A method for preparing carbon nanotube-modified palladium-loaded electrodes by electrophoresis-chemical deposition

A carbon nanotube, chemical deposition technology, applied in electrochemical water/sewage treatment, electrophoretic plating, electrolytic coatings, etc., can solve problems such as difficult to achieve results, improve efficiency, enhance stability and activity, and improve specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Put CNTs in mixed acid Ultrasonic at medium temperature for 4 hours, reflux at 60°C for 2 hours, filter and wash until neutral, dry and set aside;

[0029] (2) Dip the titanium (Ti) mesh in 40% NaOH solution at 80°C for 2 hours to remove surface oil stains, wash it with distilled water until neutral, then immerse it in 15% oxalic acid solution to remove surface oxides, at 98°C Keep it for 2 hours, rinse it with distilled water, and dry it with nitrogen for later use;

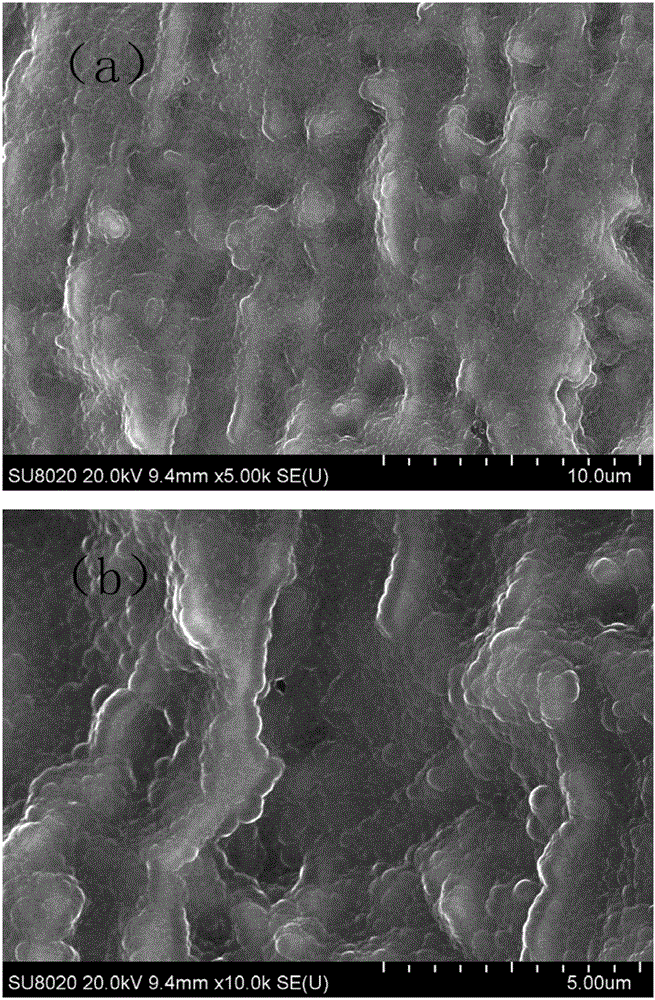

[0030] (3) prepare the Py solution of 0.04mmol / L, wherein the concentration of SLS is 1mmol / L, H 2 SO 4 The concentration is 0.05mol / L. The Ti mesh processed in step (2) is used as the anode, the Pt sheet is used as the cathode, the Py solution is used as the plating solution, the current is adjusted to 3mA, and the time is 5min, and the electrochemical method deposits a PPy film on the surface of the Ti mesh to obtain a PPy / Ti electrode;

