P-n type lead telluride/polypyrrole double-layer thermoelectric thin film material and preparation method thereof

A technology of pyrrole double layer and thermoelectric thin film, which is applied in the direction of thermoelectric device node lead-out material, thermoelectric device manufacturing/processing, etc., to achieve the effect of low cost and good thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present invention provides a p-n type lead telluride / polypyrrole double-layer thermoelectric film material, which adopts a hydrothermal method combined with a gas phase method to prepare a p-n type lead telluride / polypyrrole double-layer thermoelectric film.

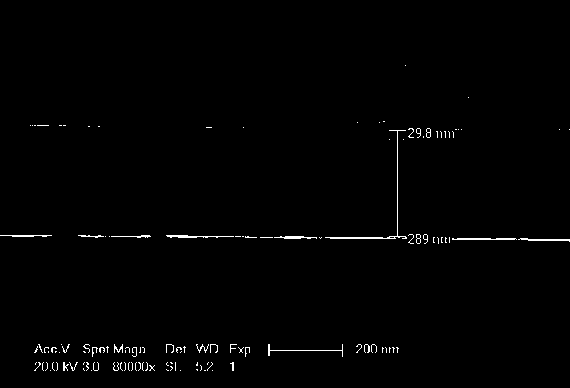

[0020] (1) Prepare lead telluride film, dissolve lead acetate, sodium telluride, sodium hydroxide, and sodium citrate into a mixture of alcohol and water. The quality of lead acetate, sodium telluride, sodium hydroxide, and sodium citrate The ratio is: 1:1.5:0.5:0.2, add the above mixture to the PTFE lining of the reactor, and place the silicon wafer with electrodes in the PTFE lining at an angle of 35°C, the reaction temperature is 100°C, and the reaction time is 6h. After the reaction, the sample is taken out, and the resulting sample is washed several times with deionized water and alcohol, and dried at 50°C for 2h. The lead telluride layer The thickness of the film is 28.9nm;

[0021] (2) Prepare a polypyrrole...

Embodiment 2

[0024] The present invention provides a p-n type lead telluride / polypyrrole double-layer thermoelectric film material, which adopts a hydrothermal method combined with a gas phase method to prepare a p-n type lead telluride / polypyrrole double-layer thermoelectric film.

[0025] (1) Prepare the lead telluride film, dissolve lead acetate, sodium telluride, sodium hydroxide, and sodium citrate into a mixture of alcohol and water. The quality of lead acetate, sodium telluride, sodium hydroxide, and sodium citrate The ratio is 1:1.5:0.5:0.2, and the ratio of alcohol to water is 1:2. Add the above mixture to the PTFE lining of the reactor, and place the silicon wafer with the electrode on the poly In the tetrafluoroethylene lining, the inclination angle is 10°, then the reaction temperature is 100°C, and the reaction time is 5h. After the reaction is over, the sample is taken out, and the resulting sample is washed several times with deionized water and alcohol. After drying at 50℃ for...

Embodiment 3

[0028] The present invention provides a p-n type lead telluride / polypyrrole double-layer thermoelectric film material, which adopts a hydrothermal method combined with a gas phase method to prepare a p-n type lead telluride / polypyrrole double-layer thermoelectric film.

[0029] (1) Prepare lead telluride film, dissolve lead acetate, sodium telluride, sodium hydroxide, and sodium citrate into a mixture of alcohol and water. The quality of lead acetate, sodium telluride, sodium hydroxide, and sodium citrate The ratio is: 1:2: 0.8: 0.5, add the above mixture to the PTFE lining of the reactor, and place the silicon wafer with the electrode in the PTFE lining at an angle of 45°C, the reaction temperature is 150°C, and the reaction time is 15h. After the reaction is over, the sample is taken out, and the resulting sample is washed several times with deionized water and alcohol, and dried at 60°C for 5 hours. The lead telluride layer The thickness of the film is 300nm;

[0030] (2) Prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com