High thermal conductivity magnesium alloy and preparation method thereof

A magnesium alloy, high thermal conductivity technology, applied in the field of magnesium alloys, can solve problems such as high cost and affect production efficiency, and achieve the effects of low cost, no pollutant discharge, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

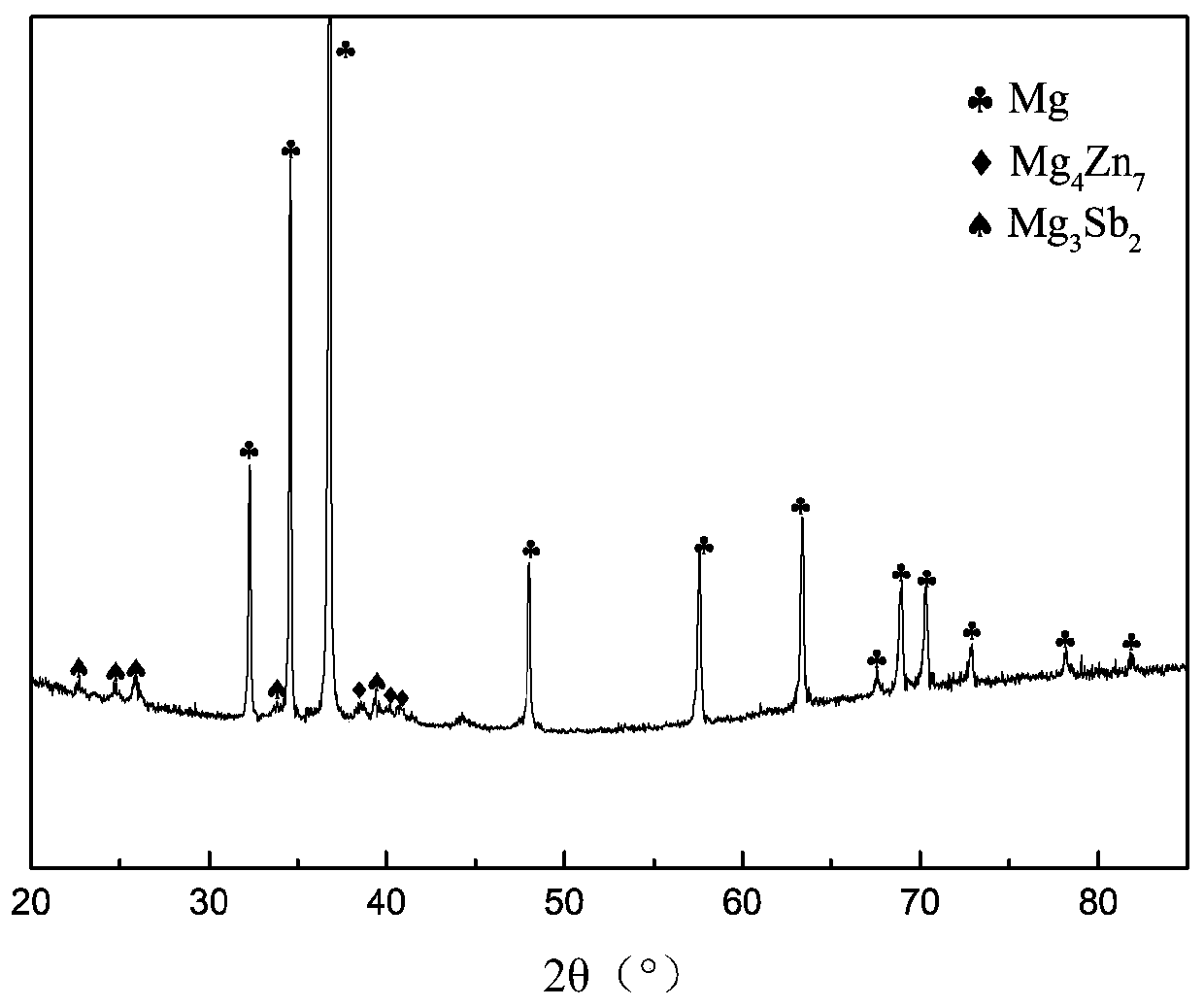

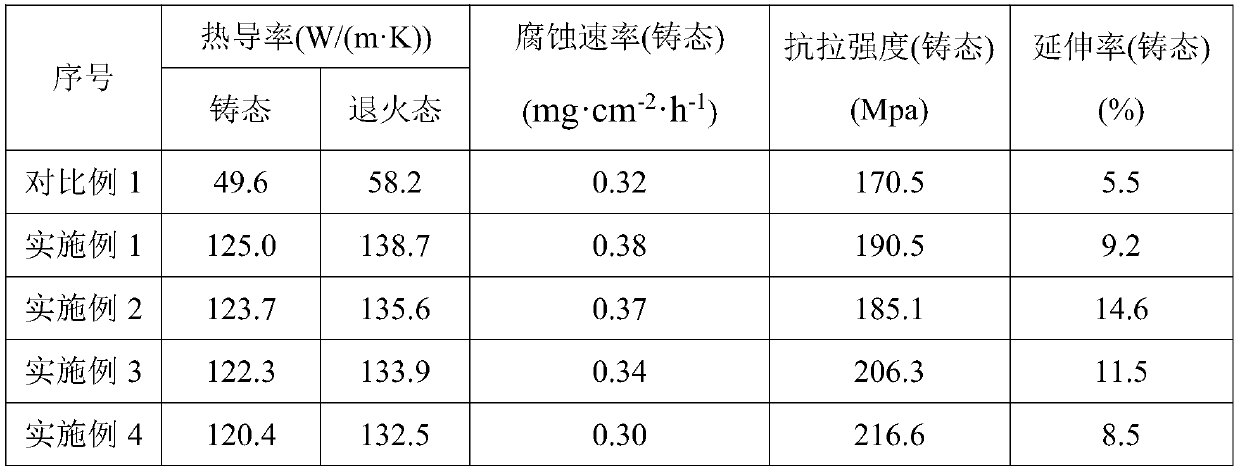

[0053] Example 1: Mg-4Zn-0.8Sb-0.1Al-0.1Mn-0.2Ce alloy

[0054] The alloy composition prepared in this example is Mg-4Zn-0.8Sb-0.1Al-0.1Mn-0.2Ce alloy, using industrially pure Mg, high-purity Zn, high-purity Sb, high-purity Al, Mg-10Mn and Mg-20Ce The master alloy is prepared, and its composition by weight percentage is: Zn: 4%, Sb: 0.8%, Al: 0.1%, Mn: 0.1%, Ce: 0.2%, and the balance is Mg.

[0055] Alloy smelting, melt treatment process and its process parameters are as follows:

[0056] (1) Molten magnesium alloy

[0057] According to the composition ratio requirements, weigh the raw materials, in SF 6 +N 2 Under the protection of Mg, industrial pure magnesium is first melted, and the melting temperature is 720°C; high-purity Zn and high-purity Sb are added to the Mg melt, stirred for 5 minutes after melting, and kept for 10 minutes to obtain Mg-Zn-Sb alloy melt body.

[0058] (2) microalloying treatment

[0059] The prepared Mg-Zn-Sb alloy melt of step (1) is scraped ...

Embodiment 2

[0069] Example 2: Mg-4Zn-0.5Sb-0.3Al-0.1Mn-0.5Ce alloy

[0070] The types of alloying elements in this embodiment are the same as those in Embodiment 1, except that the addition amount of alloying elements is different. The alloy composition prepared in this example is Mg-4Zn-0.5Sb-0.3Al-0.1Mn-0.5Ce, using industrial pure Mg, high-purity Zn, high-purity Sb, high-purity Al, Mg-10Mn and Mg-20Ce The alloy is prepared, and the composition is by weight percentage: Zn: 4%, Sb: 0.5%, Al: 0.3%, Mn: 0.1%, Ce: 0.5%, and the balance is Mg.

