Method for preparing flexible N type silver telluride nanowire thermoelectric thin film

A technology of thermoelectric thin film and silver telluride, applied in the direction of thermoelectric device lead-out wire materials, etc., can solve the problems of complex preparation process, poor flexibility, high cost, etc., and achieve the effect of excellent thermoelectric performance, good flexibility, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) ultrasonically disperse 30 mg of silver telluride nanowires and 1.5 mg of polyvinylpyrrolidone in 5 mL of ethylene glycol to obtain a silver telluride nanowire dispersion;

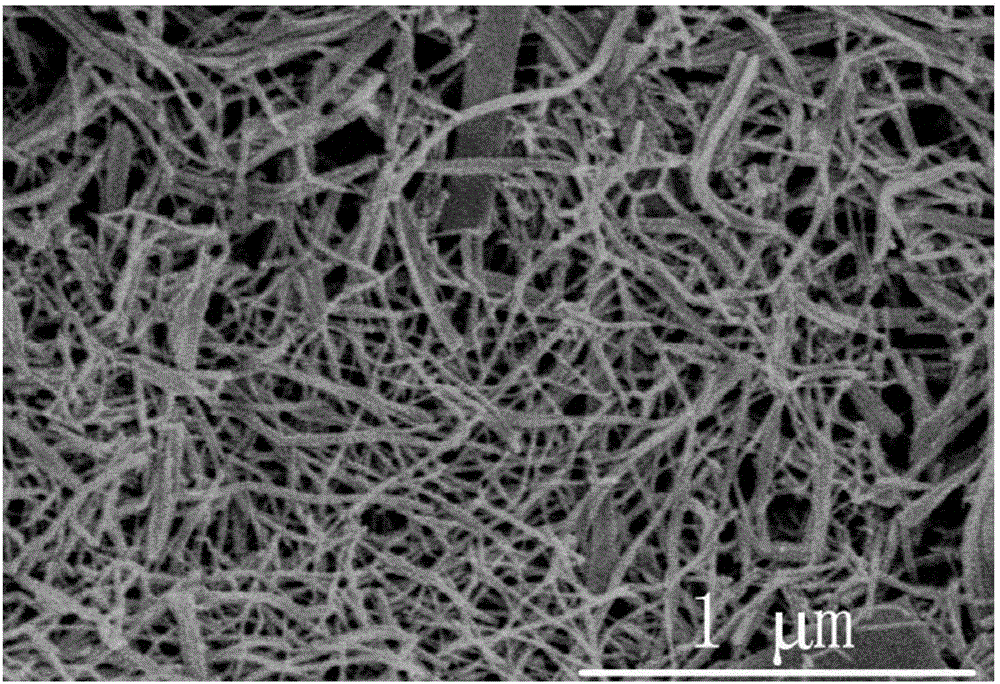

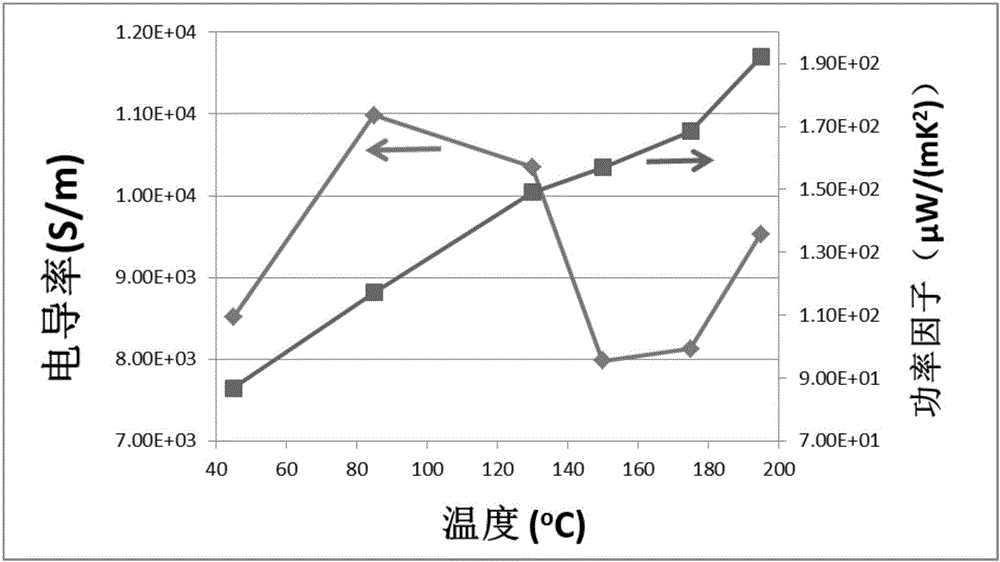

[0034] (2) With the assistance of vacuum filtration, evenly drop-coat 0.75mL of silver telluride nanowire dispersion on a 2.5cm×0.5cm glass fiber filter membrane, and drain the liquid; The glass fiber filter membrane was vacuum-dried at 75°C to obtain a silver telluride nanowire film adhered to the glass fiber filter membrane. The scanning electron microscope photos are as follows: figure 1 shown;

