Method for preparing and recovering ternary anode material from waste nickel-cobalt-manganese ternary lithium ion batteries

A technology for nickel-cobalt-manganese-lithium and ion batteries is applied in the field of preparing nickel-cobalt-manganese ternary positive electrode materials, which can solve the problems of complex process and low electrical performance of products, and can shorten the process flow, improve the electrochemical performance, and achieve high repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

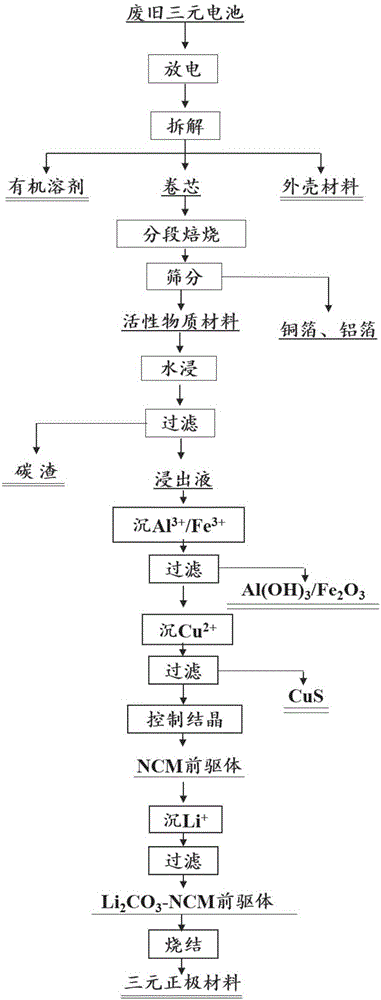

[0076] Disassemble the waste ternary lithium-ion battery after safe discharge and remove the winding core. After the winding core is broken, it is first placed in the air and roasted at 400°C for 5h at a heating rate of 5°C / min. Under roasting for 3h. Sieve the active material and pole pieces, and put the powder (active material) in water for leaching. After the reaction is complete, filter out the black insoluble matter, add 2mol / L NaOH solution to the filtrate to adjust the pH=3, after the reaction is complete, filter the insoluble precipitate, then add sodium thiosulfate until no more precipitate occurs, and filter again.

[0077] Measure the ratio of Ni, Co, and Mn of the filtrate after impurity removal, and add corresponding sulfate thereto according to the ratio, adjust the ratio to 1:1:1, and then add 2mol / L NaOH solution to adjust the pH=10. After the reaction is complete, add sodium carbonate therein, control the addition so that Li: (Ni+Co+Mn)=1.05, make Li 2 CO 3...

Embodiment 2

[0084] Disassemble the waste ternary lithium-ion battery after safe discharge and take out the winding core. After the winding core is broken, it is first placed in the air and roasted at 500°C for 3 hours at a heating rate of 10°C / min. Under roasting for 3h. Sieve the active material and pole pieces, and put the powder (active material) in water for leaching. After the reaction is complete, filter out the black insoluble matter, add 5 mol / L NaOH solution to the filtrate to adjust the pH=4, after the reaction is complete, filter the insoluble precipitate, then add sodium thiosulfate until no more precipitate occurs, and filter again.

[0085] Measure the ratio of Ni, Co and Mn of the filtrate after impurity removal, and add corresponding sulfate thereto according to the ratio, adjust the ratio to 1:1:1, and then add 2mol / L NaOH solution to adjust the pH=10.5. After the reaction is complete, add sodium carbonate therein, control the addition so that Li: (Ni+Co+Mn)=1.1, make Li...

Embodiment 3

[0087] Disassemble the waste ternary lithium-ion battery after safe discharge and take out the winding core. After the winding core is broken, it is first placed in the air and roasted at 400°C for 3 hours at a heating rate of 10°C / min, and then sulfur dioxide is introduced. Under roasting for 10h. Sieve the active material and pole pieces, and put the powder (active material) in water for leaching. After the reaction is complete, filter out the black insoluble matter, add 6mol / L NaOH solution to the filtrate to adjust the pH=5, after the reaction is complete, filter the insoluble precipitate, then add sodium persulfate until no more precipitate occurs, and filter again.

[0088] Measure the ratio of Ni, Co, and Mn of the filtrate after impurity removal, and add corresponding sulfate thereto according to the ratio, adjust the ratio to 1:1:1, and then add 6mol / L NaOH solution to adjust the pH=11. After the reaction is complete, sodium carbonate is added thereto, and the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com