High-performance BiCuSeO-base thermoelectric material and preparation method thereof

A thermoelectric material, high-performance technology, applied in the direction of thermoelectric device junction lead wire material, thermoelectric device manufacturing/processing, etc., can solve the problems of poor thermoelectric performance and low conductivity of BiCuSeO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides a method for preparing a high-performance BiCuSeO-based thermoelectric material described in the above technical solution, comprising the following steps:

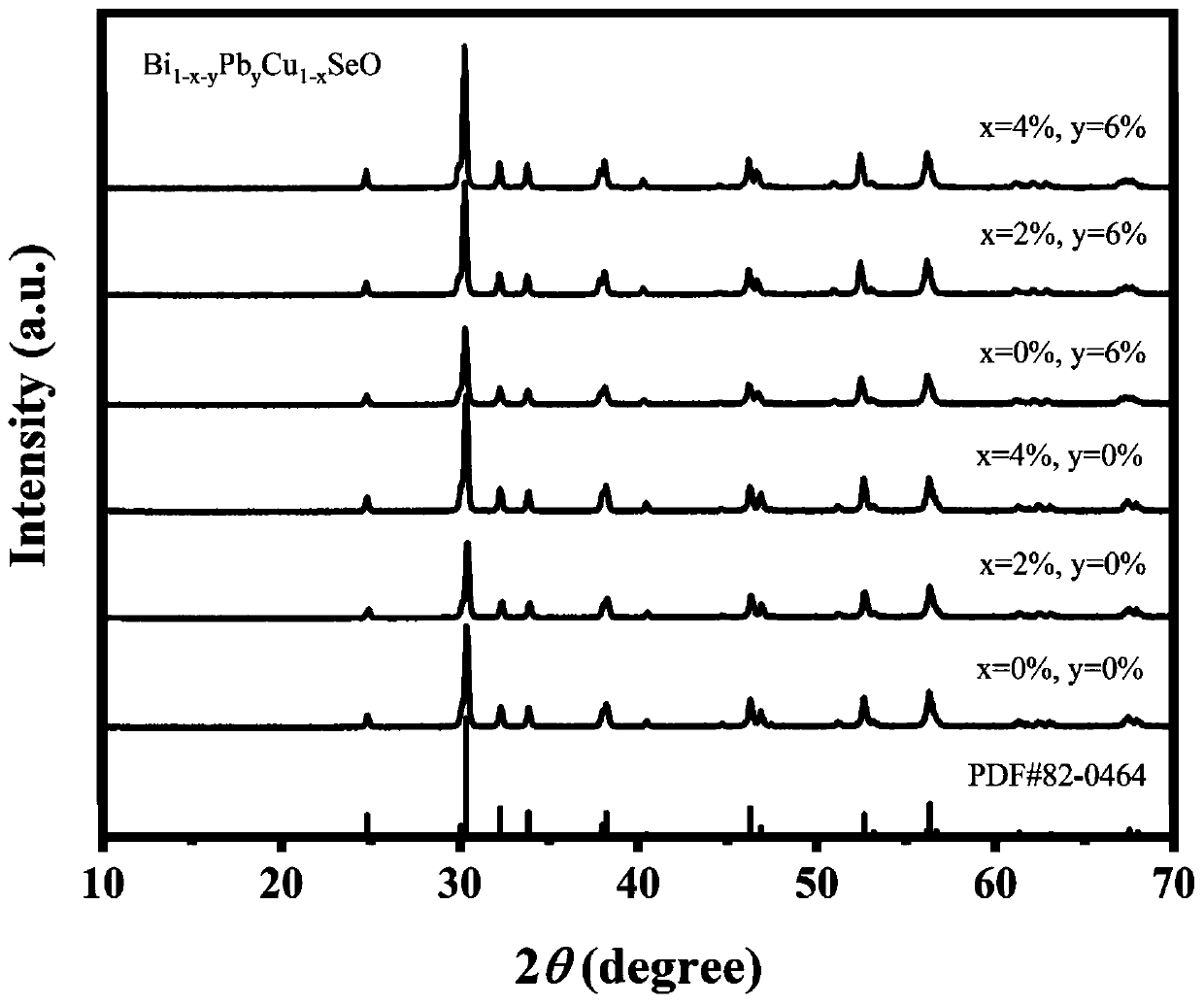

[0033] According to Bi 1-x-y A y Cu 1-x The stoichiometric ratio of SeO weighs powdered raw materials Bi, AO, Cu, Se, Bi 2 o 3 , mixed evenly under the protection of argon, vacuum-sealed and sintered to obtain an ingot; the AO is selected from CaO, SrO, BaO or PbO;

[0034] The ingot is ground into powder in an argon atmosphere, and then vacuum hot-pressed and sintered to obtain a high-performance BiCuSeO-based thermoelectric material.

