Line-frequency induction type dynamic drying machine with four quartz tubes

An induction type, quartz tube technology, used in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of secondary pollution, lack of special process equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

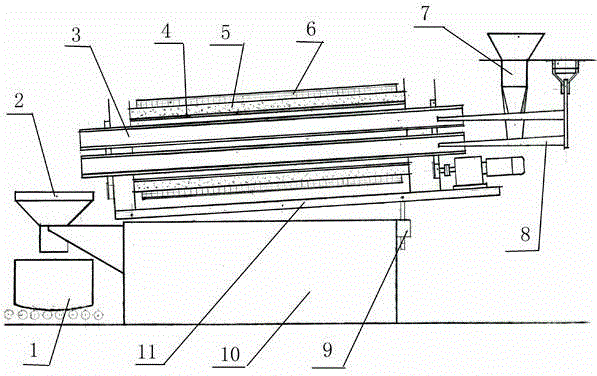

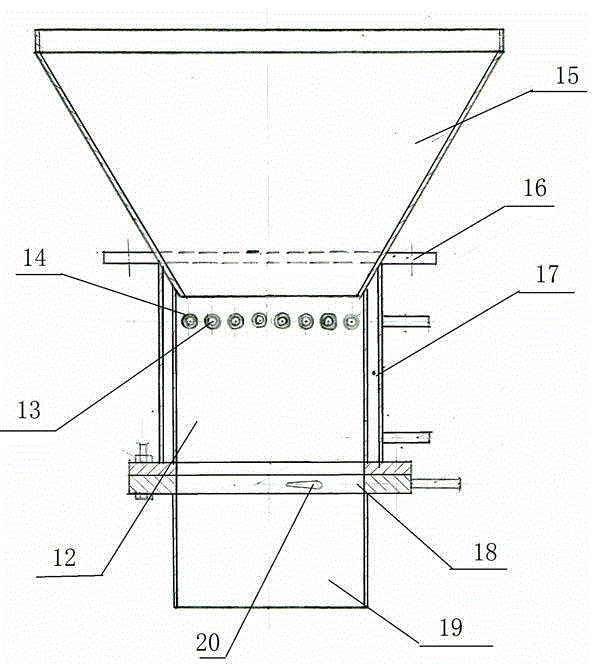

[0016] A power frequency induction type four-quartz tube dynamic dryer, including a slanted quartz glass drying material tube 3, an annular heating cylinder is arranged in the middle of the quartz glass drying material tube 3, and the upper feeding material of the quartz glass drying material tube 3 A feeder 7 is provided at the end, and a feeder is provided at the lower discharge end of the quartz glass drying material pipe 3. The quartz glass drying material pipe 3 is provided with four pieces, which are arranged in two layers up and down, and two in each layer. Both ends of the drying material tube are equipped with orbital wheels with limiting convex edges, and a set of support wheels that cooperate with the track wheels is provided under each of the two ends of the drying material tube of quartz glass. The support wheel set consists of three support wheels The middle supporting wheel is the active supporting wheel; the feeder is equipped with a silo, and a reamer breaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com