Teflon composite material, arc extinguishing nozzle, preparation method of arc extinguishing nozzle and high-voltage circuit breaker

A polytetrafluoroethylene and composite material technology, applied in the field of high-voltage circuit breakers, can solve the problems of low thermal conductivity and poor arc ablation resistance, achieve high decomposition temperature, excellent mechanical properties and high temperature resistance, and improve resistance to The effect of arc ablative properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The polytetrafluoroethylene composite material of this embodiment is composed of the following components in weight percentage: 7% cobalt aluminate, 1% boron nitride, and the balance is polytetrafluoroethylene resin.

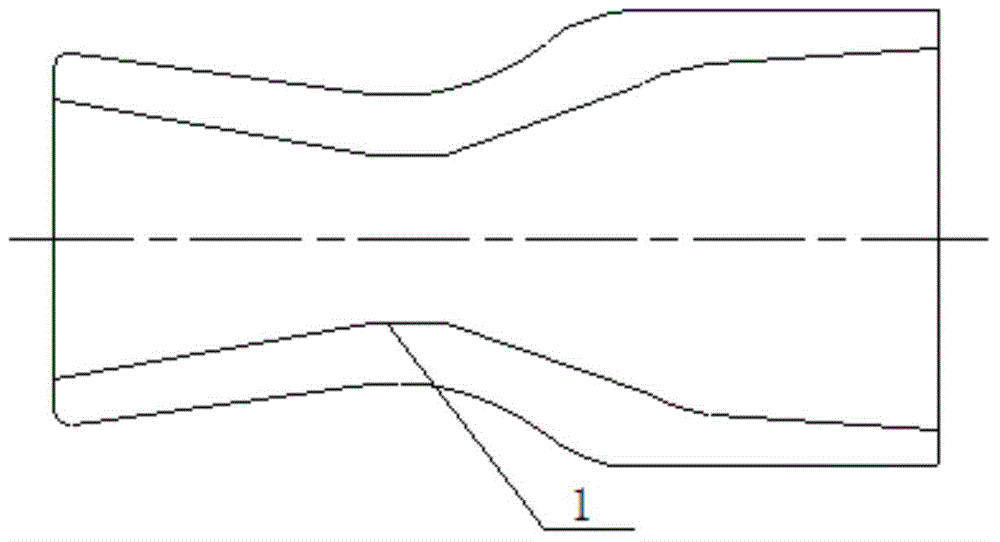

[0025] The arc extinguishing nozzle of this embodiment adopts the above-mentioned polytetrafluoroethylene composite material. The structure of the arc extinguishing nozzle is as follows figure 1 As shown, 1 is the throat of the nozzle, the breaking process of the high-voltage circuit breaker is completed inside the nozzle, and the throat 1 of the nozzle is ablated.

[0026] The preparation method of the arc extinguishing nozzle of the present embodiment comprises the following steps:

[0027] 1) Take polytetrafluoroethylene resin powder, disperse and grind it, and mix polytetrafluoroethylene resin powder with a particle size of 45 μm, cobalt aluminate powder with a particle size of 1 μm, and nitriding powder with a particle size of 5 μm according to the ...