[0035] The present invention according to Bi 1-x-y A y Cu 1-x The stoichiometric ratio of SeO weighs powdered raw materials Bi, AO, Cu, Se, Bi 2 o 3 , mixed uniformly under the protection of argon, vacuum-sealed and then sintered to obtain an ingot; the AO is selected from CaO, SrO, BaO or PbO. In the present invention, the process of sintering...

Embodiment 1

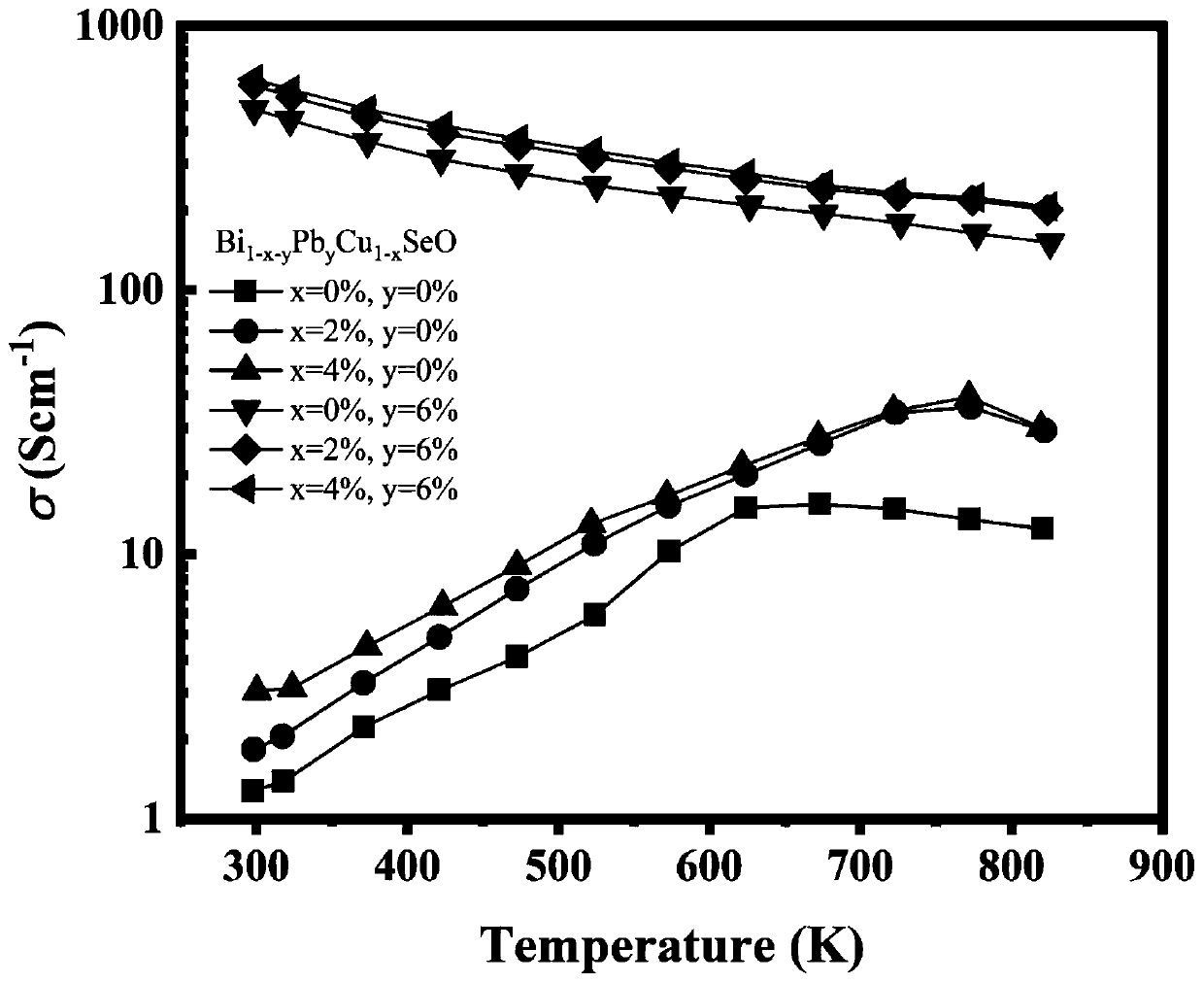

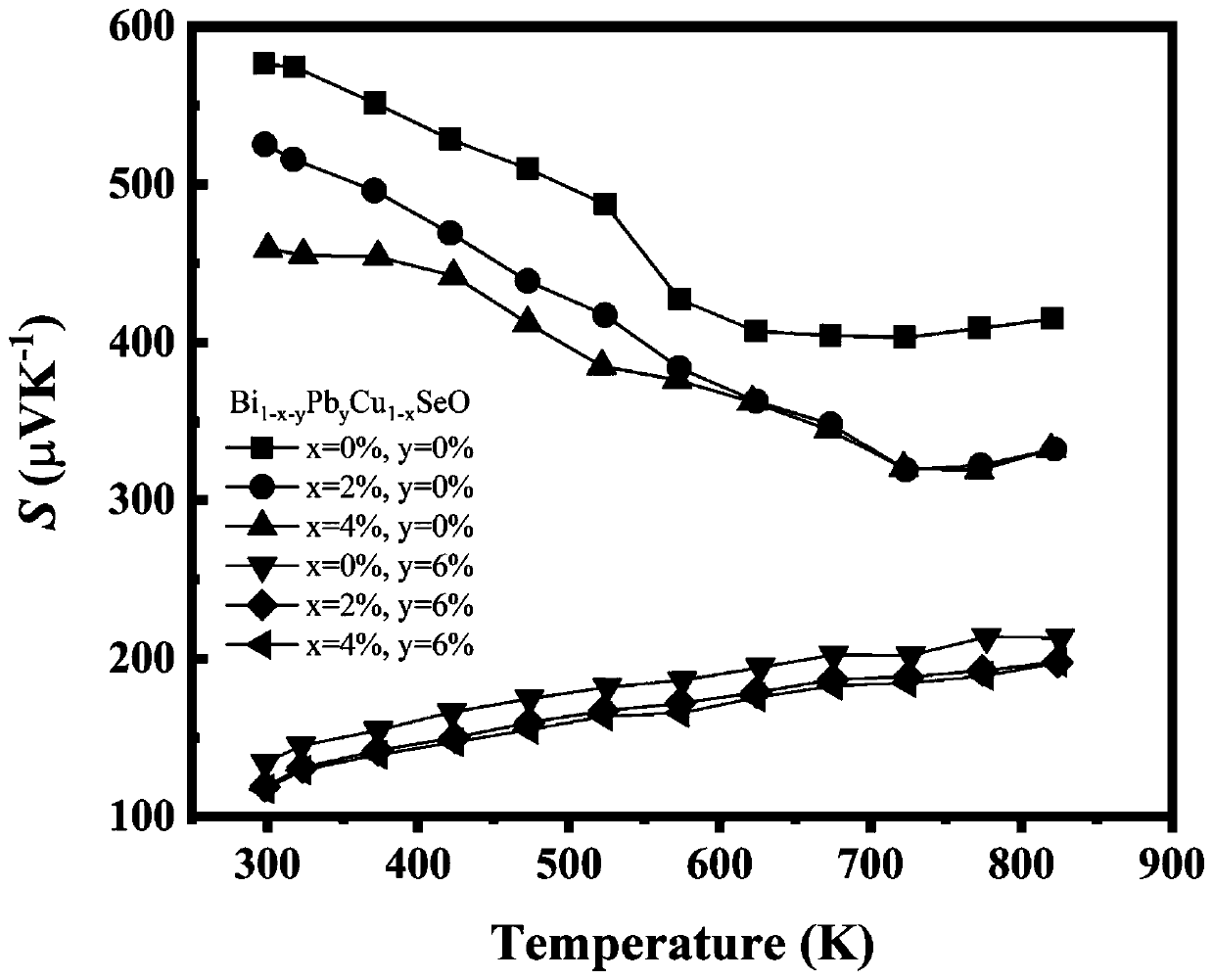

[0044] According to Bi 1-x-y Pb y Cu 1-x The stoichiometric ratio of SeO weighs powdered raw materials Bi, PbO, Cu, Se, Bi 2 o 3 , where x=0.02, y=0. After the raw materials were mixed uniformly under the protection of argon, they were vacuum-sealed in a quartz tube. Put the vacuum-sealed raw materials into the muffle furnace, first raise the temperature from room temperature to 300°C at a rate of 5°C per minute, and then keep it for 12 hours; then raise the temperature from 300°C to 700°C at a rate of 5°C per minute, and Keep warm for 10 hours; finally cool slowly to room temperature. Grind the ingot obtained in the above steps into powder under the protection of argon, put it into a graphite mold, apply axial pressure to carry out vacuum hot pressing sintering, wherein the sintering temperature is 650°C, the pressure is 80MPa, and the holding time is 30min . After cooling, the BiCuSeO-based thermoelectric material can be obtained, and its dimensionless figure of merit...

Embodiment 2

[0046] According to Bi 1-x-y Pb y Cu 1-x The stoichiometric ratio of SeO weighs powdered raw materials Bi, PbO, Cu, Se, Bi 2 o 3 , where x=0.04, y=0. After the raw materials were mixed uniformly under the protection of argon, they were vacuum-sealed in a quartz tube. Put the vacuum-sealed raw materials into the muffle furnace, first raise the temperature from room temperature to 300°C at a rate of 5°C per minute, and then keep it for 12 hours; then raise the temperature from 300°C to 700°C at a rate of 5°C per minute, and Keep warm for 10 hours; finally cool slowly to room temperature. Grind the ingot obtained in the above steps into powder under the protection of argon, put it into a graphite mold, apply axial pressure to carry out vacuum hot pressing sintering, wherein the sintering temperature is 650°C, the pressure is 80MPa, and the holding time is 30min . After cooling, the BiCuSeO-based thermoelectric material can be obtained, and its dimensionless figure of merit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com