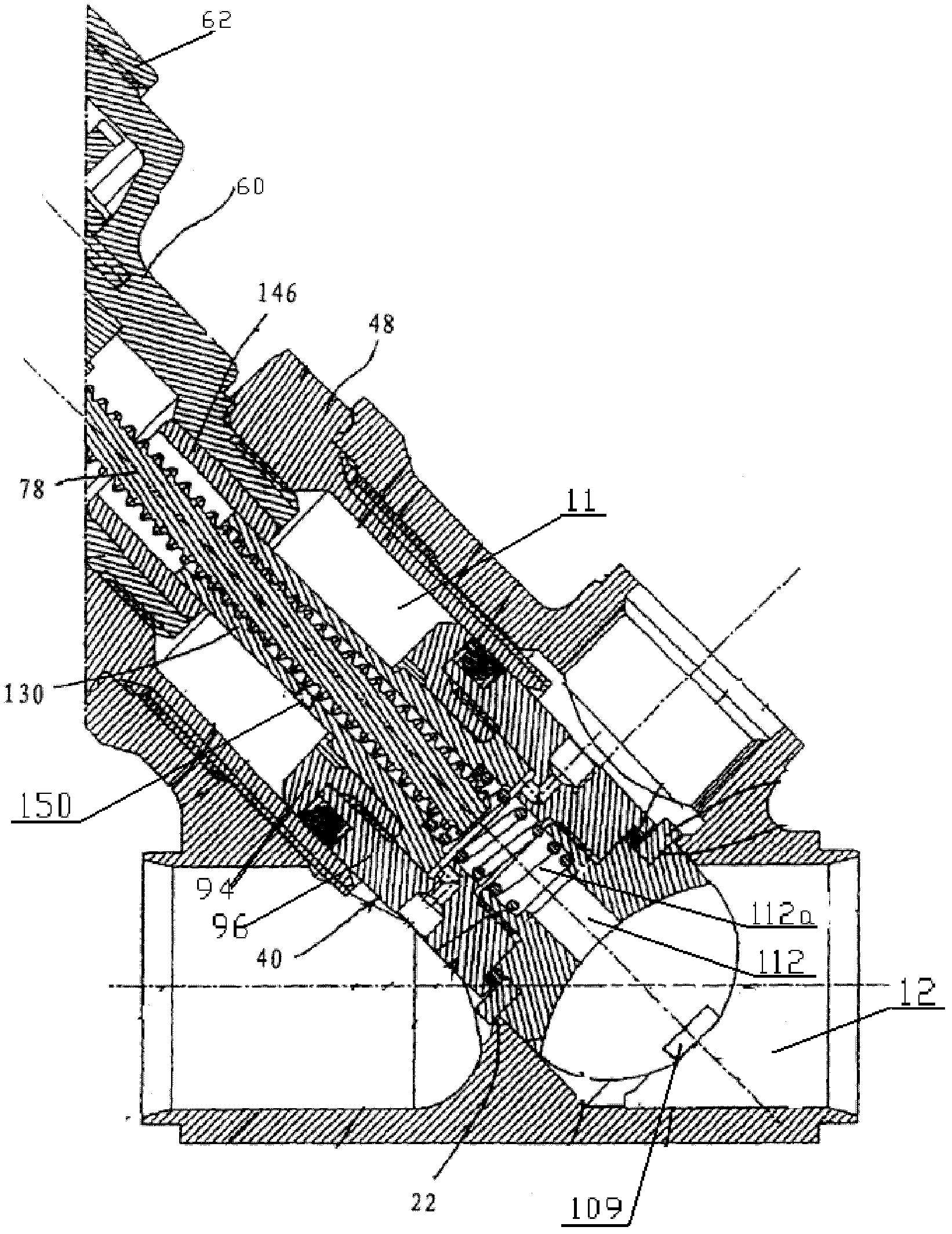

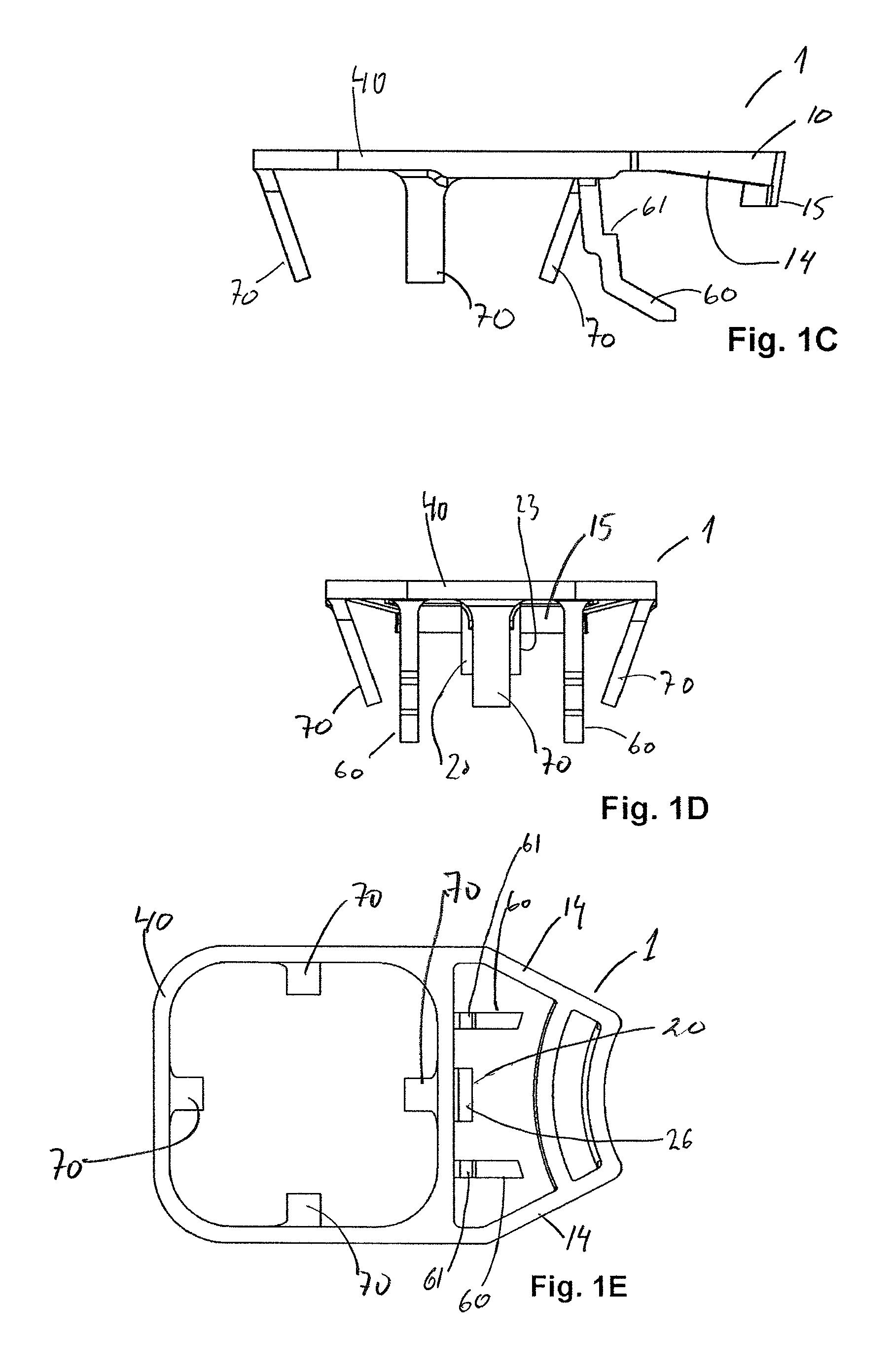

Jaw assembly for a jaw crusher

ActiveUS20100044486A1Simplify maintenance replacementReduce riskCocoaGrain treatmentsEngineeringCrusher

A jaw assembly for a jaw crusher is disclosed where the assembly comprises a jaw stock (12), a wear plate (16), and a fastening device in the form of a bolt (34) with a square head (42) at one end and a washer (56) and fastening nut (52) positioned at an end opposite to the one end. The bolt (34) extends between the jaw stock (12) and the wear plate (16). The fastening device (34, 42, 56, 52) is operative to adopt a clamped configuration where the device provides a clamping force along a fastening axis to clamp the wear plate (16) at the jaw stock (12), and a released configuration where the fastening device does not prevent the wear plate (16) from being separated from the jaw stock (12). The fastening device (34, 42, 56, 52) is accessible from a direction that is transverse to that fastening axis, to enable the device (34, 42, 56, 52) to be changed from its clamped configuration to its released configuration.

Owner:H E PARTS INT CRUSHING SOLUTIONS PTY LTD

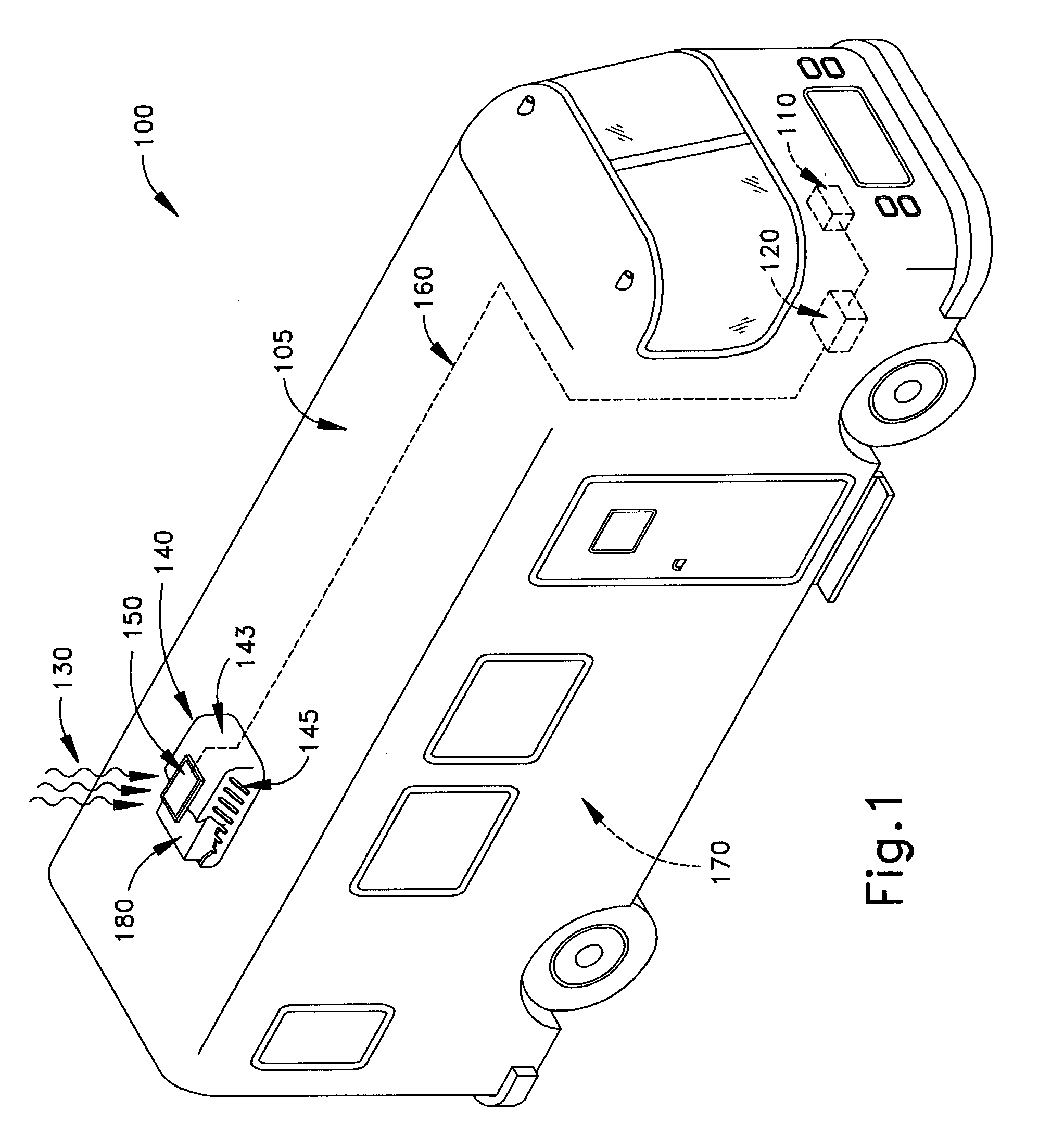

Solar panel and recreational vehicle arrangement

InactiveUS20040040325A1Reduce air resistanceLess-prone to becoming muddied and dirtiedAir-treating devicesVehicle heating/cooling devicesBattery chargeElectrical battery

An arrangement including a recreational vehicle with living space therein, a roof and a battery; an air conditioning unit proving conditioned air to the living space; a protective shroud enclosing the air conditioning unit and a solar panel for providing energy output for charging the battery wherein the solar panel is mounted on an outer surface of the protective shroud or on the air conditioning unit.

