Nano-modified polytetrafluoroethylene composite material, arc-quenching nozzle and preparation method thereof, and high voltage circuit breaker

A polytetrafluoroethylene, nano-modified technology, applied in the field of high-voltage circuit breakers, can solve the problems of insufficient arc ablation resistance, poor spout toughness and crack resistance, etc., to reduce ablation, improve thermal conductivity, The effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The nano-modified polytetrafluoroethylene composite material in this embodiment is composed of the following components in weight percentage: 1% of nano boron nitride, 10% of micro boron nitride, and the balance is polytetrafluoroethylene.

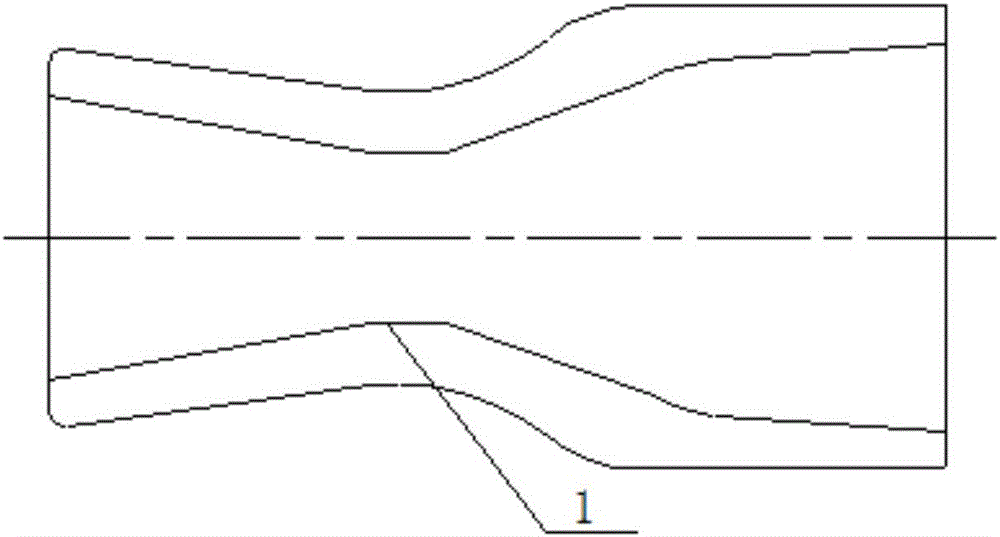

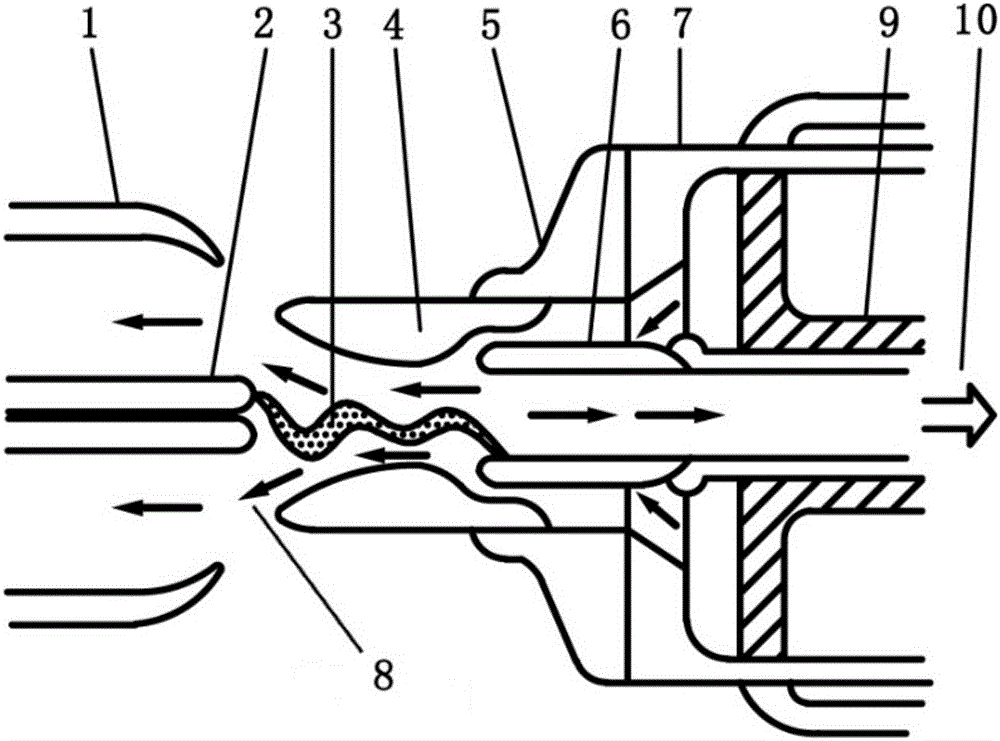

[0026] The arc extinguishing nozzle of this embodiment adopts the above-mentioned nano-modified polytetrafluoroethylene composite material, and its structure is as follows figure 1 As shown, 1 is the throat of the nozzle, the breaking process of the high-voltage circuit breaker is completed inside the nozzle, and the throat of the nozzle is ablated.

[0027] The preparation method of the arc extinguishing nozzle of the present embodiment comprises the following steps:

