Thermoelectric material and preparation method thereof

A thermoelectric material, cu1-xagxga1-yinyte2 technology, applied in the field of thermoelectric materials and their preparation, can solve problems such as difficulty in maintaining thermal stability, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

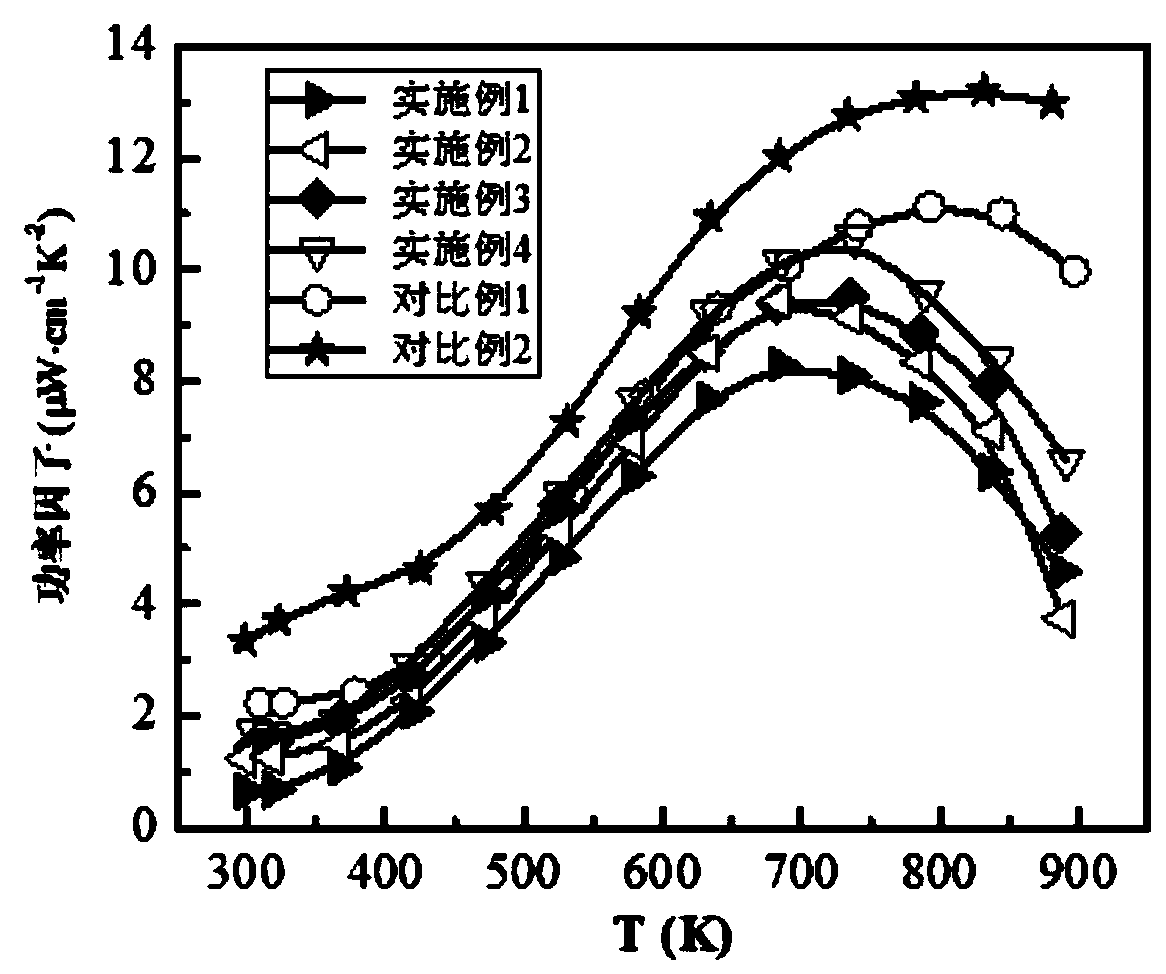

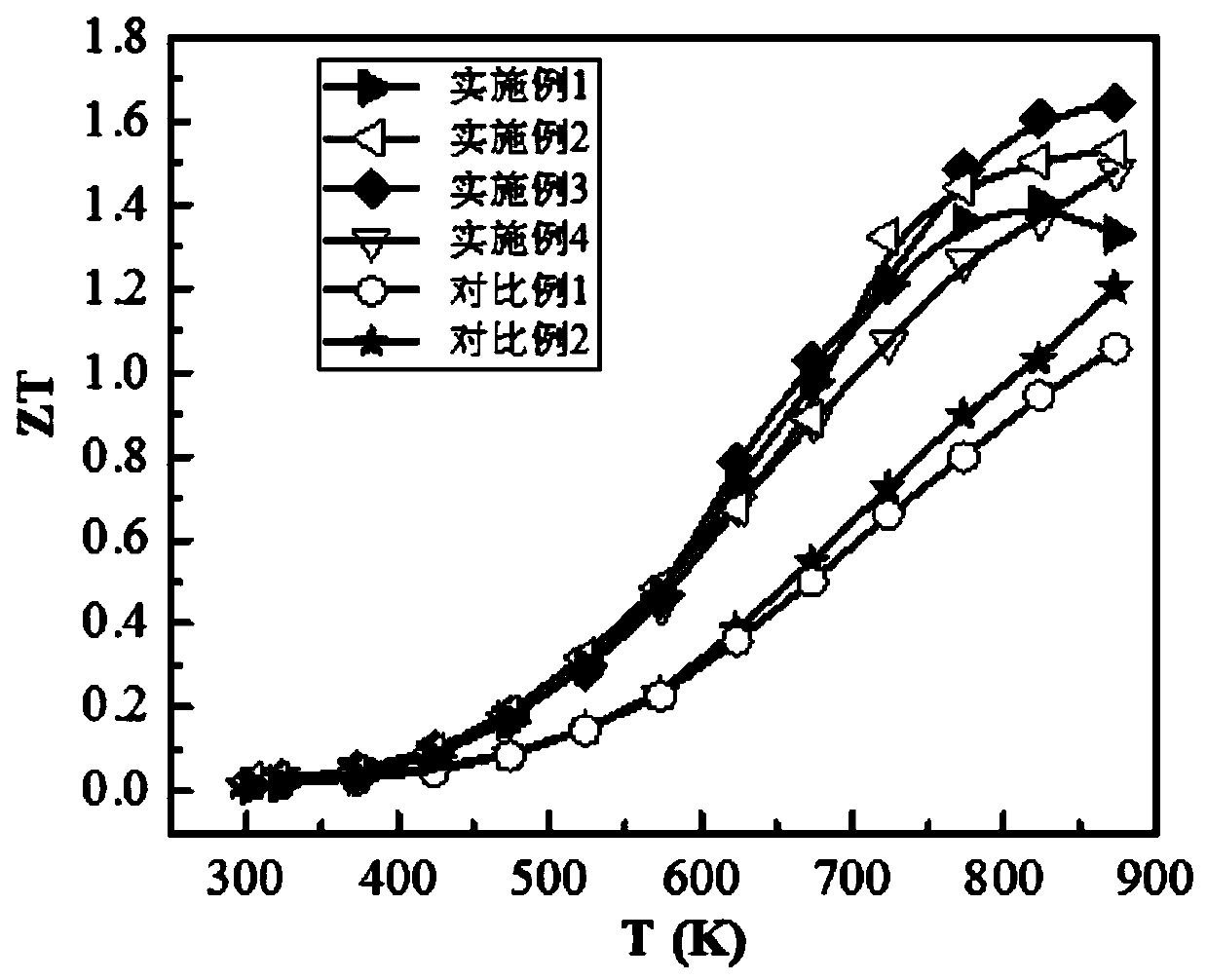

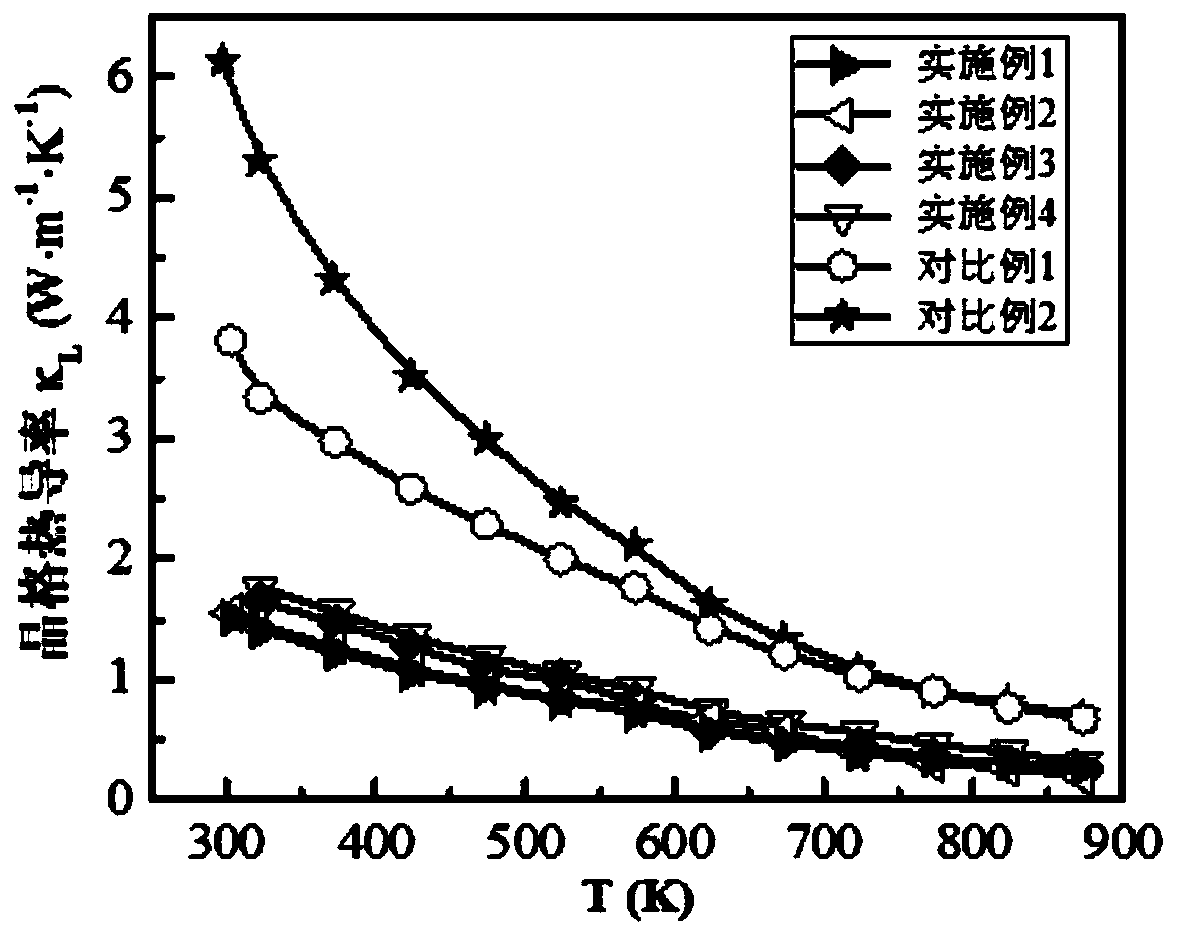

Embodiment 1

[0034] A p-type chalcopyrite-structured thermoelectric material with a chemical composition of Cu 0.6 Ag 0.4 Ga 0.4 In 0.6 Te 2 , its preparation process includes:

[0035] (1) Cu, Ag, Ga, In and Te elemental powders with a purity greater than 99% are expressed according to the chemical formula Cu 0.6 Ag 0.4 Ga 0.4 In 0.6 Te 2 Weigh the stoichiometric ratio, mix the weighed powder and seal it into a vacuum quartz tube, then put the vacuum quartz tube into a muffle furnace for melting, the melting temperature is 900-1300°C, and the melting time is 5-48h. For example, the preferred smelting temperature is 1050°C, and the preferred smelting time is 24h, and the obtained composition is Cu 0.6 Ag 0.4 Ga 0.4 In 0.6 Te 2 melting ingot;

