Straw direct combustion heating device

A heating device and straw technology, applied in the direction of combustion control, combustion equipment, solid fuel combustion, etc., can solve the problems of complex operation, low thermal efficiency, energy waste, etc., achieve simple operation, uninterrupted heating, and reduce heating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

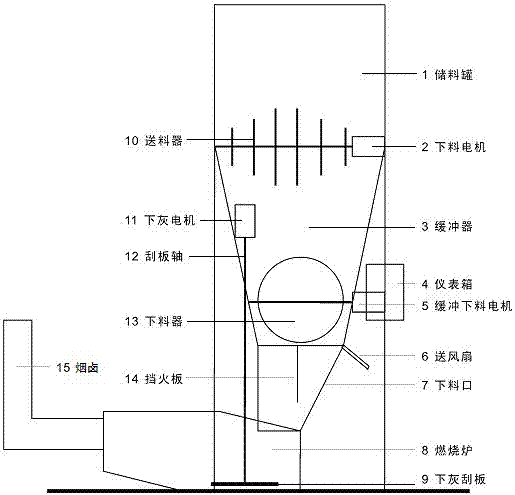

[0009] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0010] Such as figure 1 As shown, the present invention consists of a storage tank 1, a feeding motor 2, a buffer tank 3, an instrument box 4, a buffer feeding motor 5, a fan 6, a feeding port 7, a combustion furnace 8, an ash scraper 9, a feeding Device 10, lower ash motor 11, scraper shaft 12, feeder 13, fire baffle 14, chimney 15 are formed.

[0011] The feeder (13) is made into a circular hollow structure with a width of 1CM iron bars, and the circular surface is evenly distributed with thorns about 5CM long, so as to reach the purpose of quantitative stalks.

[0012] An automatic feeder 10 is set between the storage tank 1 and the buffer tank 2, an automatic feeder 13 is set between the buffer tank 3 and the feeding port 7, an automatic dust scraper is set in the combustion furnace 8, and an automatic ash scraper is set at the feeding port 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com