Owner:DOMETIC CORP

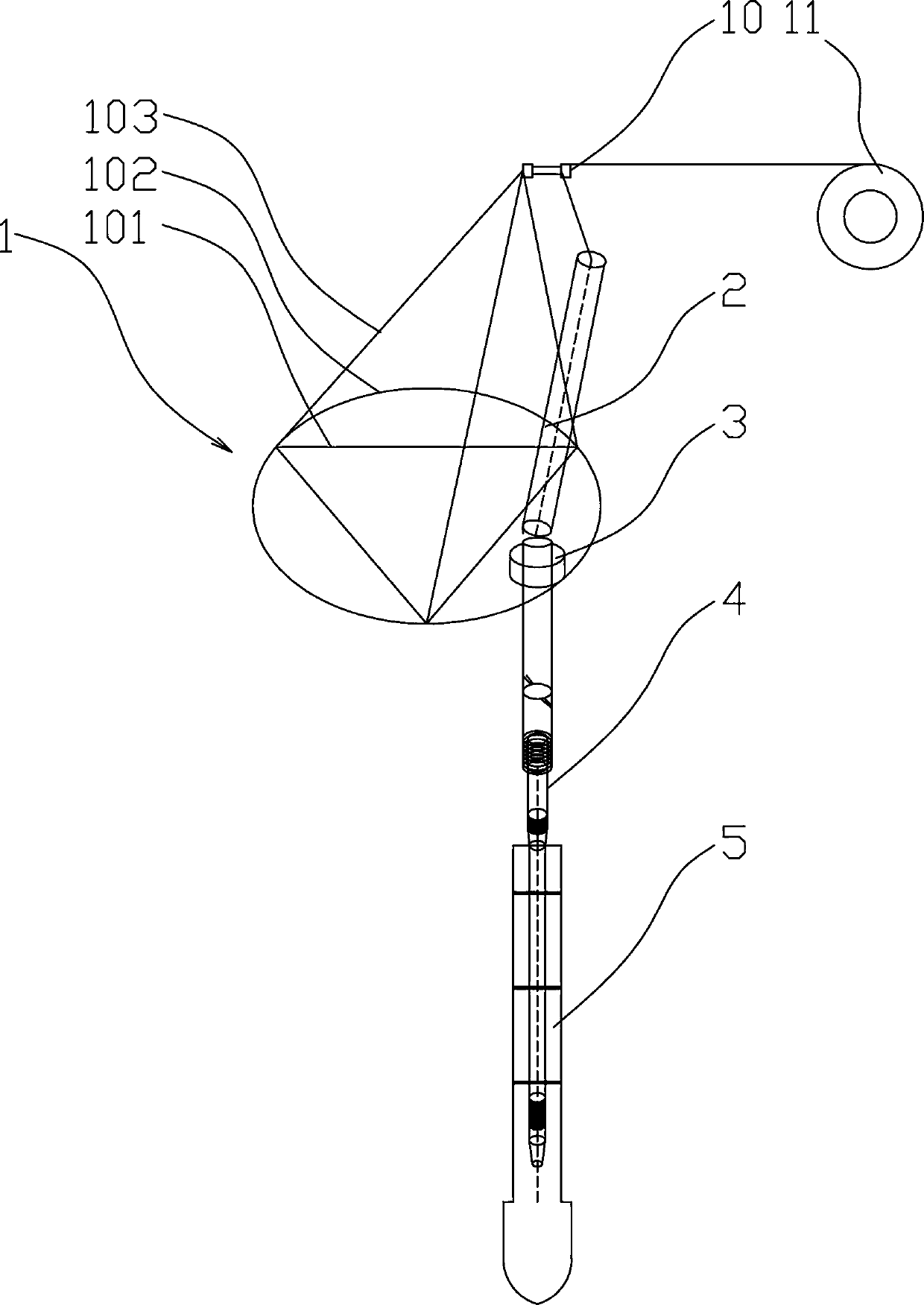

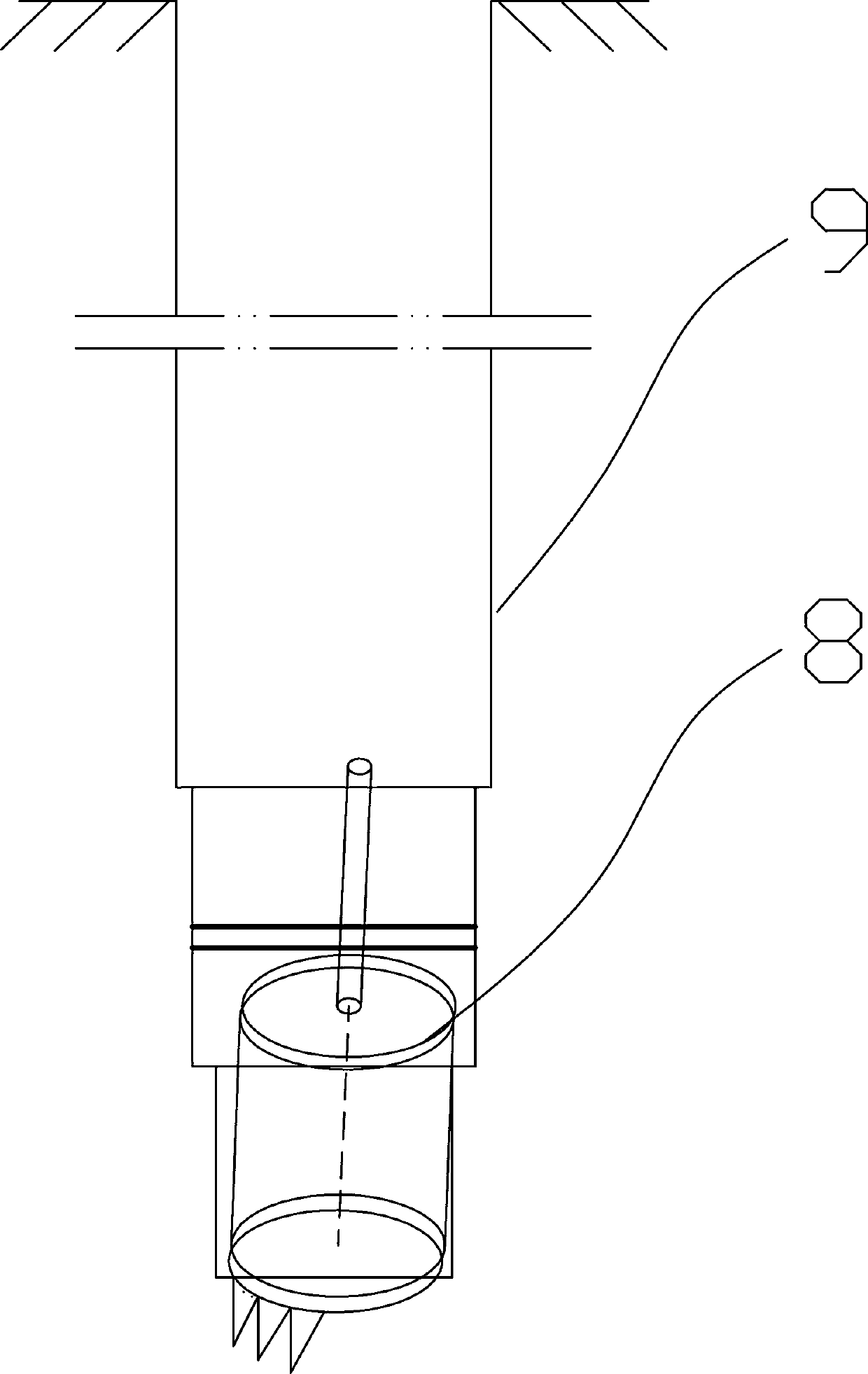

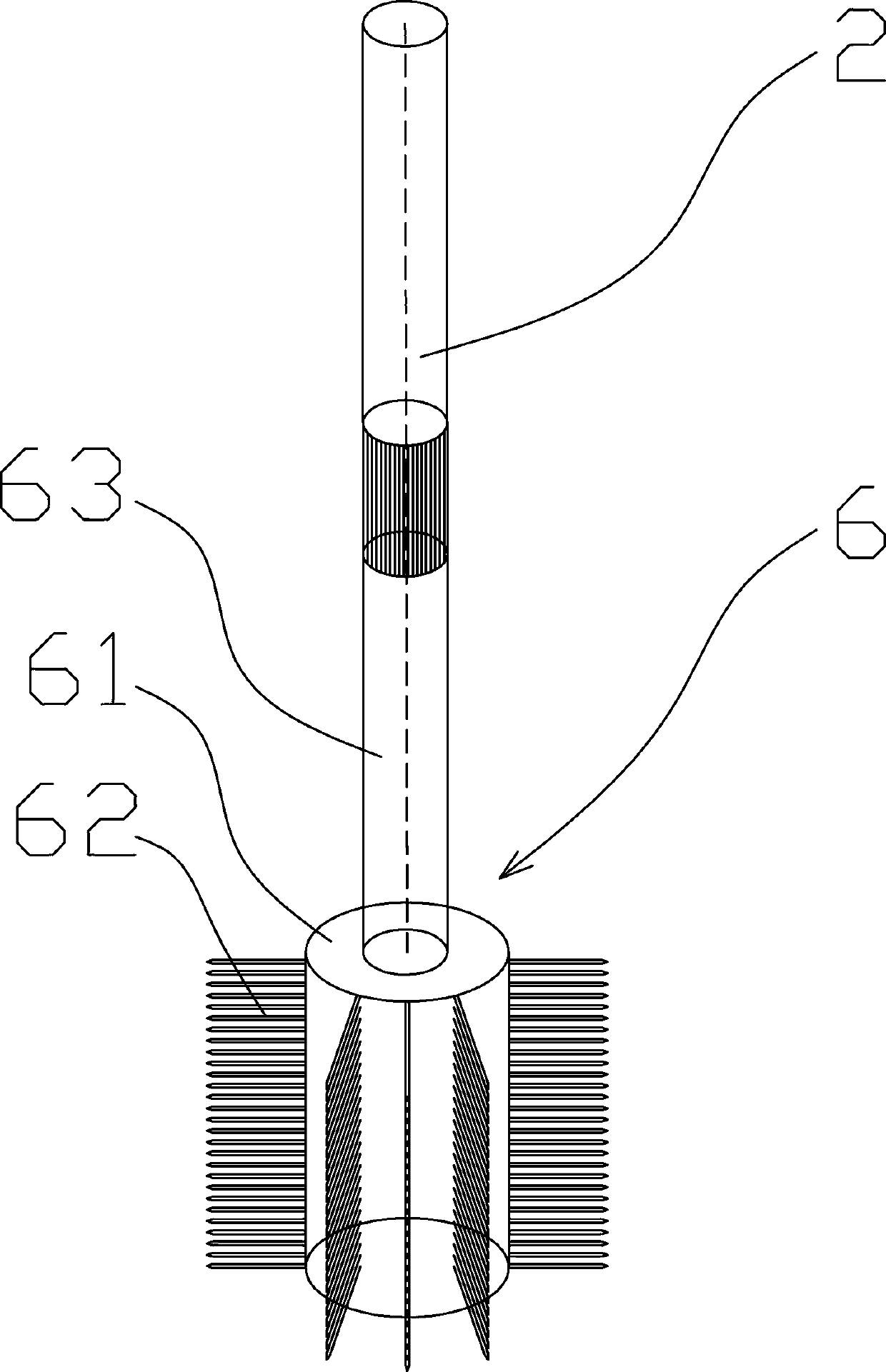

Salvage device and construction method of drill bit of spin dig drill

ActiveCN109973040AUnobstructed accessIncrease success rateCleaning apparatusHigh pressure waterHigh pressure

The invention discloses a salvage device and a construction method of a drill bit of a spin dig drill. The salvage device comprises a comb-shaped rotating drill bit, a flat bamboo cutting type drill,and an anchor type drill bit; and in the comb-shaped rotating drill bit, the lower end of a first high pressure water pipe is connected with a rotating drill bit barrel body, radially distributed rotating drill bit irons nail or elastic steel wire are arranged on the inner wall or the outer wall of the rotating drill bit barrel body, the top end of the first high-pressure water pipe is connected with a drill pipe, and water outlet holes are formed in the side wall or / and bottom of the rotating drill bit barrel body. During construction, the comb-shaped rotating drill bit removes drilling slagon the drill bit of the spin dig drill, and the drill bit of the flat bamboo cutting type drill removes attachment in the drill bit of the spin dig drill; and the anchor type drill bit lifts the drillbit of the spin dig drill. According to the fishing device and the construction method of the drill bit of the spin dig drill, the drilling slag in a borehole is cleaned in the early stage by the comb-shaped rotating drill bit and the drill of the flat bamboo cutting type drill, a passage in the borehole is unobstructed, and the success rate of drill bit salvage of the spin dig drill bit is greatly increased; and the anchor type drill bit adopts an internal bracing structure, the problem of small gap between the drill bit of the spin dig drill and the inner wall of the borehole is solved, andthe success rate of salvage is significantly increased.

Owner:CCCC SECOND HARBOR ENG +1

Portable ballistic shield

ActiveUS7971516B2Reduce weightProvide protectionTravelling sacksTravelling carriersEngineeringAssault rifle

A portable ballistic shield is disclosed. The portable ballistic shield is contoured to conform to an individual's body and may be integrated with a rucksack and frame to provide protection to the user's back and torso while still allowing the user substantially unobstructed access to all parts of the rucksack. The portable ballistic shield may also provide rigidity for the rucksack, eliminating the need for a rucksack frame. The portable ballistic shield may also comprise a shape allowing for the user to concurrently utilize an assault rifle or other firearm. During times of hostility, the user may deploy the shield from the rucksack in a minimal amount of time in order to protect the user from oncoming gunfire or shrapnel.

Owner:HOGAN GUY

Condiment container attachment device

InactiveUS20110272546A1More efficient and or reliableStable and easy attachmentCandle holdersLighting support devicesEngineeringMechanical engineering

Owner:NIELSEN CHARLOTTE

Jaw assembly for a jaw crusher

A jaw assembly for a jaw crusher is disclosed where the assembly comprises a jaw stock (12), a wear plate (16), and a fastening device in the form of a bolt (34) with a square head (42) at one end and a washer (56) and fastening nut (52) positioned at an end opposite to the one end. The bolt (34) extends between the jaw stock (12) and the wear plate (16). The fastening device (34, 42, 56, 52) is operative to adopt a clamped configuration where the device provides a clamping force along a fastening axis to clamp the wear plate (16) at the jaw stock (12), and a released configuration where the fastening device does not prevent the wear plate (16) from being separated from the jaw stock (12). The fastening device (34, 42, 56, 52) is accessible from a direction that is transverse to that fastening axis, to enable the device (34, 42, 56, 52) to be changed from its clamped configuration to its released configuration.

Owner:H E PARTS INT CRUSHING SOLUTIONS PTY LTD

Raised surface assay plate

InactiveUS20050208477A1Unobstructed accessBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringSubstrate surface

The assay plate includes a substrate having an substrate surface and at least one raised pad extending from the substrate surface. The raised pad includes a substantially planar sample receiving surface configured for holding a sample thereon for in-situ experimentation. The sample receiving surface preferably has at least one sharp edge at the junction between a sidewall coupling the sample receiving surface to the substrate surface. The sample receiving surface is preferably a circle, oval, square, rectangle, triangle, pentagon, hexagon, or octagon shape that is sized to hold a predetermined volume of the sample. A method of using the above described assay plate is also provided. Once a raised pad extending from a substrate is formed, a sample is deposited on the raised pad. Experiments are subsequently performed using the sample on the raised pad.

Owner:TRANSFORM PHARMACEUTICALS INC

Asphalt warm mixing agent

InactiveCN108530921AReduce intensityImprove permeabilityBuilding insulationsPolymer scienceWater vapor

The invention discloses an asphalt warm mixing agent, and belongs to the field of a road pavement material. A polymer is obtained by using maleic anhydride and benzene methanamine as raw materials, performing substitution reaction by using N,N-dimethyl formamide and adding paratoluenesulfonic acid as a catalyst; waste and old tire rubber powder is used as raw materials; sodium hypochlorite and microwaves are used and combined for treating the raw materials, so that the stability and the high-temperature performance of activated rubber asphalt are more prominent; moisture in zeolite during themixing of the zeolite with hot asphalt and hot aggregates is converted into water vapor, so that the asphalt volume expands to form foam asphalt, so that the asphalt and the aggregates can be mixed and compacted at low temperature. The problems that under the condition of small mixing quantity of the existing asphalt warm mixing agent, the warm mixing performance is low, and the viscosity reduction effect in a high temperature region is poor are solved; the asphalt warm mixing agent is provided.

