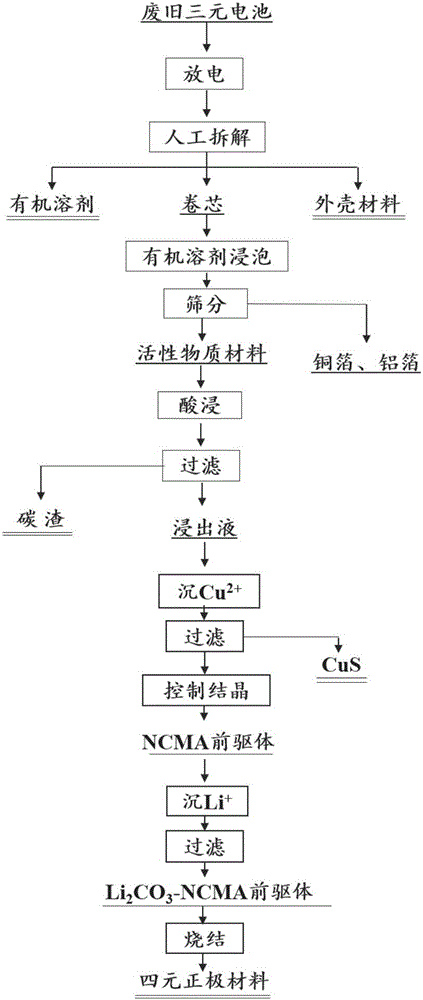

Method for recovering and preparing nickel-cobalt-manganese-aluminum quaternary positive electrode material from waste nickel-cobalt-manganese ternary lithium-ion battery

A lithium-ion battery and cathode material technology, which is applied in the field of waste lithium-ion battery recycling, can solve problems such as ineffective use of metal elements, and achieve the effects of improving electrochemical performance, shortening the process flow, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Disassemble the waste ternary lithium-ion battery after safe discharge, and obtain the core after magnetic separation and iron removal. The core is broken and soaked in NMP for 3 hours, the active material and the pole piece are screened, and the powder (active material) Placed in sulfuric acid leaching. After the reaction is complete, filter out the black insoluble matter, add thiourea to the filtrate until no precipitation occurs, and filter the insoluble matter.

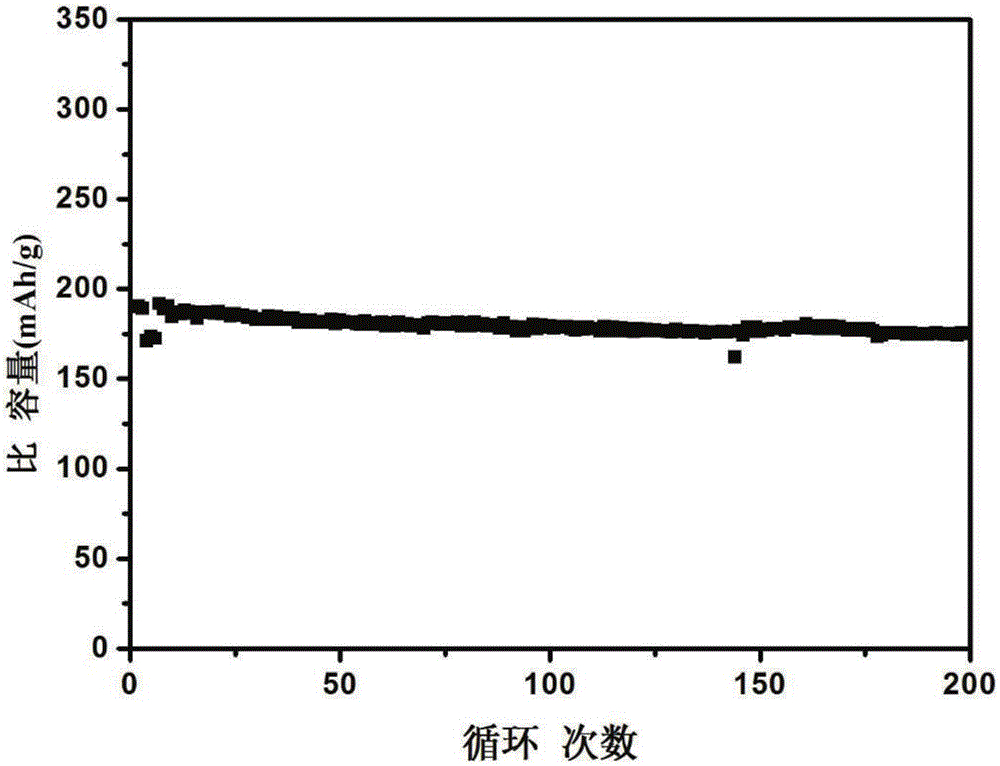

[0065] Measure the Al, Ni, Co, Mn ratio of the filtrate after impurity removal, and add corresponding vitriol wherein according to the ratio, adjust Ni, Co, Mn proportioning to 8: 1: 1, control Al content to be 2% (with The total molar weight of Al, Ni, Co, Mn is based on). Then add 2mol / L NaOH solution to adjust pH=10. After the reaction is complete, add salt of wormwood to it, control the addition so that Li: (Ni+Co+Mn+Al)=1.05, make Li 2 CO 3 Uniformly precipitated on the surface of NCMA hydroxide to...

Embodiment 2

[0070] Disassemble the waste ternary lithium-ion battery after safe discharge, and obtain the core after magnetic separation and iron removal. The core is broken and soaked in NMP for 3 hours, the active material and the pole piece are screened, and the powder (active material) Placed in sulfuric acid leaching. After the reaction is complete, filter out the black insoluble matter, add sodium thiosulfate to the filtrate until no precipitation occurs, and filter the insoluble matter.

[0071] Measure the Al, Ni, Co, Mn ratio of the filtrate after impurity removal, and add corresponding vitriol wherein according to the ratio, adjust Ni, Co, Mn proportioning to 8: 1: 1, control Al content to be 5% (with The total molar weight of Al, Ni, Co, Mn is based on). Then add 6mol / L NaOH solution to adjust pH=11. After the reaction is complete, potassium carbonate is added thereto, and the amount of control added makes Li:(Ni+Co+Mn+Al)=1.1, making Li 2 CO 3 Uniformly precipitated on the...

Embodiment 3

[0074] Disassemble the waste ternary lithium-ion battery after safe discharge, obtain the core after magnetic separation and iron removal, break the core and soak it in THF for 2 hours, sieve the active material and pole piece, and mix the powder (active material) Placed in sulfuric acid leaching. After the reaction is complete, filter out the black insoluble matter, add thiourea to the filtrate until no precipitation occurs, and filter the insoluble matter.

[0075] Measure the Al, Ni, Co, Mn ratio of the filtrate after the impurity removal, and add corresponding vitriol wherein according to the ratio, adjust Ni, Co, Mn proportioning to 6: 2: 2, control Al content to be 5% (with The total molar weight of Al, Ni, Co, Mn is based on). Then add 4mol / L NaOH solution to adjust pH=11. After the reaction is complete, add salt of wormwood wherein, control the addition and make Li:(Ni+Co+Mn+Al)=1.07, make Li 2 CO 3 Uniformly precipitated on the surface of NCMA hydroxide to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com