An organic composite thermoelectric film and a preparation method thereof

A kind of thermoelectric thin film, organic technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device junction lead-out materials, etc., can solve the problems of high thermal conductivity, difficult processing, expensive and other problems of inorganic thermoelectric thin films, and achieve excellent air stability Good properties and thermal stability, low cost, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Synthesis of polymers NDI-4, NDI-6 and NDI-10:

[0054] NDI-4: In a 50ml two-necked flask, sequentially add monomer I (3g, 1.12mmol), monomer II (1.9275g, 1.12mmol), N,N-dimethylformamide (DMF, 25ml) under nitrogen Under the protection of the atmosphere, the temperature is controlled at 150°C for 72 hours, and the reaction formula is as follows

[0055]

[0056] NDI-6: In a 50ml two-necked flask, add monomer Ⅰ (1g, 0.37mmol), monomer Ⅱ (0.4299g, 0.37mmol), N,N-dimethylformamide (DMF, 20ml) in nitrogen Under the protection of atmosphere, the temperature was controlled at 150°C for 72 hours, and the reaction formula was as follows:

[0057]

[0058] NDI-10: In a 50ml two-necked flask, add monomer Ⅰ (0.8024g, 0.30mmol), monomer Ⅱ (0.2633g, 0.30mmol), N,N-dimethylformamide (DMF, 25ml) in sequence Under the protection of nitrogen atmosphere, the temperature was controlled at 150°C for 72 hours. The reaction formula is as follows:

[0059]

[0060] After the react...

Embodiment 2

[0062] Preparation of NDI / SWCNT organic composite thermoelectric thin film:

[0063] Polymers NDI-4, NDI-6 and NDI-10 obtained in Example 1 were dissolved in chlorobenzene at a concentration of 15 mg / ml and uniformly mixed with single-walled carbon nanotubes (SWCNT), and the corresponding solution was mixed with a dropper. Drop by drop onto a glass sheet of 15mm*15mm, after the solvent volatilizes, the dense NDI-4 / SWCNT organic composite thermoelectric film, NDI-6 / SWCNT organic composite thermoelectric film and NDI-10 / SWCNT organic composite thermoelectric thin film.

Embodiment 3

[0065] Characterization and thermoelectric performance of organic thermoelectric materials NDI-4, NDI-6 and NDI-10, NDI-4 / SWCNT organic composite thermoelectric thin film, NDI-6 / SWCNT organic composite thermoelectric thin film and NDI-10 / SWCNT organic composite thermoelectric thin film test:

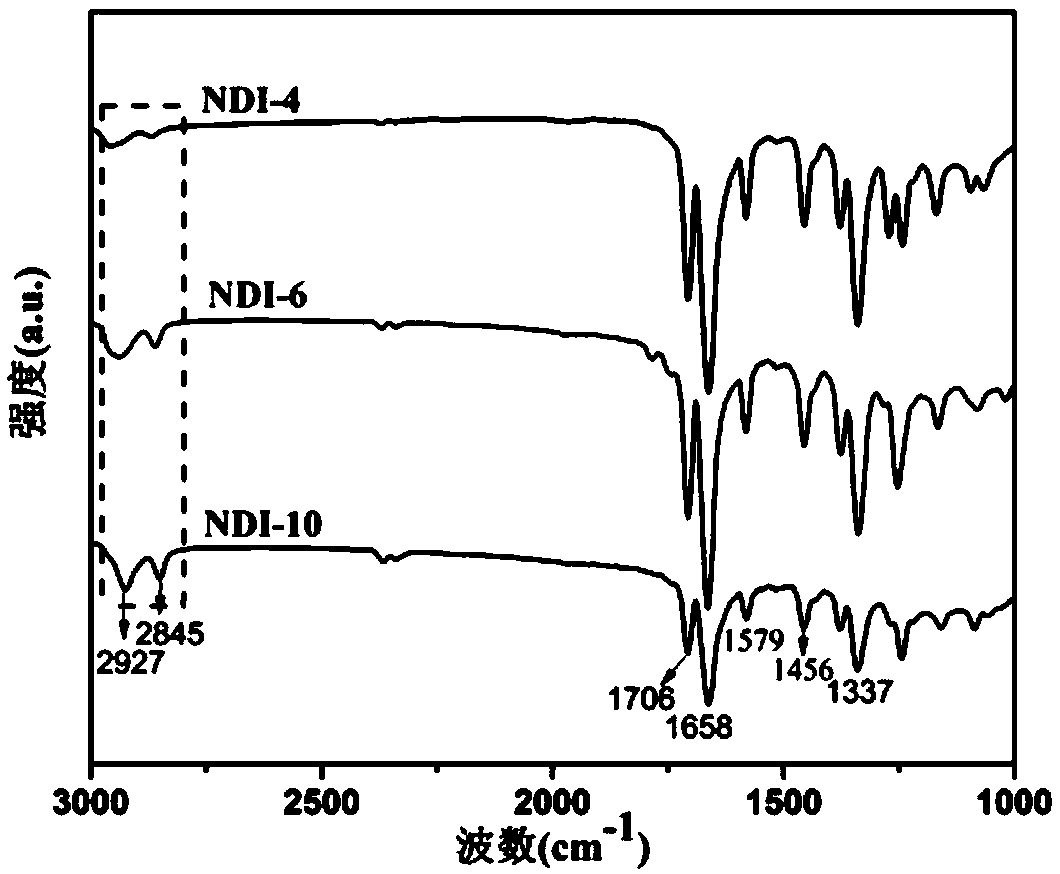

[0066] 1. The polymer functional groups of polymers NDI-4, NDI-6 and NDI-10 are tested by a Thermo Scientific Nicolet 6700 Fourier transform infrared spectrometer, and the measured Fourier transform infrared spectrogram is as follows figure 1 shown. The main absorption peaks of the three polymers are as follows: Absorption in the range bands from stretching vibrations of unsaturated C–H bonds. In the spectra of NDI-4, NDI-6 and NDI-10, 2926cm -1 、1706cm -1 、1658cm -1 and 1337cm -1 The bands at are attributed to the C-H, C=C, C=O and C-N stretching vibration modes, while the 1456cm -1 The frequency bands are attributed to C-H bending vibrations. The main absorption peak character...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com