Owner:张芸

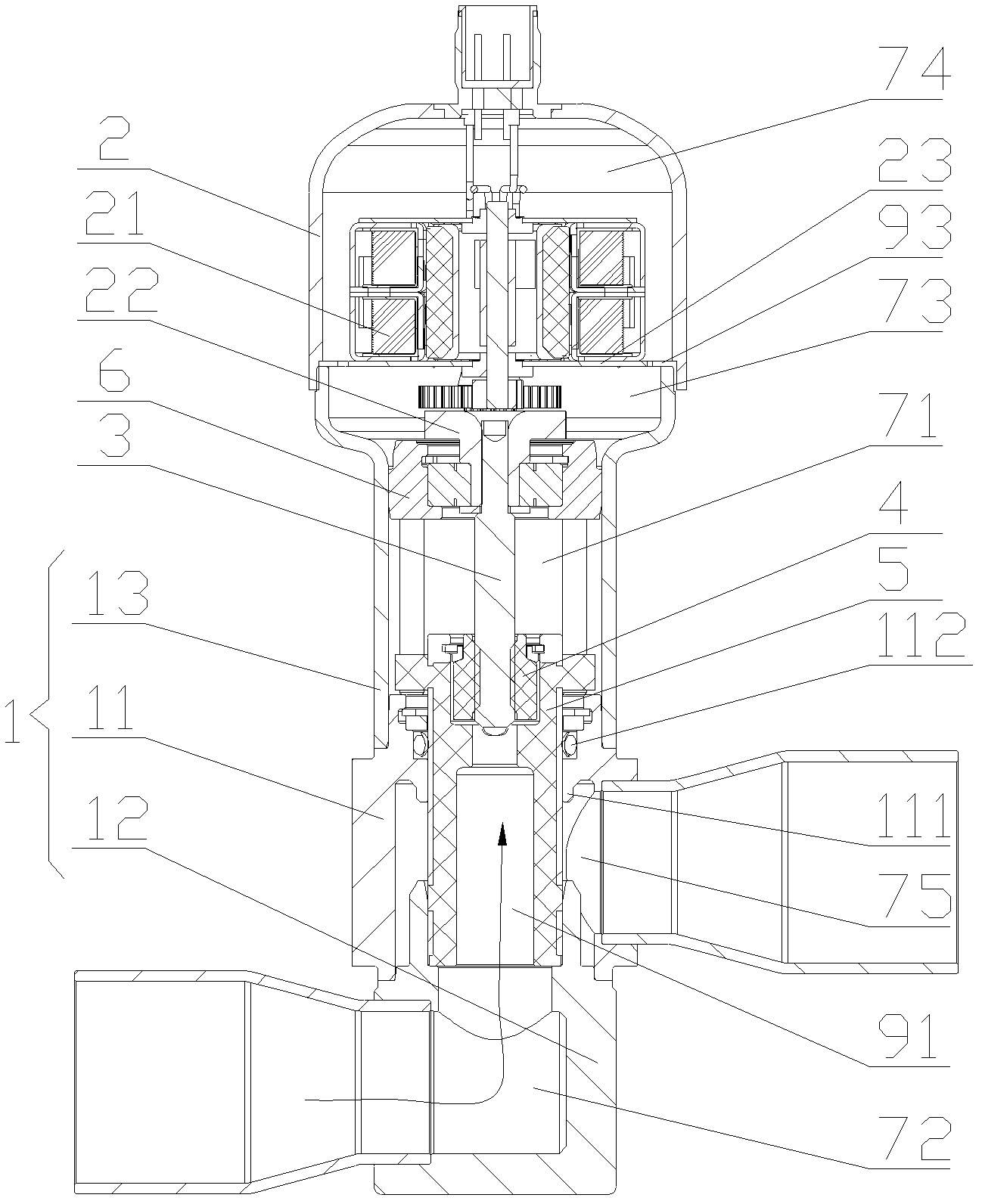

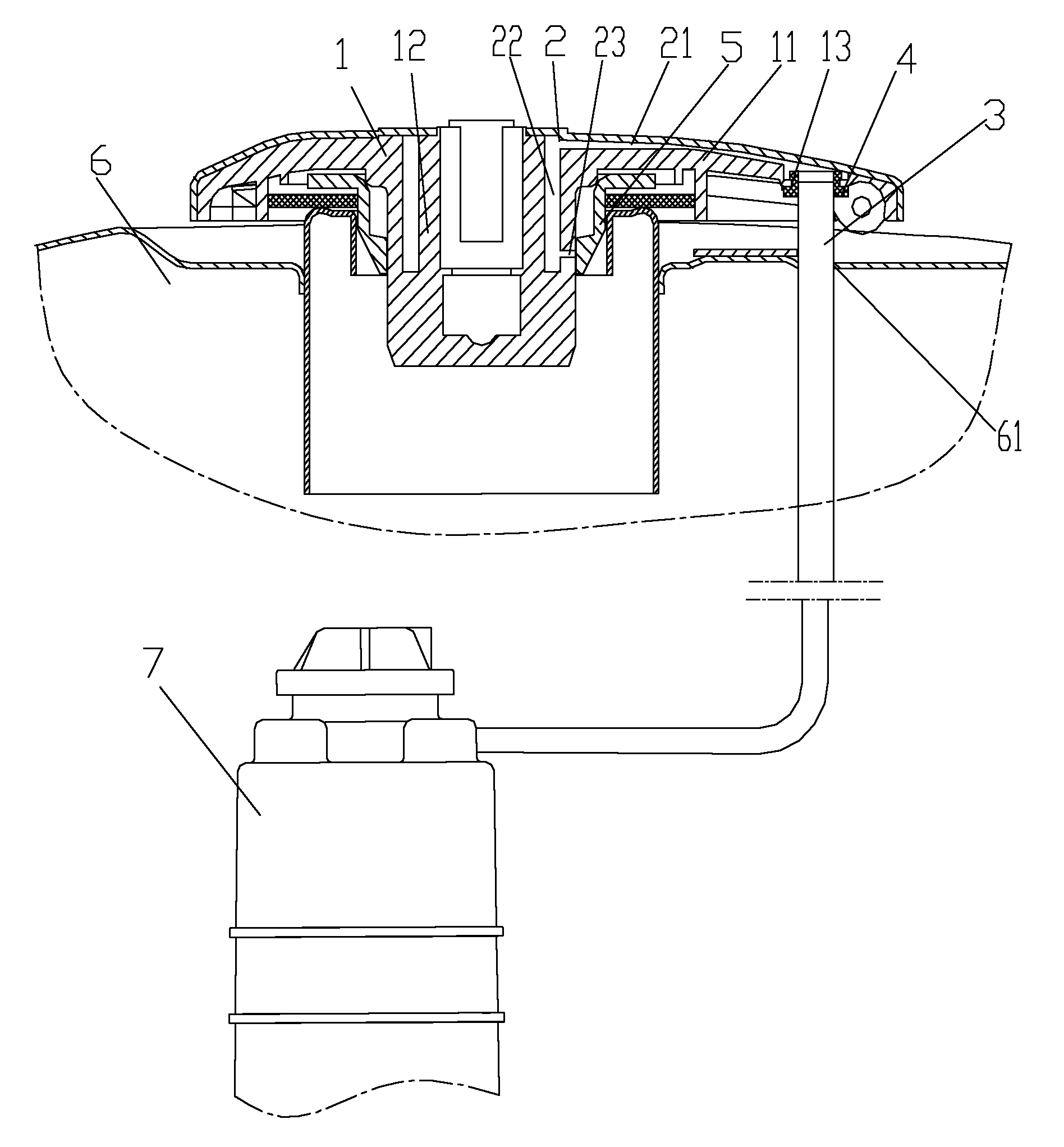

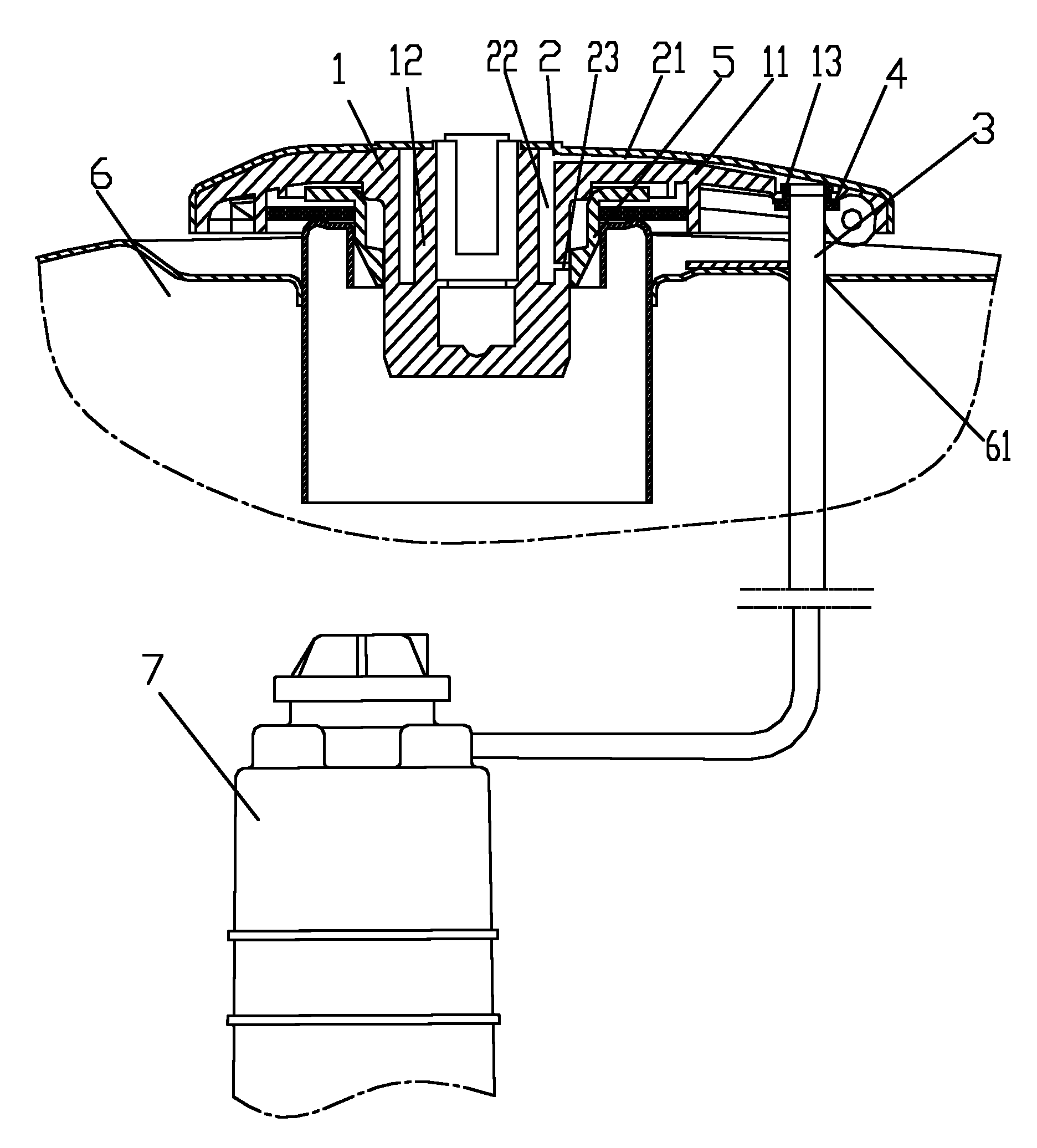

Flow control valve

ActiveCN102853101AUnobstructed accessFluid pressure balanceOperating means/releasing devices for valvesSlide valveEngineeringValve seat

The invention discloses a flow control valve. The flow control valve comprises a valve seat (1) and a shell (2), wherein a motor (21) is arranged inside the shell (2) and is connected with a screw rod (3); the screw rod (3) is connected with a nut (4); the nut (4) is connected with a valve rod (5); balance fluid channels which communicate first cavities (71) with a second cavity (72) are arranged on the valve rod (5); an installation groove (51) is arranged inside the valve rod (5); the whole nut (4) or the lower part of the nut (4) is matched in the installation groove (51); and the balance fluid channels comprise first fluid channels which are formed between the nut (4) and the inner walls of the installation groove (51). The flow control valve has the following beneficial effects that through design of the balance fluid channels, on one hand, the fluid pressure borne by the valve rod (5) can be timely and effectively balanced, and on the other hand, impacts on rotation of the screw rod (3) can be avoided.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

