Weather resistant steel plate and manufacturing method thereof

A manufacturing method and technology of steel plates, applied in the directions of temperature control, metal rolling, rolling force/roll gap control, etc., can solve the problems of increasing manufacturing costs, etc., and achieve reduced production costs, excellent low-temperature impact toughness, and excellent weldability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

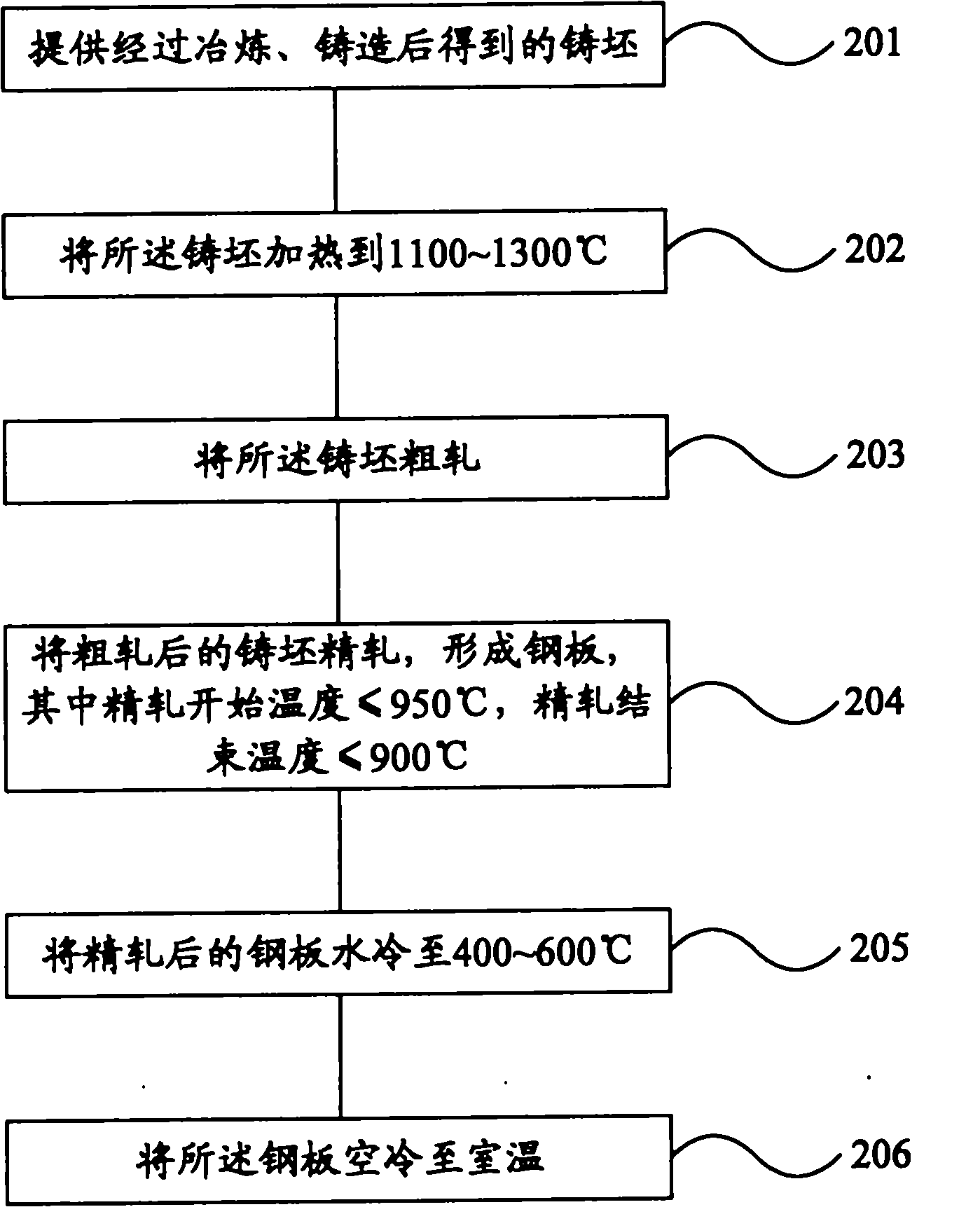

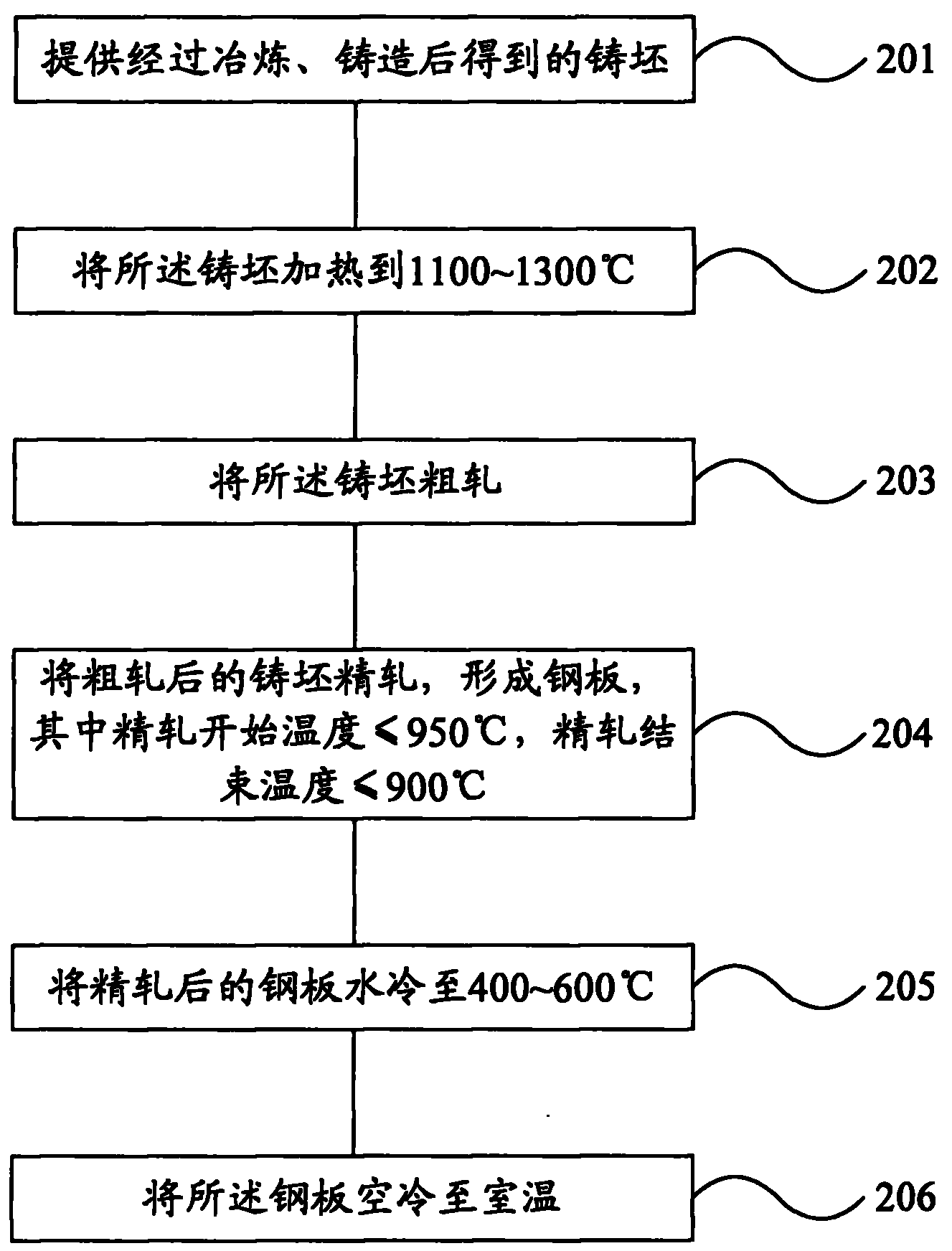

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the mass percent of the composition of the weathering steel plate is:

[0039] C: 0.082, Si: 0.30, Mn: 1.0, P: 0.011, S: 0.005, Cu: 0.30, Cr: 0.35, Ni: 0.40, Nb: 0.045, V: 0.045, Ti: 0.015, B: 0.0010, Ca: 0.0030, Al: 0.035, and the rest are Fe and other unavoidable impurities.

[0040] The production process of the weather-resistant steel plate in this embodiment is:

[0041] Provide the cast slab obtained after smelting in a 500kg vacuum induction furnace and cast by continuous casting method or die casting method; heat the cast slab to 1250°C; rough roll the cast slab, and the cast slab The cumulative reduction rate of the cast slab is ≥ 50%; the rough-rolled cast slab is finished rolled to form a 30cm thick steel plate, and the cumulative reduction rate of the cast slab during the finish rolling process is ≥ 40%, and the start temperature of the finish rolling is 930°C , the finish rolling temperature is 870°C; the steel plate after finish rolli...

Embodiment 2

[0044] In this embodiment, the mass percent of the composition of the weathering steel plate is:

[0045] C: 0.032, Si: 0.19, Mn: 1.58, P: 0.012, S: 0.003, Cu: 0.25, Cr: 0.45, Ni: 0.31, Mo: 0.40, Ti: 0.024, B: 0.0025, Ca: 0.0008, Al: 0.028, and the rest are Fe and other unavoidable impurities.

