A gas treatment method and system based on a three-device refrigerant compression cycle

A gas treatment and refrigerant technology, applied in the functional system field, can solve the problems of easy condensation and large energy consumption, and achieve the effect of ensuring the heating effect, improving the energy efficiency of the system, and improving the system function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

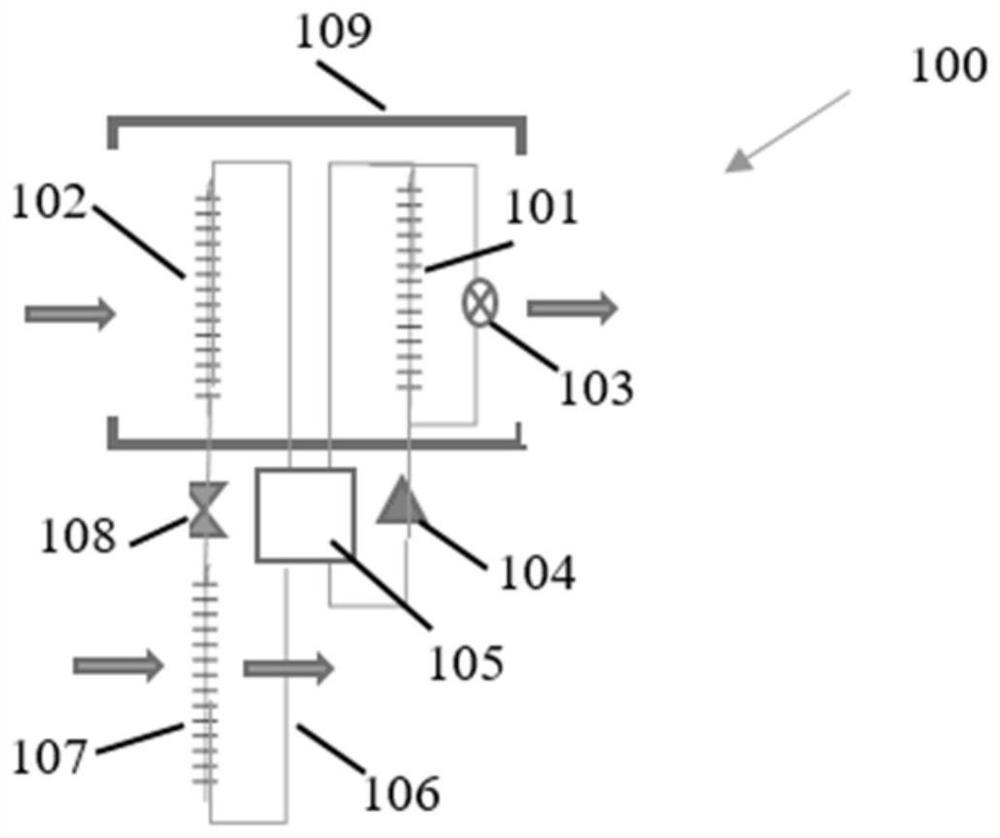

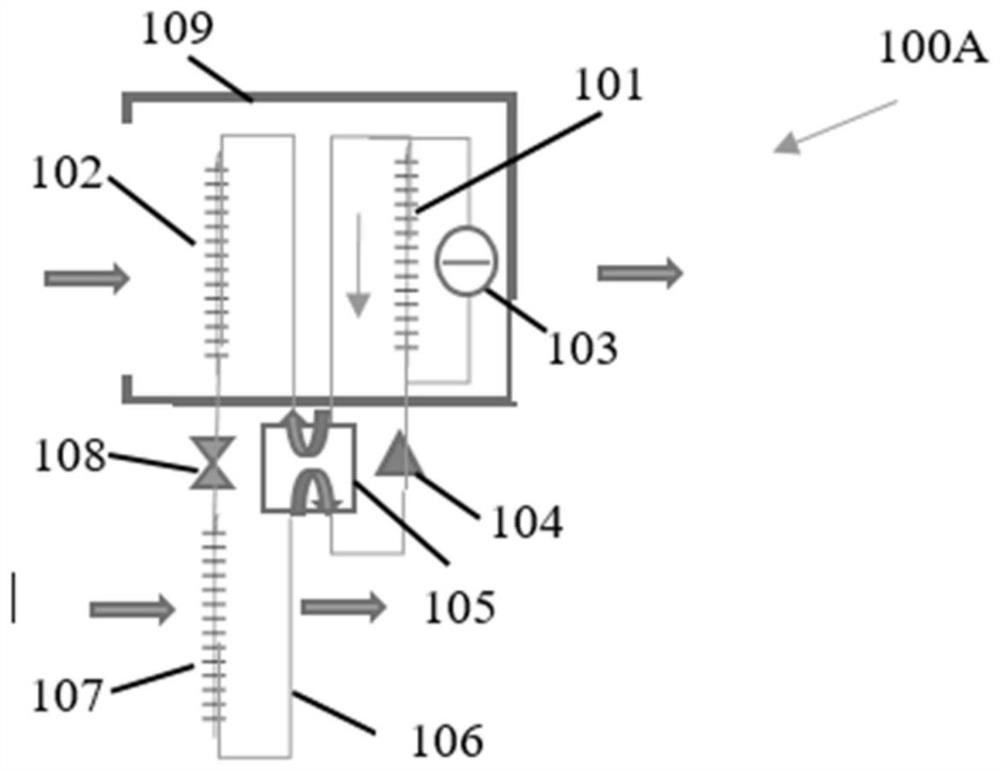

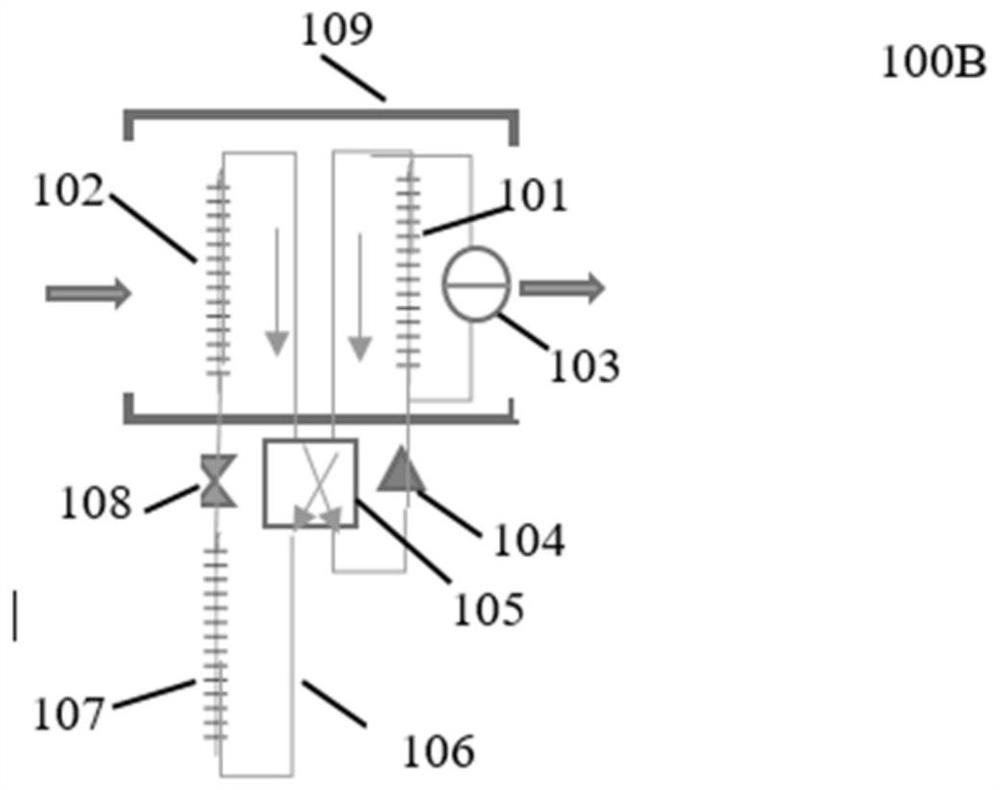

[0061] When the outdoor temperature is 0°C and the indoor air temperature is 20°C, the 100 system of the present invention (such as Figure 10 As shown) when heating indoor air (the compressor is Danfoss VZH035CJ, R410A, the evaporation temperature of the evaporator is -10°C, and the condensation temperature of the condenser is 45°C), the overall performance of the system is as follows:

[0062] 1. Total system heating, 19.8kW (10+5+2.4+2.4),

[0063] 2. Conventional system heating 15kW (10+5), of which, cooling 10kW, power consumption 5kW

[0064] 3. Add 2.4kW refrigeration for subcooling

[0065] 4. Add 2.4kW heating for subcooling

[0066] 5. Power consumption, 5kW

[0067] 6. COP, 3.96

