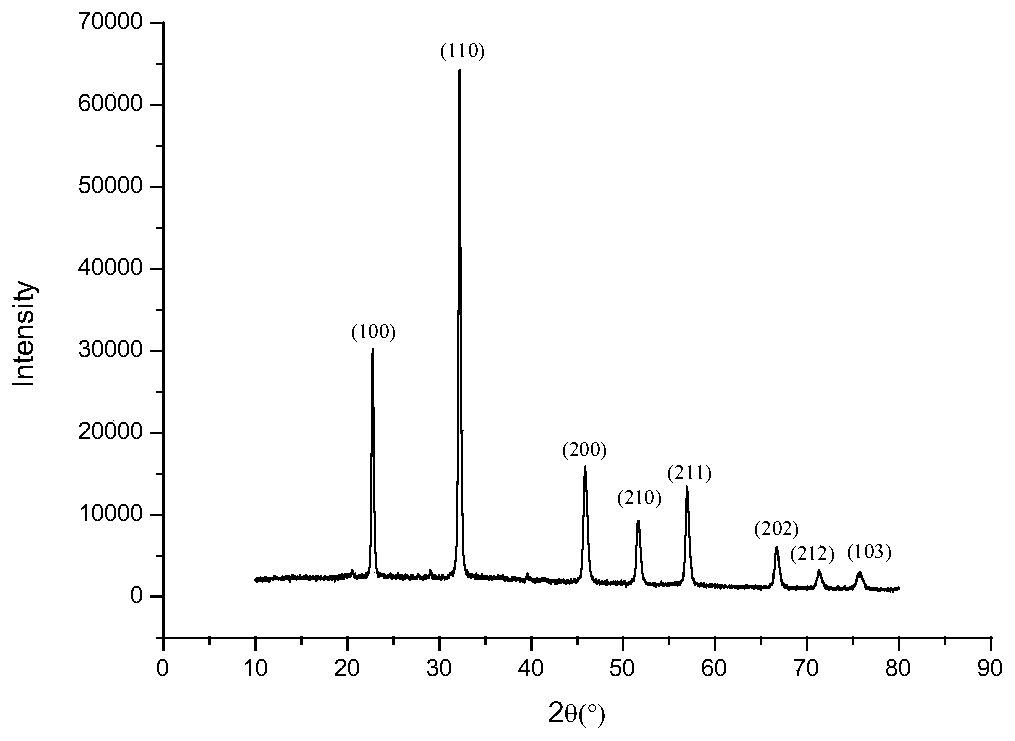

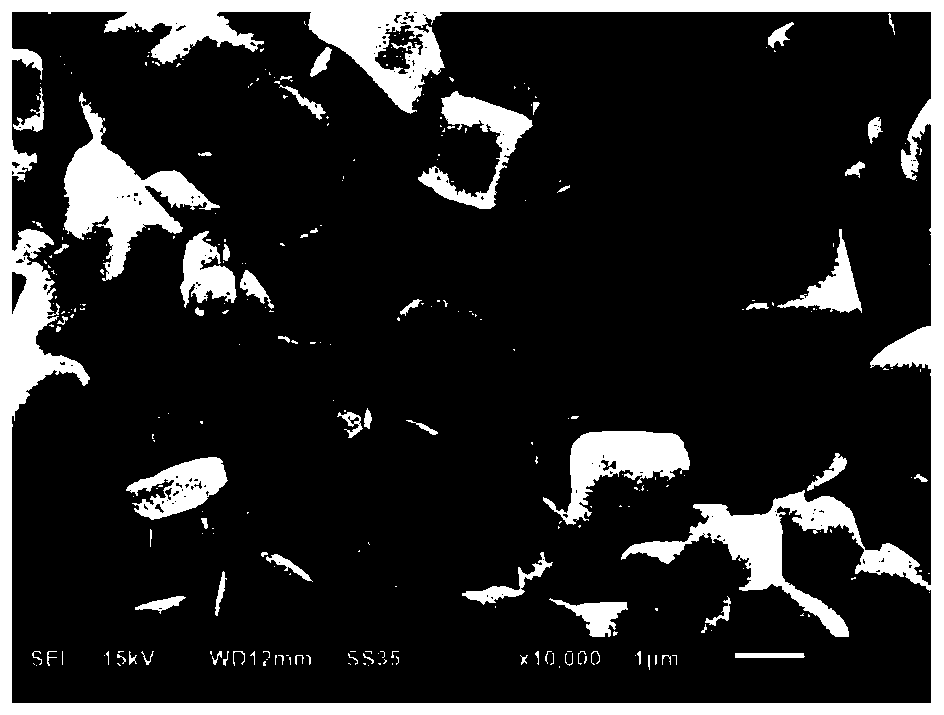

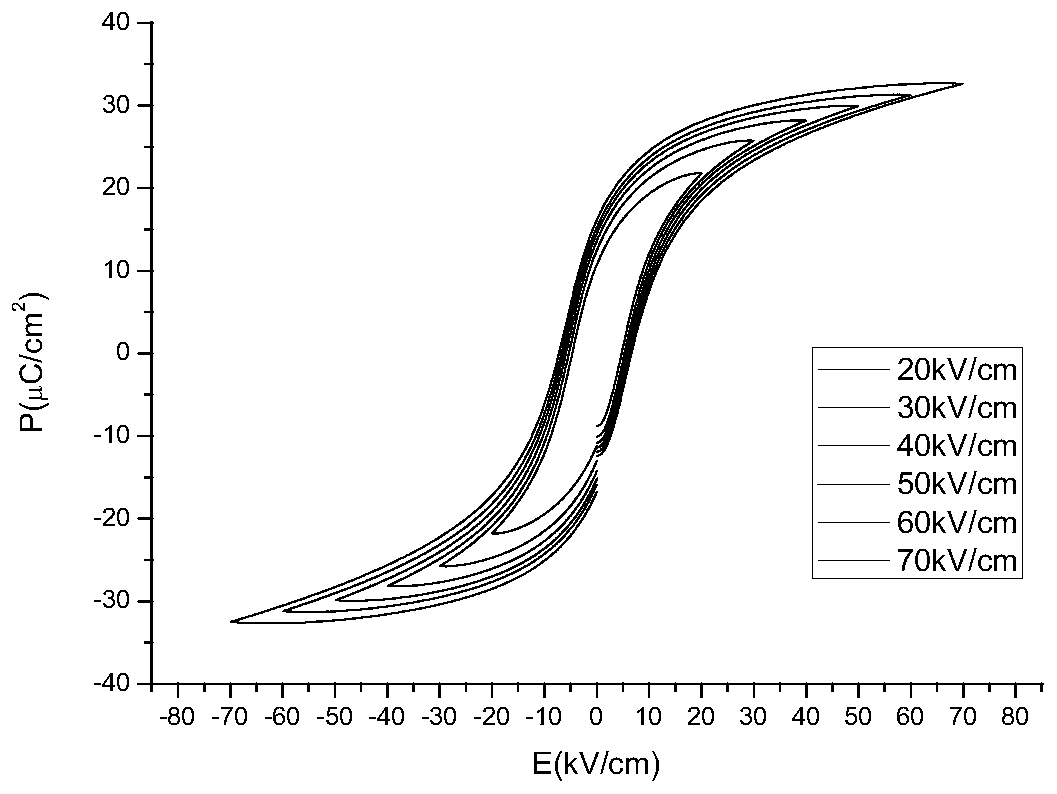

Potassium sodium niobate-based piezoelectric ceramic, and preparation method and application thereof

A potassium-sodium niobate-based, piezoelectric ceramic technology, applied in the field of piezoelectric ceramics, can solve the problems of difficulty in obtaining dense sintered bodies, poor stability of the preparation process, and sensitivity to sintering temperature, etc., and achieve improved electric field-induced strain performance, good Densification and stability improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of potassium sodium niobate-based piezoelectric ceramics described in the above technical solution, comprising the following steps:

[0029] After niobium pentoxide, potassium carbonate, sodium carbonate, antimony trioxide and manganese dioxide are sequentially mixed, calcined, granulated, pressed, debinding, sintered and silver fired, the potassium sodium niobate base pressure is obtained. electric ceramics.

[0030] In the present invention, the consumption of described niobium pentoxide, salt of wormwood, sodium carbonate and antimony trioxide is preferably according to the described K of above-mentioned technical scheme 0.48 Na 0.52 Sb 0.10 Nb 0.90 -xMnO 2 Calculated by the stoichiometric ratio, the MnO 2 The mass of niobium pentoxide, potassium carbonate, sodium carbonate and antimony trioxide is preferably 0.2% to 0.8%, more preferably 0.2% to 0.4%, and more preferably 0.2%. In the present invention, u...

Embodiment 1

[0045] 1) According to K 0.48 Na 0.52 Sb 0.10 Nb 0.90 -0.2MnO 2 The stoichiometric measurement of 24.0431g niobium pentoxide, 6.7011g potassium carbonate, 5.5225g sodium carbonate and 2.9446g antimony trioxide, 0.0784g manganese dioxide, the quality of manganese dioxide accounts for niobium pentoxide, potassium carbonate, 0.2% of the sum of the mass of sodium carbonate and antimony trioxide;

