A nanofiber that can increase the specific surface area

A technology of nanofiber and core-shell structure, applied in fiber processing, fiber chemical characteristics, conjugated artificial filament, etc., can solve the problems of nanofibers without specific surface area and high manufacturing cost, and achieve great development prospects and application value , easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Measure 50 grams of ethanol, 1 gram of tetrabutyl titanate, and 1 gram of polyvinylpyrrolidone in a container, mix and stir to obtain a uniform core layer spinning solution.

[0024] Step 2: Weighing 40g of tin tetrachloride pentahydrate, 20g of antimony trichloride and 5g of polyvinylpyrrolidone were dissolved in 40g of N,N-dimethylformamide to obtain a uniform shell spinning solution.

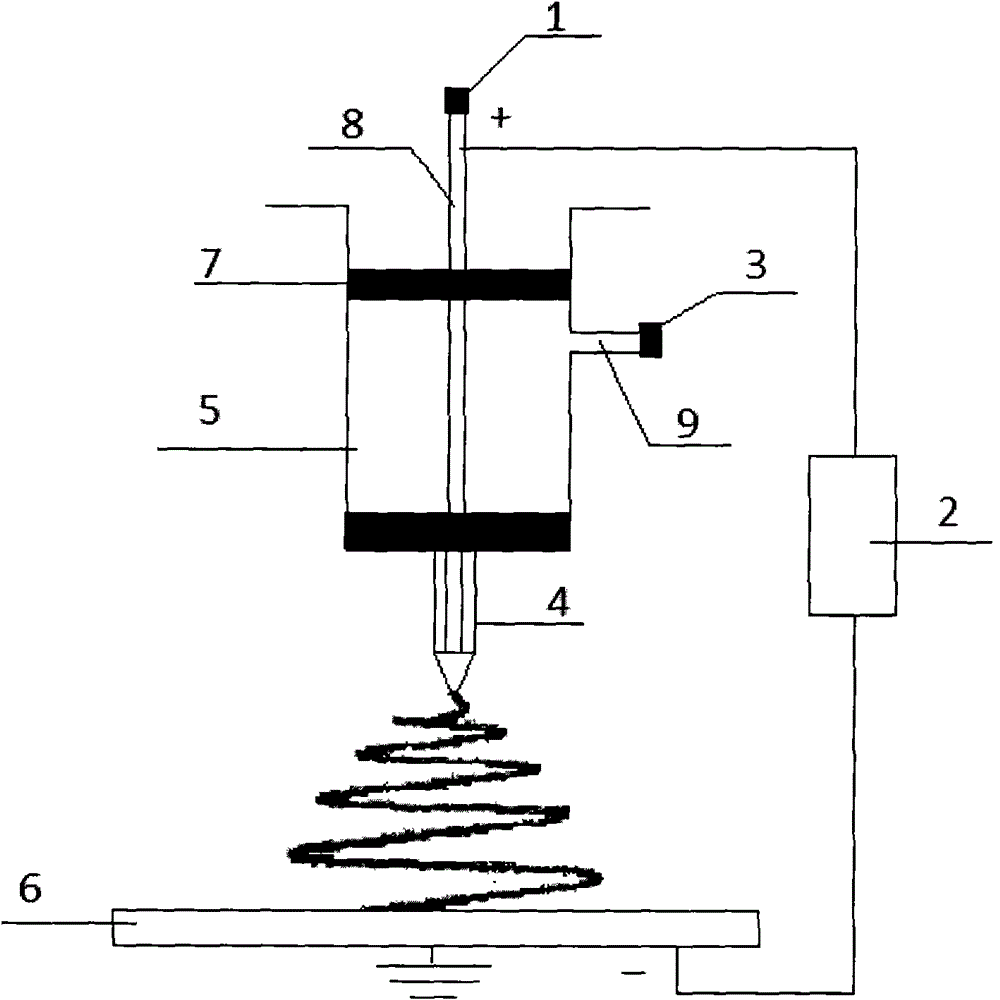

[0025] Step 3, place the spinning solution obtained in step 1 and step 2 in the electrospinning equipment, the setting distance between the spinneret and the receiving plate of the electrostatic spinning equipment is 15-20cm, and the flow rate of the nuclear layer spinning solution is 0.5 -2.0m1 / h, the diameter of the spinneret of the core layer spinning solution is 0.5-1.0mm; the flow rate of the shell spinning solution is 0.5-3.0ml / h, and the diameter of the spinneret of the shell spinning solution is 1.0-1.5mm ; After stably flowing out, apply an electrostatic voltage of 25k...

Embodiment 2

[0028] Step 1: Measure 60 grams of ethanol, 1 gram of tetrabutyl titanate, and 1 gram of polyvinylpyrrolidone in a container, mix and stir to obtain a uniform core layer spinning solution.

[0029] Step 2: Weighing 30g of tin tetrachloride pentahydrate, 20g of antimony trichloride and 5g of polyvinylpyrrolidone were dissolved in 40g of N,N-dimethylformamide to obtain a uniform shell spinning solution.

[0030] Step 3, place the spinning solution obtained in step 1 and step 2 in the electrospinning equipment, the setting distance between the spinneret and the receiving plate of the electrostatic spinning equipment is 15-20cm, and the flow rate of the nuclear layer spinning solution is 0.5 -2.0m1 / h, the diameter of the spinneret of the core layer spinning solution is 0.5-1.0mm; the flow rate of the shell spinning solution is 0.5-3.0m1 / h, and the diameter of the spinneret of the shell spinning solution is 1.0-1.5mm ; After stably flowing out, apply an electrostatic voltage of 25k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com