[0028] 1) Take the polytetrafluoroethylene resin powder, disperse it, and grind it finely. According to the formula, polytetrafluoroethylene resin powder with a particle size of 45 μm, nano-boron nitride powder with a particle size of 200 nm, and micron boron nitride...

Embodiment 2-7

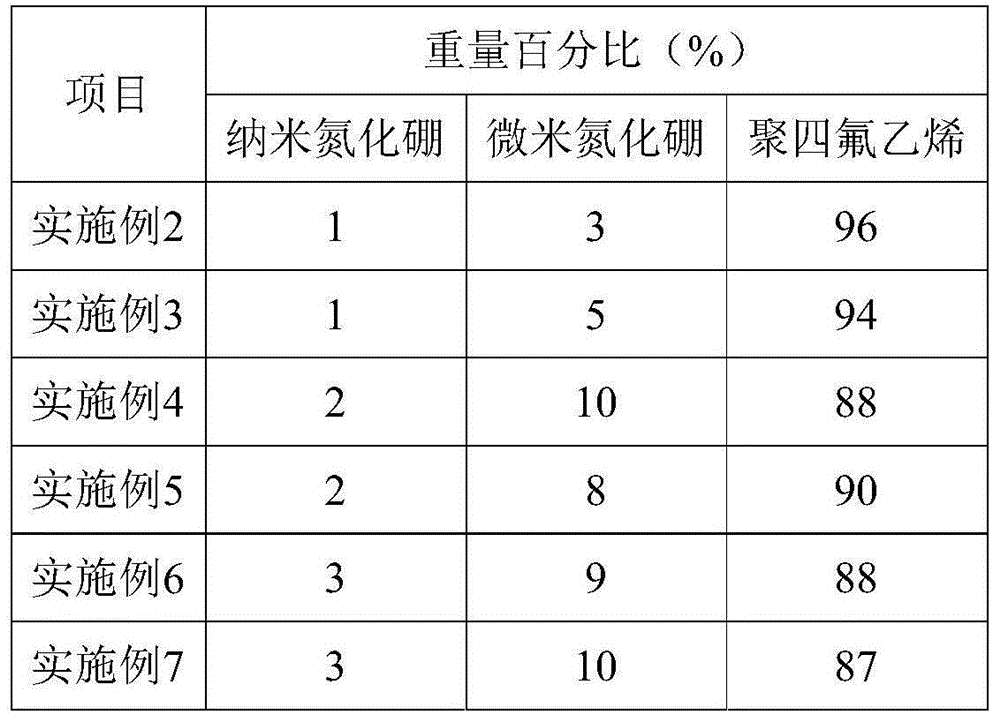

[0033] The weight percent of each component of the nano-modified polytetrafluoroethylene composite material in Examples 2-7 is shown in Table 1.

[0034] Table 1 embodiment 2-7 the weight percent of each component of nano-modified polytetrafluoroethylene composite material

[0035]

[0036] The structure of the arc extinguishing nozzle using the nano-modified polytetrafluoroethylene composite material of Examples 2-7 is the same as that of Example 1.

[0037] The arc extinguishing nozzles of Examples 2-7 were prepared by mixing, molding and sintering using the distribution ratios of the components shown in Table 1. See Table 2 for the particle size of raw materials and the test conditions for mixing, molding and sintering.

Embodiment 2~7

[0038] Table 2 The preparation process conditions of the arc extinguishing spout of embodiment 2~7

[0039]

[0040] The structure of the high-voltage circuit breaker using the arc extinguishing nozzles described in Embodiments 2 to 7 is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com