Embodiment 2-12

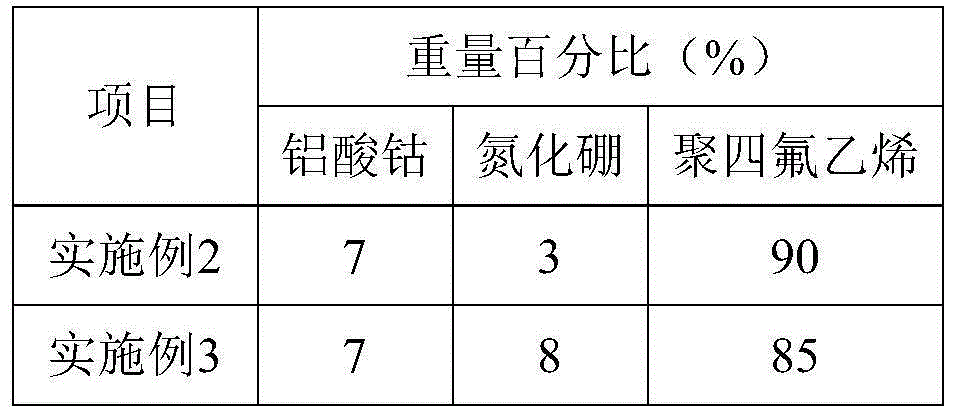

[0032] For the polytetrafluoroethylene composite material of Examples 2-12, the weight percentage of each component is shown in Table 1.

[0033] The weight percent of each component of the polytetrafluoroethylene composite material of table 1 embodiment 2~12

[0034]

[0035]

[0036] The structure of the arc extinguishing nozzle using the polytetrafluoroethylene composite material of Examples 2-12 is the same as that of Example 1.

[0037] The arc extinguishing nozzles of Examples 2-12 were prepared by mixing, molding and sintering using the proportions of the components shown in Table 1. See Table 2 for the particle size of raw materials and the test conditions for mixing, molding and sintering.

Embodiment 2~12

[0038] Table 2 Embodiment 2~12 preparation process conditions of arc extinguishing nozzle

[0039]

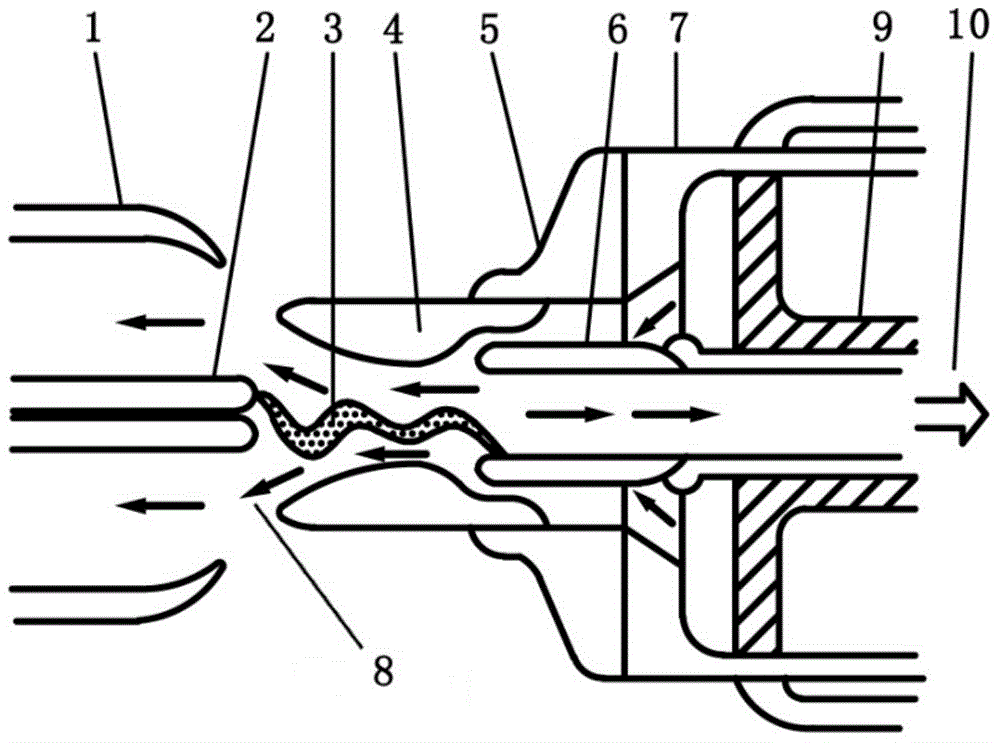

[0040] The structure of the high-voltage circuit breaker using the arc extinguishing nozzles described in Embodiments 2 to 12 is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com