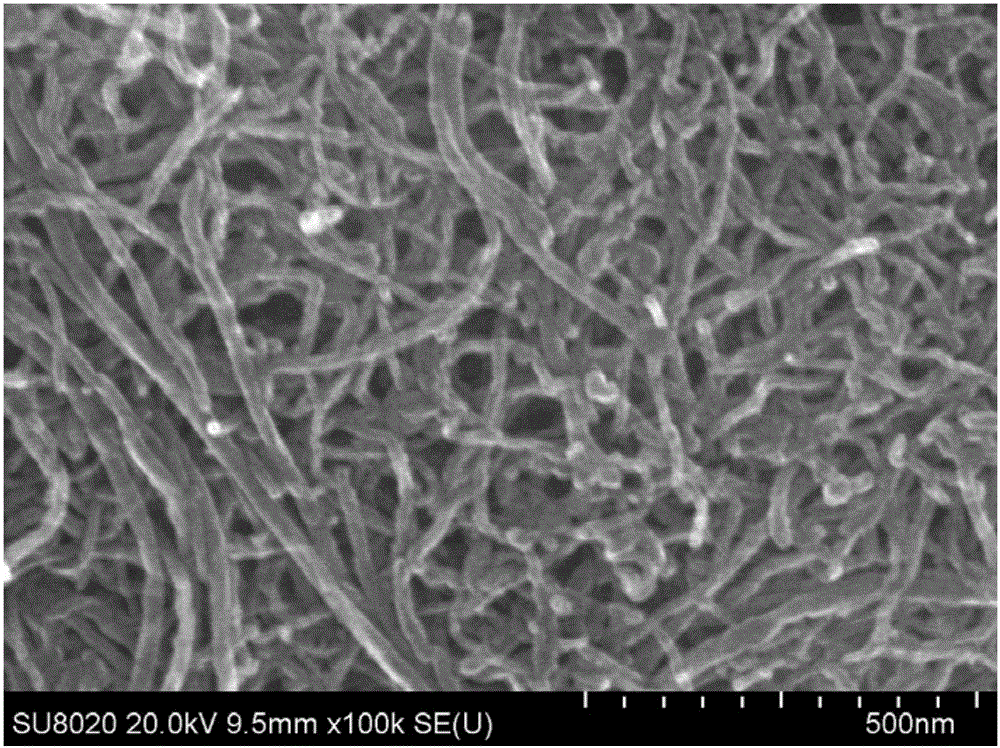

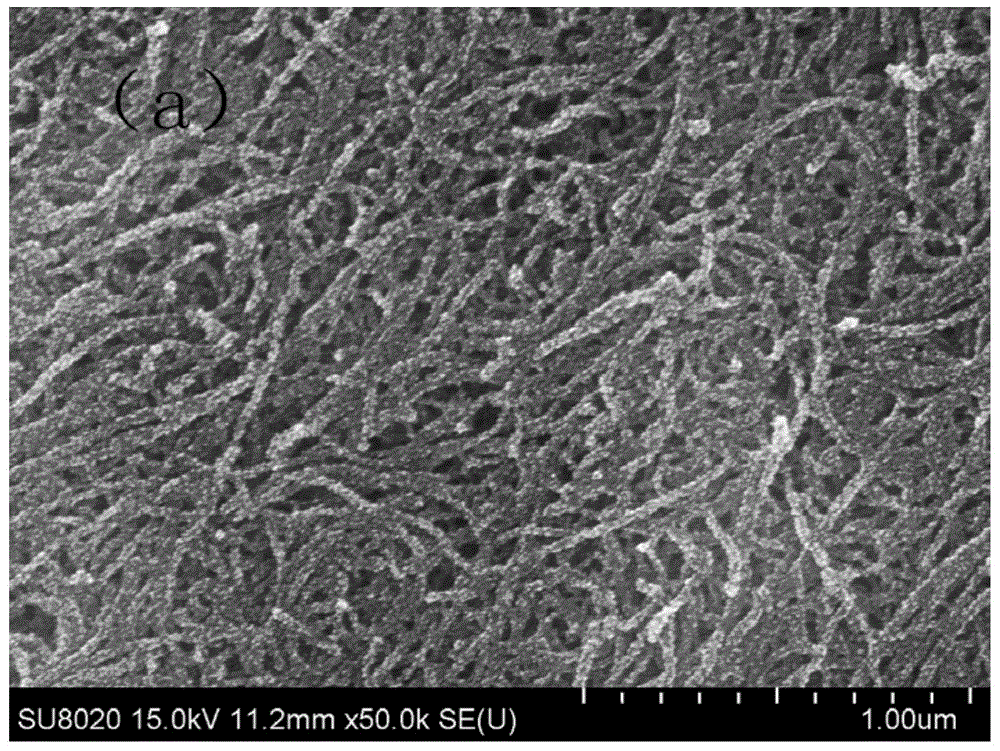

[0031] (4) Prepare a 0.5 mg / mL CNTs dispersion with the ...

Embodiment 2

[0036] (1) Put CNTs in mixed acid Ultrasonic at medium temperature for 4 hours, reflux at 60°C for 2 hours, filter and wash until neutral, dry and set aside;

[0037](2) Dip the titanium (Ti) mesh in 40% NaOH solution at 80°C for 2 hours to remove surface oil stains, wash it with distilled water until neutral, then immerse it in 15% oxalic acid solution to remove surface oxides, at 98°C Keep it for 2 hours, rinse it with distilled water, and dry it with nitrogen for later use;

[0038] (3) prepare the Py solution of 0.04mmol / L, wherein the concentration of SLS is 1mmol / L, H 2 SO 4 The concentration is 0.05mol / L. The Ti mesh processed in step (2) is used as the anode, the Pt sheet is used as the cathode, the Py solution is used as the plating solution, the current is adjusted to 3mA, and the time is 5min, and the electrochemical method deposits a PPy film on the surface of the Ti mesh to obtain a PPy / Ti electrode;

[0039] (4) Prepare a 0.5 mg / mL CNTs dispersion with the C...

Embodiment 3

[0044] (1) Put CNTs in mixed acid Ultrasonic at medium temperature for 4 hours, reflux at 60°C for 2 hours, filter and wash until neutral, dry and set aside;

[0045] (2) Dip the titanium (Ti) mesh in 40% NaOH solution at 80°C for 2 hours to remove surface oil stains, wash it with distilled water until neutral, then immerse it in 15% oxalic acid solution to remove surface oxides, at 98°C Keep it for 2 hours, rinse it with distilled water, and dry it with nitrogen for later use;

[0046] (3) prepare the Py solution of 0.04mmol / L, wherein the concentration of SLS is 1mmol / L, H 2 SO 4 The concentration is 0.05mol / L. The Ti mesh processed in step (2) is used as the anode, the Pt sheet is used as the cathode, the Py solution is used as the plating solution, the current is adjusted to 3mA, and the time is 5min, and the electrochemical method deposits a PPy film on the surface of the Ti mesh to obtain a PPy / Ti electrode;

[0047] (4) Prepare a 0.5 mg / mL CNTs dispersion with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com