Cathode and anode built-in ceramic micro-filtration membrane reactor suitable for removing pollutant in source water

A technology of ceramic microfiltration and membrane reactor, which is applied in the direction of water pollutants, water/sewage treatment, water/sewage treatment equipment, etc., can solve difficult removal problems, achieve high removal rate, low treatment cost, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

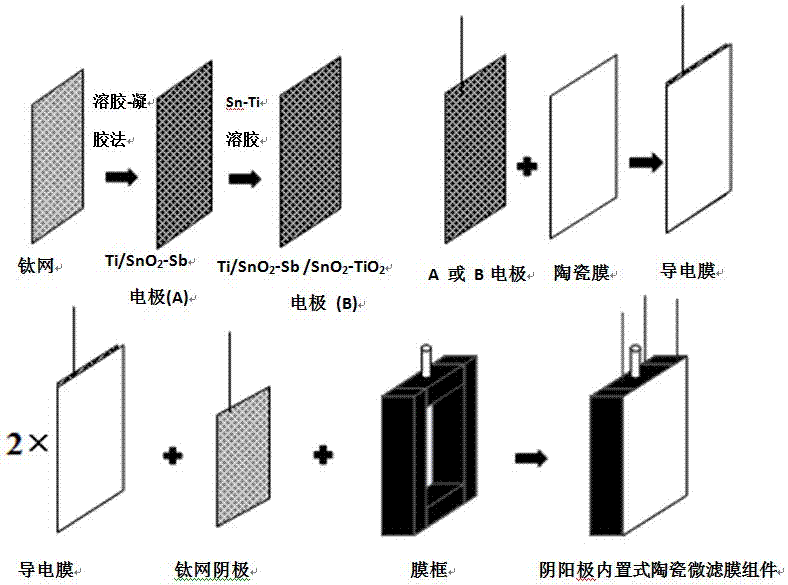

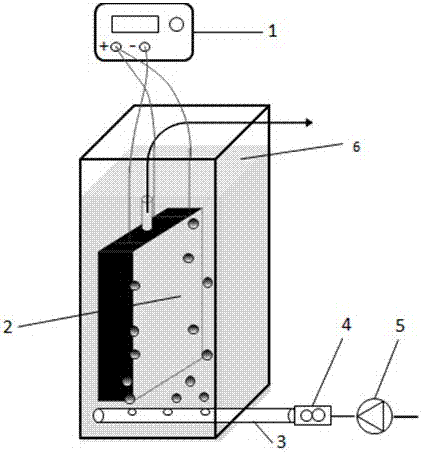

[0020] Embodiment 1: a kind of cathode and anode built-in ceramic microfiltration membrane reactor, and its production process is such as figure 1 As shown in the figure, firstly, the sol-gel with Sn:Sb ratio of 9:1 was repeatedly coated on a titanium mesh with a pore size of 100 μm, a thickness of 200 μm and a size of 5 cm × 8 cm, and then dried and calcined to obtain Sb-doped titanium-based SnO. 2 Electrode (A) with TiO supported by sol-gel method 2 , to get the supported TiO 2 Titanium based SnO 2 -Sb 2 O 5 Electrode (B), combine (A) or (B) electrode with ZrO 2 and Al 2 O 3Composition, pore size of 0.1-0.4 μm, ceramic microfiltration membrane size of 5 cm × 8 cm were laminated to obtain a ceramic microfiltration membrane anode. A titanium mesh with a pore size of 100 μm, a thickness of 200 μm, and a size of 3 cm×6 cm was placed in the PVC membrane support as the cathode, and a piece of ceramic microfiltration membrane anode was bonded to each side of the cathode to o...

Embodiment 2

[0023] Using the cathode and anode built-in ceramic microfiltration membrane reactor, in the filtration mode, the membrane separation performance of the electrochemical ceramic microfiltration membrane module was tested, and the experimental parameters were set as: flux 139 L / (m 2 • h), add 100 mg / L SiO to the water 2 Particles (particle size is 2μm), the influent turbidity is 32 NTU, and the measured effluent turbidity remains around 0.9 NTU.

Embodiment 3

[0025] The system in Example 1 was used to treat simulated low-concentration p-chloroaniline (PCA) wastewater. The experimental parameters were set as follows: the influent was 10 μM PCA, the initial pH was controlled to be 7, and the electrolyte was 50 mM Na 2 SO 4 , using a regulated DC power supply to provide an external voltage of 3 V, and setting up two electrochemical ceramic membrane reactors, respectively using Ti / SnO 2 -Sb and Ti / SnO 2 -Sb / TiO 2 -SnO 2 as an anode. The two reactors were set to operate in batch operation mode, and the electrolysis time was 4h; the two reactors were set to operate in continuous flow operation mode, and the electrochemical microfiltration membrane module was operated at a flux of 35 L / (m 2 • h) Operation (hydraulic retention time 4 h). Within a reaction time of 4 h, the Ti / SnO 2 -Sb group achieved 26% and 66% removal of PCA in batch and continuous flow modes, respectively, while Ti / SnO 2 -Sb / TiO 2 -SnO 2 The PCA removal rates of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com