[0036] (2) Grind the melted ingot obtained in step (1) into powder first, then perform dry ball milling on the powder to make the powder nanometer, the dry ball milling time is 0.5-100h, if the preferred dry ball milling time is 1h, the...

Embodiment 2

[0039] A p-type chalcopyrite-structured thermoelectric material with a chemical composition of Cu 0.65 Ag 0.35 Ga 0.4 In 0.6 Te 2 , its preparation process includes:

[0040] (1) Cu, Ag, Ga, In and Te elemental powders with a purity greater than 99% are expressed according to the chemical formula Cu 0.65 Ag 0.35 Ga 0.4 In 0.6 Te 2 Weigh the stoichiometric ratio, mix the weighed powder and seal it into a vacuum quartz tube, then put the vacuum quartz tube into a muffle furnace for melting, the melting temperature is 900-1300°C, and the melting time is 5-48h. For example, if the preferred melting temperature is 1050°C and the melting time is 24 hours, the obtained composition is Cu 0.65 Ag 0.35 Ga 0.4 In 0.6 Te 2 melting ingot;

[0041] (2) Grind the melted ingot obtained in step (1) into powder first, then perform dry ball milling on the powder to make the powder nanometer, the dry ball milling time is 0.5-100h, if the preferred dry ball milling time is 1h, then ...

Embodiment 3

[0044] A p-type chalcopyrite-structured thermoelectric material with a chemical composition of Cu 0.7 Ag 0.3 Ga 0.4 In 0.6 Te 2 , its preparation process includes:

[0045] (1) Cu, Ag, Ga, In and Te elemental powders with a purity greater than 99% are expressed according to the chemical formula Cu 0.7 Ag 0.3 Ga 0.4 In 0.6 Te 2 Weigh the stoichiometric ratio, mix the weighed powder and seal it into a vacuum quartz tube, then put the vacuum quartz tube into a muffle furnace for melting, the melting temperature is 900-1300°C, and the melting time is 5-48h. For example, if the preferred melting temperature is 1050°C and the melting time is 24 hours, the obtained composition is Cu 0.7 Ag 0.3 Ga 0.4 In 0.6 Te 2 melting ingot;

[0046] (2) Grind the melted ingot obtained in step (1) into powder first, then perform dry ball milling on the powder to make the powder nanometer, the dry ball milling time is 0.5-100h, if the preferred dry ball milling time is 1h, then The na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com