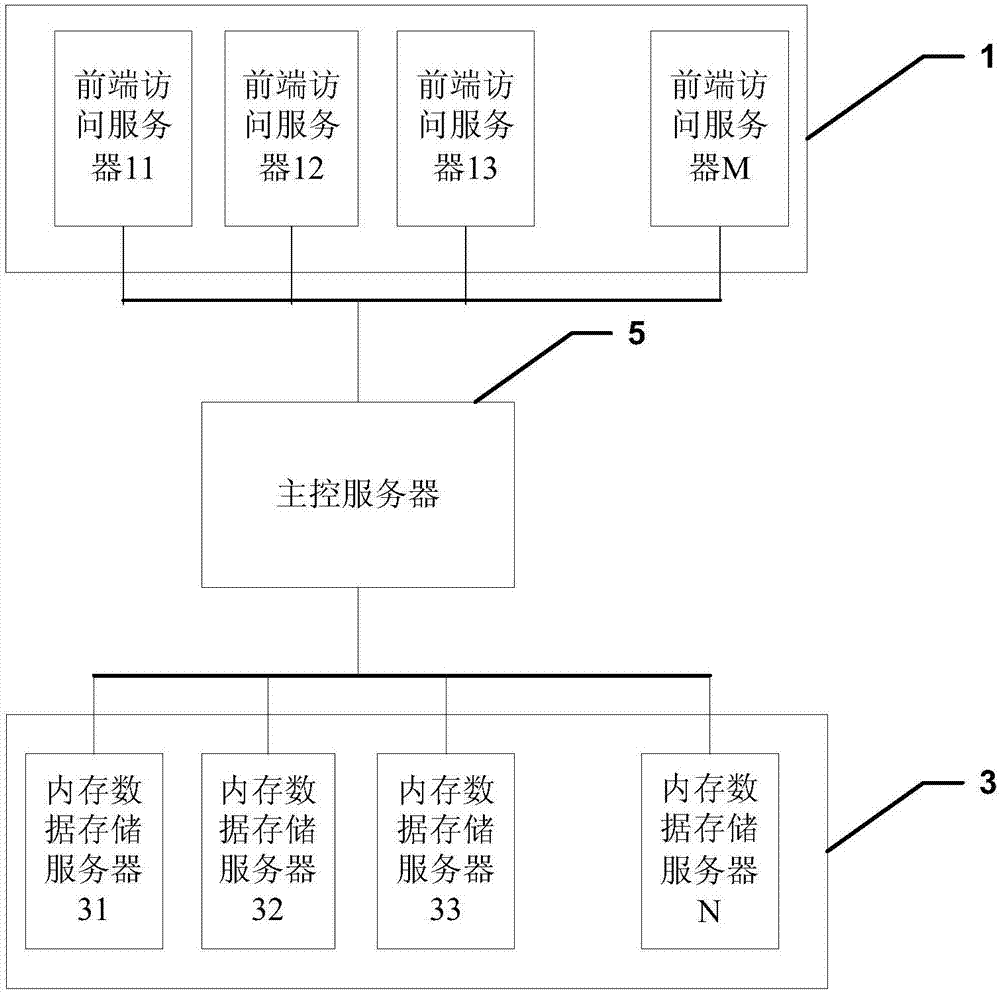

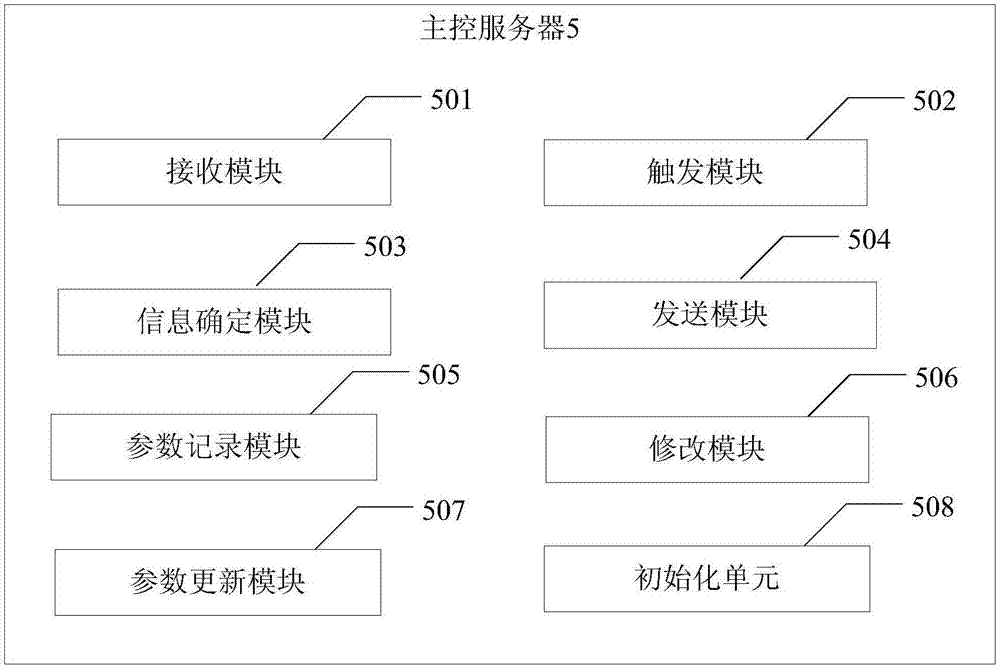

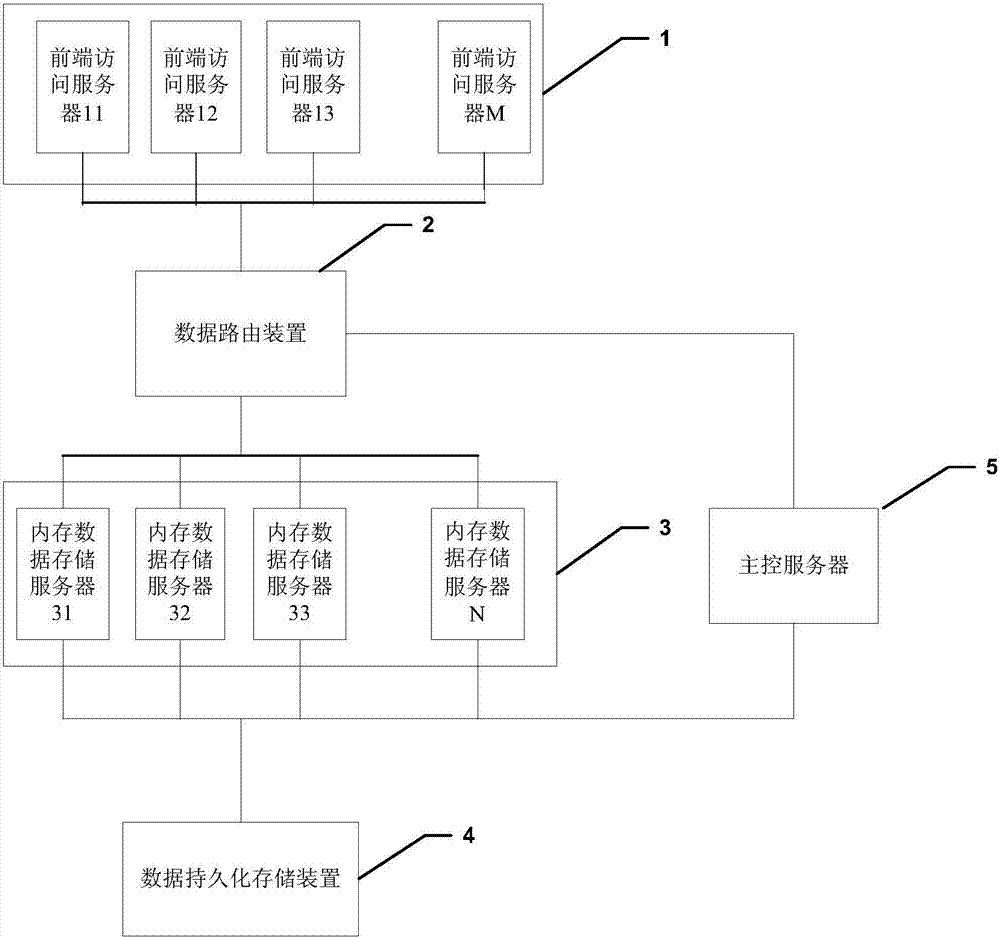

Redistribution method and system for distributed memory data, and master control server

ActiveCN106973091AUnobstructed accessDoes not affect real-time performanceData switching networksDistributed memoryIp address

The present invention provides a redistribution method and system for distributed memory data, and a master control server. The method comprises: receiving memory usage data of each memory data storage server sent by a memory data storage server cluster; if the memory usage data of at least one memory data storage server is greater than a preset memory usage threshold, triggering a data redistribution process; determining data migration information, the data migration information including an IP address of a server of which data needs to be migrated, a HASH value to be migrated, the amount of service data to be migrated and an IP address of a target server; migrating the service data to be migrated to the target server according to the data migration information, the target server being a memory data storage server newly added in the memory data storage server cluster. The technical solution may support continuous service when the added server performs data redistribution.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