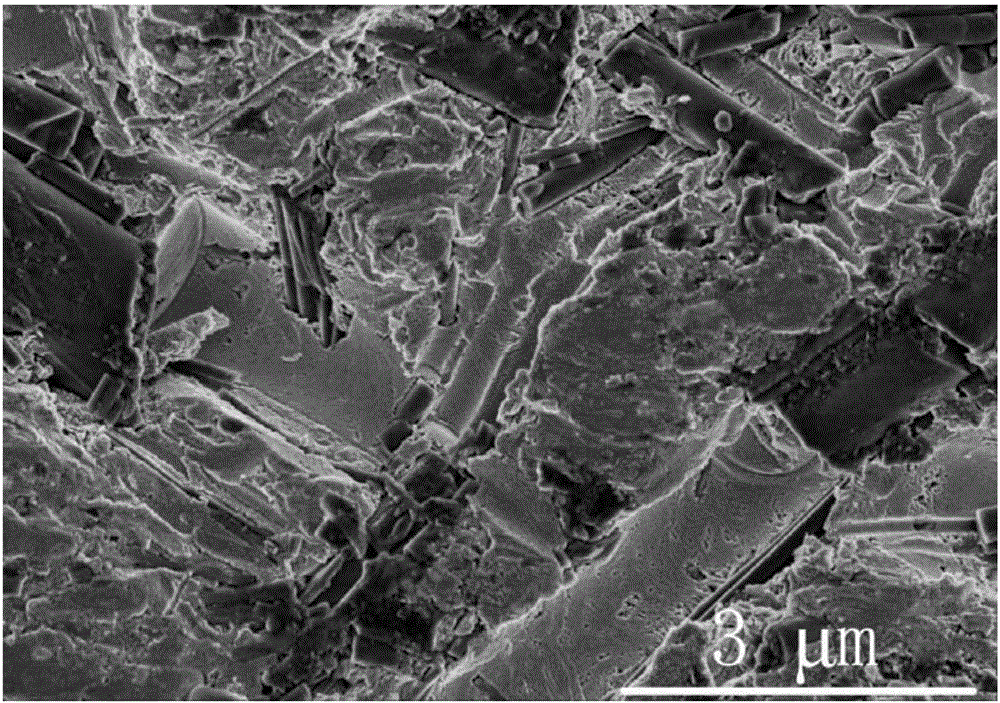

[0035] (3) the silver telluride nanowire thin film adhered on the glass fiber filter membrane that step (2) obtains is clamped between two copy papers, transfers in the tablet press, under 30MPa pressure extrusion molding, makes The silver telluride nanowire film is transferred to a piece of copy paper, and then the glass fiber filter fragments on the back of the silver telluride nanowire film are s...

Embodiment 2

[0043] (1) ultrasonically disperse 35 mg of silver telluride nanowires and 3.5 mg of polyvinylpyrrolidone in 7 mL of ethylene glycol to obtain a silver telluride nanowire dispersion;

[0044] (2) With the assistance of vacuum filtration, evenly drop-coat 1.0mL of silver telluride nanowire dispersion on a 2.5cm×0.5cm glass fiber filter membrane, and drain the liquid; The glass fiber filter membrane was vacuum-dried at 75° C. to obtain a silver telluride nanowire film adhered to the glass fiber filter membrane;

[0045] (3) the silver telluride nanowire thin film adhered on the glass fiber filter membrane that step (2) obtains is sandwiched between two copy papers, transferred in the tablet press, extruded under 10MPa pressure, then Use a brush to sweep away the glass fiber filter fragments on the back of the silver telluride nanowire film to obtain paper with the silver telluride nanowire film;

[0046] (4) Finally, put the paper with silver telluride nanowire thin film obtain...

Embodiment 3

[0048] (1) ultrasonically disperse 40 mg of silver telluride nanowires and 10 mg of polyvinylpyrrolidone in 10 mL of ethylene glycol to obtain a silver telluride nanowire dispersion;

[0049](2) With the assistance of vacuum filtration, evenly drop-coat 0.90mL of silver telluride nanowire dispersion on a 2.5cm×0.5cm glass fiber filter membrane, and drain the liquid; The glass fiber filter membrane was vacuum-dried at 75° C. to obtain a silver telluride nanowire film adhered to the glass fiber filter membrane;

[0050] (3) the silver telluride nanowire film adhered on the glass fiber filter membrane that step (2) obtains is sandwiched between two copy papers, transferred in the tablet press, extruded under 5MPa pressure, then Use a brush to sweep away the glass fiber filter fragments on the back of the silver telluride nanowire film to obtain paper with the silver telluride nanowire film;

[0051] (4) Finally, place the paper with the silver telluride nanowire film obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com