Control method for plasma reinforced chemical meteorology deposition apparatus

A technology of meteorological deposition and enhanced chemistry, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of cumbersome, loss, equipment reliability and safety cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

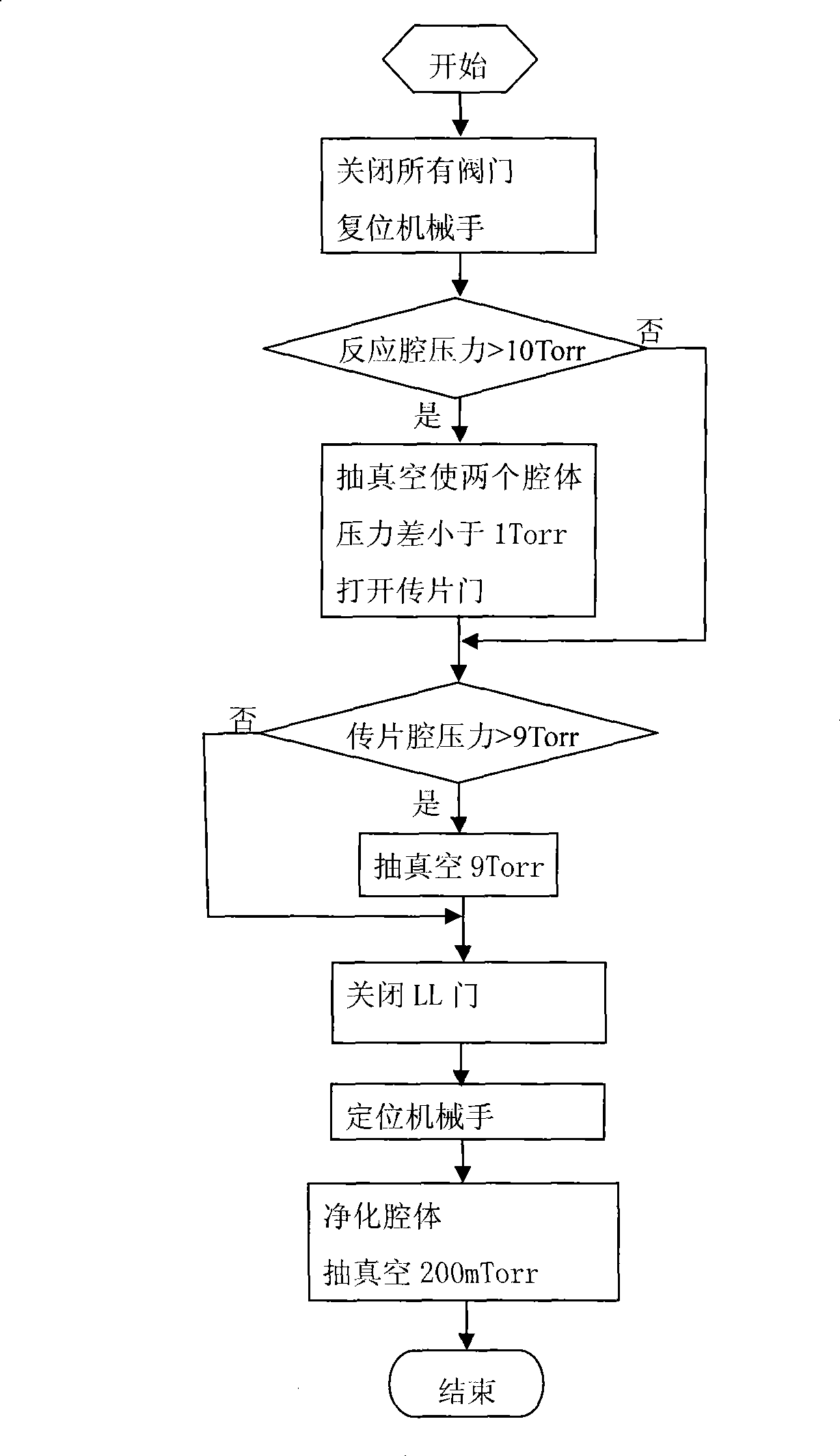

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

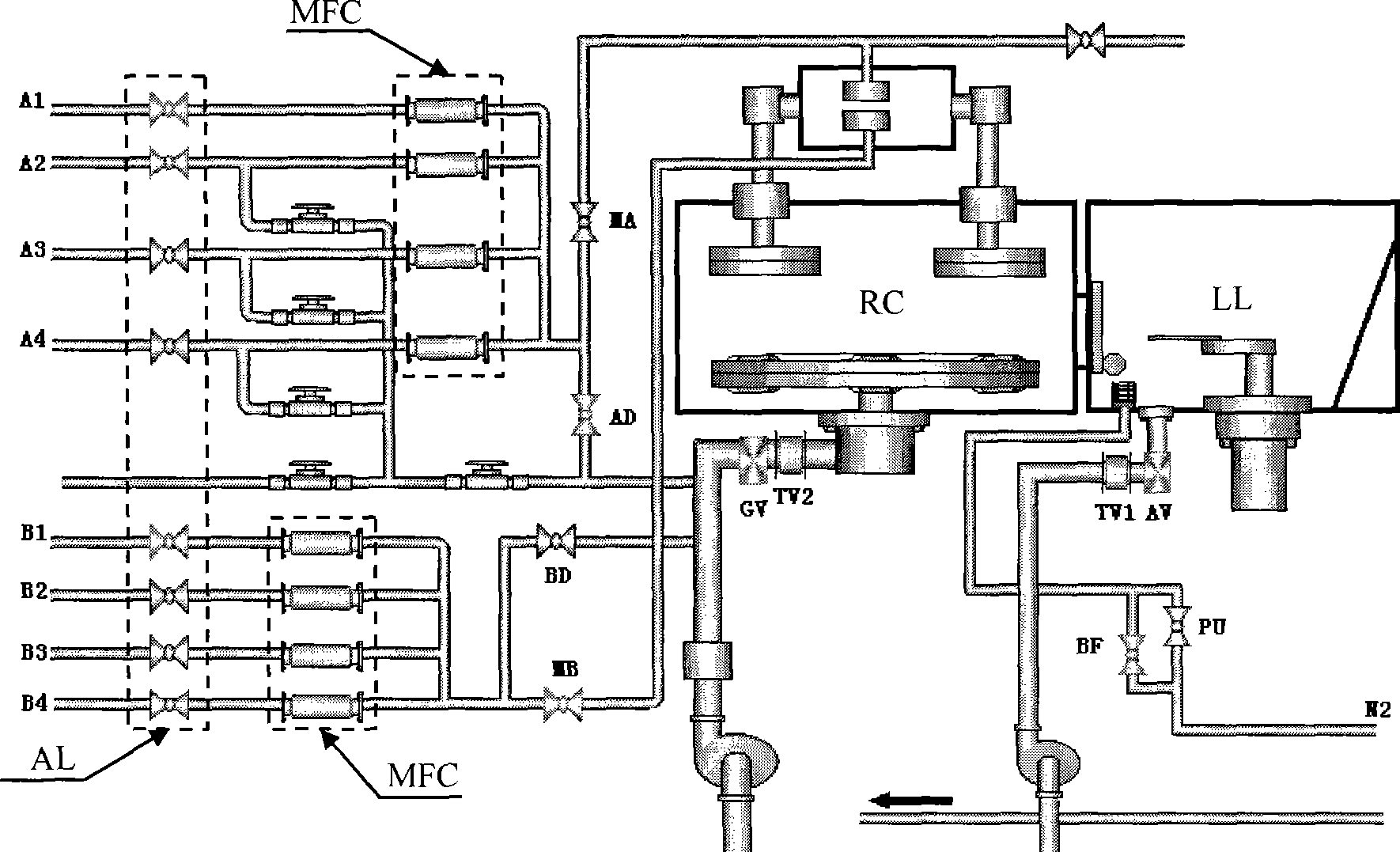

[0040] The equipment involved in the present invention is constituted as follows:

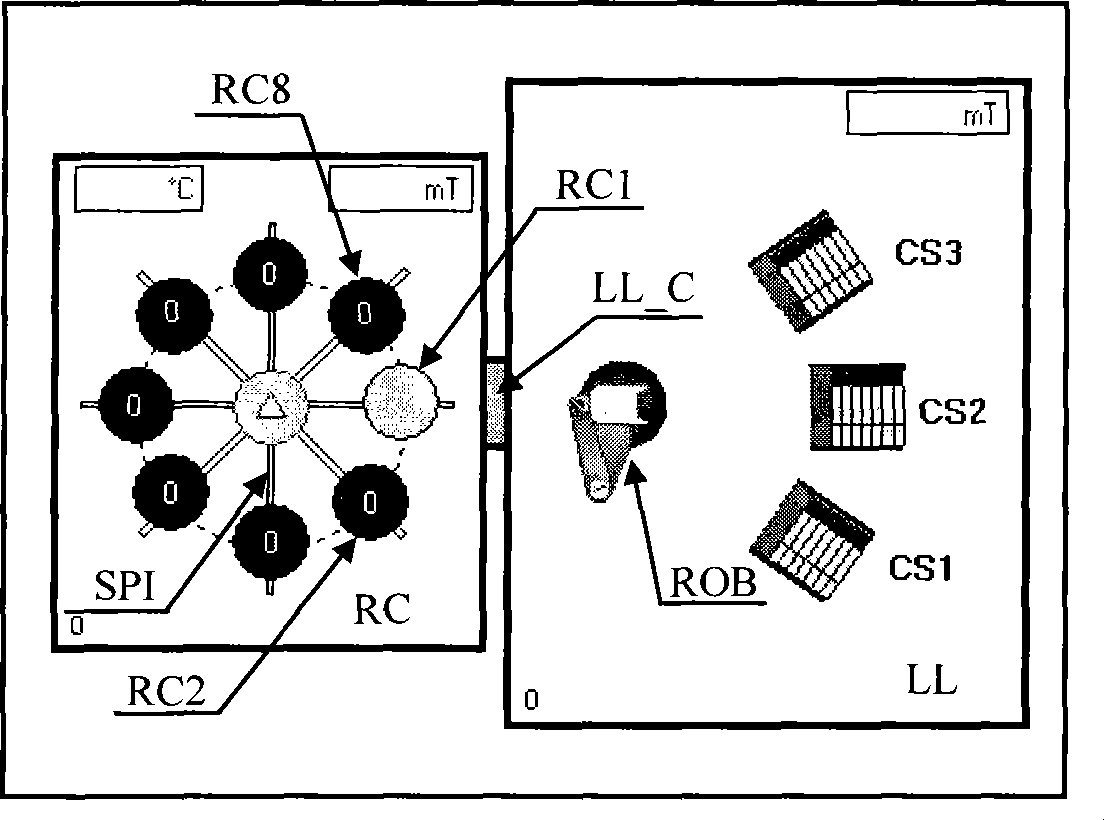

[0041] like figure 1 As shown, the plasma enhanced chemical vapor deposition equipment has two chambers, the transfer chamber LL is responsible for the transfer of the wafer; the reaction chamber RC is responsible for the wafer deposition. The two cavities need to be in harmony and cooperate with each other to meet the requirements of the process indicators. Wafer transfer is to control the manipulator to complete the actions such as taking and placing the wafers. During the deposition process, the two chambers need to work in a low-pressure environment to ensure the cleanness of the deposition environment and to avoid affecting the uniformity and cleanliness of the wafer due to environmental factors.

[0042] figure 1 Middle: ROB is the robot arm; SPI is the sample fork; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com