Salvage device and construction method of drill bit of spin dig drill

A salvage device and rotary drilling technology, which is applied to earth-moving drilling, cleaning equipment, wellbore/well components, etc., can solve the problems of difficult operation of the grab bucket structure, collapsed holes, easy falling off, etc., so as to reduce manual entry. The probability of operation to the wellbore, improve the success rate, and avoid the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

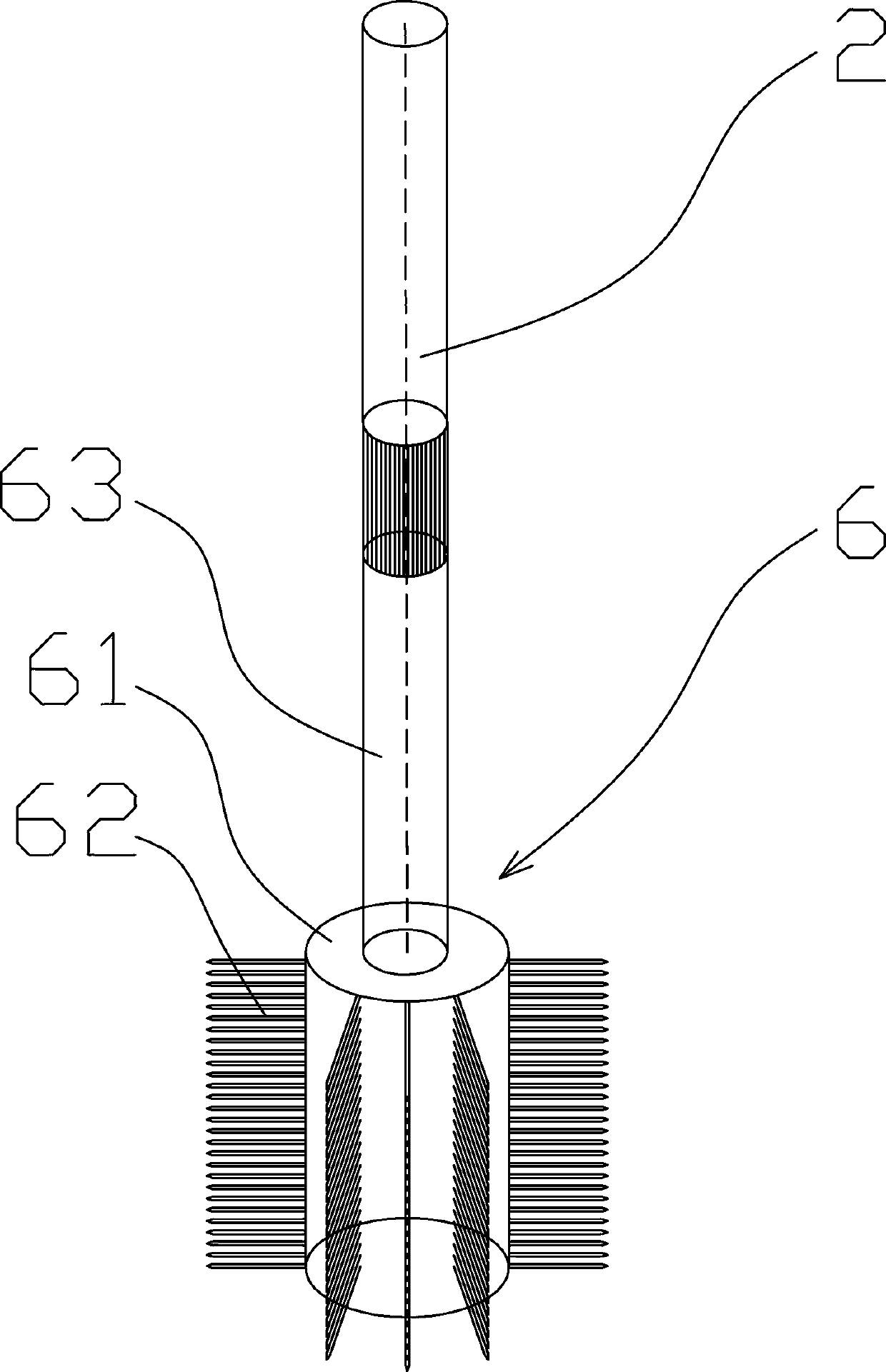

[0045] Such as image 3 Among them, a rotary drilling drill bit fishing device, which includes a comb-shaped rotary head 6;

[0046] In the comb-shaped rotor 6, the lower end of the first high-pressure water pipe 63 is connected to the rotor cylinder 61, and the inner or outer wall of the rotor cylinder 61 is provided with radially distributed rotor nails 62 or elastic steel wires. The top of the high-pressure water pipe 63 is connected to the drill pipe 2, and the side wall or / and bottom of the rotary head cylinder 61 are provided with water outlet holes. With this structure, the comb-shaped rotary head 6 is used to clean the drilling slag in the well hole 9 and the drilling slag and clay on the surface of the rotary drilling bit 8 , and to open up a reliable channel for the fishing of the rotary drilling bit 8 . And can correct collapse hole and shrinkage cavity defects. The set rotating head nails 62 or elastic steel wires break up the drilling slag, and transport it to t...

