Oxygen-doped Sb nanometer phase change thin-film materials and preparation method thereof and application thereof

A thin film material, nanophase technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of long phase transition time, inability to meet the design requirements of high-speed PCRAM, and low thermal stability of materials. problems, to achieve the effect of improving stability, increasing storage speed, and reducing operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

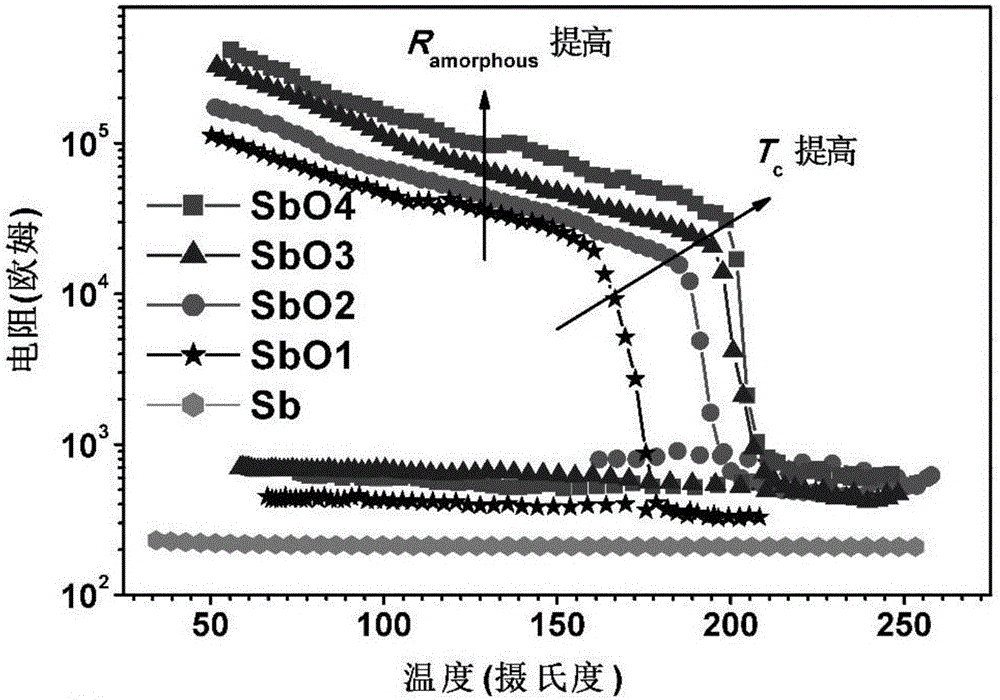

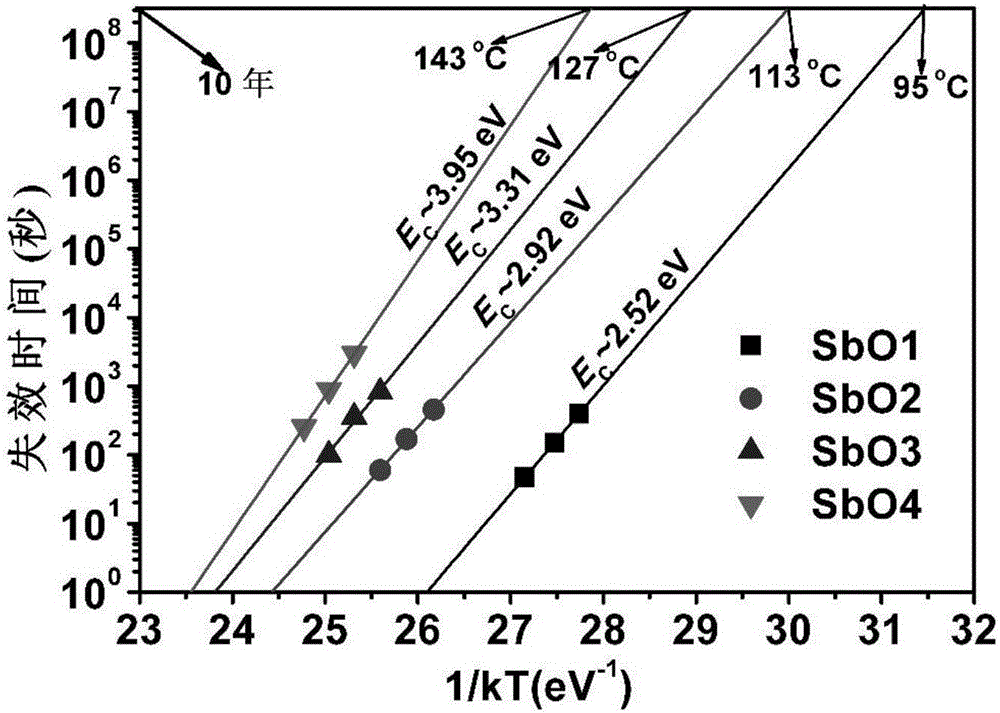

[0033] The structure of the oxygen-doped Sb nano phase change thin film material prepared in this embodiment is specifically represented as SbO1.

[0034] The preparation steps are:

[0035] 1. Clean the SiO2 / Si(100) substrate, clean the surface and back, remove dust particles, organic and inorganic impurities;

[0036] a) strong ultrasonic cleaning in acetone solution for 3-5 minutes, and rinse with deionized water;

[0037] b) Strong ultrasonic cleaning in ethanol solution for 3-5 minutes, rinse with deionized water, and dry the surface and back with high-purity N2;

[0038] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0039] 2. Preparation of SbO by RF sputtering method 1 Film preparation:

[0040] a) The Sb sputtering target is installed, the purity of the target reaches 99.999% (atomic percentage), and the background vacuum is evacuated to 1×10 -4 Pa;

[0041] b) Set the sputtering power to 30W;

[0042] c) Using high-purity Ar and high-purity O...

Embodiment 2

[0048] Prepare the SbOx nano phase change thin film material of the present embodiment, its specific structure is respectively SbO 2 and SbO 3 and SbO 4 , and the SbO 2 and SbO 3 and SbO 4 The thickness of the nano phase change thin film material is 50nm.

[0049] The above SbO 2 and SbO 3 and SbO 4 The preparation method of nanometer phase-change film material is identical with example 1, just prepares SbO 2 The Ar gas flow rate set by the nano phase change thin film material is 28sccm, O 2 The flow rate is 2 sccm; the preparation of SbO 3 The Ar gas flow rate set by the nano phase change thin film material is 27sccm, O 2 The flow rate is 3 sccm; the preparation of SbO 4 The Ar gas flow set by the nano phase change thin film material is 26sccm, O 2 The flow rate is 4 sccm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com