[0071] The smelting and melt treatment process of the alloy in this example is the same as that in Example 1, except that the process parameters are different. The specific process and its process parameters are as follows:

[0072] (1) Molten magnesium alloy

[0073] According to the composition ratio requirements, weigh the raw materials, in SF 6 +N 2Under the protection of the protection, industrial pure magnesium is first melted, and the mel...

Embodiment 3

[0082] Example 3: Mg-5Zn-1.2Sb-0.2Al-0.3Mn-0.3Ce alloy

[0083] The types of alloying elements in this embodiment are the same as those in Embodiment 1, except that the addition amount of alloying elements is different. The alloy composition prepared in this example is Mg-5Zn-1.2Sb-0.2Al-0.3Mn-0.3Ce, using industrial pure Mg, high-purity Zn, high-purity Sb, high-purity Al, Mg-10Mn and Mg-20Ce The alloy is prepared, and the composition is by weight percentage: Zn: 5%, Sb: 1.2%, Al: 0.2%, Mn: 0.3%, Ce: 0.3%, and the balance is Mg.

[0084] The smelting and melt treatment process of the alloy in this example is the same as that in Example 1, except that the process parameters are different. The specific process and its process parameters are as follows:

[0085] (1) Molten magnesium alloy

[0086] According to the composition ratio requirements, weigh the raw materials, in SF 6 +N 2 Under the protection of the protection, industrial pure magnesium is first melted, and the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com