[0046] The production process of the weather-resistant steel plate in this embodiment is:

[0047] Provide the cast slab obtained by smelting in a 500kg vacuum induction furnace and cast by continuous casting method or mold casting method; heat the cast slab to 1150°C; rough roll the cast slab, and the cast slab is The cumulative reduction rate of the cast slab is ≥ 50%; the rough-rolled cast slab is finished rolled to form a 30cm thick steel plate, and the cumulative reduction rate of the cast slab in the finish rolling process is ≥ 40%, and the start temperature of the finish rolling is 950°C , the finish rolling temperature is 840°C; the steel plate after finish rolling is water-c...

Embodiment 3

[0050] In this embodiment, the mass percent of the composition of the weathering steel plate is:

[0051] C: 0.061, Si: 0.34, Mn: 1.33, P: 0.010, S: 0.0024, Cu: 0.40, Cr: 0.55, Ni: 0.20, Nb: 0.040, V: 0.031, Ti: 0.0023, Al: 0.040, and the rest are Fe and other unavoidable impurities.

[0052] The production process of the weather-resistant steel plate in this embodiment is:

[0053] Provide the cast slab obtained after smelting in a 500kg vacuum induction furnace and casting by continuous casting method or die casting method; heat the cast slab to 1200°C; rough roll the cast slab, and the cast slab is The cumulative reduction rate of the cast slab is ≥ 50%; the rough-rolled cast slab is finished rolled to form a 30cm thick steel plate, and the cumulative reduction rate of the cast slab in the finish rolling process is ≥ 40%, and the start temperature of the finish rolling is 900°C , the finish rolling temperature is 880°C; the steel plate after finish rolling is water-cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com