Annular furnace base movable thread stand bolt positioning method

A bolt positioning and annular furnace technology, which is applied in infrastructure engineering, construction and other directions, can solve problems such as affecting the quality of bolt installation, many procedures for installing bolts, and difficult to ensure accuracy, and achieves solutions to large material consumption, reduction of construction procedures, and reduction of engineering. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

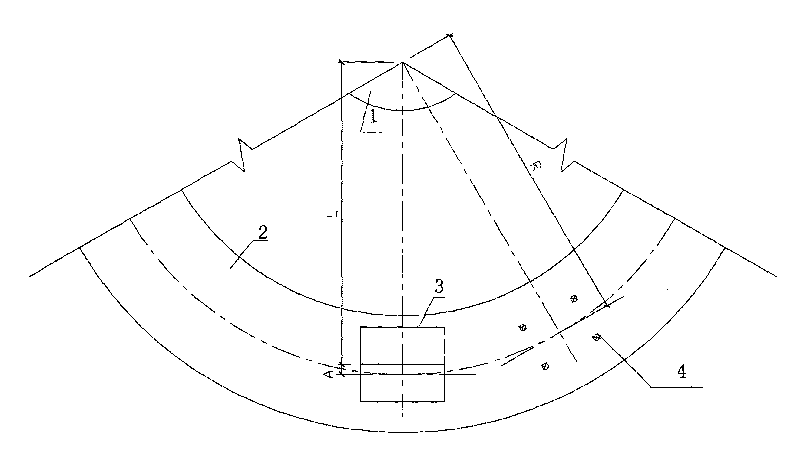

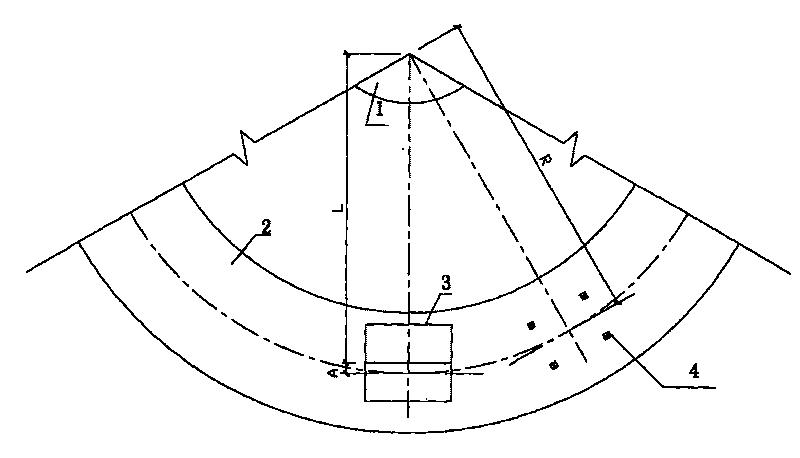

[0020] The present invention is further illustrated below by specific examples.

[0021] This embodiment is an application example in the φ177 oil pipe engineering annular furnace foundation.

[0022] 1. Equipment and material preparation:

[0023] a. Welding equipment: one electric welding machine.

[0024] b. ∠50×5 angle steel, §=6mm steel plate, φ20 threaded steel bar.

[0025] c. One total station.

[0026] 2. Production of movable wire frame:

[0027] a. Use ∠50×5 angle steel to weld the 800×600 frame, and use a 6mm thick 600×400 steel plate in the middle to weld firmly with the angle steel frame.

[0028] b. Make two perpendicular lines at the center of the steel plate and mark them.

[0029] 3. Welding of steel bar fixing frame: Weld a closed and continuous fixing frame on the bound steel mesh, as a measurement point, the fixing frame should be stable and firm.

[0030] 4. Total station ranging projection point:

[0031] a. Set up the total station at the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com