Method for preparing nano crystal TiO2 porous film using high viscosity solvent

A technology of porous thin film and nanocrystal, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Reduce the order degree, decrease the specific surface area of the film, etc., to achieve the effect of improving the degree of regularity and order, improving equipment efficiency, and increasing the thickness of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Butyl titanate

[0019] Butyl titanate

[0020] Lifting speed: 5.5cm / min

[0021] Calcination heating rate: 2°C / min

[0022] Calcination temperature: 550°C

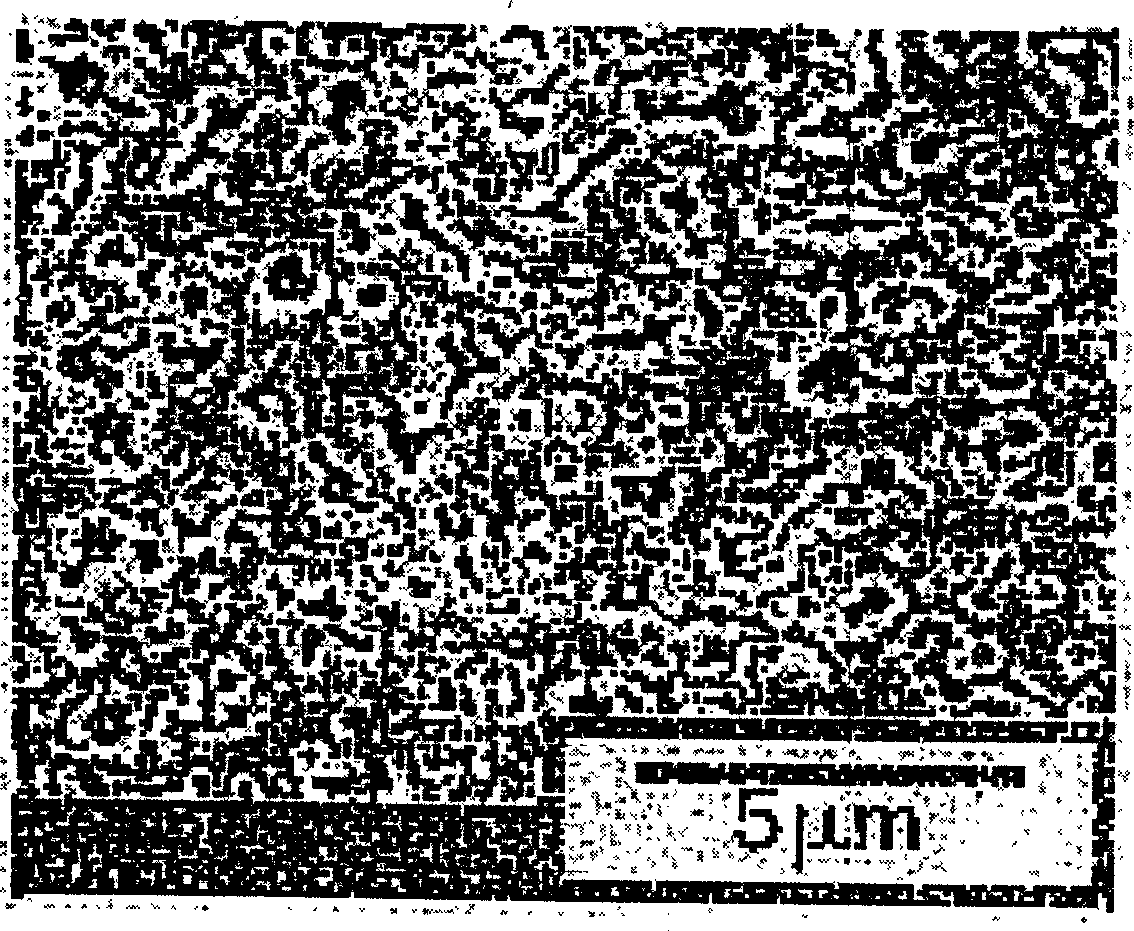

[0023] The resulting TiO 2 Properties of porous film: After high-temperature calcination, the surface of the film produces a network-like regular porous structure, with a high degree of pore arrangement order and a large specific surface area; the thickness of the film obtained by a single coating is significantly increased. TiO in film 2 It is in the anatase crystal form, and the grain size is 10-30nm.

[0024] Aperture

[0025] Aperture

[0026] Nanocrystalline TiO of the present invention 2 The regularity and degree of order of the pore structure of the porous film can be improved by figure 1 and figure 2 clearly seen in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com