A flexible thin film solar-thermo electricity conversion device

A flexible thin film, photothermoelectric technology, applied in the direction of thermoelectric device parts, photovoltaic power generation, electrical components, etc., can solve the problems of limited photoelectric conversion efficiency, achieve the effect of improving energy utilization rate, concise structure design, and increasing open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

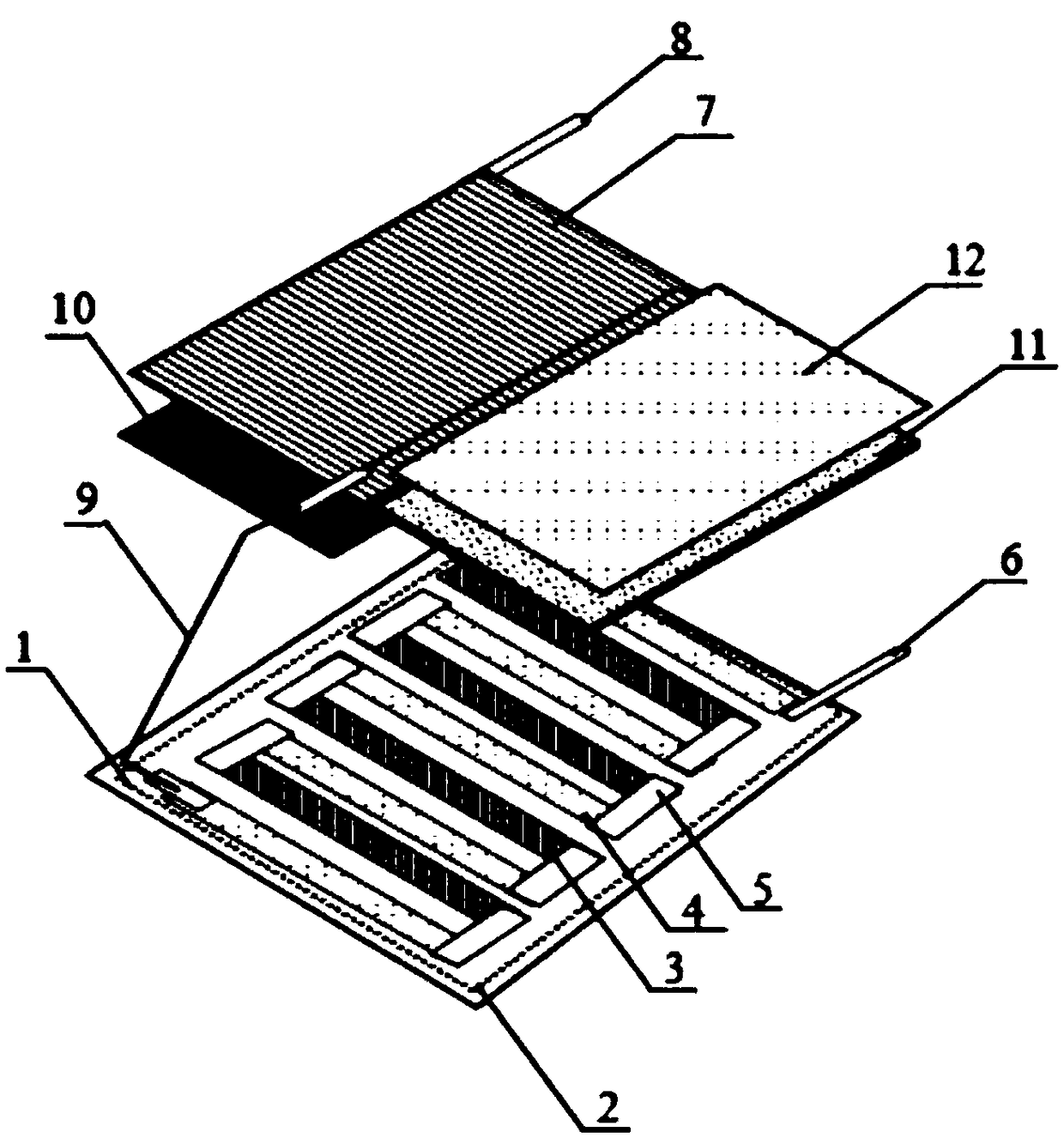

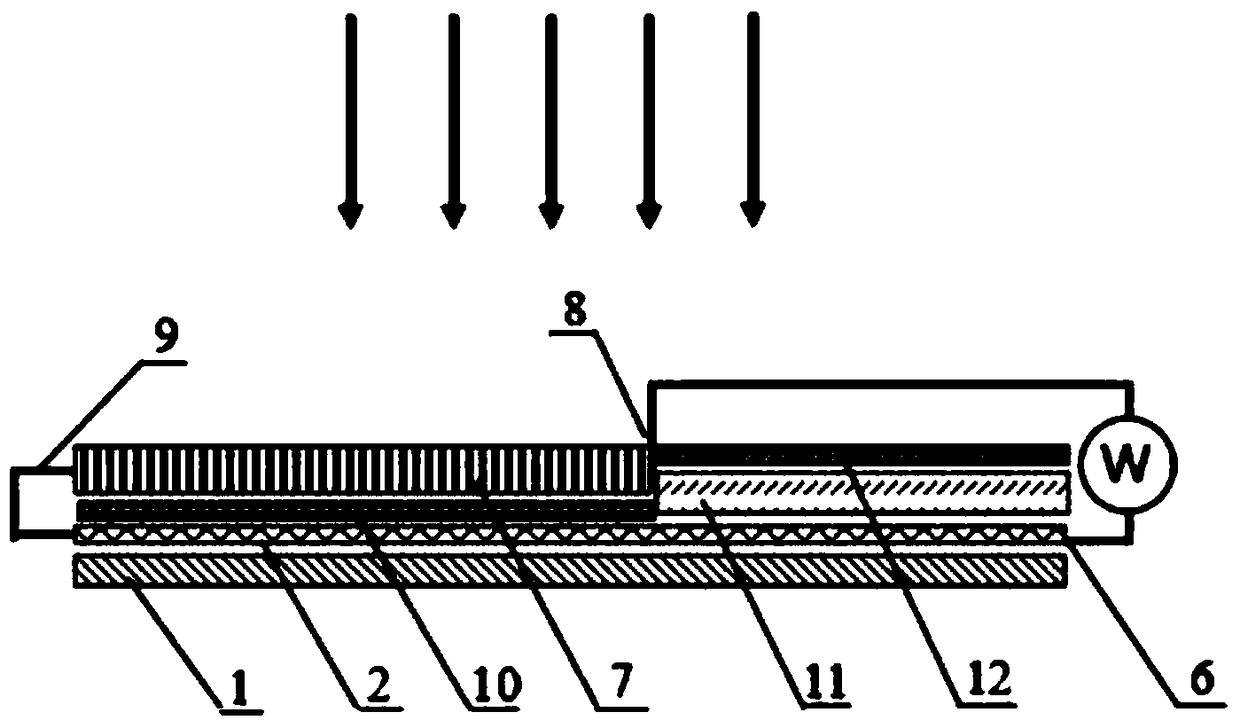

[0025] Such as figure 1 As shown, a flexible film photothermal conversion device includes: a flexible film substrate 1, a flexible thermoelectric film module 2, a flexible photovoltaic film module 7, a photovoltaic thermoelectric general output port 9, a flexible heat conducting layer 10, a flexible heat insulating layer 11 and Flexible reflective layer 12. The flexible thermoelectric thin film module 2 includes a P-type thermoelectric thin film 3 , an N-type thermoelectric thin film 4 , conductive silver glue 5 and a thermoelectric output port 6 ; the flexible photovoltaic thin film module 7 includes a flexible photovoltaic thin film battery and a photovoltaic output port 8 .

[0026] This embodiment uses a polyimide film with dimensions of 5 cm x 6 cm as a flexible substrate.

[0027] A flexible thermoelectric thin film module is placed on the flexible substrate, and the flexible thermoelectric thin film module consists of 12 P / N type Bi with a size of 3mm×4cm 2 Te 3 The ...

Embodiment 2

[0032] The result of this example is the same as Example 1. The difference is that:

[0033] In this embodiment, a high temperature resistant polyester film with a size of 6 cm x 6 cm is used as a flexible substrate.