[0068] Using conventional systems such as Figure 11 shown), when heating the indoor air (the compressor is Danfoss VZH044CJ, R410A, the evaporation temperature of the evaporator is -10°C, and the condensation temperature of the condenser is 45°C), the overall performance of the syste...

Embodiment 2

[0082] When the outdoor air is -10°C, adopt the 100 system of the present invention (such as Figure 10 As shown) when the fresh air is heated (the compressor is Danfoss VZH028CH, R410A, the evaporation temperature of the evaporator is -20°C, and the condensation temperature of the condenser is 45°C), the overall performance of the system is as follows:

[0083] 1. Heating, 14.8kW (5+3.8+3+3),

[0084] 2. Conventional system heating 8.8kW (5+3.8), cooling 5kW, power consumption 3.8kW

[0085] 3. Add 3kW refrigeration for subcooling

[0086] 4. Add 3kW heating for subcooling

[0087] 5. Power consumption, 3.8kW

[0088] 6. COP, 3.9

[0089] Using conventional systems such as Figure 13 shown), when heating the indoor air (the compressor is Danfoss DCJ106T2, R410A, the evaporation temperature of the evaporator is -20°C, and the condensation temperature of the condenser is 45°C), the overall performance of the system is as follows:

[0090] 1. Heating, 15.43kW

[0091] 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com