Rapid sludge granulation and drying treatment system and method based on medium loading

A technology of sludge granulation and medium loading, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of high energy consumption, lower sludge moisture content, low heat transfer efficiency, etc., and achieve high thermal efficiency and heating temperature. And the speed is controllable and adjustable, and the operation is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

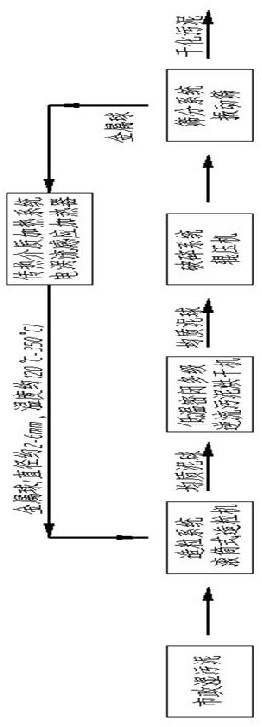

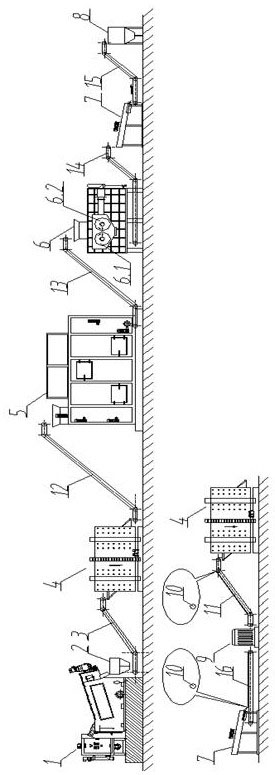

[0040] Such as figure 1 , 2As shown, the rapid sludge granulation and drying treatment system based on medium loading of the present invention includes a sludge dehydration device 1 connected in sequence, a heat transfer medium heating device 9, a granulator 4, and a low-temperature closed multi-stage countercurrent sludge Dryer 5, rolling crushing device 6, screening device 7, the system is a modular combination, and the adjacent modules are connected by conveyor belts, which saves manpower and improves the degree of automation; the output end of the sludge dewatering device 1 A mud collection bucket 2 is arranged below, and a first conveyor belt 3 is arranged below the mud collection bucket 2. The output end of the first conveyor belt 3 is connected to the feed end of the drum granulator 4, and the wet sewage coming out of the sludge dewatering device 1 The mud falls into the mud collecting hopper 2, and is evenly distributed on the first conveyor belt 3 through the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com