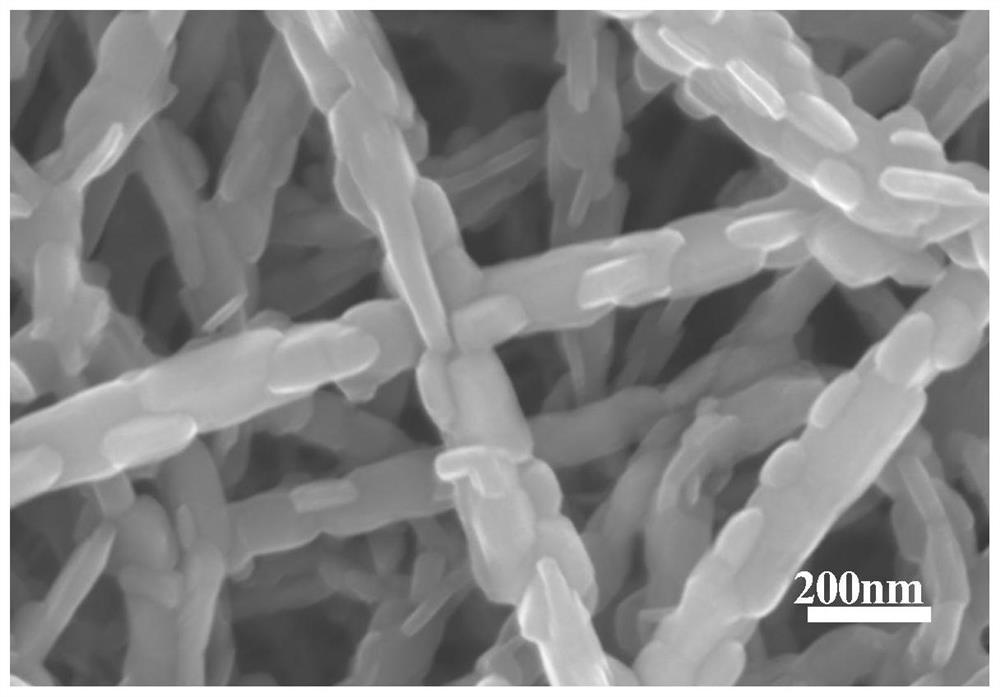

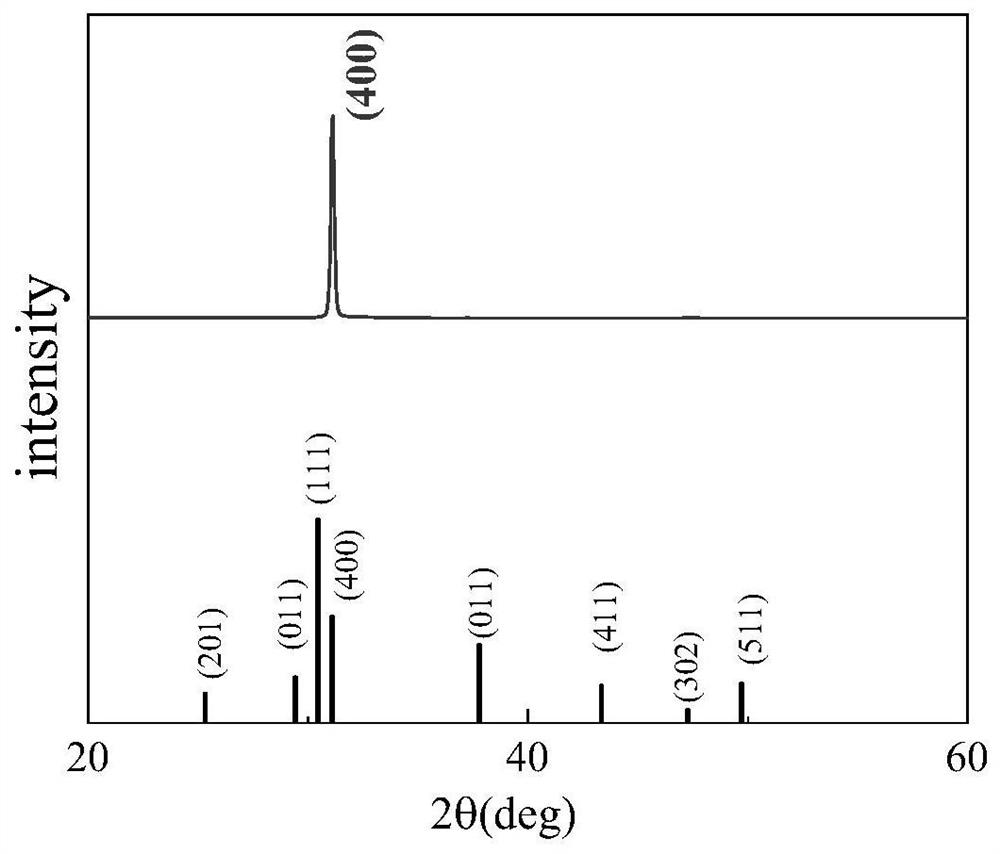

SnSe/CNT high-temperature flexible thermoelectric thin film material and preparation method thereof

A thermoelectric thin film, high-temperature flexible technology, applied in the field of tin selenide/carbon nanotube high-temperature flexible thermoelectric thin film material and its preparation, can solve the problems of low thermal conductivity, etc., achieve high crystallinity, improve flexibility, and ensure thermoelectric performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the preparation method of SnSe / CNT high-temperature flexible thermoelectric thin film material includes the following steps:

[0036] (S1) Surface treatment:

[0037] Clean the surface of the substrate (such as: silicon dioxide wafer), rinse with alcohol, acetone and deionized water for 12 minutes, and then heat and bake at 398K for 20 minutes in a vacuum environment;

[0038] The substrate (such as: CNT) is fixed on the metal bracket by electrostatic force, and the metal bracket is fixed on the coated sample plate with silver glue, and baked at 398K for 20 minutes;

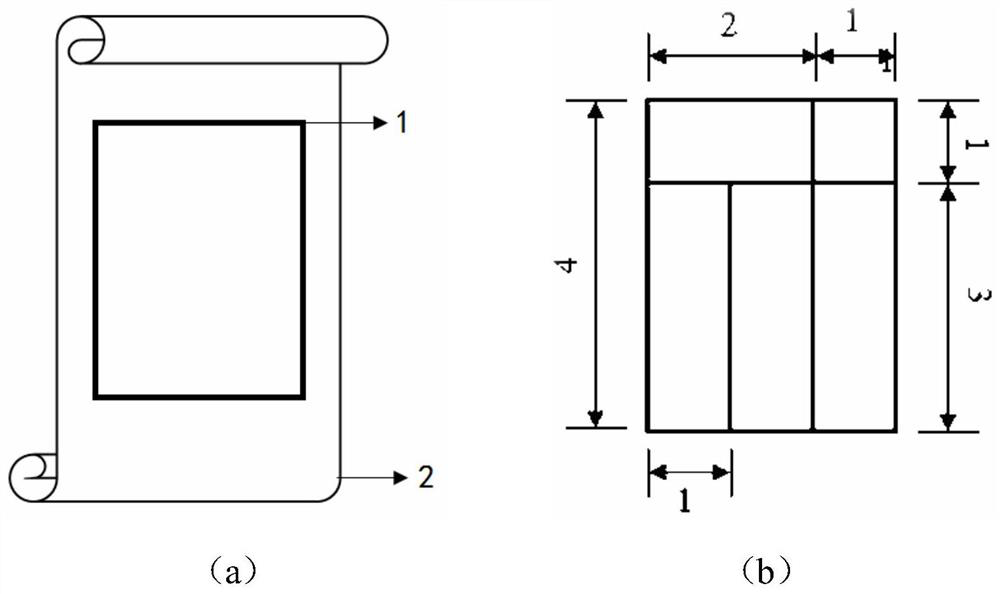

[0039] Such as image 3 As shown, the structure of the metal bracket is to carve out 5 small frames of size from a 4cm×3cm copper plate: three 3cm×1cm are arranged side by side vertically, one 1cm×1cm and one 2cm×1cm are facing each other horizontally, The metal material used is copper, and the dimensions are shown in the schematic diagram. The carbon nanotubes 2 can be flatly spread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com