Preparation method of high-mechanical strength Ti-based double-interlayer anode

A mechanical strength, double interlayer technology, applied in chemical instruments and methods, water treatment of special compounds, water pollutants, etc., can solve the problems of powdery electrode surface, easy to crack, easy to foam, etc., to achieve stable mechanical properties , increase the mechanical strength, the effect of cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the present invention will be further described in conjunction with embodiment:

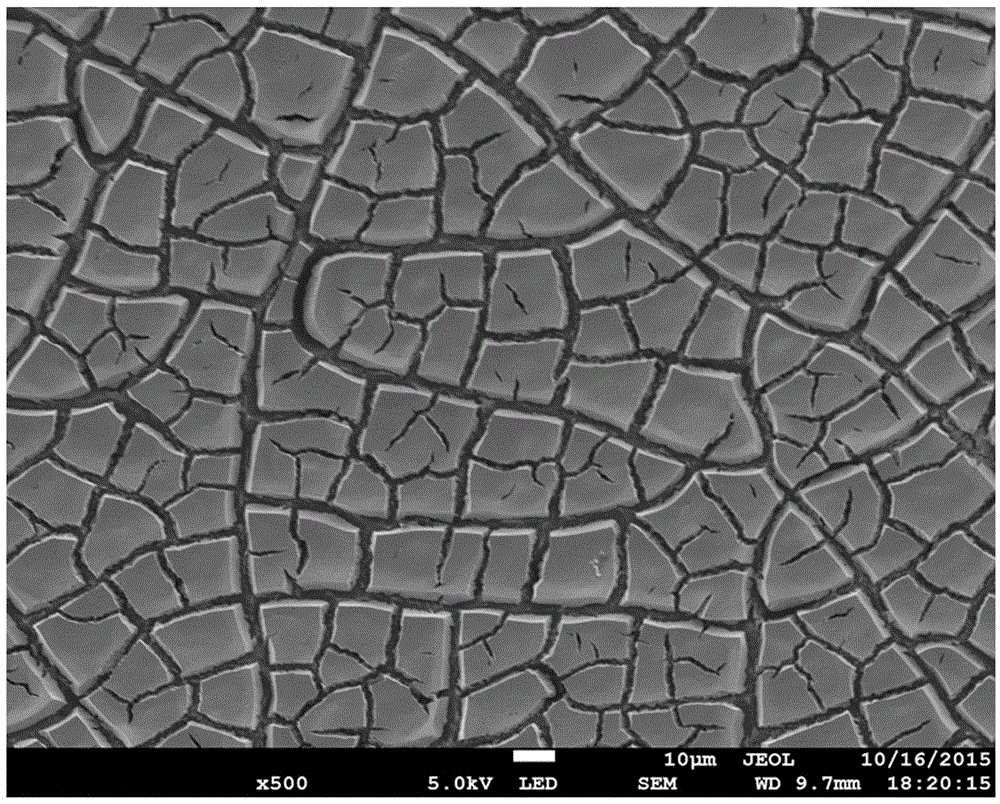

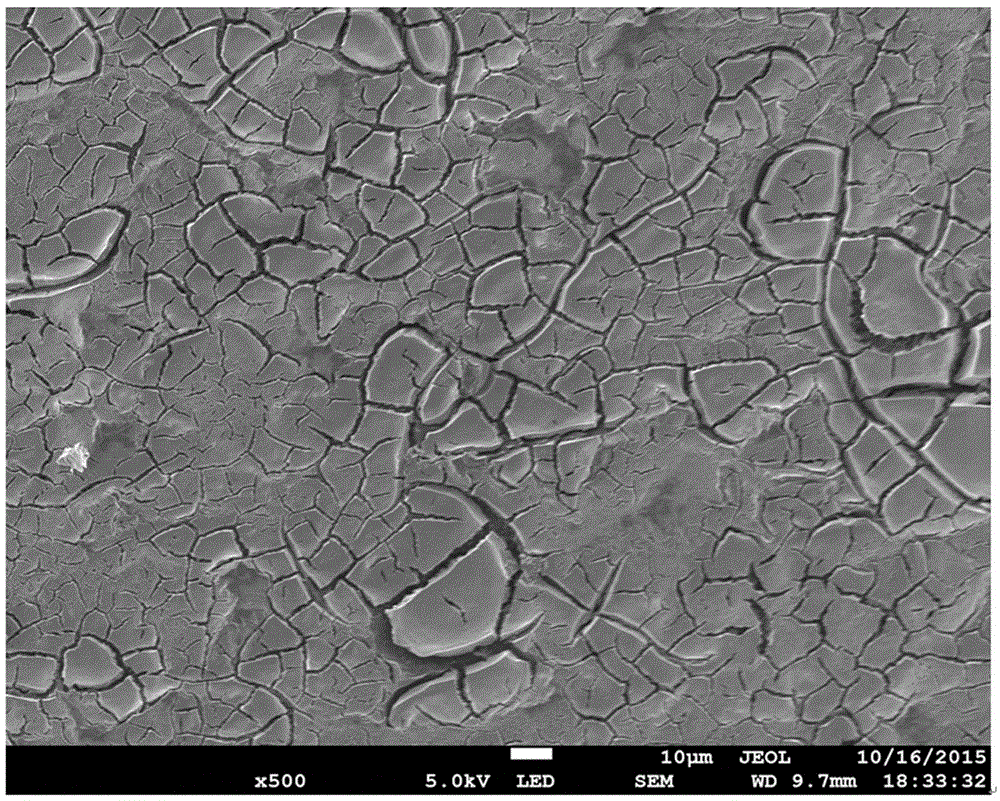

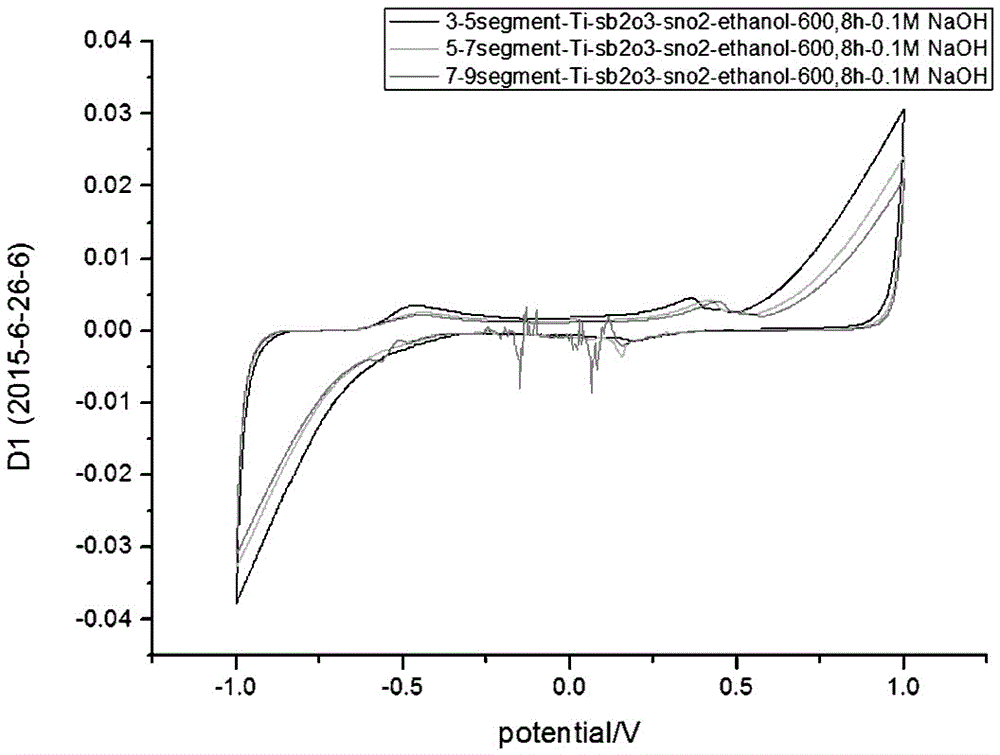

[0027] A method for preparing a Ti-based double-sandwich layer anode with high mechanical strength, using a pure Ti plate or a Ti alloy plate as a substrate, using a mixed alcohol solution, and doping Sb elements at the same time to obtain Ti-Sb 2 o 3 -SnO 2 Composite catalytic anode. After the anode is prepared, the yellow conductive layer TiO is slowly formed in the aqueous solution, and finally the double interlayer Ti-TiO / Sb 2 o 3 -SnO 2 anode. Due to the conductivity of TiO and the relationship with SnO 2 The binding force is higher than that of pure Ti, which further enhances the mechanical strength of the coated electrode.

[0028] The above one is based on a pure Ti plate or a Ti alloy plate, and Sb is doped with SnO 2 The preparation method and process of the electrode comprises the following steps:

[0029] Step (1), cut the commercially available pure titanium pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com