[0034] A flexible thermoelectric thin film module is placed on the flexible substrate, and the flexible thermoelectric thin film module consists of 16 P / N type Bi with a size of 2mm×6cm 2 Se 3 The thermoelectric thin films are connected in series, the thickness of each thermoelectric thin film is 20 μm, and the distance between the thin films is 1 mm. The edge thermoelectric films are respectively connected to silver bars as thermoelectric output ports.

[0035] A flexible photovoltaic thin film module is placed on the upper half of the flexible thermoelectric thin film module, and a flexible perovskite solar cell with a size of 6cm×3cm and a thickness of 1mm is used as a flexible photoelectric thin film module component. Between the flexible thermoelectric ...

Embodiment 3

[0039] In this embodiment, a polyimide film with a size of 4 cm×6 cm is used as a flexible substrate. A flexible thermoelectric thin film module is placed on the flexible substrate, and the flexible thermoelectric thin film module consists of 10 P / N type Bi with a size of 2mm×6cm 2 Te 3 The thermoelectric thin films are connected in series, the thickness of each thermoelectric thin film is 15 μm, and the distance between the thin films is 2 mm. The edge thermoelectric films are respectively connected to silver bars as thermoelectric output ports. A flexible photovoltaic thin film module is placed on the upper half of the flexible thermoelectric thin film module, and a flexible perovskite solar cell with a size of 4cm×3cm and a thickness of 0.45mm is used as a flexible photovoltaic thin film module component. Between the flexible thermoelectric thin film module and the flexible photovoltaic thin film module, a thermally conductive double-sided adhesive tape with a size of 4cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com