Biomass briquette combustion system

A molding fuel and combustion system technology, applied in the direction of solid fuel combustion, combustion methods, and controlled combustion, can solve problems such as difficult to clean ash, small furnace capacity, and easy smoke from the furnace, so as to reduce the generation of NOx and the heating area The effect of large and large furnace space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention is described in more detail to facilitate understanding of the present invention.

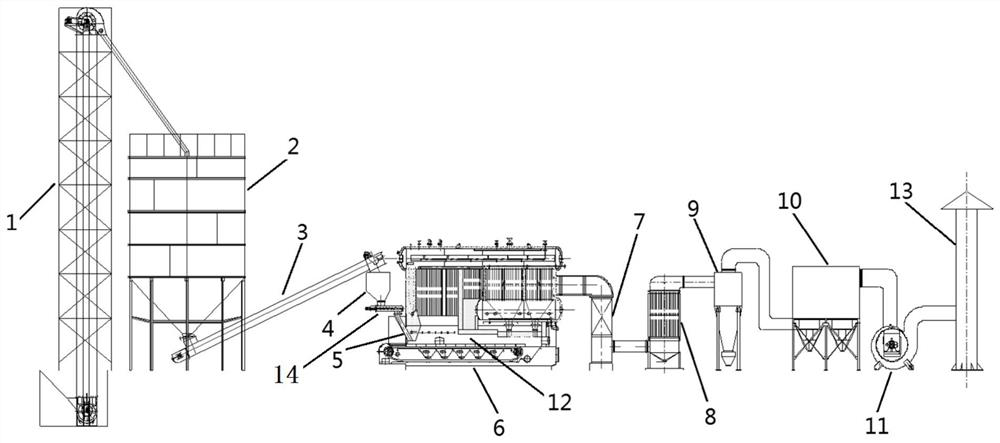

[0026] Such as figure 1 As shown, the biomass briquette fuel combustion system of the present invention includes a feeding system, a boiler host 6, an economizer 7, an air preheater 8, a cyclone dust collector 9, a bag filter 10, an induced draft fan 11, and a chimney 13 and control system, the feeding system includes a closed bucket elevator 1, a closed storage bin 2, a closed scraper conveyor 3, a daily feed bin 4 and a screw feeder 5 in front of the furnace, and the described The closed bucket elevator 1 is used to lift the biomass briquette to the top of the closed storage bin 2; the closed scraper conveyor 3 is used to lift the biomass briquette inside the closed storage bin 2 Transported to the daily feed bin 4 in front of the furnace; the screw feeder 5 is provided with a variable frequency motor inside, and the biomass briquette fuel in the dai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com