Three-dimensional particle electrode loaded with catalyst active carbon and preparation method thereof

A technology that supports catalysts and particle electrodes. It is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc. It can solve the problems of low catalyst activity, large catalyst particle size and high price, and achieve no secondary pollution. The effect of high catalytic activity, low catalyst loss and high pollutant removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

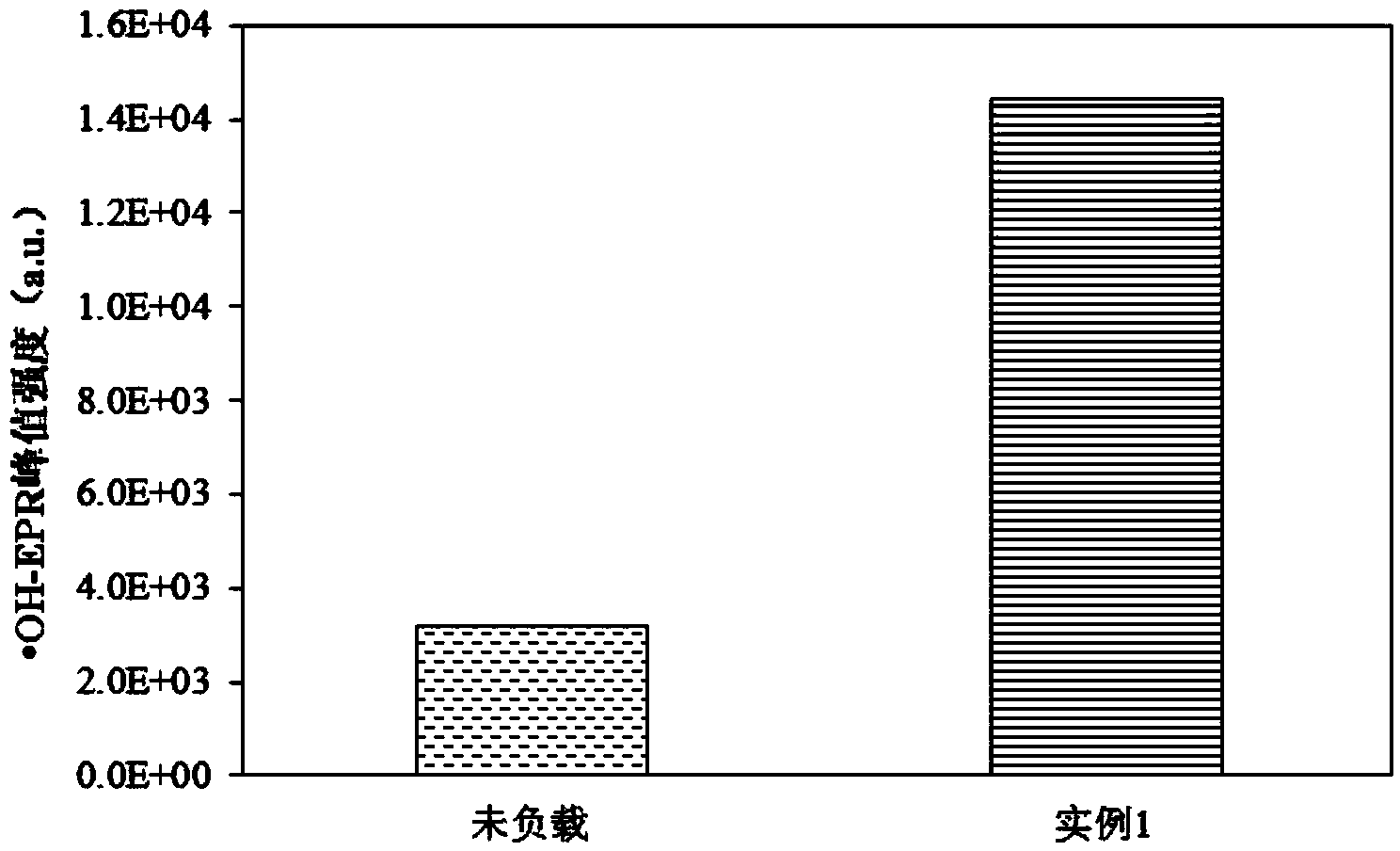

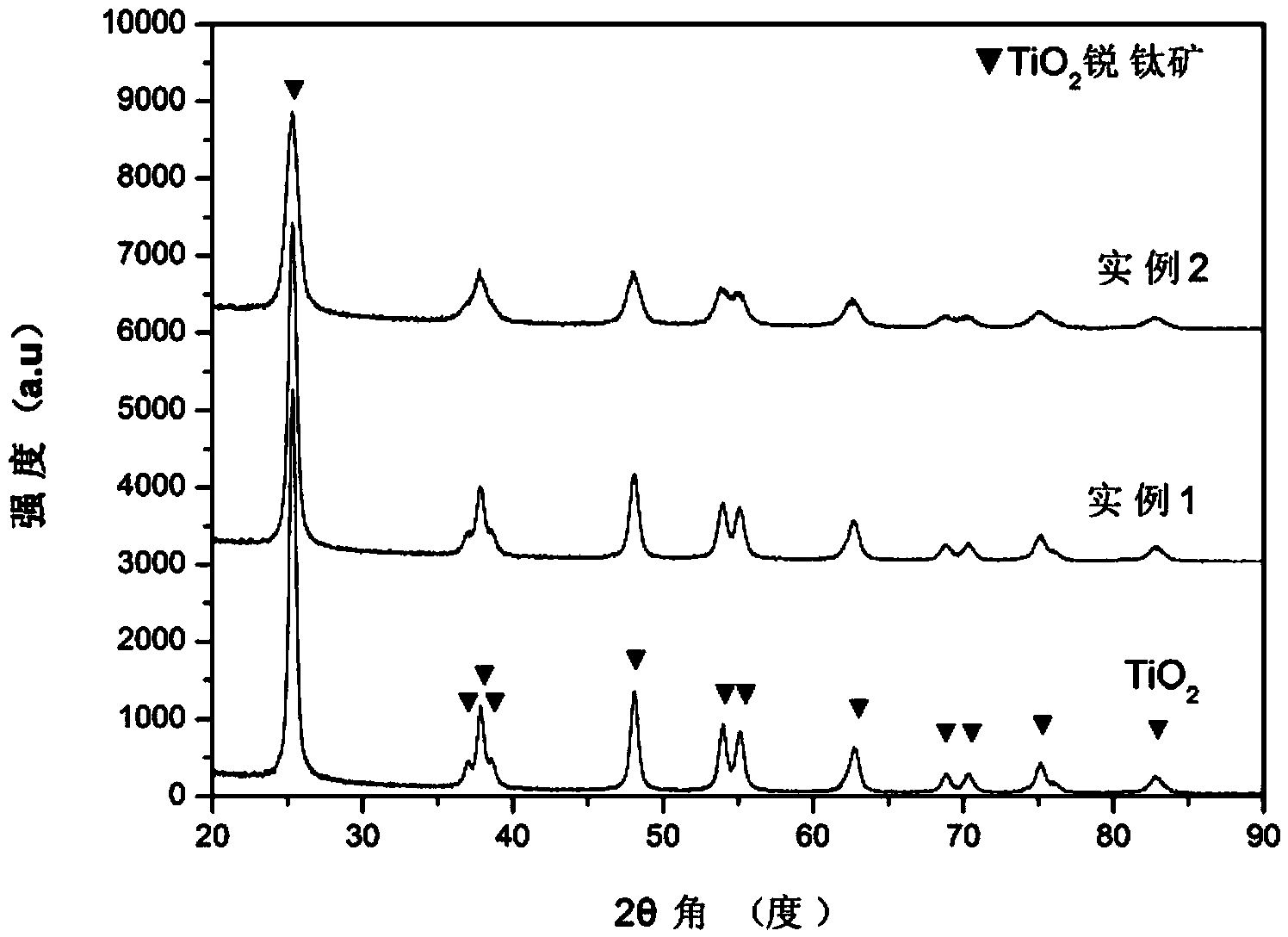

[0020] The supported three-dimensional particle electrode of this embodiment is made of granular activated carbon and TiO doped with Sn and Sb on the granular activated carbon. 2 Composite catalyst; the TiO doped with Sn and Sb 2 The molar ratio of Sn to Ti in the composite catalyst is 0.005:1; the molar ratio of Sn to Sb is 10:1. The preparation method includes the following steps:

[0021] 1) Pretreatment of granular activated carbon: soak the granular activated carbon in deionized water for cleaning, determine that the conductivity of the cleaning water is consistent with deionized water, filter out the excess water, dry it in an oven at 100°C and cool to room temperature for later use;

[0022] 2) Catalyst preparation: weigh 5.7×10 -2 mol tetrabutyl titanate, 2.85×10 -4 mol SnCl 4 ·5H 2 O, 2.85×10 -5 mol SbCl 3 Dissolve in 40mL of absolute ethanol and stir quickly for 30min to prepare solution A. Weigh 5 mL of deionized water, and dissolve 1.5 mL of acetic acid in 40 mL of abso...

Embodiment 2

[0027] The supported three-dimensional particle electrode of this embodiment is made of granular activated carbon and TiO doped with Sn and Sb on the granular activated carbon. 2 Composite catalyst; the TiO doped with Sn and Sb 2 The molar ratio of Sn to Ti in the composite catalyst is 0.03:1; the molar ratio of Sn to Sb is 20:1. The preparation method includes the following steps:

[0028] 1) Pretreatment of granular activated carbon: soak the granular activated carbon in deionized water for cleaning, determine that the conductivity of the cleaning water is consistent with that of deionized water, filter out the excess water, dry it in an oven at 200°C and cool it to room temperature for later use;

[0029] 2) Catalyst preparation: weigh 5.7×10 -2 mol tetrabutyl titanate, 1.71×10 -3 mol of SnCl 4 ·5H 2 O, 8.55×10 -5 mol of SbCl 3 Dissolve in 40 mL of absolute ethanol, stir quickly for 30 minutes to prepare solution A; weigh 5 mL of deionized water, and dissolve 1.5 mL of acetic aci...

Embodiment 3

[0034] The supported three-dimensional particle electrode of this embodiment is made of granular activated carbon and TiO doped with Sn and Sb on the granular activated carbon. 2 Composite catalyst; the TiO doped with Sn and Sb 2 The molar ratio of Sn to Ti in the composite catalyst is 0.01:1; the molar ratio of Sn to Sb is 10:1.

[0035] The preparation method includes the following steps:

[0036] 1) Pretreatment of granular activated carbon: soak the granular activated carbon in deionized water to clean, measure the conductivity of the cleaning water to be consistent with deionized water, filter out the excess water and put it in an oven at 150℃ to dry and cool to room temperature for later use;

[0037] 2) Catalyst preparation: weigh 5.7×10 -2 mol tetrabutyl titanate, 5.7×10 -4 mol SnCl 4 ·5H 2 O, 5.7×10 -5 mol SbCl 3 Dissolve in 40mL of absolute ethanol and stir quickly for 30min to prepare solution A. Weigh 5 mL of deionized water, and dissolve 1.5 mL of acetic acid in 40 mL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com