Process for preparing carbon electrode array with high surface area and high gap filling capacity

A high-surface-area, carbon-electrode technology, applied in electrode manufacturing, chemical instruments and methods, photoplate-making process on patterned surfaces, etc., to achieve the effects of simple production, enhanced energy storage capacity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

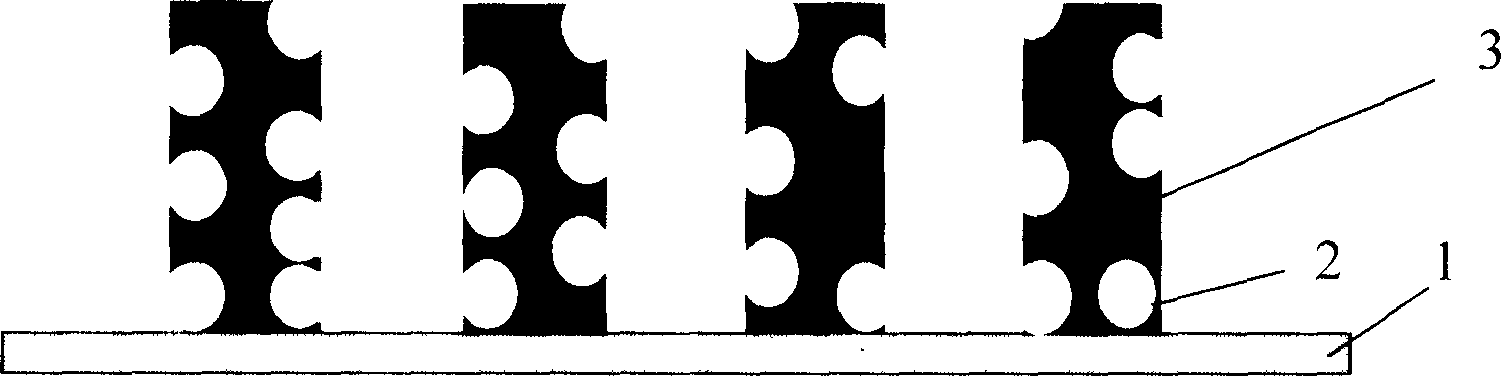

[0016] The present invention proposes a method for preparing a carbon electrode array with high surface area and high interstitial capacity. Its implementation consists of three steps:

[0017] 1) A high polymer expandable microsphere composed of a thermoplastic shell and a thermal expansion agent inside. The shell is a copolymer of monomers such as acrylonitrile and vinylidene chloride, and the thermal expansion agent is usually isobutane or isopentane. Add to photoresist for thick resist photolithography:

[0018] First add 0.1-30% volume percentage of polymer expandable microspheres into the photoresist and mix them uniformly, and then evenly coat them on silicon wafers, silicon nitride, silicon dioxide, quartz glass or metal linings, etc. On the bottom surface, the film thickness is about tens to hundreds of microns. After pre-baking, exposure, development and other photolithography processes, a patterned photoresist structure with a certain aspect ratio is formed;

[0...

Embodiment

[0025] Add high polymer expandable microspheres with a diameter of 6 microns to the SU-8 light by volume ratio of 5% by the thermoplastic shell of the copolymer of monomers such as acrylonitrile and vinylidene chloride and isobutane heat expansion agent. In the resist, mix evenly, and then evenly coat it on the surface of the silicon wafer substrate, the film thickness is about tens to hundreds of microns, after pre-baking, exposure, development and other photolithography processes, place it at a temperature of 80-300 ° Lower the pre-bake, control the upper limit of the temperature to 300°C, remove the organic solvent in the photoresist, place it in an open quartz tube heating furnace, feed 2000sccm of nitrogen gas and raise the temperature to 900°C at a heating rate of 10°C / min, Then modified 5% H 2 and N 2 The mixed gas is kept at 2000sccm for 1 hour, and finally 2000sccm of nitrogen gas is used to cool to room temperature, and the photoresist is subjected to pyrolytic carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com