Embodiment 2

[0059] A construction method using the above-mentioned rotary drilling drill bit fishing device, comprising the following steps:

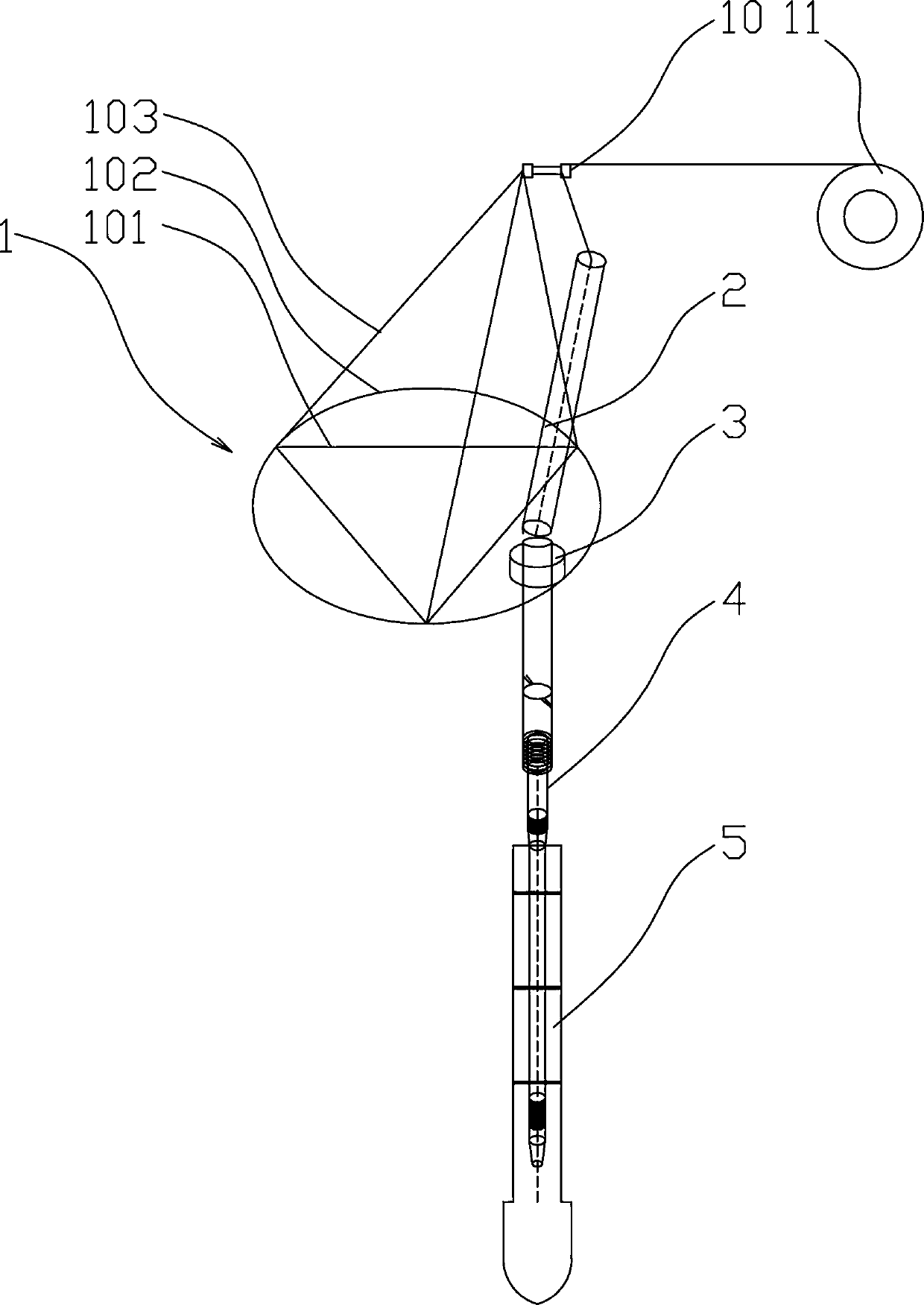

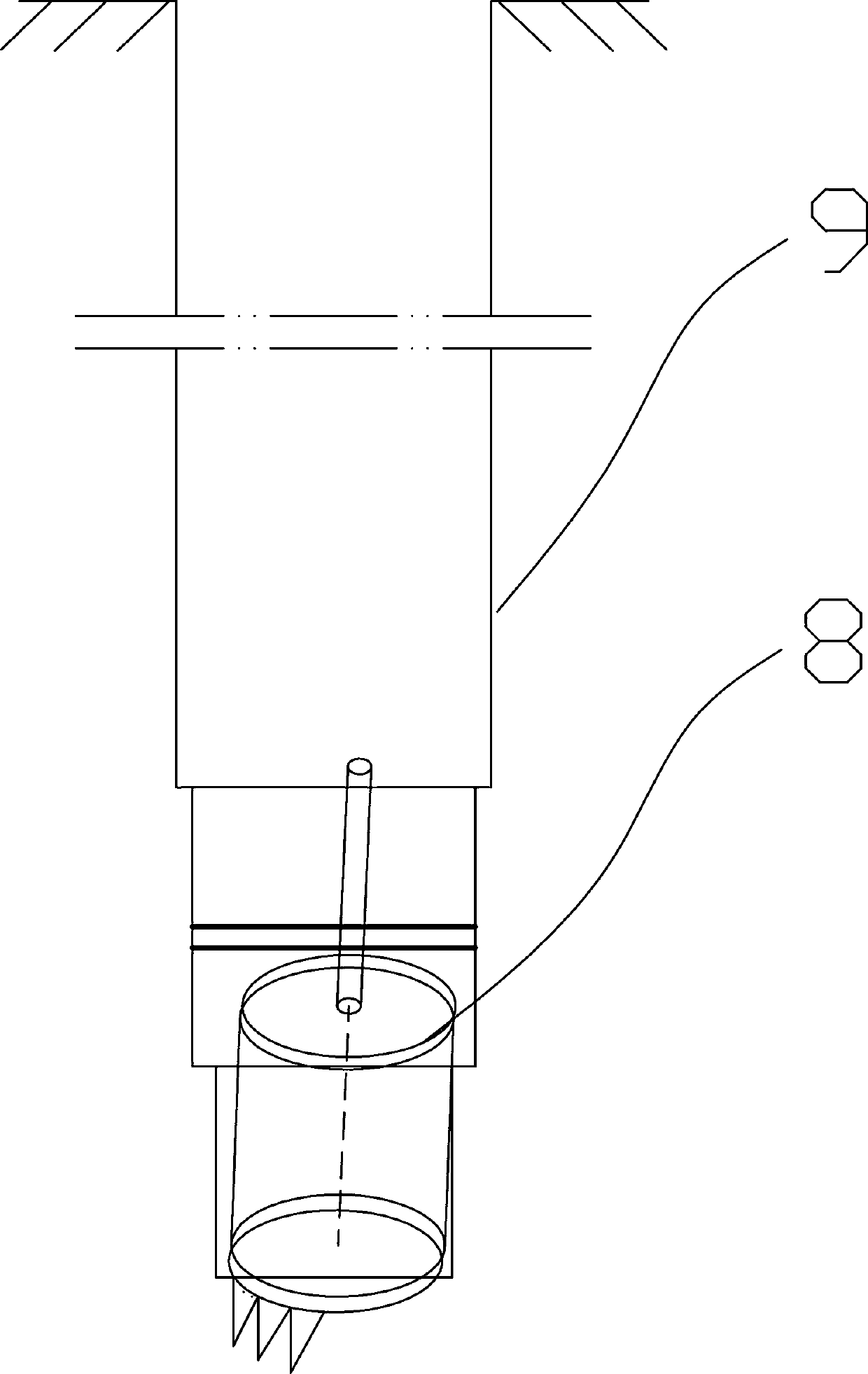

[0060] S1. Install the complete structure of the drilling rig including the drill rod support 1, hoisting device 11 and disc drill 3. The drill rod 2 is slidably installed in the guide wheel 10. The drill rod 2 is a hollow drill rod with a standard section of 5m and a diameter of 12cm. The lower end of the drill pipe 2 is fixedly connected with the comb-shaped rotary head 6 through threads, and the top end of the drill pipe 2 is connected with the mud pump. A high-pressure water pipe 63 circulates for flushing, and the disc drilling rig 3 drives the drill pipe to rotate as a whole to remove the drilling slag and viscous mud in the well hole 9 above the rotary drilling bit 8 and on the surface of the rotary drilling bit 8, so as to facilitate subsequent lifting and rotary drilling The construction of the drill bit 8, decompression drilling and lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com