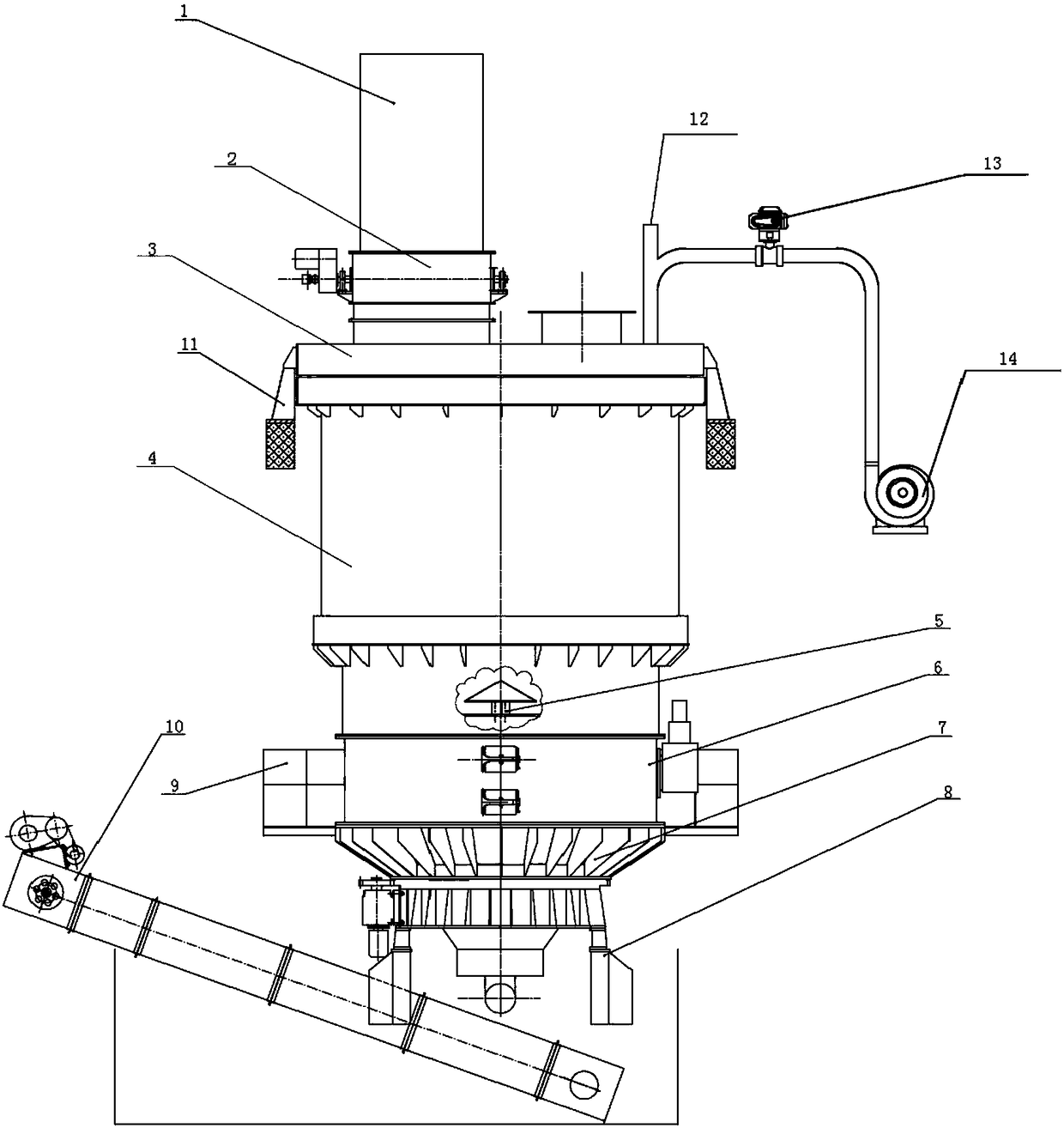

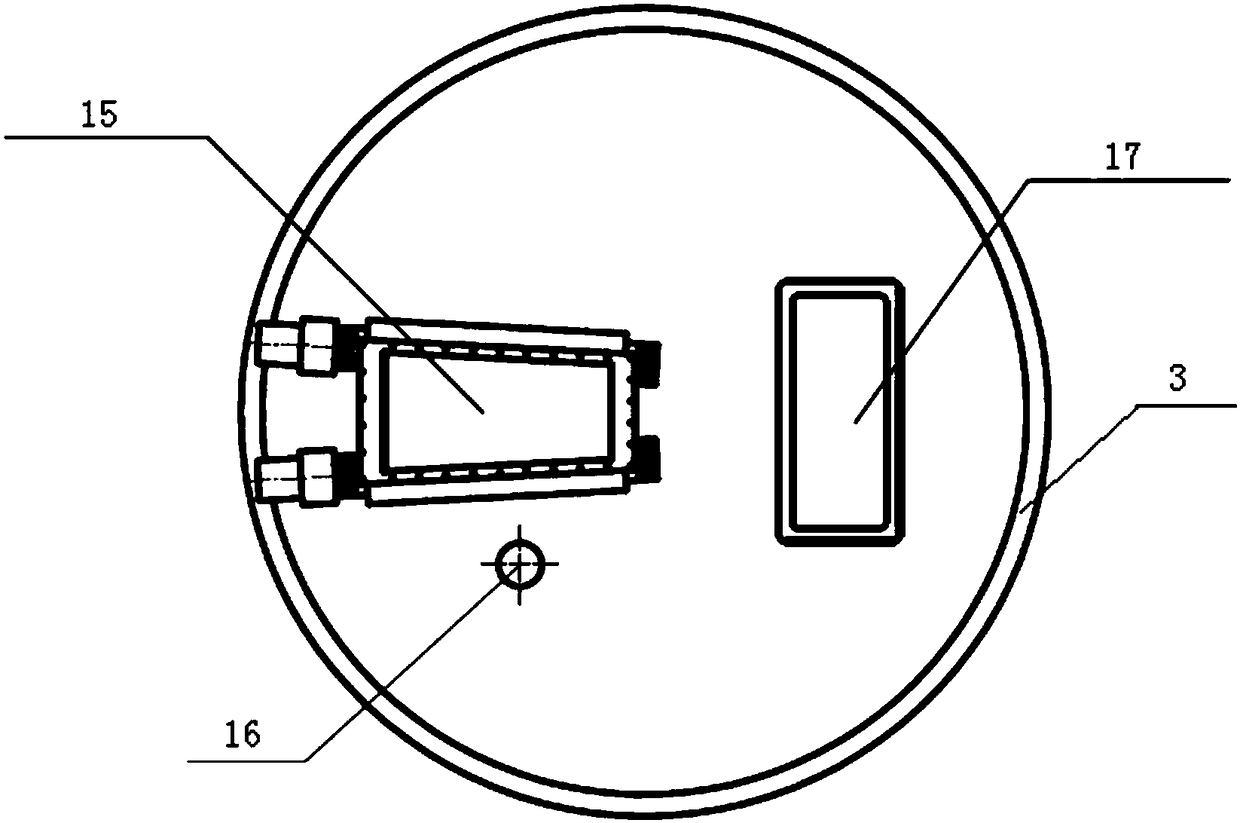

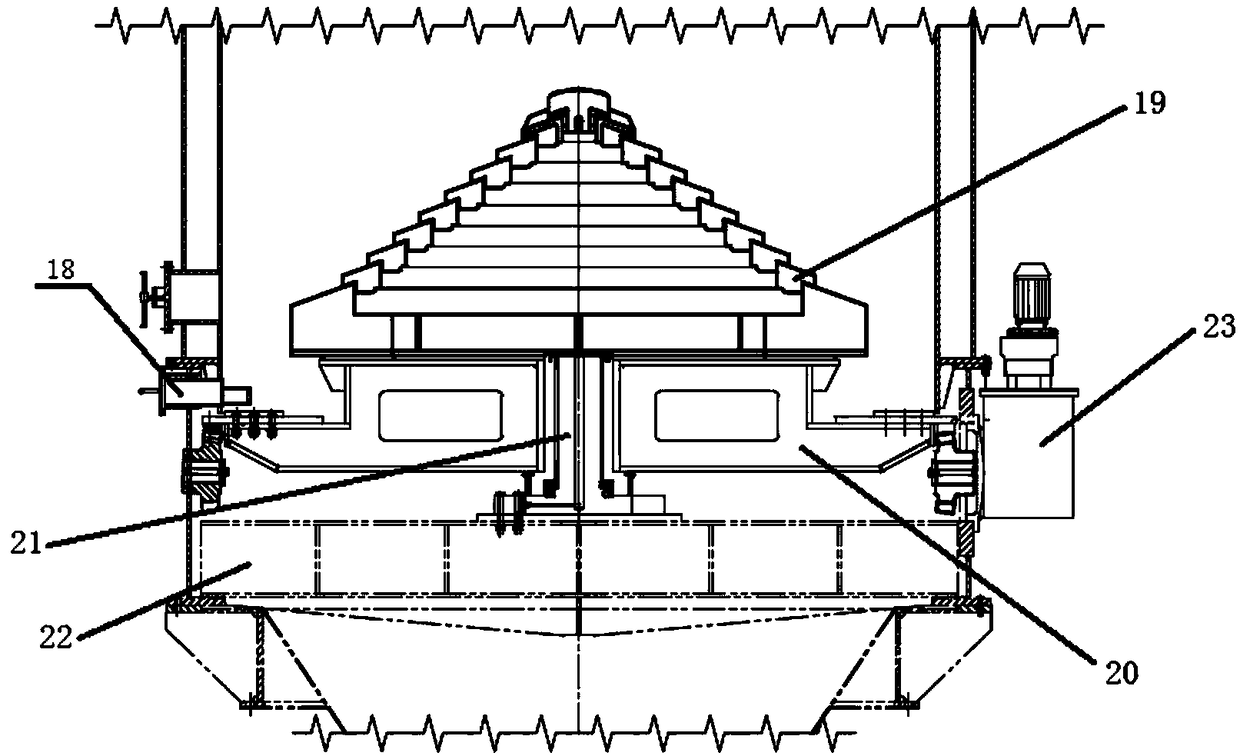

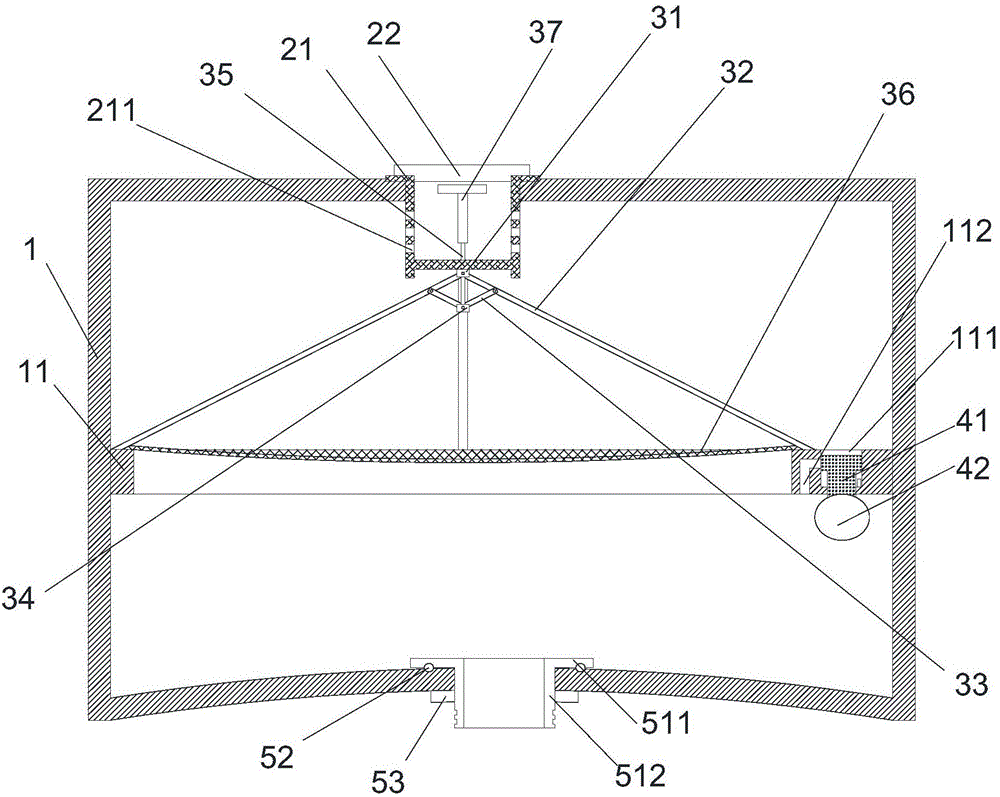

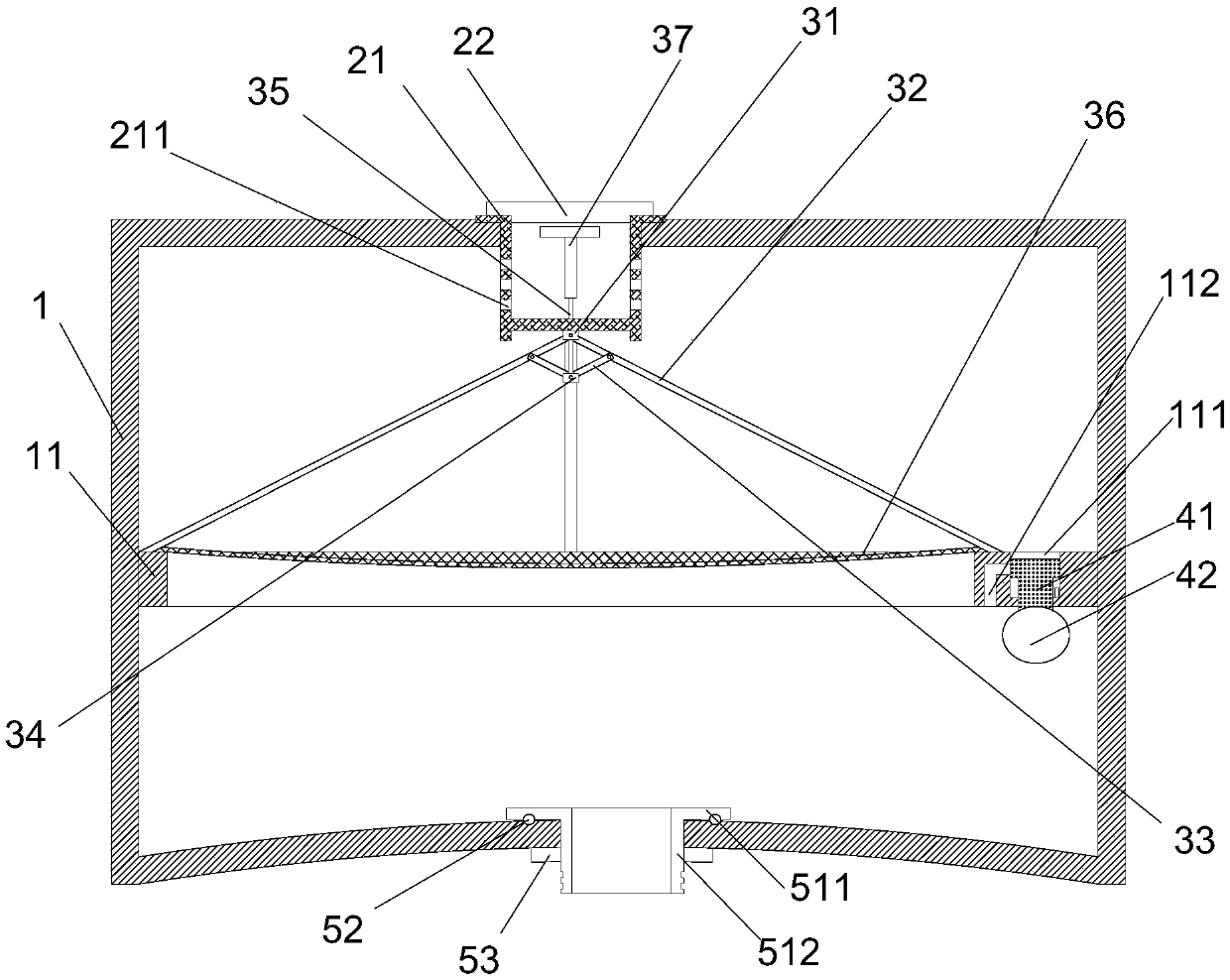

Pyrolysis and gasification incinerator for garbage and method

ActiveCN108204591AEven air distributionBurn fullyIncinerator apparatusSolid removalCombustion chamberSlag

The invention provides a pyrolysis and gasification incinerator for garbage and a method. The incinerator comprises an incinerator body, a fire grate, and an air supplementing device which is arrangedat the upper side of the incinerator body, wherein a supplemented air inlet of the air supplementing device is formed in a cover at the upper end of the incinerator body; the fire grate, comprising amulti-layer annular grid tray, is fixed to the inner lower part of the incinerator body; the multi-layer annular grid tray is coaxially arranged and overlapped in a tower shape. According to the pyrolysis and gasification incinerator for the garbage and the method, the supplemented air inlet is formed in the cover, so that the combustion in the incinerator can be completely carried out, and as aresult, the incinerating efficiency can be improved; an upper area in the incinerator body can be used as a secondary combustion chamber, so that the used area can be greatly saved, and the design cost can be saved; the multi-layer annular grid tray of the fire grate is coaxially arranged; slag discharging and air supplying are independent and do not influence each other, so that dust can be smoothly discharged, and the supplied air can smoothly enter the incinerator, and as a result, the combustion in the incinerator is completely carried out, and the combustion efficiency is improved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Novel salt solution impurity removing box

ActiveCN106582082AAvoid accumulationEffective filteringStationary filtering element filtersSoftware engineeringSalt solution

The invention provides a novel salt solution impurity removing box. The novel salt solution impurity removing box comprises a main box body, a liquid inlet plug and a filtering mechanism, wherein a liquid inlet is formed in the top of the main box body, and a liquid outlet is formed in the lower part of the main box body; multiple air holes are formed in a liquid inlet plug body; the filtering mechanism comprises a first movable connecting block, multiple first connecting rods, multiple second connecting rods, a second movable connecting block, an adjusting lever and a filter screen, the second connecting rods and the first connecting rods are in one-to-one correspondence, a movable groove is formed in the second movable connecting block, and the shape of the lower part of the adjusting rod is rotationally matched with that of the movable groove; the periphery of the filter screen is connected with the lower ends of the first connecting rods; an annular inner convex part is arranged in the main box body. The novel salt solution impurity removing box is low in manufacturing cost and long in service life, impurities in the salt solution impurity removing box are effectively filtered, and the novel salt solution impurity removing box can be cleaned conveniently.

Owner:中盐东兴盐化股份有限公司

Motorcycle fuel evaporation system and motorcycle thereof

InactiveCN102072052AImprove the blocking effectGuaranteed unobstructedNon-fuel substance addition to fuelFuel tanksFuel tankEvaporation

The invention discloses a motorcycle fuel evaporation system and a motorcycle thereof. The system comprises a fuel evaporation pipe, a carbon tank and a fuel tank lock body, wherein the fuel tank lock body is provided with a gas path; one end of the gas path is communicated with the fuel tank, and the other end is communicated with the fuel evaporation pipe and is sealed with the outside; the fuel evaporation pipe is connected between the carbon tank and the gas path; and the port of the fuel evaporation pipe is positioned on the position out of the engine fuel tank and is communicated with the gas path in the fuel tank lock body. Fuel steam can smoothly enter and exit via the gas path, and liquid is blocked because the port of the fuel evaporation pipe is positioned out of the fuel tank.When the motorcycle fuel evaporation system is applied to the motorcycle, fuel can be prevented from splashing or infiltrating into the fuel evaporation pipe so as to prevent the fuel evaporation pipe from being blocked, thereby guaranteeing balanced pressure in the fuel tank, bringing convenience for lowering emission and fuel consumption, prolonging the service life of the carbon tank and guaranteeing the dynamic performance and the use performance of the whole motorcycle. A gas and fuel separator, a dumping valve and other components are omitted, which lowers cost and makes the structural arrangement of the whole motorcycle simpler.

Owner:CHONGQING LONCIN MOTOR

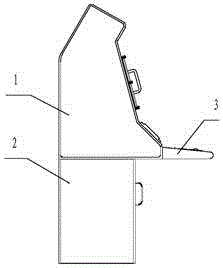

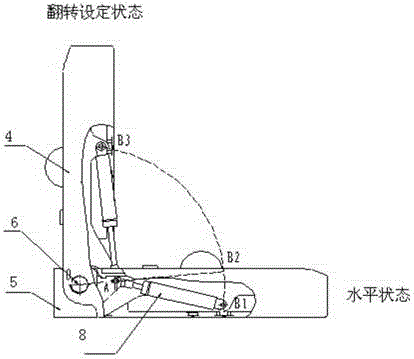

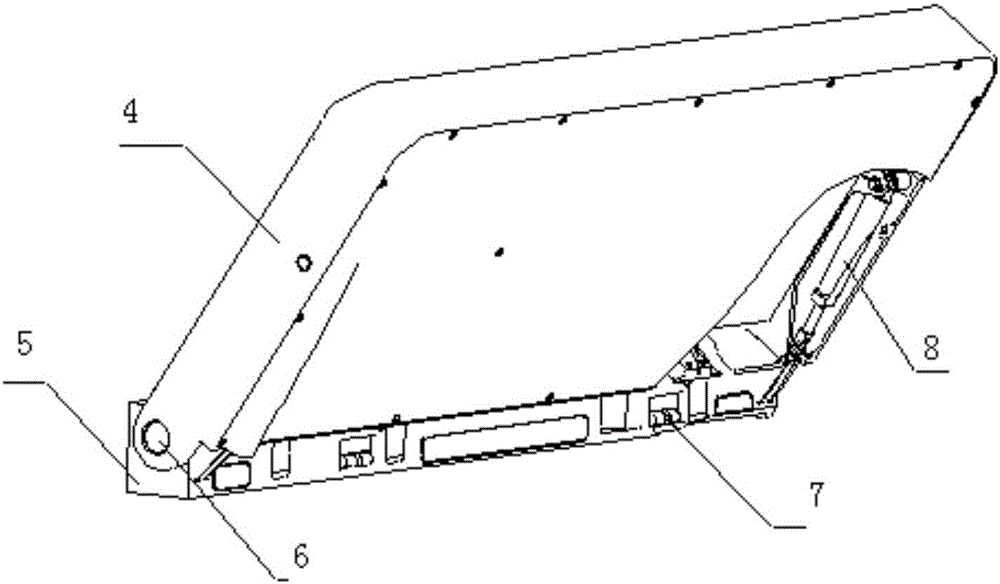

Control table board used for display control panel and provided with turning device

The invention relates to a control table board used for a display control panel and with a turning function. The control table board comprises a front mounting plate (4), a rear mounting part (5) and a turning device. The turning device comprises a rotary bearing (6), a locking part (7) and a gas spring (8). The front mounting plate (4) is connected with the rear mounting part (5) through the rotary bearing (6). The locking part (7) comprises a locking part A and a locking part B which are respectively mounted on the front mounting plate (4) and the rear mounting part (5). One end of the gas spring (8) is fixed on the front mounting plate (4), and the other end thereof is fixed on the rear mounting part (5). The control table board has the advantages that the control table board can be conveniently switched between an upper turning position and a horizontal position, an operator can enter and get out smoothly by turning the control table board, detection and maintenance of structural functional equipment below the control table board are benefited, the packaging size of the display control panel can be controlled effectively, and transportation convenience is achieved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Motorcycle fuel evaporation system and motorcycle thereof

InactiveCN102072052BSimple manufacturing processUnobstructed accessNon-fuel substance addition to fuelFuel tanksFuel tankEvaporation

The invention discloses a motorcycle fuel evaporation system and a motorcycle thereof. The system comprises a fuel evaporation pipe, a carbon tank and a fuel tank lock body, wherein the fuel tank lock body is provided with a gas path; one end of the gas path is communicated with the fuel tank, and the other end is communicated with the fuel evaporation pipe and is sealed with the outside; the fuel evaporation pipe is connected between the carbon tank and the gas path; and the port of the fuel evaporation pipe is positioned on the position out of the engine fuel tank and is communicated with the gas path in the fuel tank lock body. Fuel steam can smoothly enter and exit via the gas path, and liquid is blocked because the port of the fuel evaporation pipe is positioned out of the fuel tank.When the motorcycle fuel evaporation system is applied to the motorcycle, fuel can be prevented from splashing or infiltrating into the fuel evaporation pipe so as to prevent the fuel evaporation pipe from being blocked, thereby guaranteeing balanced pressure in the fuel tank, bringing convenience for lowering emission and fuel consumption, prolonging the service life of the carbon tank and guaranteeing the dynamic performance and the use performance of the whole motorcycle. A gas and fuel separator, a dumping valve and other components are omitted, which lowers cost and makes the structural arrangement of the whole motorcycle simpler.

Owner:CHONGQING LONCIN MOTOR

Condiment container attachment device

InactiveUS9493282B2More efficient and or reliableStable and easy attachmentCandle holdersLighting support devicesEngineeringMechanical engineering

Owner:NIELSEN CHARLOTTE

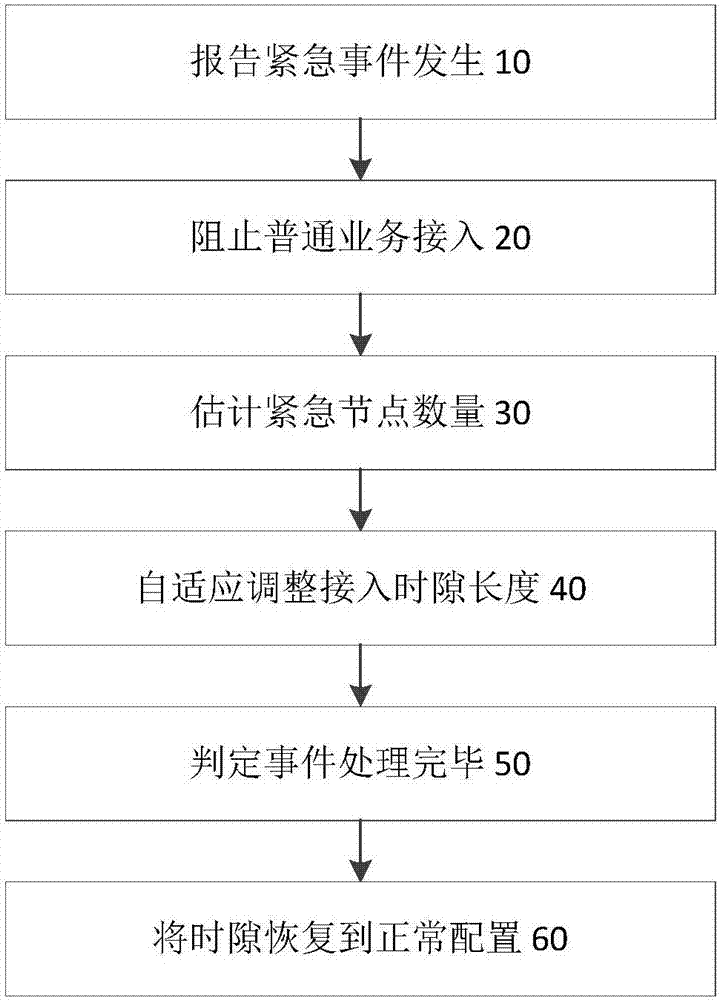

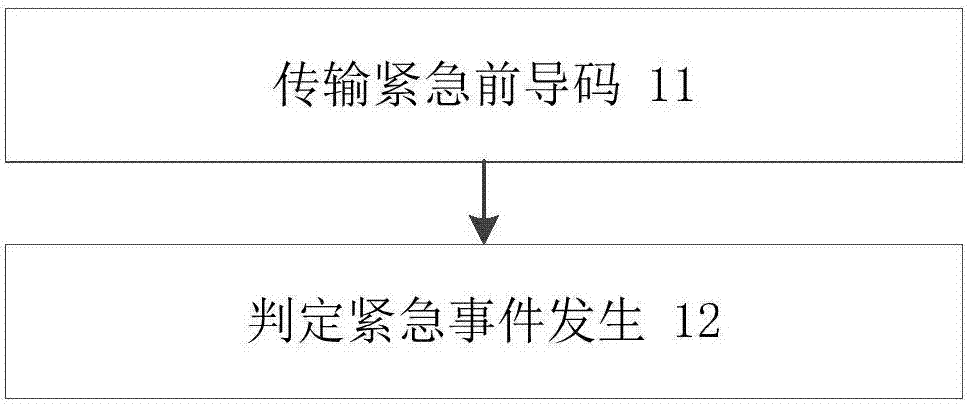

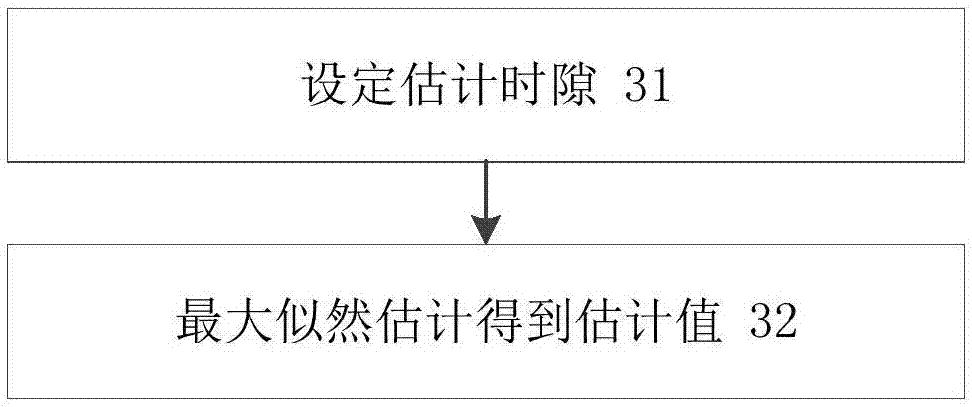

M2M communication access control optimizing method for emergency event of LTE network

