Method for improving Seebeck coefficient of carbon fiber cement-based composite material

A composite material and carbon fiber technology, which is applied in the field of cement-based composite material preparation, can solve the problems of reduced mechanical properties and large water ash, and achieve the effects of moderate particle size, stable chemical composition, and improved Seebeck coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

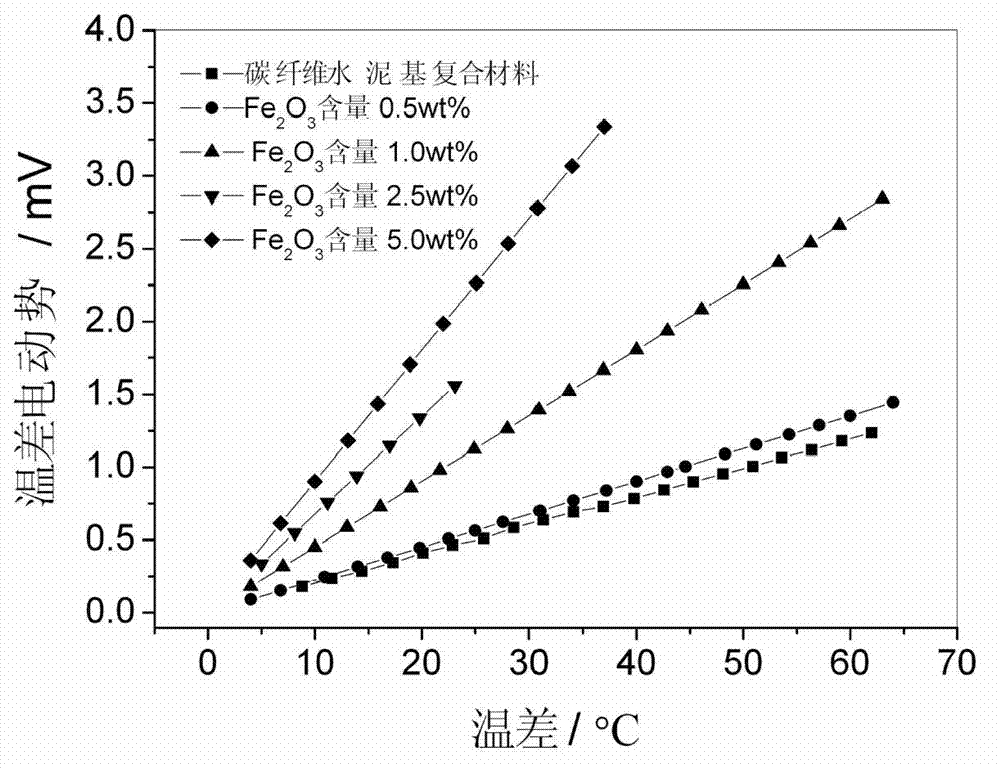

[0021] Embodiment 1: prepare the cavity to be the steel mold of cuboid, be the ratio of 0.01:0.01:1 according to mass ratio, get Fe 2 o 3 powder, PAN based chopped carbon fiber and sulphoaluminate cement.

[0022] Use ultrasonic wave to disperse PAN-based chopped carbon fiber in water evenly, form a mixture of chopped carbon fiber and water, add it to the mixer, and then add sulphoaluminate cement and Fe 2 o 3 powder, and 0.5% polycarboxylate superplasticizer by cement mass can also be added at the same time, and further stirred to form a carbon fiber cement mixture. The carbon fiber cement mixture is poured into a steel mold, and solidified in the mold to form a carbon fiber cement-based composite material sample.

[0023] A flat heater is used to generate a temperature difference ΔT on two opposite sides of the carbon fiber cement-based composite sample, one of which is gradually heated to 90°C by the flat heater (heating rate is 0.01°C / s), and the other side is kept roo...

Embodiment 2

[0024] Embodiment 2: prepare the cavity to be the steel mold of cuboid, be the ratio of 0.05:0.01:1 according to mass ratio, get Fe 2 o 3 powder, PAN based chopped carbon fiber and sulphoaluminate cement.

