Method for preparing TiC/CuW alloy contact material

A contact material and alloy technology, applied in the direction of contacts, electrical components, electrical switches, etc., can solve the problem of high temperature strength drop of tungsten, and achieve the effect of improving arc ablation resistance, high electrical conductivity, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example

[0027] According to the above preparation method, the relevant process parameters in the following Table 1 are selected to prepare the TiC-containing CuW alloy. The proportioning content of the twelve examples is shown in Table 1, and the process parameters of the twelve examples are shown in Table 1. 2 shown.

[0028] Table 1 The proportion content and process parameter table of the twelve examples

[0029] Example

[0030] Table 2 Process control parameter table of twelve embodiments

[0031]

[0032] Example 3

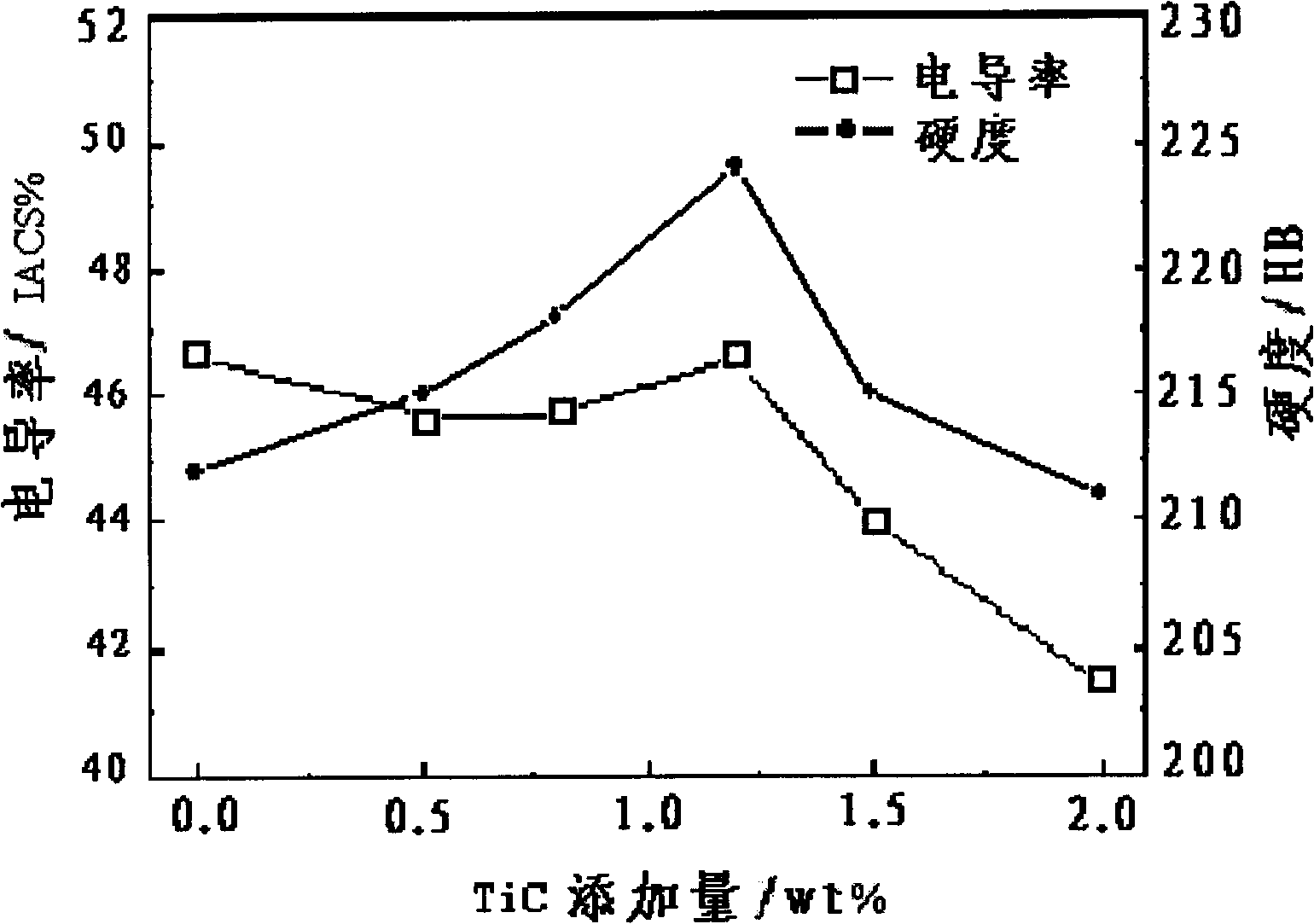

[0033] The TiC-containing CuW alloy materials prepared in the above twelve embodiments were subjected to a vacuum electrical breakdown experiment in a TDR-40A single crystal furnace. The surface of the TiC-CuW material was polished to a mirror surface and then loaded into the vacuum chamber as a cathode. Use diameter as The needle-shaped pure W rod of 3 was used as the anode, a DC voltage of 8kV was applied between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com