ActiveCN107086900AReduce conflictUnobstructed accessAssess restrictionPilot signal allocationAccess timeNormal values

The invention discloses an M2M communication access control optimizing method for an emergency event of the LTE network. The method comprises the following steps of (10) reporting occurrence of the emergency event, in which a machine node sends a specific lead code to a base station; (20) preventing access of a common service by placing the emergency event in the highest priority according to the specific lead code; (30) estimating the number of emergency nodes, in which the base station estimates the number of nodes that request access; (40) adjusting the length of an access time slot adaptively, in which the base station adjusts the length of the access time slot adaptively according to the number of the nodes; (50) determining the event is processed, in which the emergency event is determined to be processed if there is no node transmission lead code; and (60) recovering the time slot of the base station to normal configuration, in which access forbidden parameters of common machine nodes are recovered to normal values, and the time length of the access time slot is recovered to normal configuration. Via the access control optimizing method, access is smooth, and the reliability is high.

Owner:PLA UNIV OF SCI & TECH

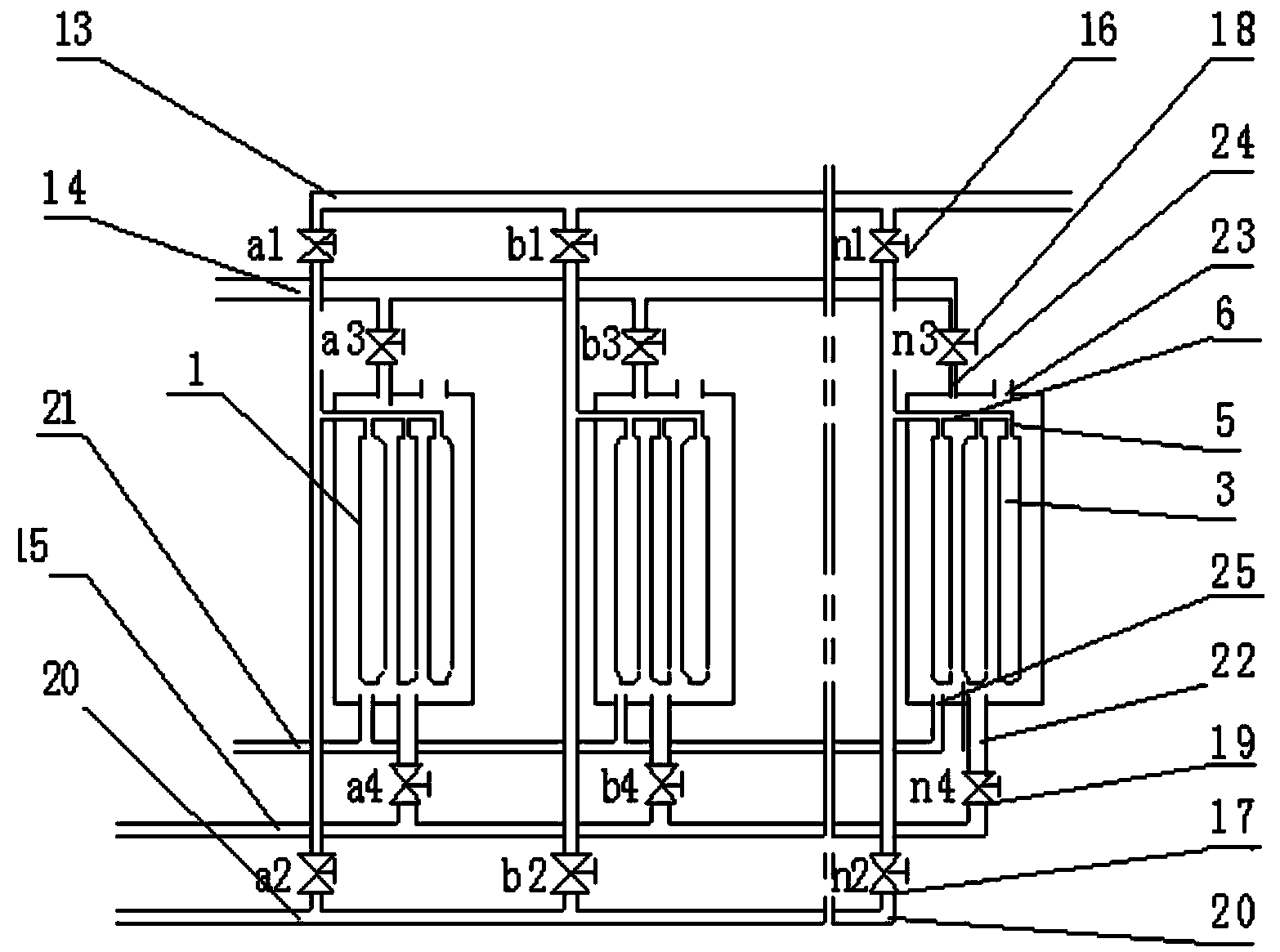

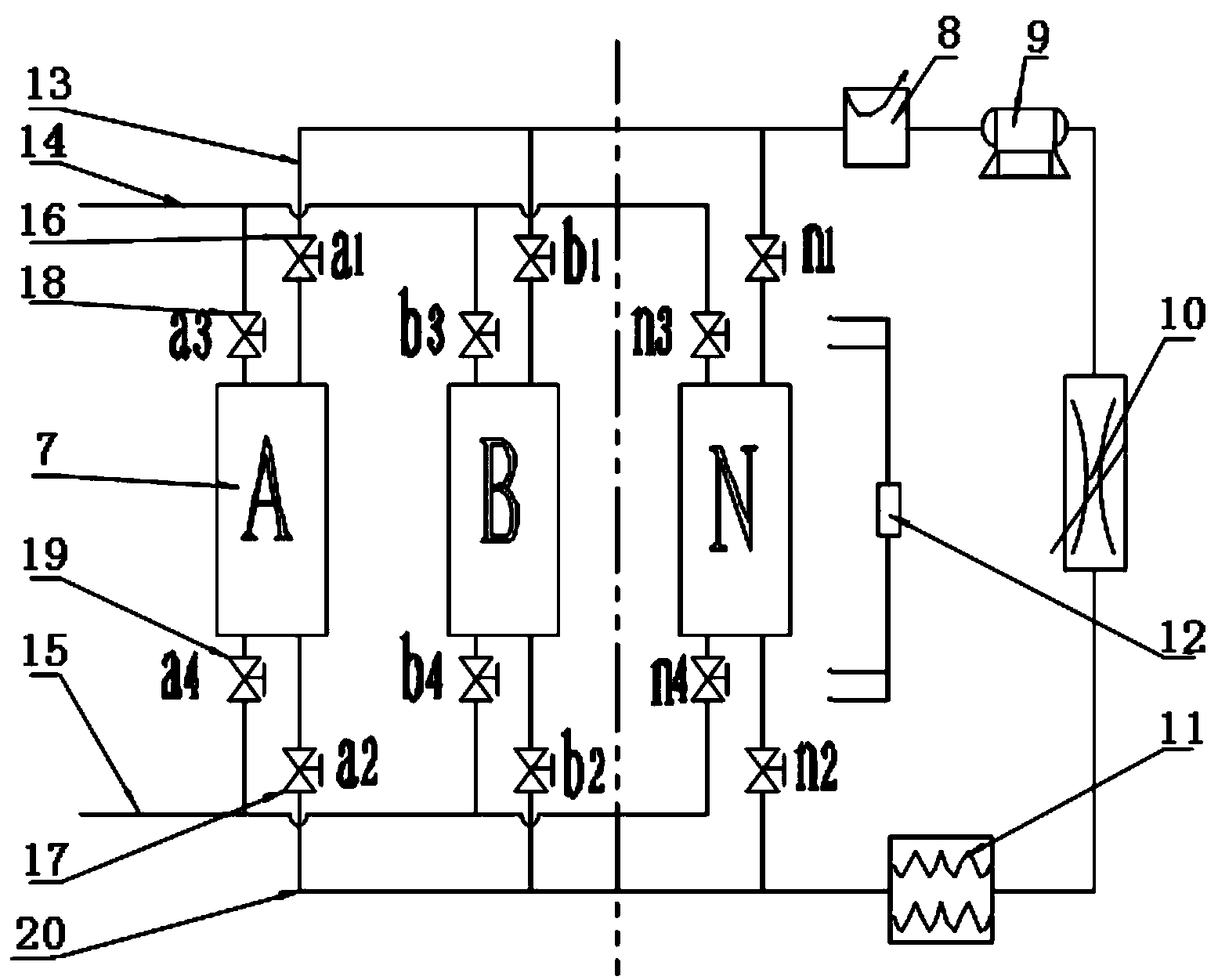

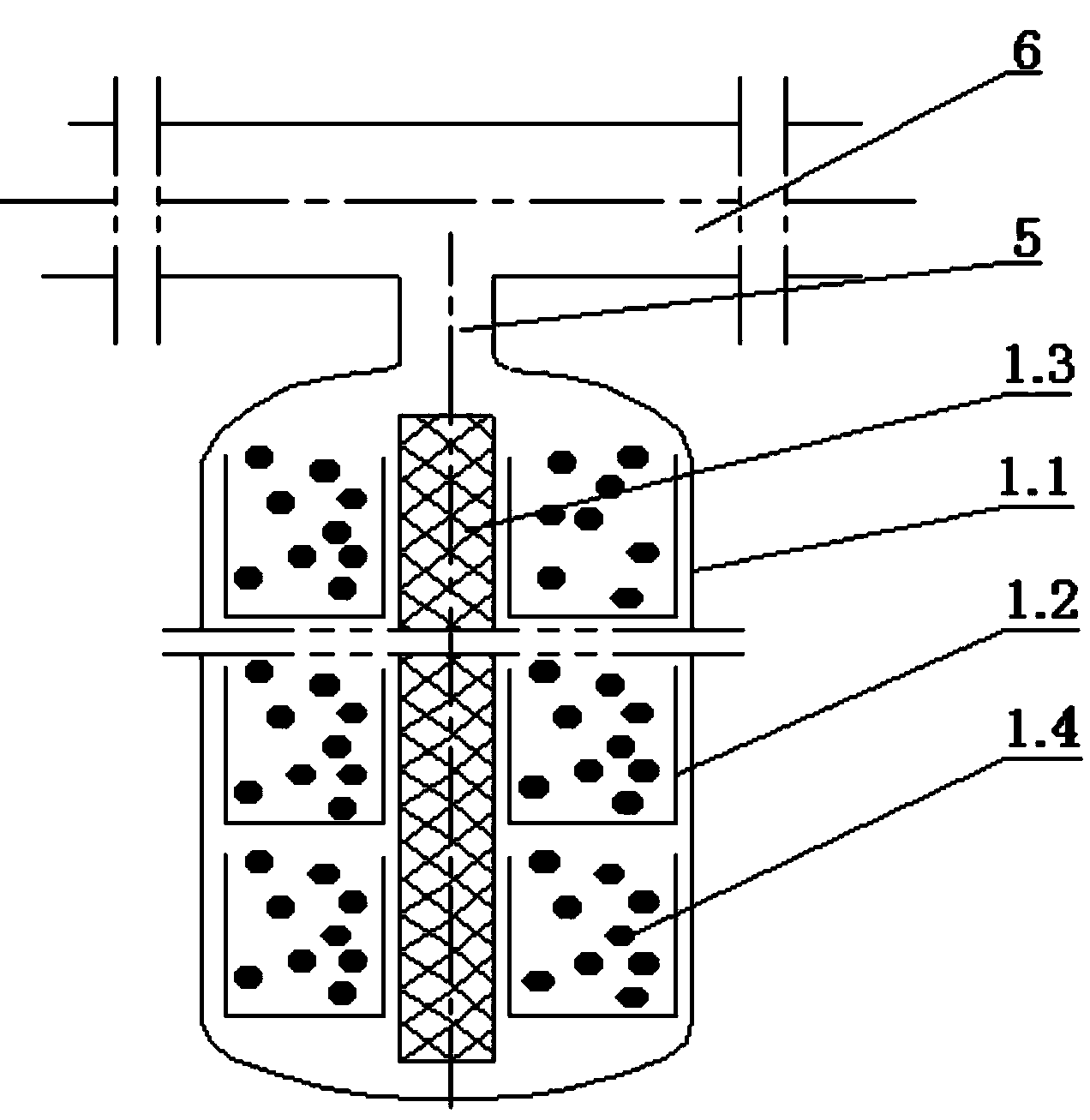

Chemical adsorption type heat refrigeration system employing alkaline-earth metal halide

ActiveCN104048440AImprove cooling effectAdd depthEnergy efficient heating/coolingClimate change adaptationAlkaline earth metalDesorption

The invention discloses a chemical adsorption type heat refrigeration system employing an alkaline-earth metal halide. The chemical adsorption type heat refrigeration system comprises N adsorption bed components, wherein each adsorption bed component comprises an adsorption bed unit tube component, an ammonia gas adsorption pipeline and an ammonia gas desorption pipeline, a heat source inlet pipeline, a cooling water inlet pipeline and a cooling water return pipeline; each adsorption bed unit tube component comprises M adsorption unit tubes, each adsorption unit tube comprises an adsorption outer tube, a plurality of trays arranged in the adsorption outer tube and a filter screen arranged between two adjacent rows of trays, an adsorbent is arranged in each tray, and the top ends of the adsorption outer tubes are connected to a gas manifold; a condenser, a liquid ammonia tank, a throttle valve and an evaporator are connected between each ammonia gas adsorption pipeline and each ammonia gas desorption pipeline in sequence. According to the chemical adsorption type heat refrigeration system, through cooperative application of chemical adsorption beds for adsorption and desorption, the uninterrupted heating or cooling is realized, and the refrigerating capacity and the refrigeration depth are improved under the same heat source condition.

