Scandium doped stannic oxide micropore anode, preparation method and application thereof

A tin dioxide and electrode technology, applied in chemical instruments and methods, electrode shape/type, sterilization/microdynamic water/sewage treatment, etc., can solve the difficulty of Ti/BDD electrode preparation, doping has not been reported, water body Secondary pollution and other problems, to achieve the effect of good industrial application prospects, high catalytic activity, and high mineralization rate of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

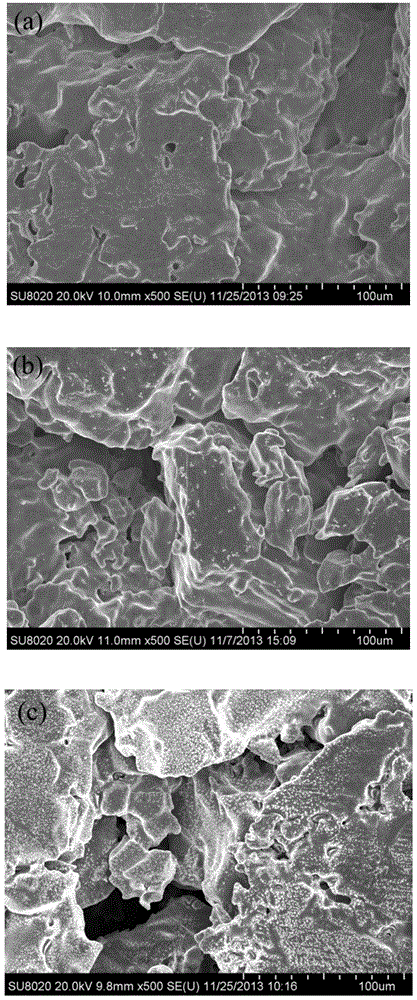

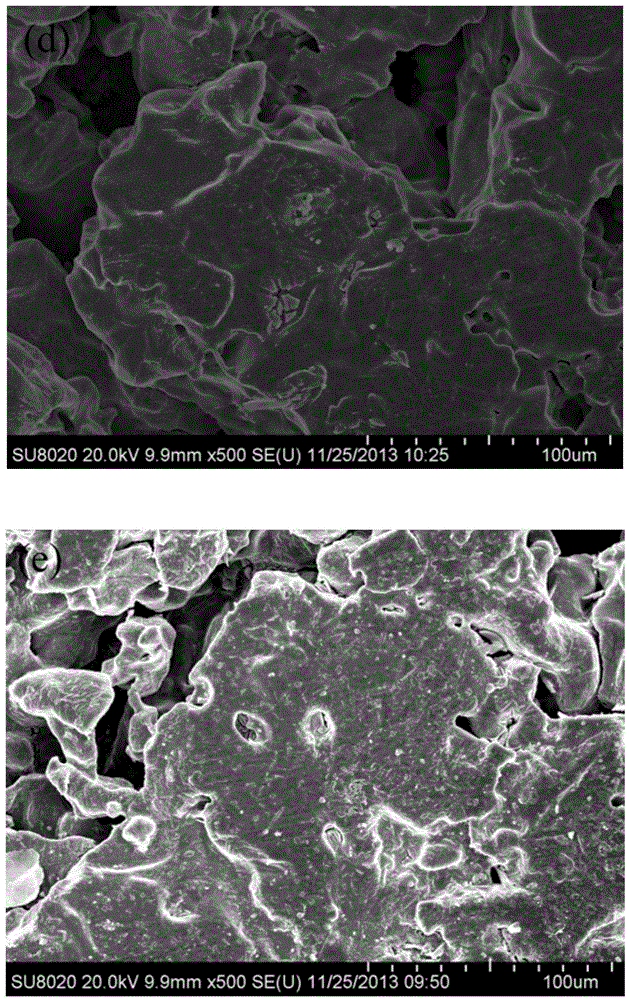

Examples

Embodiment 1

[0028] 1. Preparation of electroplating solution: SbCl 3 The powder is dissolved in concentrated HCl, and a certain amount of SnCl is added 4 ·5H 2 O, fully dissolved with absolute ethanol, the volume ratio of absolute ethanol to concentrated HCl is 50:1, SnCl in the final solution 4 The concentration is 0.45~0.50mol / L, the molar ratio of Sn:Sb is 100:10, and it is stored for a period of time for later use.

[0029] 2. Preparation of impregnation solution: Scandium oxide (Sc 2 o 3 ) powder is dissolved in an appropriate amount of concentrated HCl, boiled in an electric furnace until the powder is dissolved, and SbCl is added 3 Crystals, stir well until dissolved, add SnCl 4 ·5H 2 O crystals, add a certain amount of n-butanol to dissolve, and under the assistance of ultrasound, heat to form a uniform and stable solution. The volume ratio of n-butanol to concentrated HCl is 20:1, and the SnCl in the final solution 4 The concentration is 0.80-0.85 mol / L, the molar ratio of...

Embodiment 2

[0037] Embodiment 2: (Sn:Sc molar ratio is 100:1, other conditions are the same as embodiment 1)

[0038] 1. Preparation of electroplating solution: SbCl 3 The powder is dissolved in concentrated HCl, and a certain amount of SnCl is added 4 ·5H 2 O, fully dissolved with absolute ethanol, the volume ratio of absolute ethanol to concentrated HCl is 50:1, SnCl in the final solution 4 The concentration is 0.45-0.50mol / L, the molar ratio of Sn:Sb is 100:10, and it is stored for a period of time for later use.

[0039] 2. Preparation of impregnation solution: Scandium oxide (Sc 2 o 3 ) powder is dissolved in an appropriate amount of concentrated HCl, boiled in an electric furnace until the powder is dissolved, and SbCl is added 3 Crystals, stir well until dissolved, add SnCl 4 ·5H 2 O crystals, add a certain amount of n-butanol to dissolve, and under the assistance of ultrasound, heat to form a uniform and stable solution. The volume ratio of n-butanol to concentrated HCl is ...

Embodiment 3

[0046] Embodiment 3: (Sn:Sc molar ratio is 400:1, other conditions are the same as embodiment 1)

[0047] 1. Preparation of electroplating solution: SbCl 3 The powder is dissolved in concentrated HCl, and a certain amount of SnCl is added 4 ·5H 2 O, fully dissolved with absolute ethanol, the volume ratio of absolute ethanol to concentrated HCl is 50:1, SnCl in the final solution 4 The concentration is 0.45~0.50mol / L, the molar ratio of Sn:Sb is 100:10, and it is stored for a period of time for later use.

[0048] 2. Preparation of impregnation solution: Scandium oxide (Sc 2 o 3 ) powder is dissolved in an appropriate amount of concentrated HCl, boiled in an electric furnace until the powder is dissolved, and SbCl is added 3 Crystals, stir well until dissolved, add SnCl 4 ·5H 2 O crystals were dissolved by adding a certain amount of n-butanol, and heated to form a uniform and stable solution with the assistance of ultrasound. The volume ratio of n-butanol to concentrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com