Thin-gauge non-oriented silicon steel 35BW440 and production method thereof

A technology of oriented silicon steel and production method, which is applied in the field of alloy smelting, can solve problems such as normalization annealing, and achieve the effect of improving surface quality and improving electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a thin non-oriented silicon steel 35BW440, the non-oriented silicon steel 35BW440 includes the following elements by mass percentage:

[0036] C: ≤0.003%, Si: 0.8%-2.0%, Mn: 0.4%-1.2%, P: ≤0.015%, S: ≤0.003%, Als: 0.25%-0.6%, N: ≤0.003%, Sb: 0.04%-0.1%, O: ≤0.0025%, the rest is Fe and unavoidable impurities.

[0037] On the premise that there is no electromagnetic stirring equipment to increase the magnetic induction intensity of non-oriented silicon steel, by adding Sb elements, the {110} and {100} texture components that are beneficial to electromagnetic properties are added to improve electromagnetic properties. Specifically, Sb elements are in the grain boundary Nearby segregation improves the formation of {100} and {110} texture components that are beneficial to electromagnetic properties, improves the magnetic induction of non-oriented silicon steel, and reduces the iron loss value.

[0038] Furthermore, by adding Sb element, the electrom...

Embodiment 2

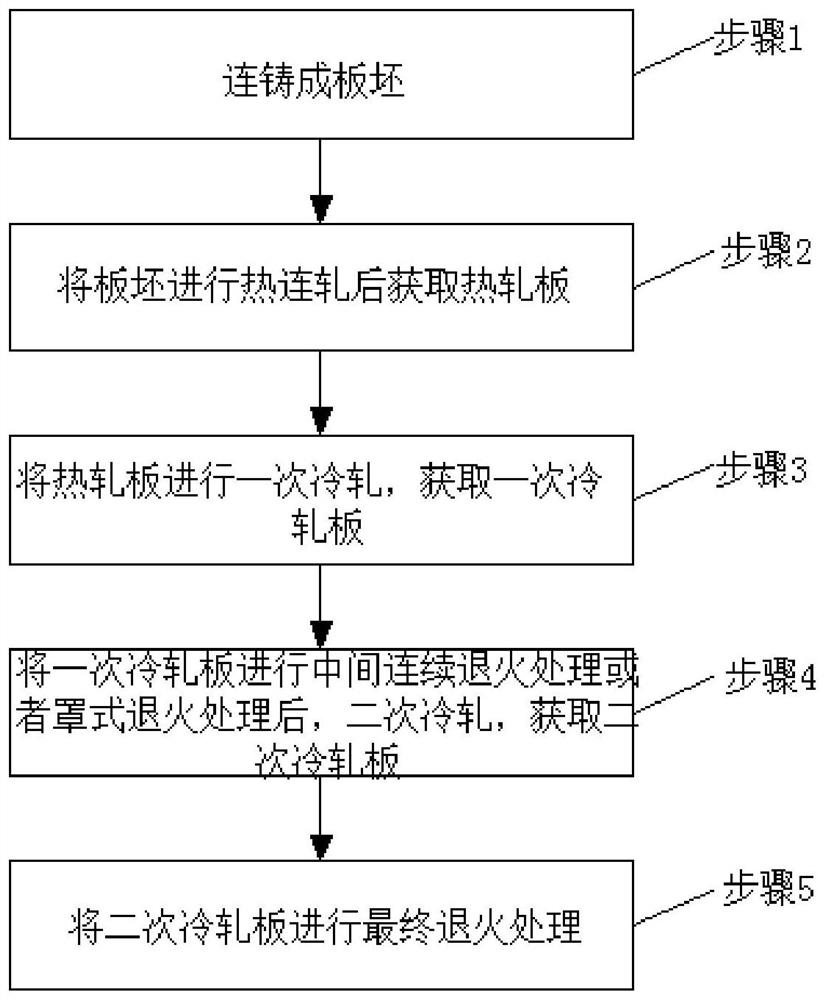

[0043] figure 1 A schematic flow chart showing a method for producing thin-gauge non-oriented silicon steel 35BW440 according to an embodiment of the present invention is shown.

[0044] like figure 1 As shown, the present embodiment provides a production method of thin-gauge non-oriented silicon steel 35BW440, the production method comprising the following steps:

[0045] Step 1, continuous casting into a slab;

[0046] Step 2, hot-rolling the slab to obtain a hot-rolled plate;

[0047] Step 3, performing a cold rolling on the hot-rolled plate to obtain a cold-rolled plate;

[0048] Step 4, performing intermediate continuous annealing or bell annealing on the primary cold-rolled sheet, and performing secondary cold-rolling to obtain a secondary cold-rolled sheet;

[0049] In step 5, the secondary cold-rolled sheet is subjected to final annealing treatment.

[0050] It should be noted that after obtaining the hot-rolled sheet, it is necessary to perform normalization trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iron loss | aaaaa | aaaaa |

| Magnetic sense | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com