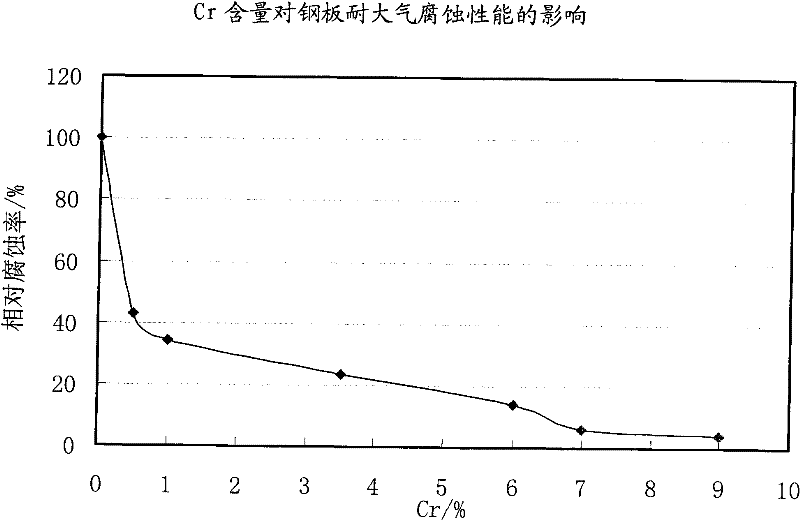

Cr-contained weathering steel with excellent toughness and high corrosion resistance

A weather-resistant steel, content technology, applied in the direction of temperature control, etc., can solve the problems of unfavorable steel plate welding and toughness, increase manufacturing cost and manufacturing difficulty, achieve excellent atmospheric corrosion resistance, reduce use and maintenance costs, and ensure delivery cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The chemical composition of the embodiment is shown in Table 1. According to the composition requirements of the steel grade of the present invention, the steel is smelted in a 500kg vacuum induction furnace, the heating temperature of the billet is controlled between 1200-1250 ° C, the rough rolling temperature is controlled above 950 ° C, and the deformation is ≥ 80%; final rolling temperature 800-900°C, accelerated cooling after rolling to 550°C-650°C for coiling, then air-cooled to room temperature. The specific operating parameters and the mechanical properties of the obtained weathering steel are shown in Table 2. Composition detection is carried out according to JIS G 1253-2002 (iron and steel - photoelectric emission spectroscopic analysis method) and GB / T20124-2006 (inert gas fusion thermal conductivity method for determination of nitrogen content in iron and steel), tensile performance test is according to GB / T228-2002 (Metal material room temperature tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com