Electroluminescent display panel, preparation method thereof and display device

An electroluminescent display and panel technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve problems such as the coffee ring effect, achieve the effect of improving the uniformity of film thickness and improving the display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

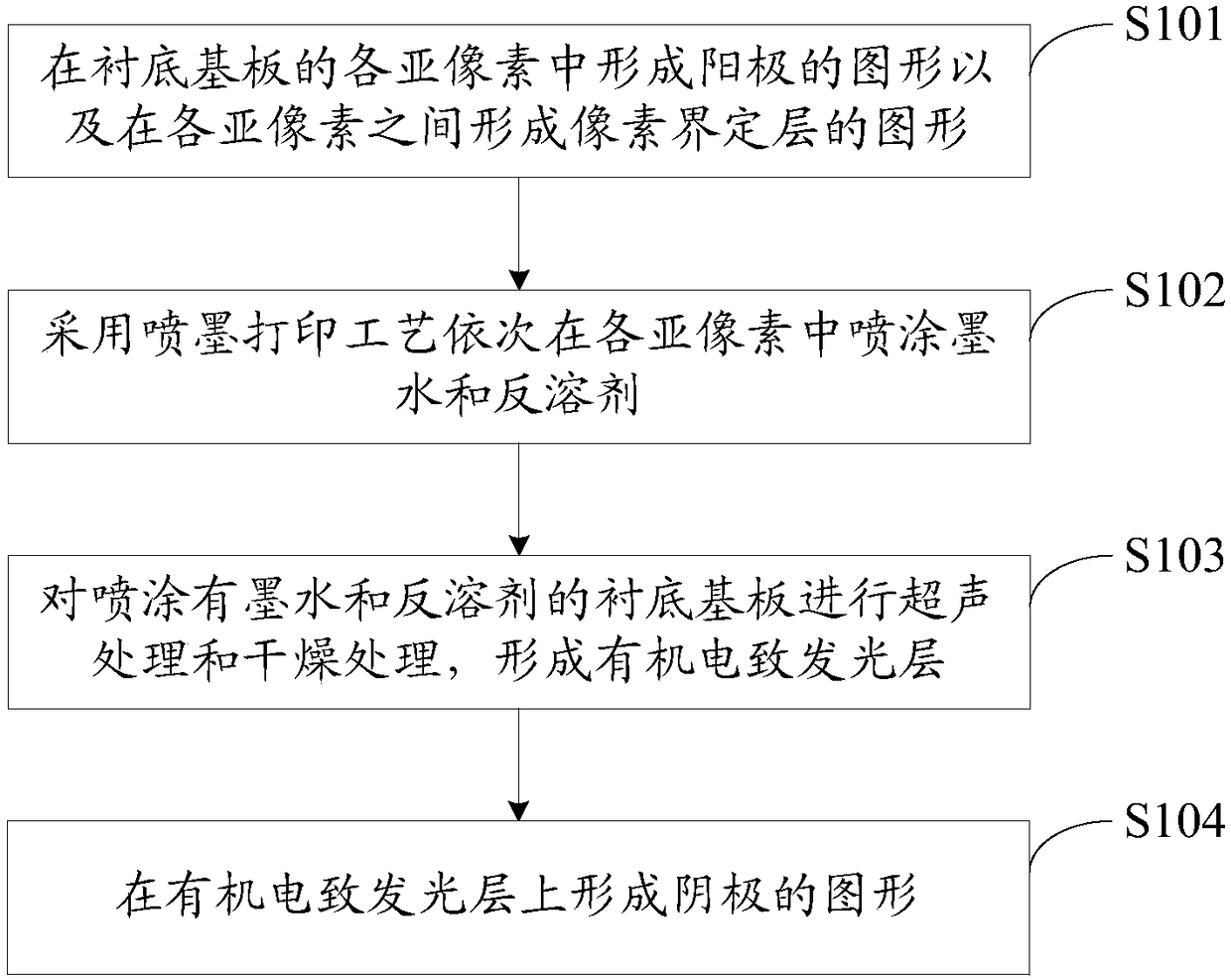

[0029] Embodiments of the present invention provide a method for preparing an electroluminescent display panel, such as figure 1 As shown, the preparation method may include the following steps:

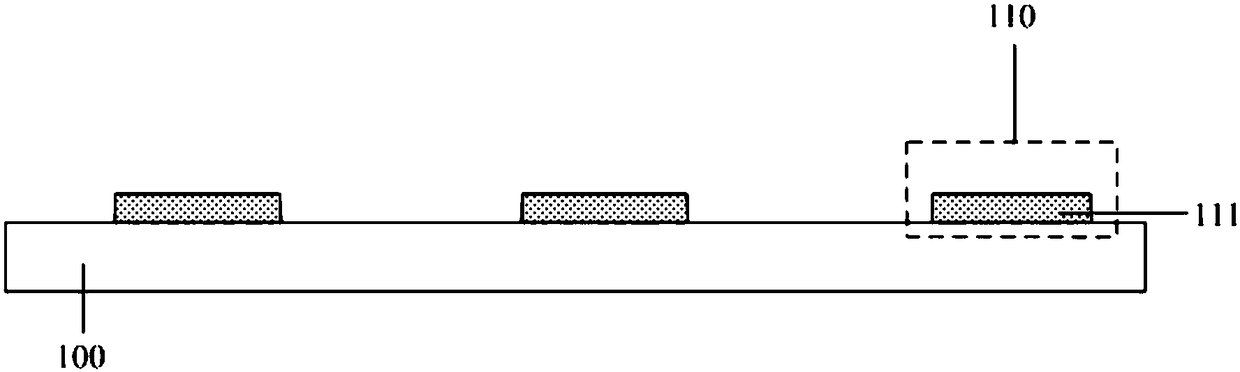

[0030] S101, forming a pattern of an anode in each sub-pixel of the base substrate and forming a pattern of a pixel defining layer between each sub-pixel.

[0031] Specifically, a single patterning process is used to form the patterns of the anodes in the sub-pixels of the base substrate. Wherein, the material of the anode may include a transparent conductive material. Wherein, the transparent conductive material may include one or a combination of indium tin oxide (ITO), indium zinc oxide (IZO), carbon nanotubes, graphene, nano gold and nano silver, which is not limited herein.

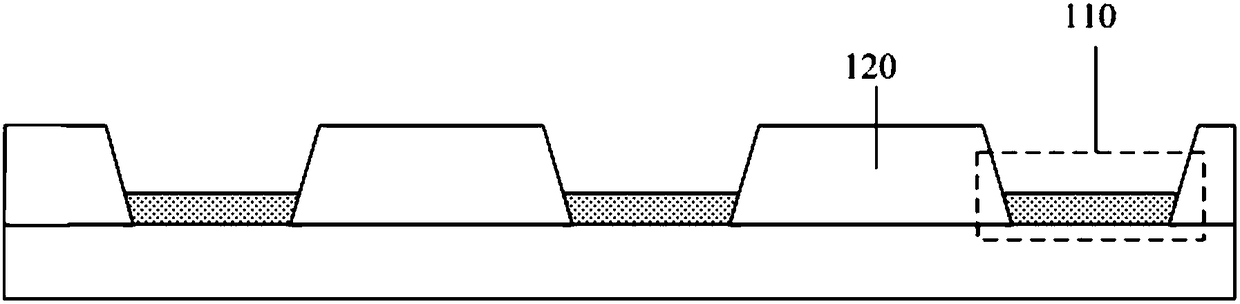

[0032] A patterning process is used to form the graphics of the pixel defining layer between the sub-pixels.

[0033] S102. Using an inkjet printing process to spray ink and anti-solvent in each sub-pixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com