Pyrolysis and gasification incinerator for garbage and method

A pyrolysis gasification and incinerator technology, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of large equipment area, low combustion efficiency, insufficient combustion, etc., to save area and improve The effect of combustion efficiency and design cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

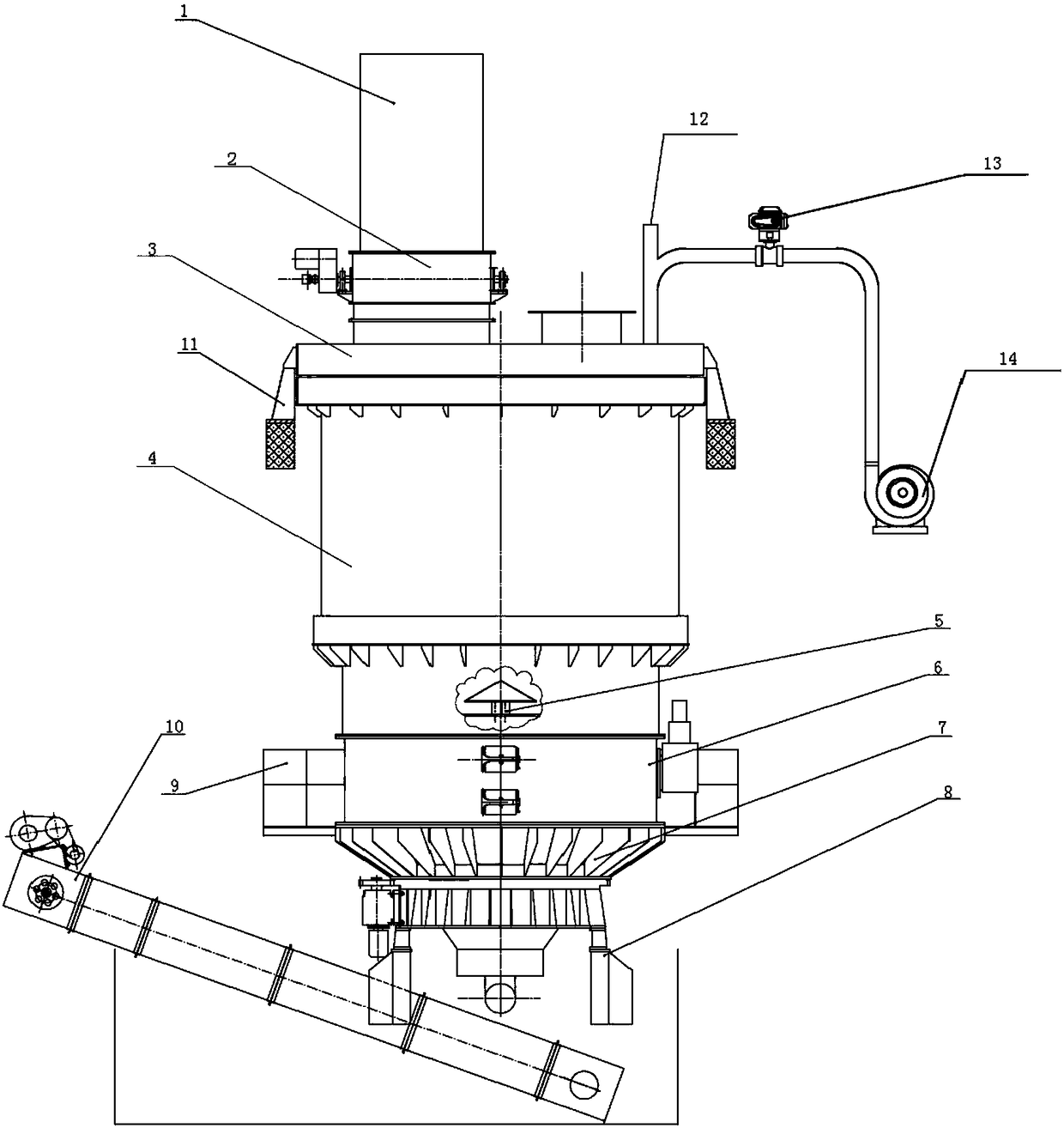

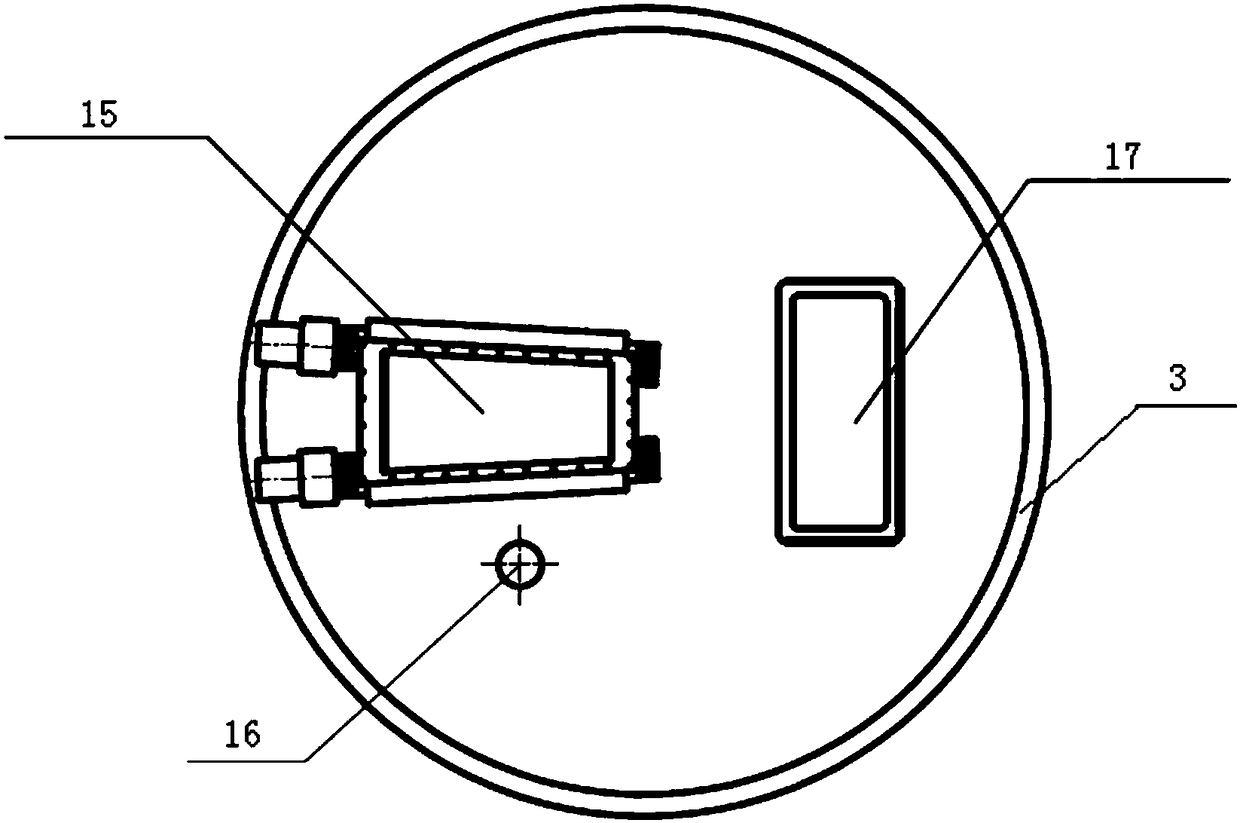

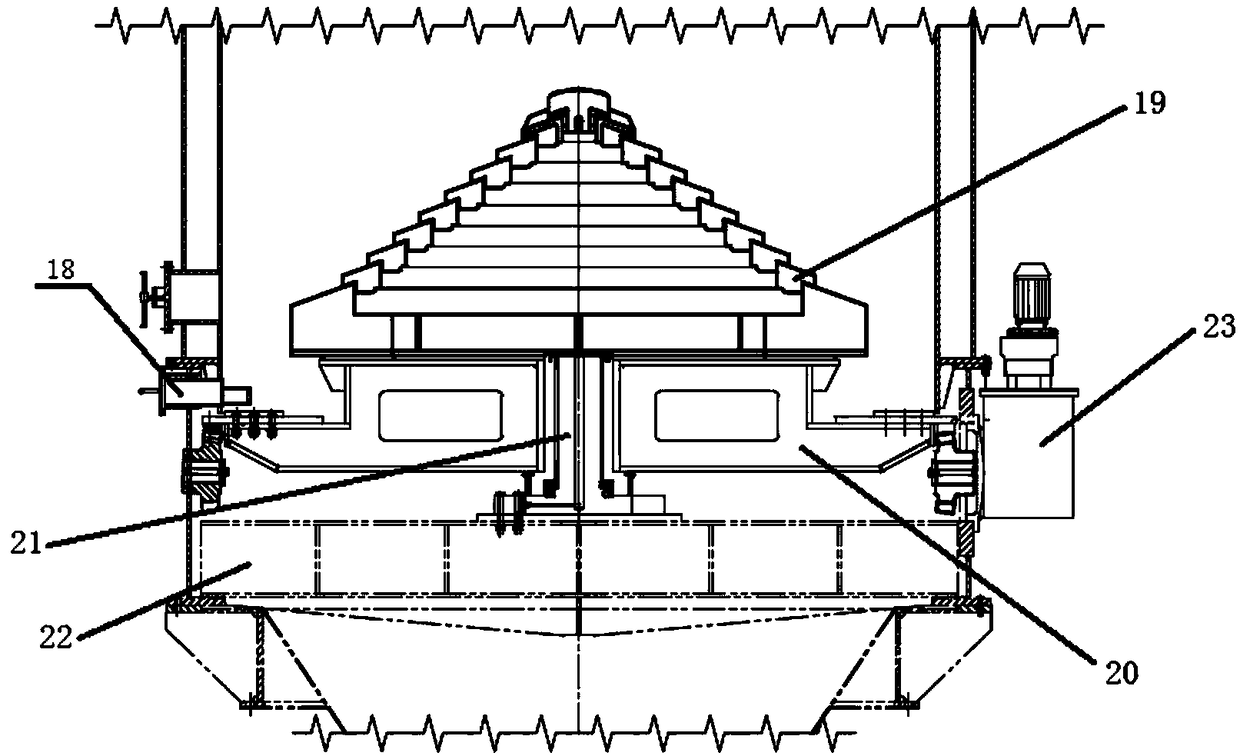

[0032] This embodiment provides a garbage pyrolysis gasification incinerator based on the present invention, and the overall structure schematic diagram of the incinerator can be referred to figure 1 with figure 2 , the incinerator comprises: a furnace body 4, a fire grate 5, and an air supply device arranged on the upper side of the furnace body 4; on the cover 3; the grate 5 is fixed on the lower part inside the furnace body 4, refer to image 3 , the grate 5 includes a multi-layer annular grid plate 19, the multi-layer annular grid plate 19 is stacked in a tower shape, and the multi-layer annular grid plate 19 is coaxially arranged.

[0033] The waste pyrolysis gasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com