[0025] Use ultrasonic wave to disperse PAN-based chopped carbon fiber evenly in water to form a mixture of chopped carbon fiber and water, add it to the mixer, and then add sulphoaluminate cement and Fe 2 o 3 powder, and 0.5% polycarboxylate superplasticizer by cement mass can also be added at the same time, and further stirred to form a carbon fiber cement mixture. The carbon fiber cement mixture is poured into a steel mold, and solidified in the mold to form a carbon fiber cement-based composite material sample.

[0026] A flat heater is used to generate a temperature difference ΔT on the two opposite sides of the carbon fiber cement-based composite sample, one of which is gradually heated to 60°C by the flat heater (heating rate is 0.01°C / s), and the other side is kep...

Embodiment 3

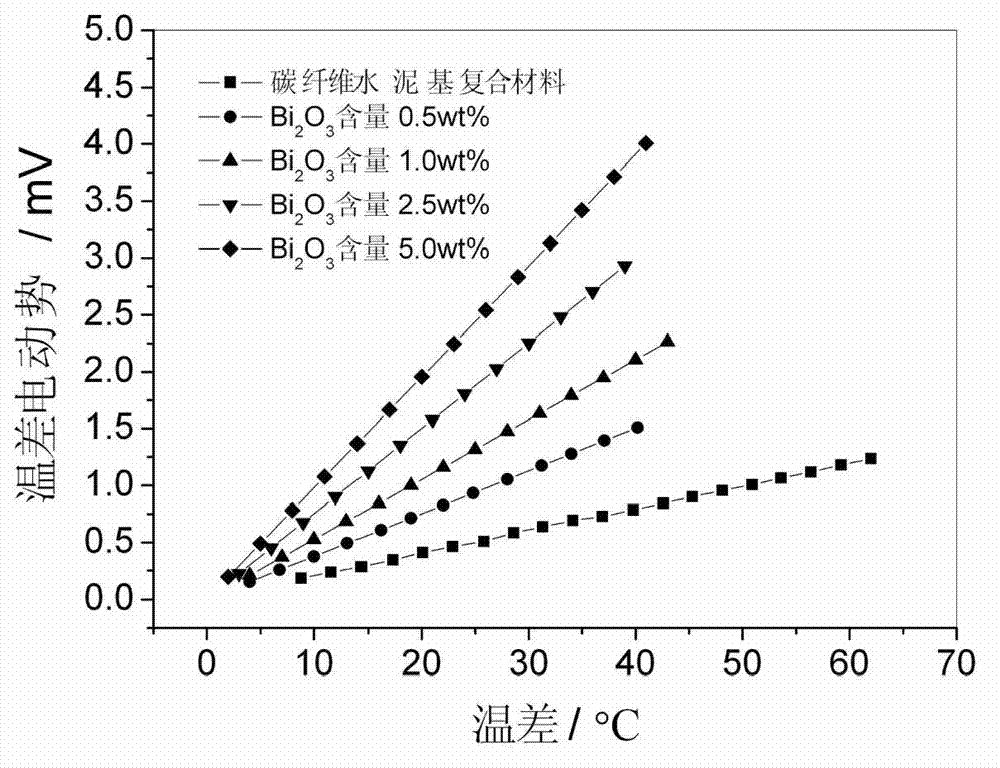

[0027] Embodiment 3: prepare the cavity to be the steel mold of cuboid, be the ratio of 0.005:0.01:1 according to mass ratio, get Bi 2 o 3 powder, PAN based chopped carbon fiber and sulphoaluminate cement.

[0028] Use ultrasonic wave to disperse PAN-based chopped carbon fiber evenly in water to form a mixture of chopped carbon fiber and water, add it to the mixer, and then add sulphoaluminate cement and Bi 2 o 3 powder, and 0.5% polycarboxylate superplasticizer by cement mass can also be added at the same time, and further stirred to form a carbon fiber cement mixture. The carbon fiber cement mixture is poured into a steel mold, and solidified in the mold to form a carbon fiber cement-based composite material sample.

[0029] A flat heater is used to generate a temperature difference ΔT on the two opposite sides of the carbon fiber cement-based composite sample, one of which is gradually heated to 75°C by the flat heater (heating rate is 0.01°C / s), and the other side is ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com