Multi-fuel heat pipe indirect heating hot air stove

A multi-fuel, hot blast stove technology, used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of small heat exchange area between cold air and hot flue gas, low heat exchange efficiency, and small heat exchange. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

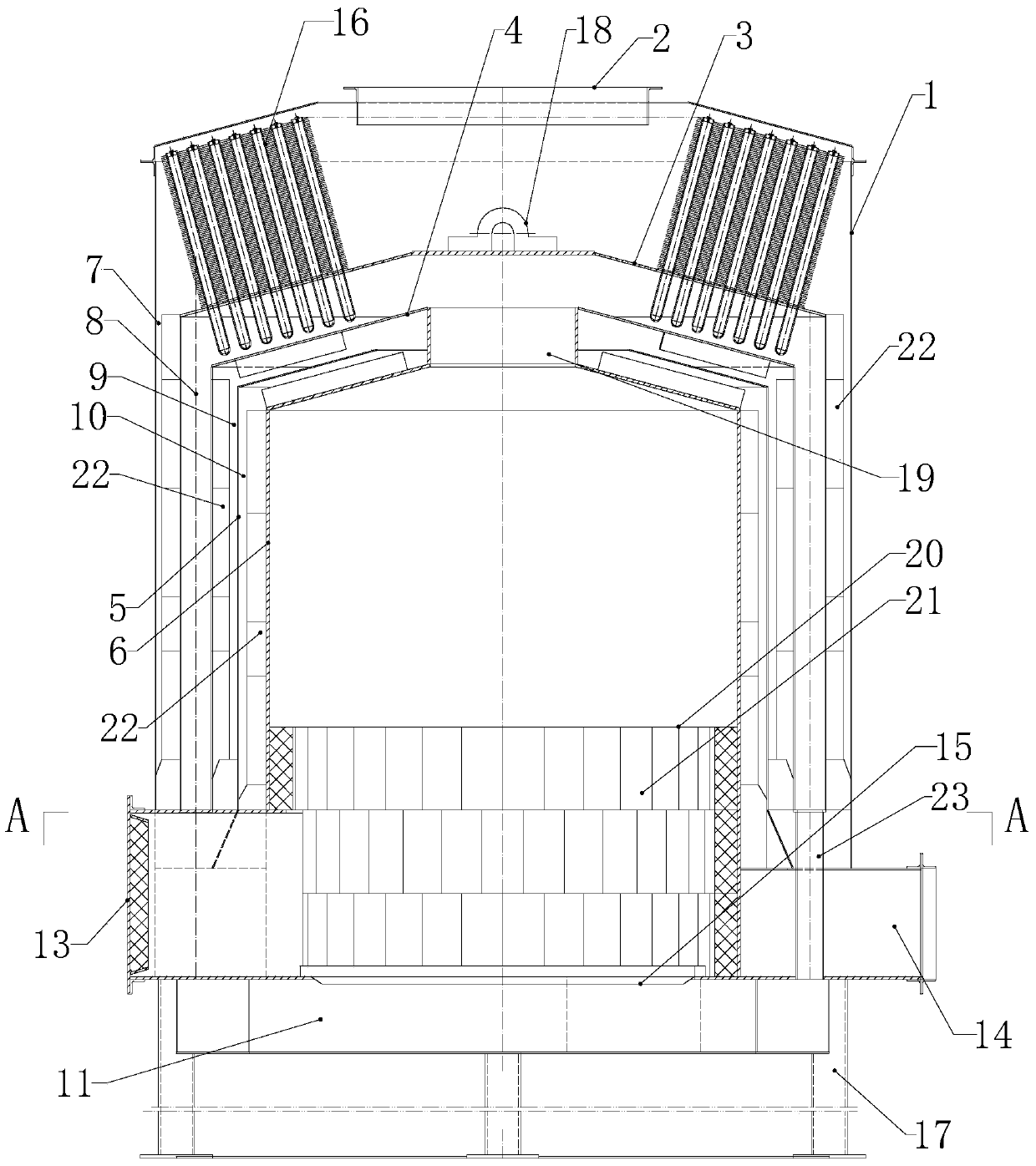

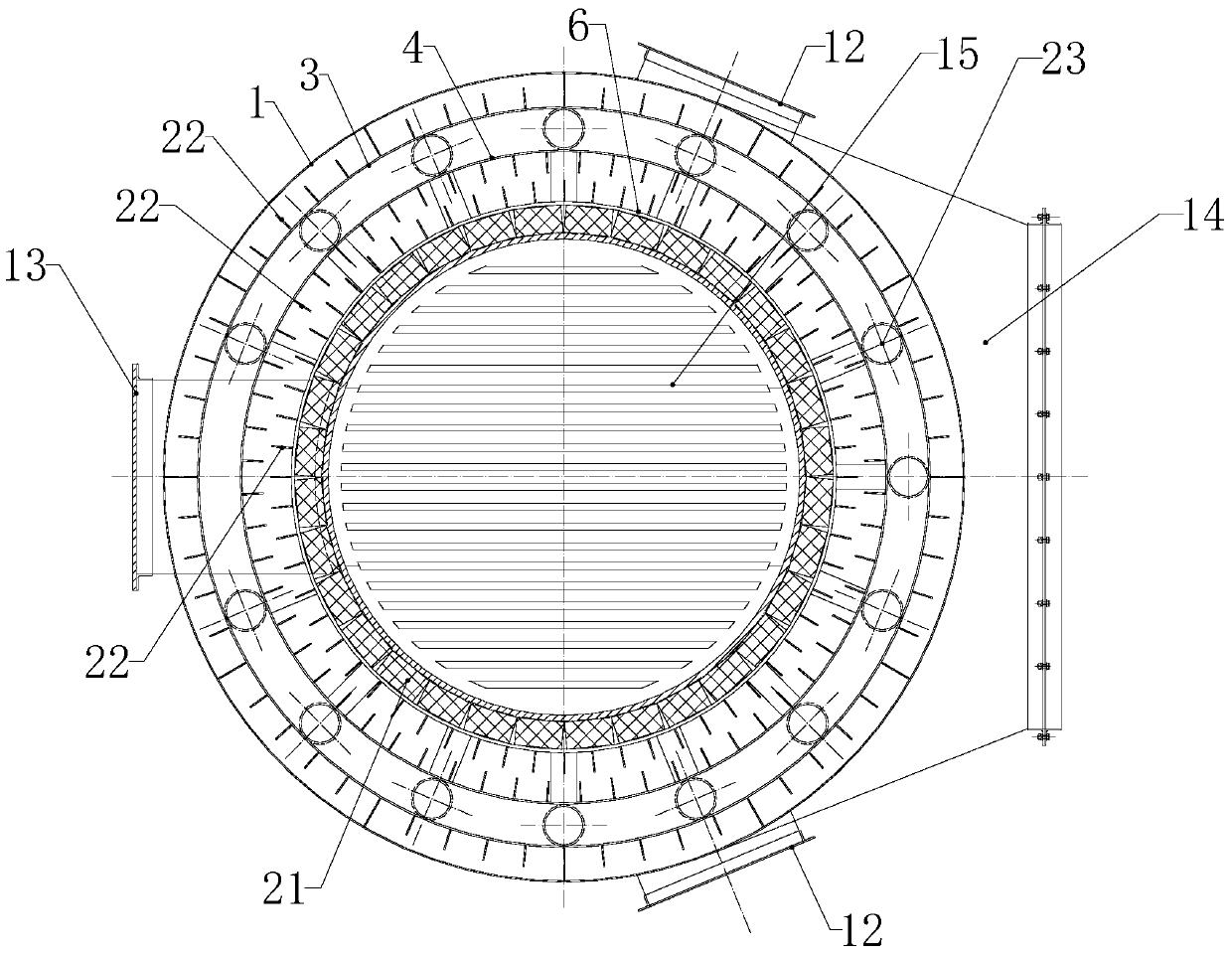

[0020] see figure 1 with figure 2 , a kind of multi-fuel heat pipe indirect heating hot blast stove of a preferred embodiment of the present invention, comprises

[0021] An outer shield 1, an air inlet 2 is opened on the top surface of the outer shield, and a plate heat exchanger is arranged inside the outer shield, and the plate heat exchanger includes a first shell 3, a second shell arranged in the first shell Housing 4, the third housing 5 arranged in the second housing and the fourth housing 6 arranged in the third housing, the space between the inner surface of the outer shield and the outer surface of the first housing is the second housing. A descending air duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com