[0046] 2) Dry the above-mentioned raw materials in an oven at 120°C for 5 hours, then add them to a ball mill tank in turn, use absolute ethanol as the medium, and use a mixture of zirconia balls with a particle size of 10mm, 5mm, and 3mm as the ball milling medium. The particle size is divided into 10mm, 5mm and 3mm zirconia balls with a ratio of 5:3:2, and the mass ratio of the mixed material, the mixture of zirconia balls and absolute ethanol is 1:2:2 in the ball mill tank After mixing in the medium, put it into a planetary ball mill, and mix for 12 hours at a speed of 250r / min; ...

Embodiment 2

[0067] 1) according to K 0.48 Na 0.52 Sb 0.10 Nb 0.90 -0.8MnO 2 The stoichiometric measure weighs respectively 24.0431g niobium pentoxide, 6.7011g potassium carbonate, 5.5225g sodium carbonate and 2.9446g antimony trioxide, 0.3137g manganese dioxide, and the quality of manganese dioxide accounts for niobium pentoxide, potassium carbonate, 0.8% of the sum of the mass of sodium carbonate and antimony trioxide;

[0068] 2) Dry the above-mentioned raw materials in an oven at 120°C for 5 hours, then add them to a ball mill tank in turn, use absolute ethanol as the medium, and use a mixture of zirconia balls with a particle size of 10mm, 5mm, and 3mm as the ball milling medium. The particle size is divided into 10mm, 5mm and 3mm zirconia balls with a ratio of 5:3:2, and the mass ratio of the mixed material, the mixture of zirconia balls and absolute ethanol is 1:2:2 in the ball mill tank After mixing in the medium, put it into a planetary ball mill, and mix for 12 hours at a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com