Heliostat device

A technology of heliostats and plane mirrors, applied in the field of solar energy applications, can solve the problems of difficult mass modular production, large quantity, and enlarged area, and achieve the effects of reducing the difficulty of production and installation and debugging, reducing costs, and reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

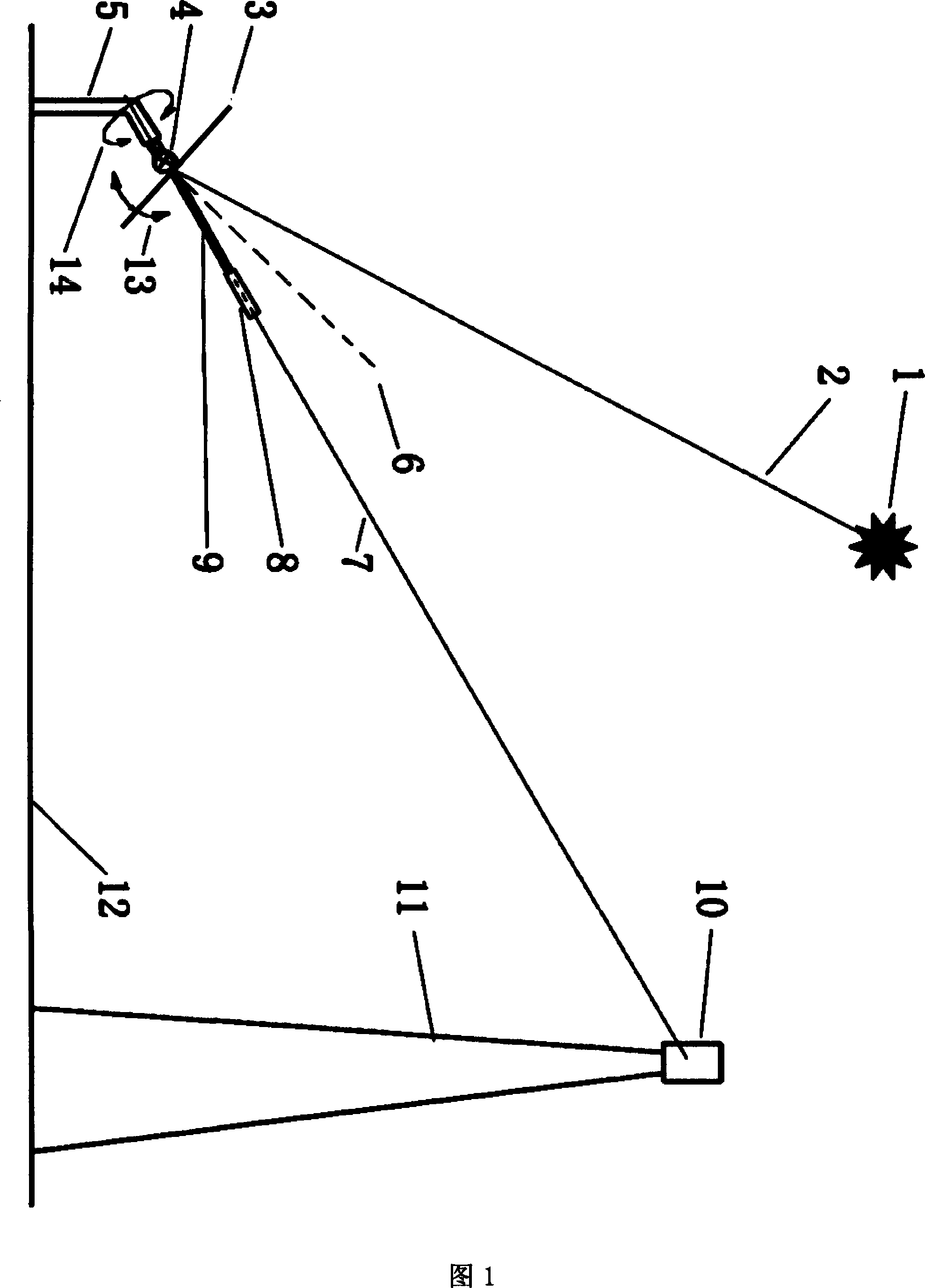

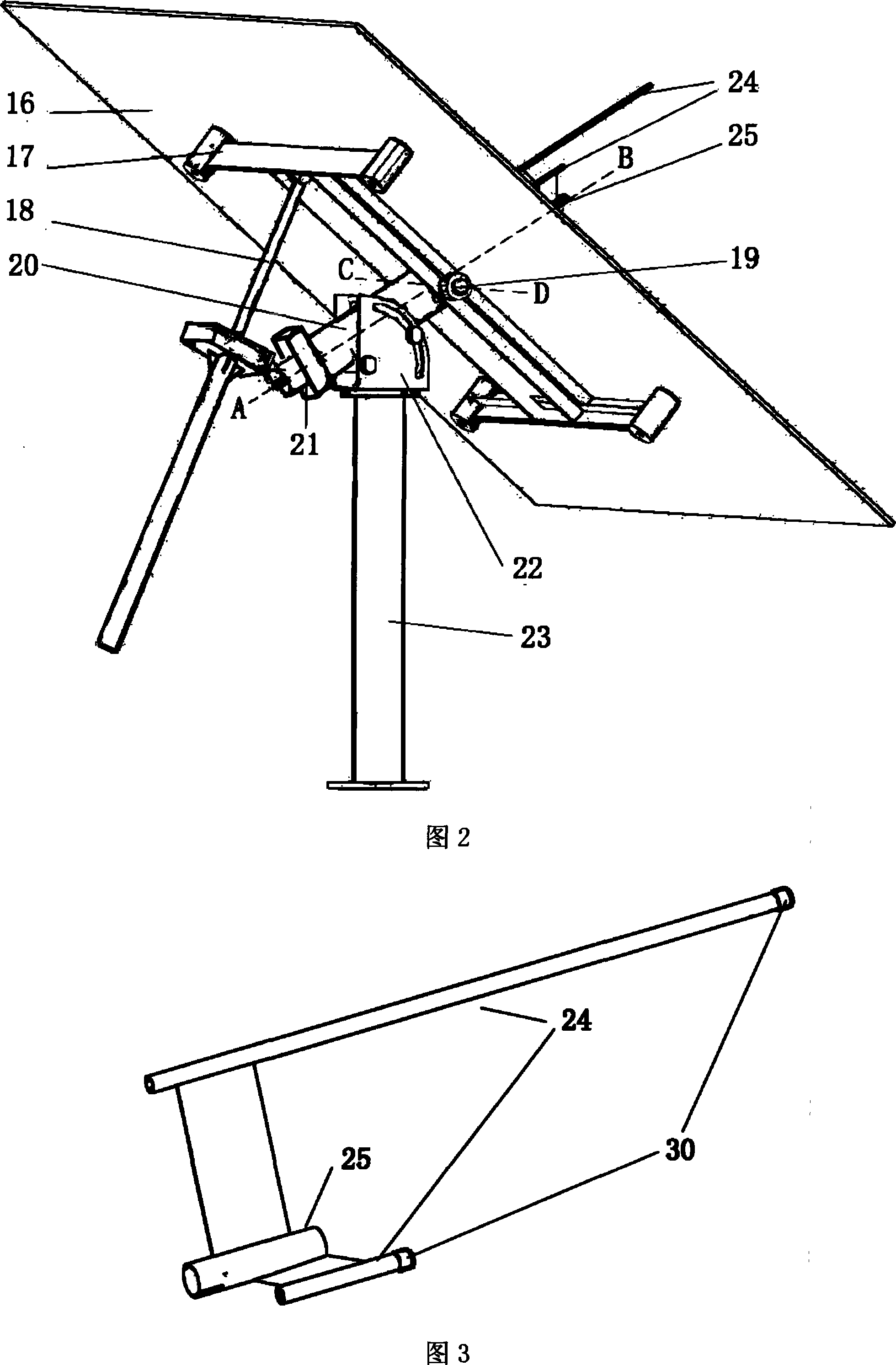

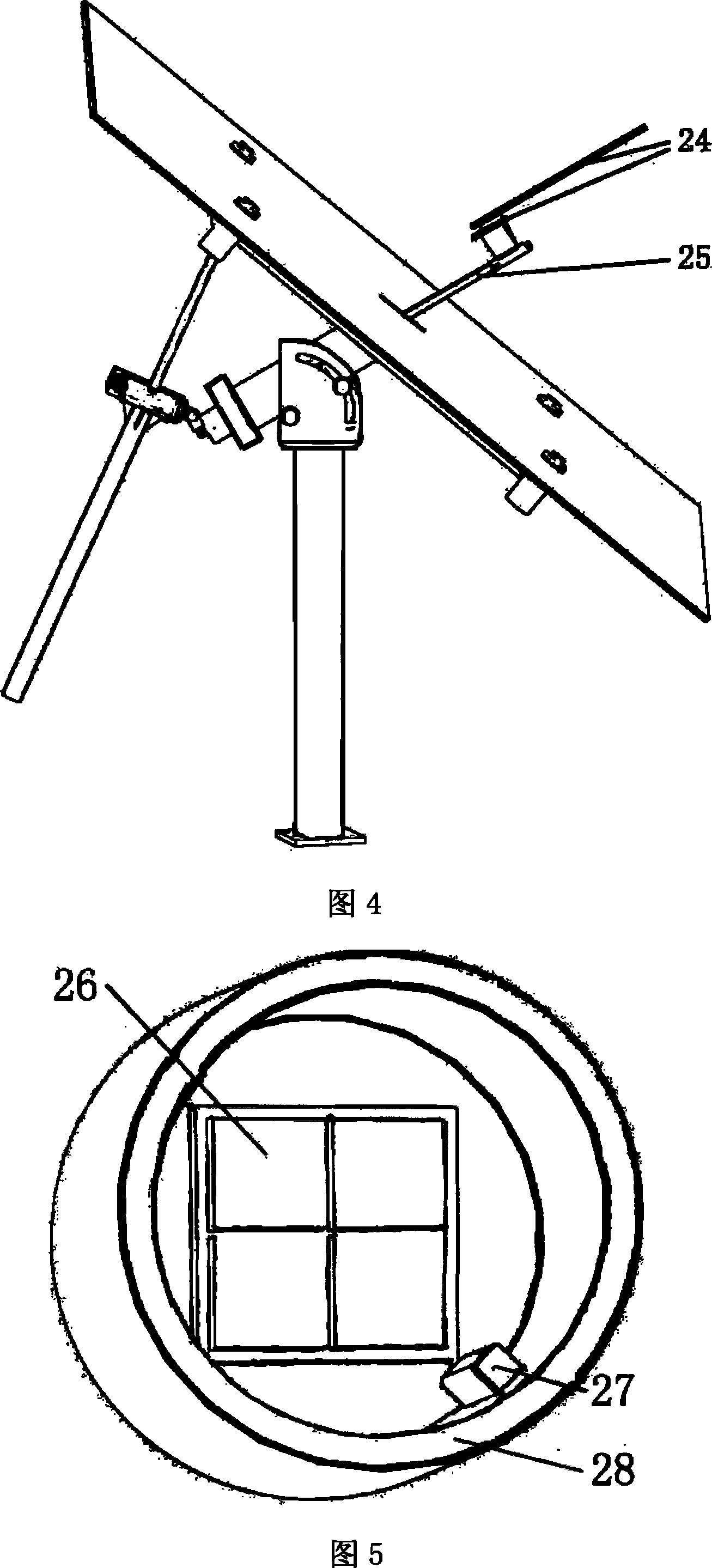

[0024] This embodiment adopts the spin plus elevation angle tracking method, as shown in FIG. 1 . It is composed of a mirror 3, an elevation angle adjustment mechanism 4, a bracket 5, a positioning sensor group 8, and the like. The mirror surface 3 is a flat mirror with sufficient strength. 