Owner:武汉箕星制冷有限公司

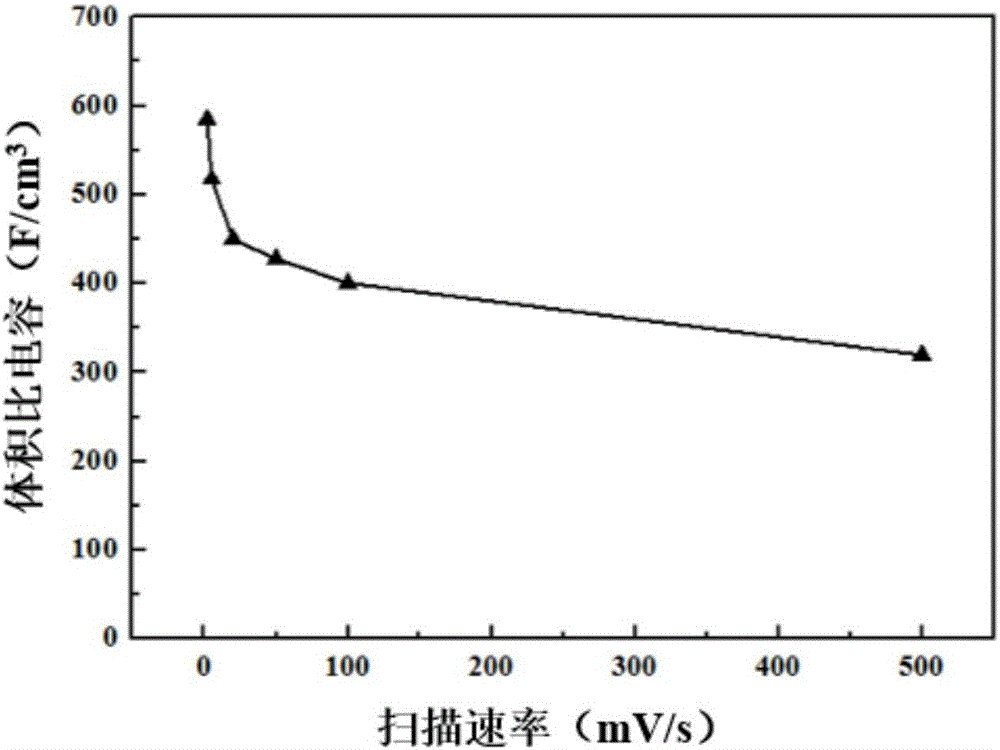

High volumetric specific capacitance flexibility molybdenum sulfide gel film electrode materials and preparation method thereof

InactiveCN106803463AHigh densityHigh Volumetric CapacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceCellulose

The present invention relates to a high volumetric specific capacitance flexibility molybdenum sulfide gel film electrode materials and a preparation method thereof. The concrete steps of the method comprise: (1) mixing molybdenum sulfide powder and n-butyllithium normal hexane solution to perform a lithium intercalation reaction, wherein the reaction products are cleaned by employing normal hexane; (2) adding deionized water into the products, configuring the molybdenum sulfide dispersion liquid, and performing peeling fragmentation processing by employing an ultrasonic wave cell disruptor; (3) performing centrifugation of the molybdenum sulfide dispersion liquid with peeling fragmentation, and obtaining a metallicity molybdenum sulfide dispersion liquid; (4) employing a mixed cellulose filter film to perform vacuum filtration of the metallicity molybdenum sulfide dispersion liquid; and (6) putting molybdenum sulfide gel attached to the mixed cellulose filter film into the ionic liquid aqueous solution for replacement, and obtaining the product after vacuum drying. Compared with the prior art, the prepared molybdenum sulfide gel film electrode materials has high volumetric specific capacitance are taken as a supercapacitor electrode to display the good volumetric specific capacitance.

Owner:TONGJI UNIV

A kind of salt solution miscellaneous box

ActiveCN106582082BAvoid accumulationEffective filteringStationary filtering element filtersSoftware engineeringSalt solution

The invention provides a novel salt solution impurity removing box. The novel salt solution impurity removing box comprises a main box body, a liquid inlet plug and a filtering mechanism, wherein a liquid inlet is formed in the top of the main box body, and a liquid outlet is formed in the lower part of the main box body; multiple air holes are formed in a liquid inlet plug body; the filtering mechanism comprises a first movable connecting block, multiple first connecting rods, multiple second connecting rods, a second movable connecting block, an adjusting lever and a filter screen, the second connecting rods and the first connecting rods are in one-to-one correspondence, a movable groove is formed in the second movable connecting block, and the shape of the lower part of the adjusting rod is rotationally matched with that of the movable groove; the periphery of the filter screen is connected with the lower ends of the first connecting rods; an annular inner convex part is arranged in the main box body. The novel salt solution impurity removing box is low in manufacturing cost and long in service life, impurities in the salt solution impurity removing box are effectively filtered, and the novel salt solution impurity removing box can be cleaned conveniently.

