High-electric-conductivity carbon pantograph pan and preparation method thereof

A pantograph carbon slide, high conductivity technology, applied in carbon preparation/purification, electric vehicle charging technology, current collectors, etc. High, weak mechanical strength and other problems, to achieve the uniform distribution of solute elements, improve the impregnation effect, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

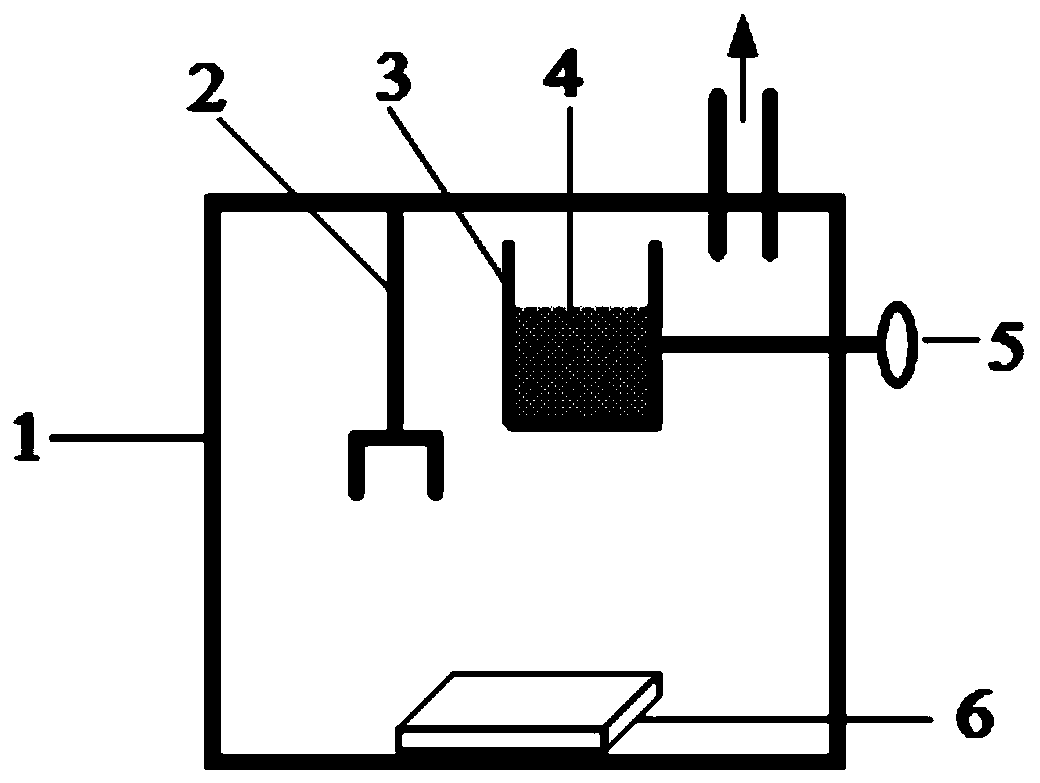

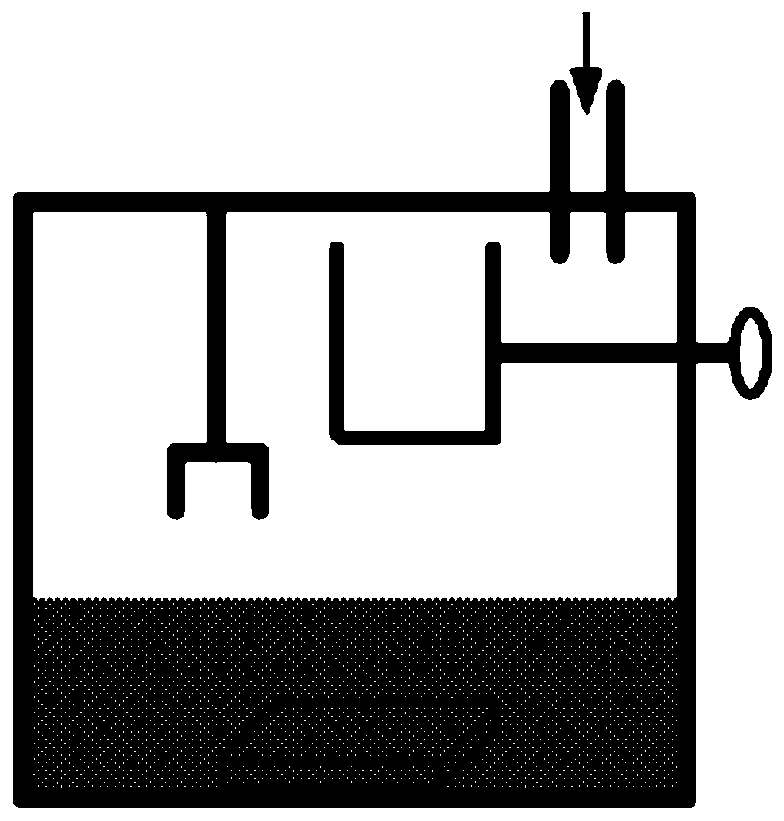

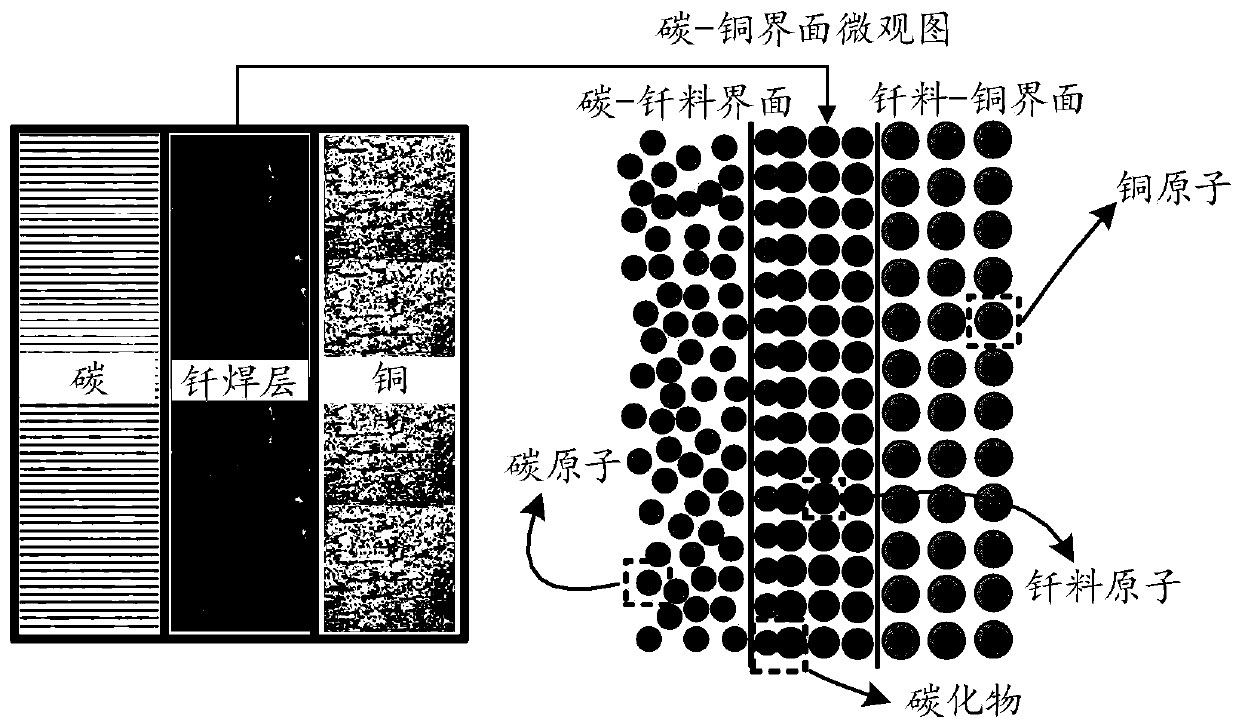

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of a high-conductivity pantograph carbon slide plate, comprising the following steps:

[0048] 1. Kneading: Take 65 parts by mass of pitch coke powder, 25 parts by mass of graphite powder and 8 parts by mass of high-temperature pitch as the base material; put the pitch coke powder and graphite powder into the kneading pot according to the weight ratio, and add The total mass of the base material is 5% methyl cellulose, fully mixed for 1 hour, the diameter of the used methyl cellulose is 0.2mm, and the length is 70mm; then add molten high-temperature asphalt and mix evenly, after cooling, put the mixture into a ball mill Grinding treatment is carried out in the medium to obtain carbon skateboard aggregate with a particle size of about 250 mesh.

[0049] 2. Pressing: pre-press the carbon skateboard aggregate into a carbon-based cylinder of 25mm*35mm*1200mm in a 200T hydraulic press, then raise the temperature of the carbon-based cylinder to about 80°C...

Embodiment 2

[0054] A preparation method of a high-conductivity pantograph carbon slide plate, comprising the following steps:

[0055] 1. Kneading: Take 70 parts by mass of pitch coke powder, 20 parts by mass of graphite powder and 10 parts by mass of high-temperature pitch as the base material; put pitch coke powder and graphite powder of two particle sizes into the kneading pot according to the weight ratio , and add ammonium carbonate accounting for 15% of the total mass of the base material, fully mix for 1h, the diameter of the ammonium carbonate used is 0.1mm, and the length is 50mm; then add molten high-temperature asphalt and mix evenly, after cooling, put the mixture into a ball mill Grinding treatment is carried out in the medium to obtain carbon skateboard aggregate with a particle size of about 200 mesh.

[0056] 2. Pressing: pre-press the carbon skateboard aggregate into a carbon-based cylinder of 25mm*35mm*1200mm in a 200T hydraulic press, then raise the temperature of the c...

Embodiment 3

[0061] A preparation method of a high-conductivity pantograph carbon slide plate, comprising the following steps:

[0062] 1. Kneading: Take 60 parts by mass of pitch coke powder, 30 parts by mass of graphite powder and 5 parts by mass of high-temperature pitch as the base material; put the pitch coke powder and graphite powder of two particle sizes into the kneading pot according to the weight ratio, And add methyl cellulose accounting for 3% of the total mass of the base material, fully mix for 1 hour, the diameter of the methyl cellulose used is 0.3 mm, and the length is 100 mm; then add molten high-temperature asphalt, and mix for 4 hours at a temperature of 160 ° C , after cooling, put the mixture into a ball mill for pulverization treatment, and obtain a carbon skateboard aggregate with a particle size of about 300 mesh.

[0063] 2. Pressing: pre-press the carbon skateboard aggregate into a carbon-based cylinder of 25mm*35mm*1200mm in a 200T hydraulic press, then raise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com