11 is the receiving tower, 12 is the ground, 13 is the elevation adjustment direction of the mirror 3, and 14 is the spin adjustment direction of the mirror 3. The reflected light 7 irradiated to the bull's-eye of the heat collector 10 is the reflected light 2 emitted by the sun 1 and irradiated on the mirror 3 . 6 is the vertical line of the mirror surface 3. The centerline of the positioning sensor group 8 is parallel to the centerline of the pointing tube 9 . As long as the reflected light 7 can pass through the positioning guide tube and reach the center of the four-quadrant photosensitive element of the positioning sensor group 8, it can be ensured that the reflected light spot of t...

Embodiment 2

[0031] The schematic diagram of the heliostat device in this embodiment is shown in Figure 6, which adopts the azimuth plus elevation angle tracking method. It consists of a mirror 3, an elevation angle adjustment mechanism 4, a bracket 5, a positioning sensor group 8, a positioning sensor group bracket 9, and the like. 11 is the receiving tower, 12 is the ground, 13 is the elevation adjustment direction of the mirror 3, and 14 is the azimuth adjustment direction of the mirror 3. The reflected light 7 irradiated to the bull's-eye of the heat collector 10 is the reflected light 2 emitted by the sun 1 and irradiated on the mirror 3 . 6 is the vertical line of the mirror surface 3. The center line of the positioning sensor group 8 coincides with the line connecting the center point of the mirror surface 3 and the bull's-eye of the heat collector 10 . As long as the reflected light 7 can pass through the positioning guide tube and reach the positioning sensor group 8 , it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com