Cage type compound

A compound and cage-type technology, applied in the field of cage compounds, can solve problems such as limited lattice atom adjustment ability and poor thermoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] The present invention provides a more specific embodiment, the preparation method in this embodiment includes the following steps:

[0086] (a) providing a mixture of 9.2 to 16 molar fractions of component M, (x to 1.5x) molar fraction of component A, and (0.8 to 1.2)*(y-x) molar fraction of component B;

[0087] Wherein M is an alkaline earth metal, a rare earth metal, an alkali metal, a Cd atom or a combination thereof,

[0088] A is Ga, Al, In, Zn or a combination thereof;

[0089] B is Ge, Si, Sn, Ni or a combination thereof;

[0090] 12≤x≤16, 40≤y≤43, x and y are each integer or non-integer;

[0091] (b) quenching after heating the mixture in step (a) to a fully molten state to obtain a quenched mixture;

[0092] (c) Grinding the quenched mixture in step (b) into powder, removing impurities and excess raw materials to obtain quenched mixture powder;

[0093] (d) Sintering the quenched mixture powder in step (c) by a pulsed current rapid sintering method to obta...

Embodiment 1

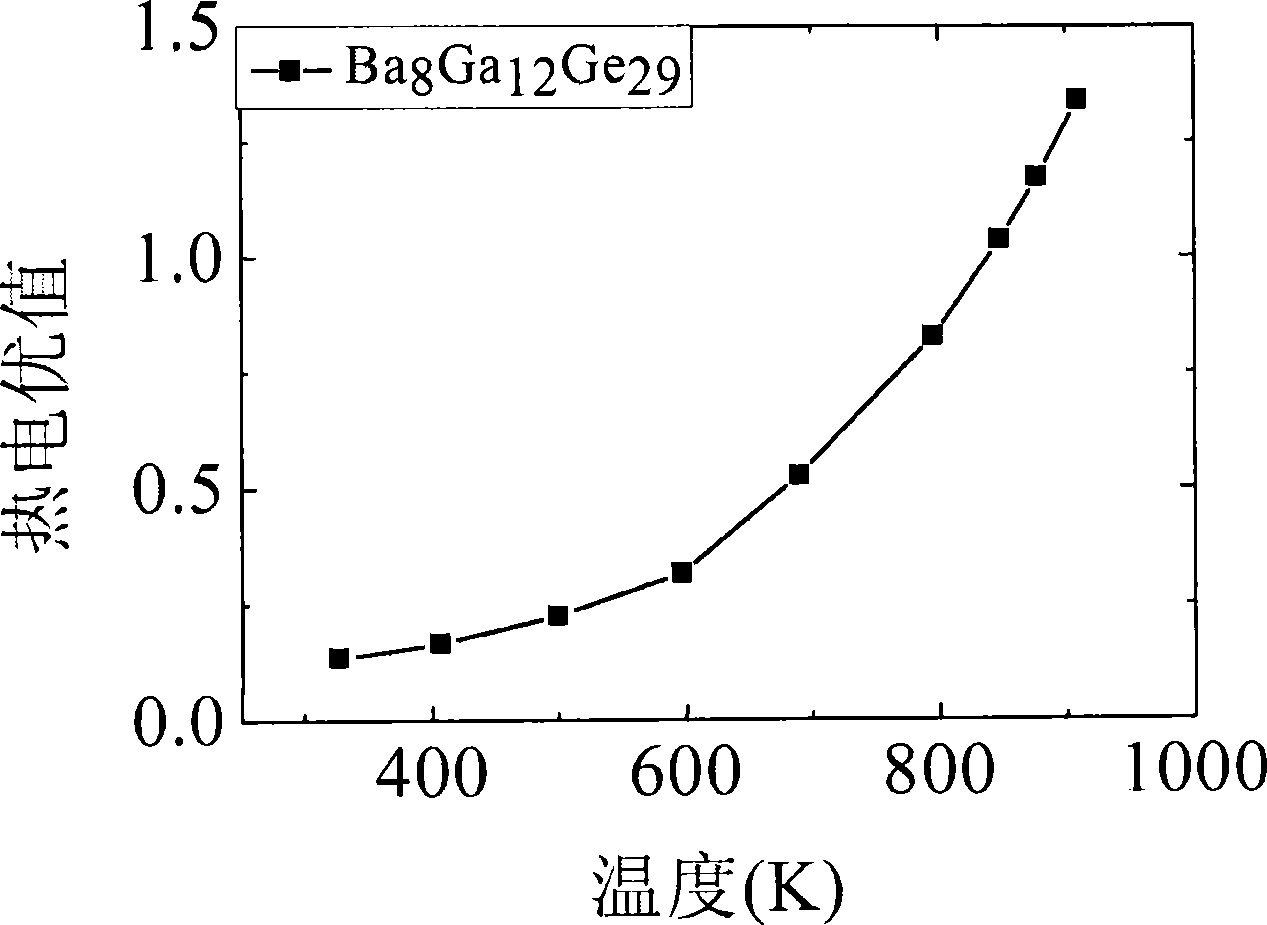

[0147] Example 1 Ba 8 Ga 12 Ge 29 Preparation of cage compounds

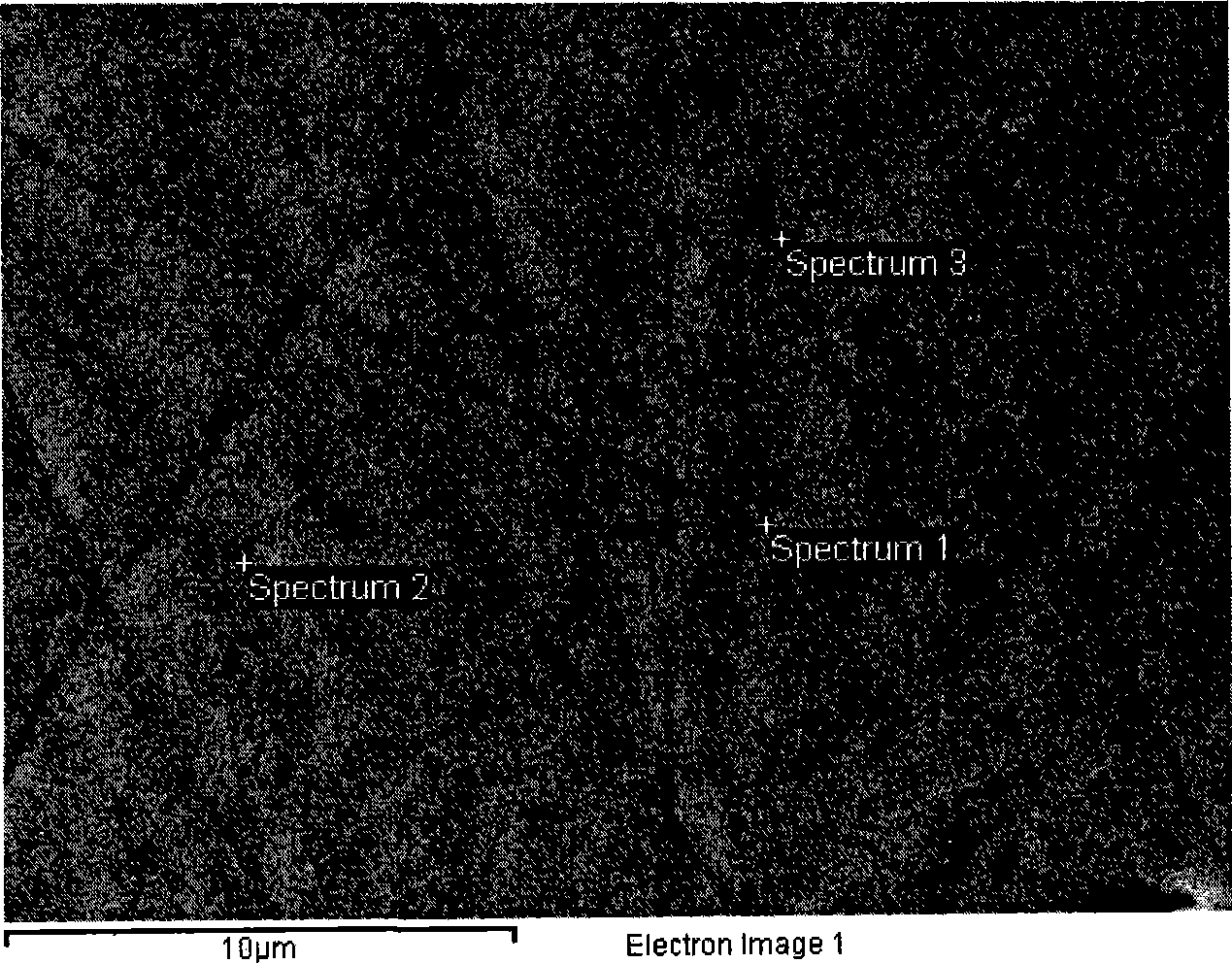

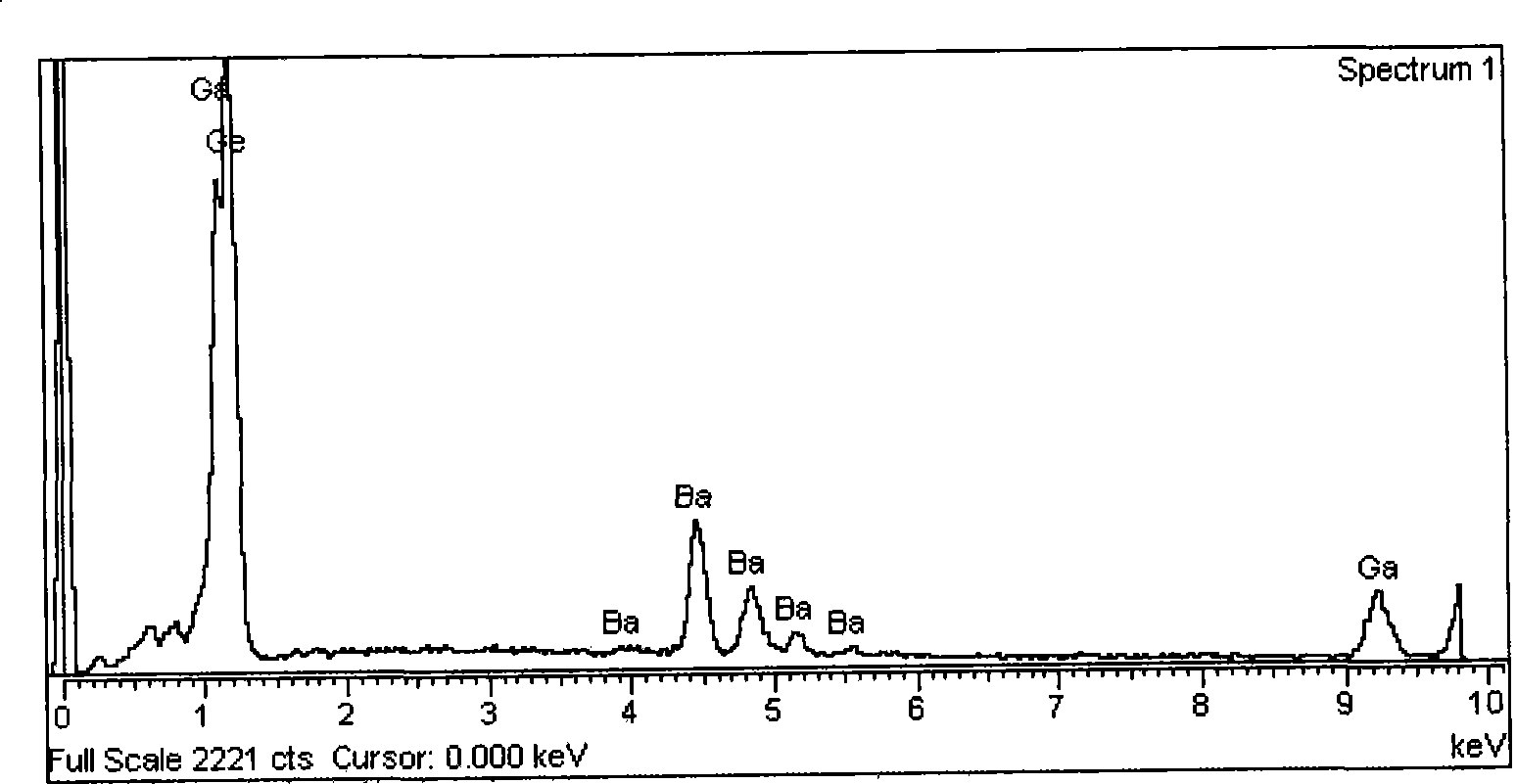

[0148] The metal raw materials Ba, Ga and Ge are dosed according to the molar ratio of 9.3 (16.2% in excess): 14.5 (20.8% in excess): 29, and sealed in a quartz tube. The packaged raw material is heated to 1080° C. for 10 hours and then quenched with water to obtain crystal ingots. The powder obtained by grinding the ingot is soaked in hydrochloric acid (30% concentration, the weight ratio of acid to powder is 100:1) and pickled. The dried powder after pickling is sintered into a dense block by using the pulse energization rapid sintering sintering technology (heating rate 100 degrees / min) at 730° C. for 3 minutes under vacuum (vacuum degree 6 Pa). Scanning electron microscope photo SEM of the polished surface (such as figure 1 ) and energy spectrum analysis diagrams (such as figure 2 ), indicating that the obtained material is a pure phase. Table 3 is figure 1 The atomic percentage results of the three...

Embodiment 2

[0149] Example 2 Sr 8 Ga 13 Ge 27 Preparation of cage compounds

[0150] The metal raw materials Sr, Ga and Ge are dosed according to the molar ratio of 9.25 (15.6% in excess): 15.4 (18.5% in excess): 27, and sealed in the quartz tube. The packaged raw materials were heated to 1080° C. for 4 hours and then oil quenched to obtain crystal rods. The powder obtained by grinding the ingot is soaked in hydrochloric acid (50% concentration, the weight ratio of acid to powder is 50:1) and pickled. The dried powder after pickling is sintered into a dense block at 650°C under vacuum using the pulse energization rapid sintering sintering technology. Its performance is shown in the performance examples. like Figure 5 The X-ray diffraction pattern of the obtained material shows that the obtained material is a cage phase of a type I cage (clathrate) structure. According to energy spectrum analysis, it is measured that each part of the material has a uniform composition Sr 8 Ga13 Ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com