UV-curing coating

A technology for curing coatings and ultraviolet light, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of heat resistance and corrosion resistance, etc., and achieve fast curing speed of coatings, coating High hardness and low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

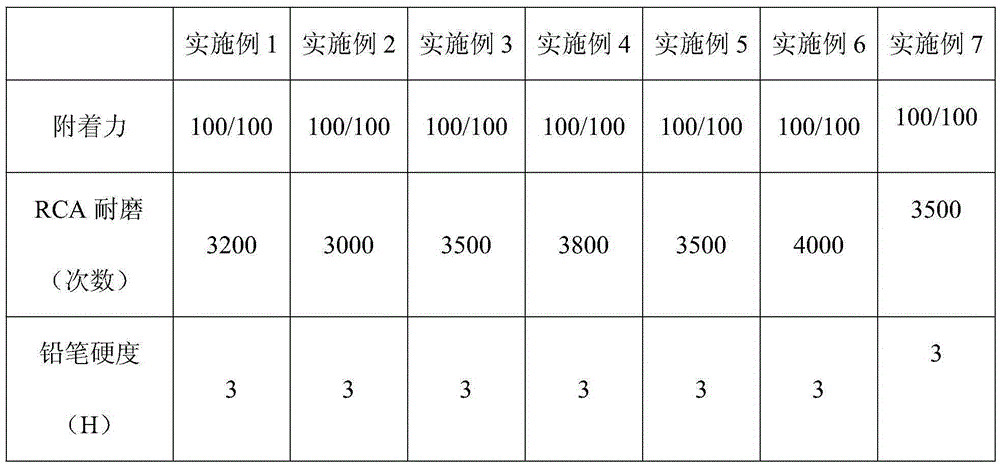

Embodiment 1

[0023] Recipe: a UV-curable coating consisting of the following components in parts by weight: 18 parts of bisphenol A epoxy acrylate, 5 parts of novolac epoxy acrylate, 8 parts of epoxy oil propionate, 12 parts of tripropylene glycol acrylate 2 parts, 2 parts of benzophenone, 8 parts of triethylamine, 0.6 parts of polymethylalkylsiloxane solution, 0.8 parts of BYK-10320, 0.6 parts of acrylic functional polydimethylsiloxane, ethylene glycol ether 35 servings.

Embodiment 2

[0025] Recipe: a UV-curable coating, consisting of the following components in parts by weight: 19 parts of bisphenol A epoxy acrylate, 7 parts of novolac epoxy acrylate, 10 parts of epoxy propionate, ethoxylated trimethylol 13 parts of propane triacrylate, 2 parts of 2,4,6-trimethylbenzoyl diphenylphosphine oxide, 8 parts of N,N-dimethylbenzylamine, 0.6 parts of polymethylalkylsiloxane solution 0.3 parts of Ciba EFKA-4010, 0.5 parts of acrylic functional polydimethylsiloxane, and 38 parts of methyl-isoamyl ketone.

Embodiment 3

[0027] Recipe: a UV-curable coating consisting of the following components in parts by weight: 16 parts of bisphenol A epoxy acrylate, 5 parts of novolac epoxy acrylate, 15 parts of epoxy oil propionate, neopentyl glycol di 10 parts of acrylate, 2 parts of benzoin dimethyl ether, 6 parts of N,N-dimethylbenzylamine, 0.4 parts of polymethylalkylsiloxane solution, 0.5 parts of Ciba EFKA-40100, acrylic functional group polydimethylsiloxane 0.5 parts of oxane, 30 parts of ethylene glycol methyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com