Silver-base electric contact head materials

An electrical contact material, silver-based technology, applied in contact materials and other directions, to achieve the effects of improved arc erosion resistance, high self-lubricating performance, and reduced mechanical wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

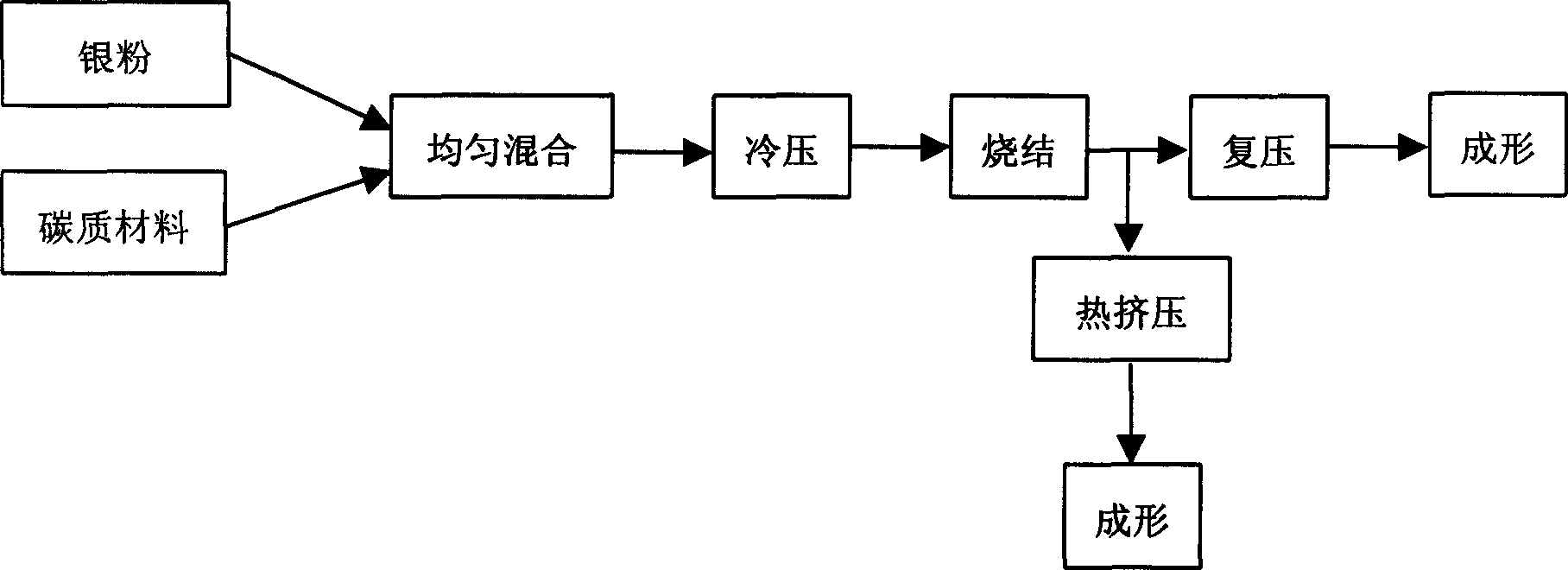

[0021] Such as figure 1 As shown, the preparation process of one-dimensional nano-carbon material / silver-based electrical contact is:

[0022] The Ag powder of said ratio and the second phase (carbon nanotubes, carbon nanofibers, graphite nanopowder or diamond powder), also comprising the mixture of these carbonaceous materials, and their mixture with common graphite powder, mix homogeneously (ball milling 1 to 10 hours; the present embodiment is 5 hours) respectively cold pressing (under 1000MPa pressure), sintering (300 to 600°C, heat preservation for 1 to 10 hours; the present embodiment is 500°C, heat preservation for 5 hours) and subsequent processing and densification (300-600°C, 800MPa repeatedly hot-pressed; in this example, 3 times hot-pressed at 300°C, 500°C, and 600°C), a silver-based electrical contact material with high wear resistance and arc erosion resistance was obtained. , the basic parameter of the obtained contact material is density 8.0~9.0g / cm 3 , Rockw...

Embodiment 2

[0025] The multi-walled carbon nanotubes prepared by gas-phase decomposition of hydrocarbons are added to the silver-based contact as an additional phase. Mix 95wt% silver powder and 5wt% multi-walled carbon nanotubes (average diameter is 40nm) evenly, use the preparation process of embodiment 1 one-dimensional nanocarbon material / silver-based electrical contact, mix, cold press, sinter into Blank, multi-walled carbon nanotubes / silver electrical contact material prepared by conventional silver contact production processes such as hot extrusion, rolling, etc.

Embodiment 3

[0027] The single-walled carbon nanotubes prepared by gas-phase decomposition of hydrocarbons are added to the silver-based contact as an additional phase. Mix 99wt% silver powder and 1wt% single-walled carbon nanotubes evenly, use the preparation process of the one-dimensional nanocarbon material / silver-based electrical contact in Example 1, go through ball milling, cold pressing, sintering into a billet, repressing, etc. The single-wall carbon nanotube / silver electrical contact material prepared by the process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com