Owner:中盐东兴盐化股份有限公司

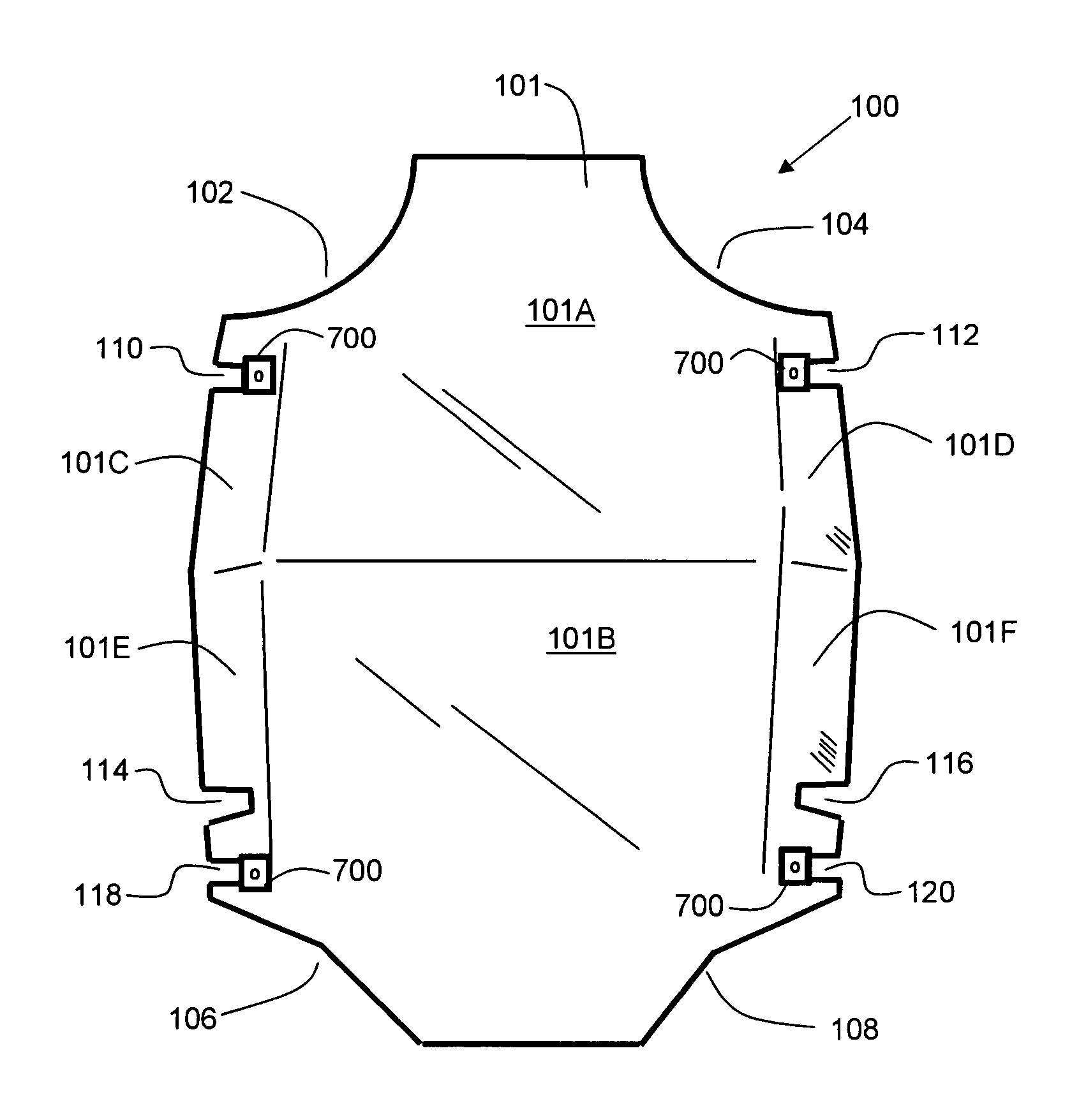

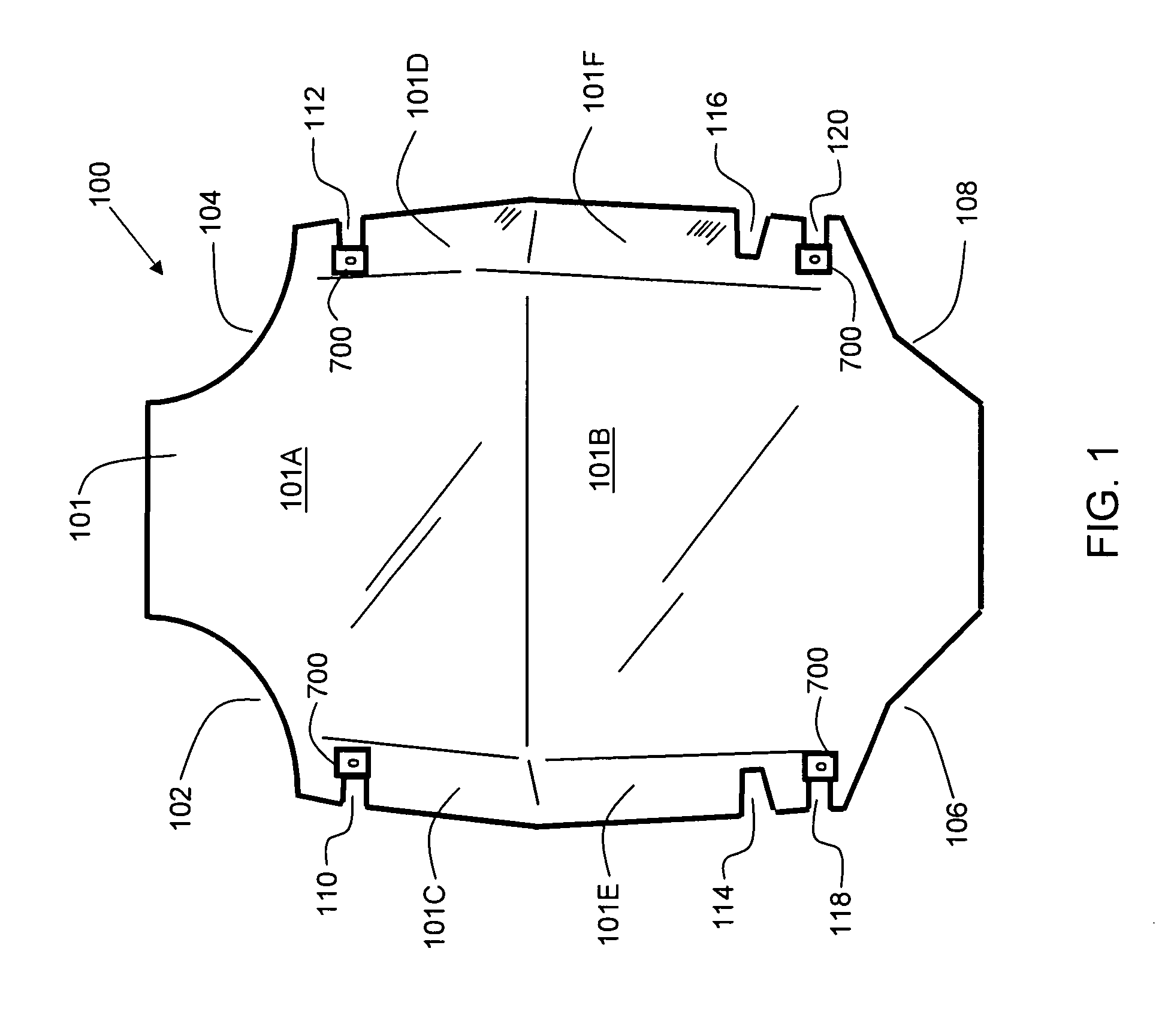

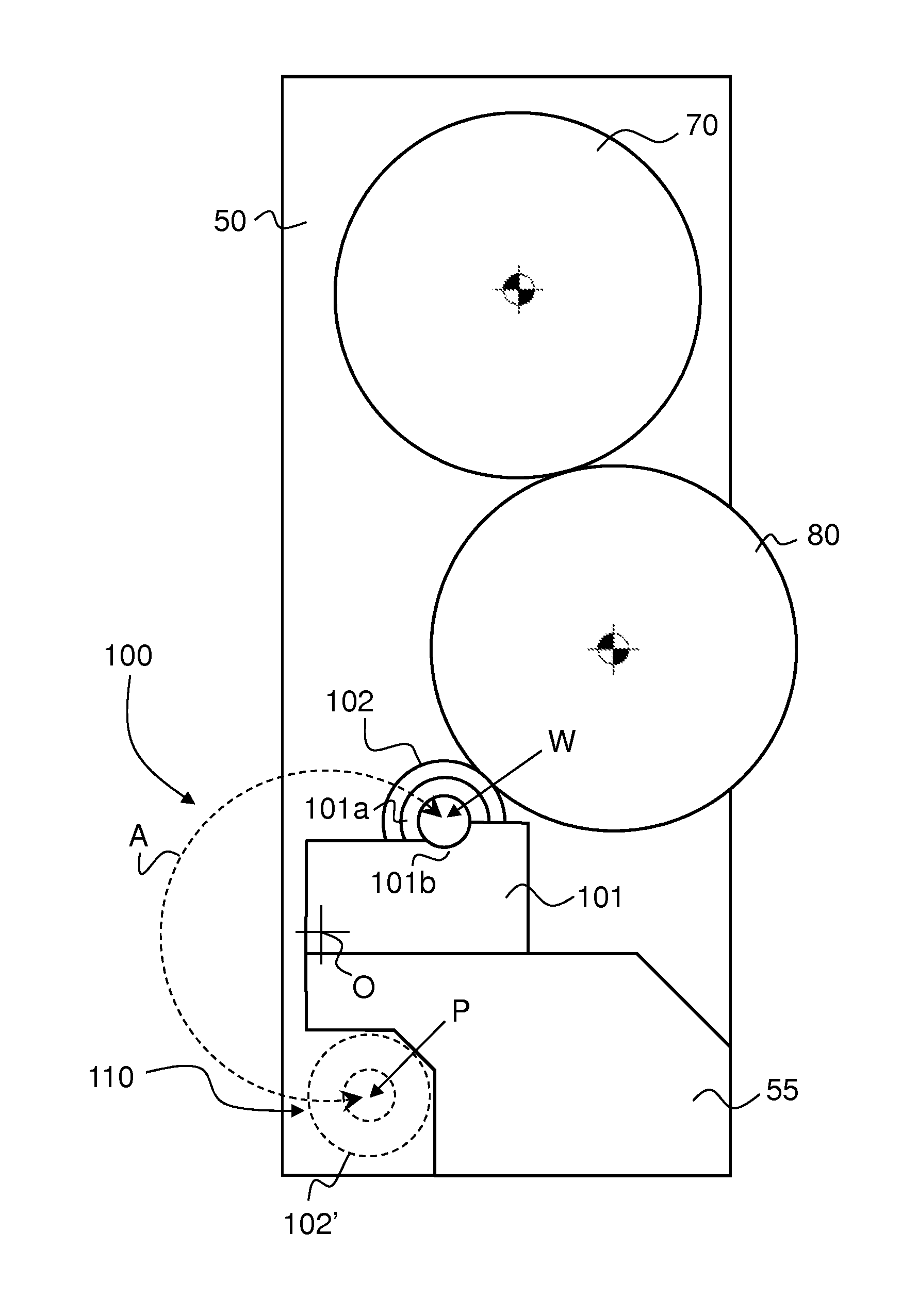

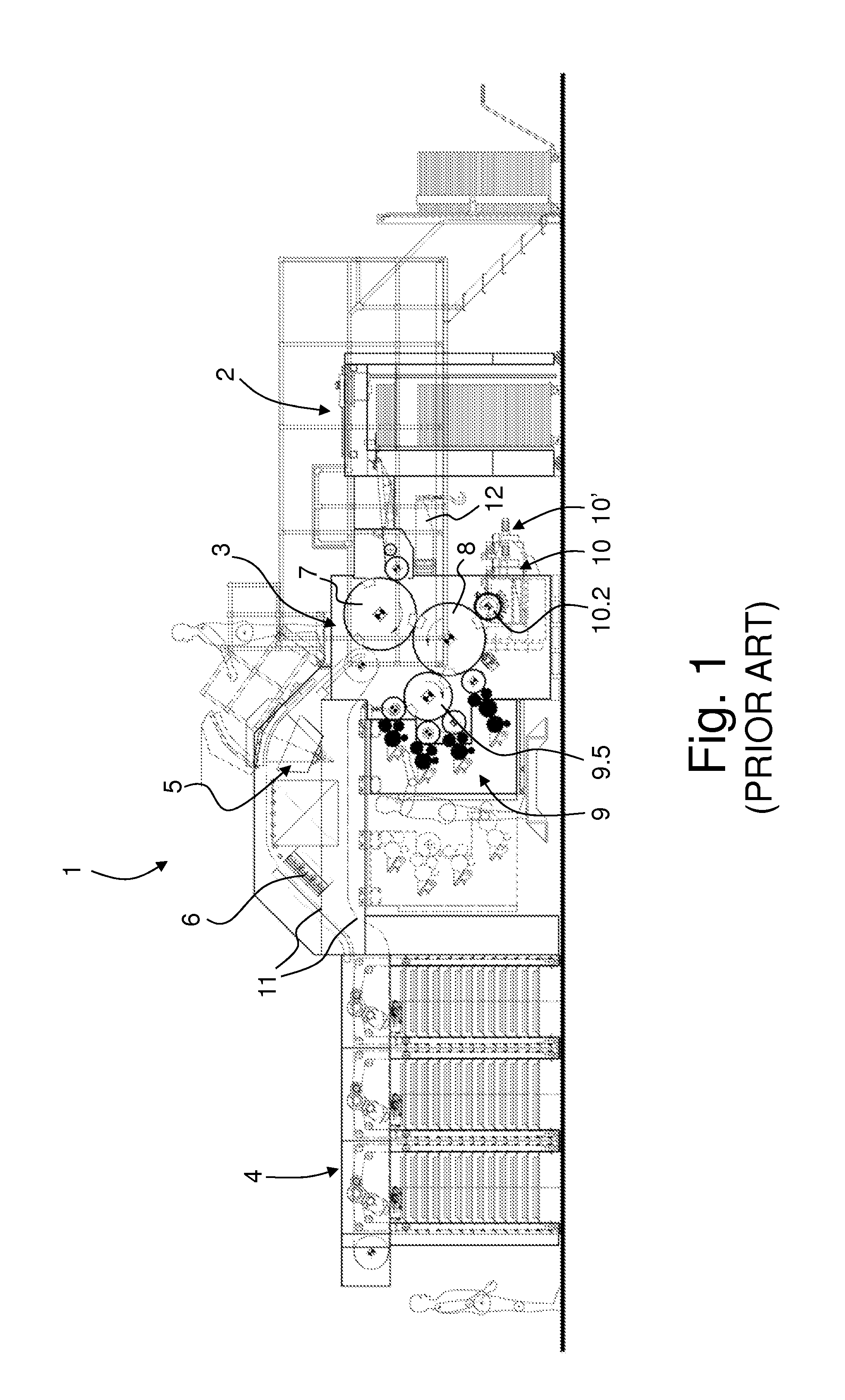

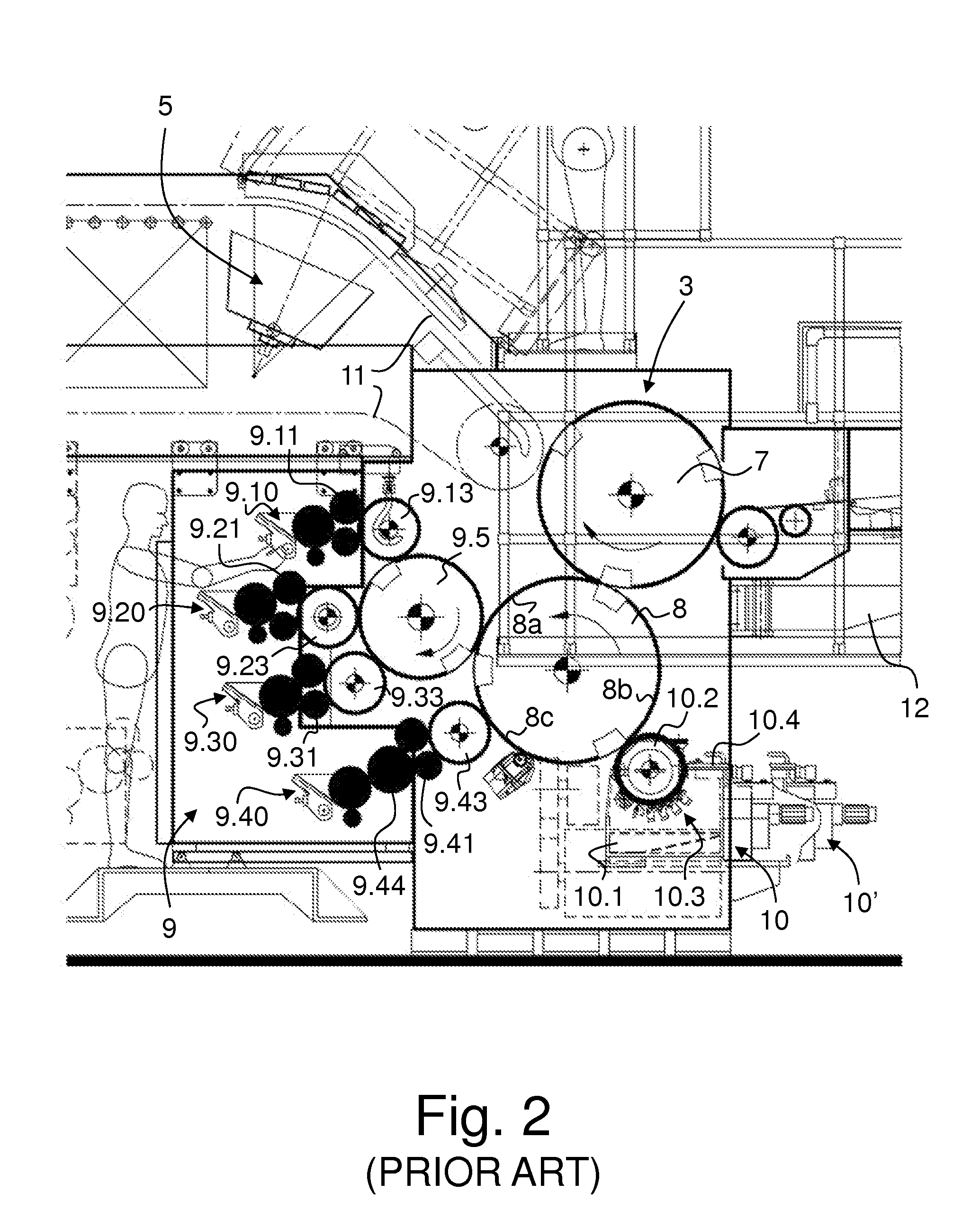

Ink wiping system of an intaglio printing press and intaglio printing press comprising the same

ActiveUS9475273B2Easy maintenance and operationEasily and quickly exchangedRotary intaglio printing pressPrinting press partsEngineeringPrinting press

There is described an ink wiping system (100; 100′; 100″) of an intaglio printing press comprising a wiping tank (101) and a rotatable wiping roller assembly (102; 102*) supported on and partly located in the wiping tank (101) for wiping excess ink from the surface of a rotatable intaglio printing cylinder (80) of the intaglio printing press. The ink wiping system (100; 100′; 100″) comprises a wiping roller retracting device (150) which forms an integral part of the ink wiping system (100; 100′; 100″) and is adapted to be coupled to the wiping roller assembly (102; 102*) to move the wiping roller assembly (102; 102*) between a working position (W) where the wiping roller assembly (102; 102*) is supported on and partly located in the wiping tank (101) for cooperation with the intaglio printing cylinder (80) and a parking position (P) where the wiping roller assembly (102; 102*) is retracted out of the wiping tank (101) and away from the intaglio printing cylinder (80). In the working position (W) of the wiping roller assembly (102; 102*), the wiping roller retracting device (150) is coupled to the wiping roller assembly (102; 102*). The ink wiping system (100; 100′; 100″) further includes, at the parking position (P), a storage section (110) adapted to receive the wiping roller assembly (102; 102*) which is retracted by the wiping roller retracting device (150).

Owner:KBA NOTASYS SA

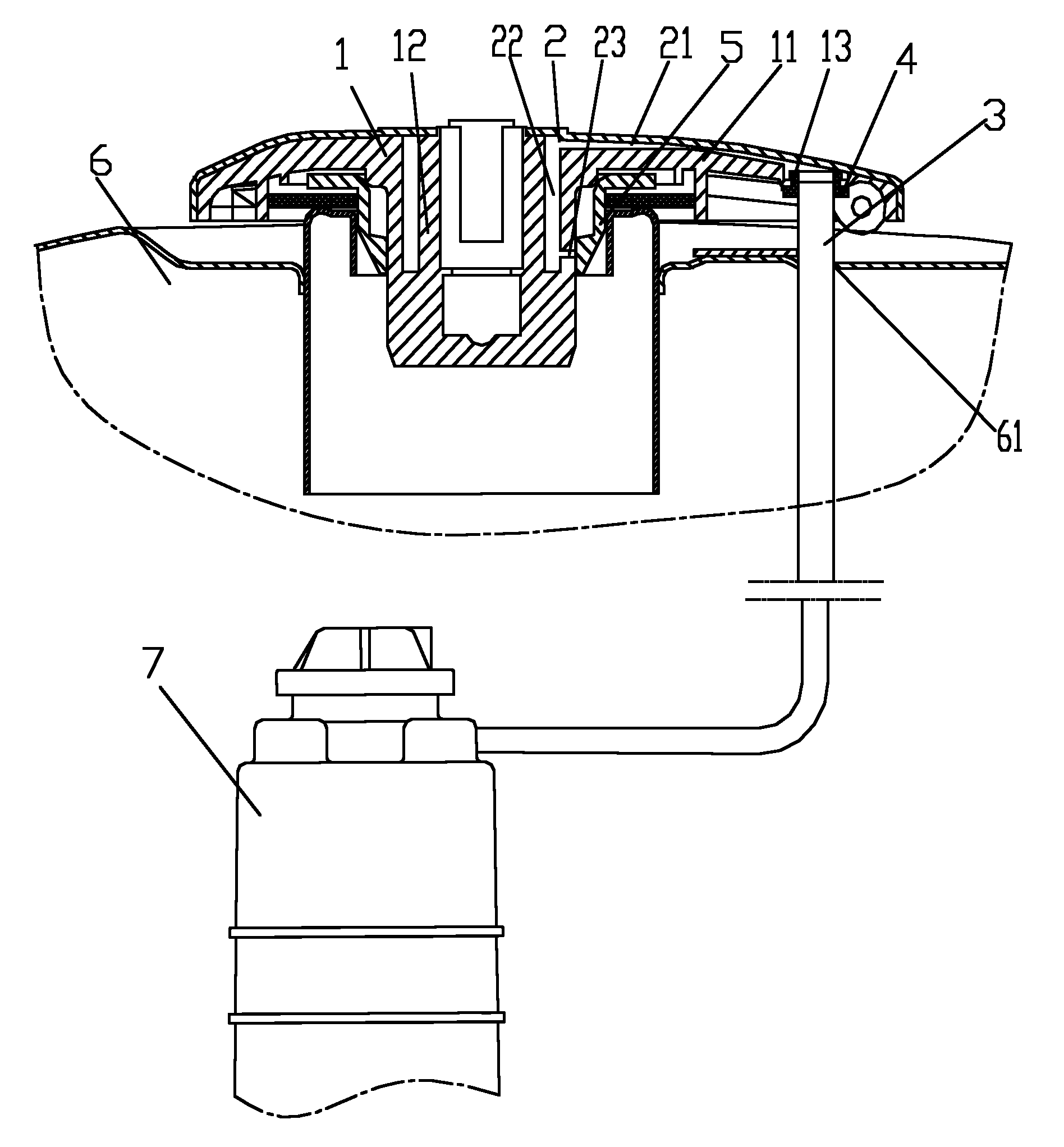

Deodorant toilet lid plate

The invention discloses a deodorant toilet lid plate which comprises an upper cover, a seat ring and a rotary shaft sleeve. The upper cover and the seat ring are pivoted to the rotary shaft sleeve. The deodorant toilet lid plate further comprises a deodorant component which is used to pump gas in a toilet bowl and filter and deodorize the pumped gas. The deodorant component is contained in the rotary shaft sleeve. The deodorant component is used to pump the gas in the toilet bowl and filter and deodorize the pumped gas so as to prevent the fouling gas from drifting in air to pollute the inner environment of a bathroom. The deodorant component is contained in the rotary shaft sleeve, saves space of the bathroom and other spaces and is concealed. The deodorant component is axially inserted into the rotary shaft sleeve from the end of the rotary shaft sleeve, or is radially inserted into the rotary shaft, and accordingly the deodorant toilet lid plate is convenient to install.

Owner:彭东 +1

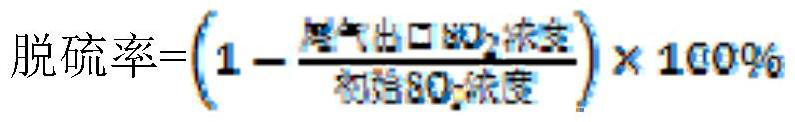

Flexible MOFs material doped with porous ZIF-8 on surface, preparation method and application

ActiveCN112979983AGood choiceEfficient regenerationGas treatmentOther chemical processesSelective adsorptionAqueous solution

The invention discloses a flexible MOFs material doped with porous ZIF-8 on the surface, a preparation method and application of the flexible MOFs material, wherein the flexible MOFs material is composed of ZIF-8 and a flexible metal organic framework material MOFs, and is prepared through a hydrothermal synthesis method. The preparation method comprises the following steps: synthesizing a flexible metal organic framework material MOFs through an organic ligand and a metal salt, then doping a nanoscale Zn (II) salt on the surface of the MOFs through constant-temperature heating, finally adding the MOFs into a 2-methylimidazole aqueous solution, and carrying out hydrothermal synthesis activation to obtain the flexible MOFs material with the surface doped with porous ZIF-8. The material is simple in preparation method, has rich pore structures and large adsorption capacity, can selectively adsorb SO2, is good in reproducibility, and is especially suitable for absorbing trace SO2 in flue gas under the medium-temperature condition.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com