Solid-state imaging device and solid-state imaging device manufacturing method

A technology of a solid-state imaging device and manufacturing method, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., and can solve problems such as reliability influence, color mixing, line shade sensitivity error deterioration, deformation, etc., so as to prevent color mixing and improve line shade , Reduce the effect of sensitivity error and color spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

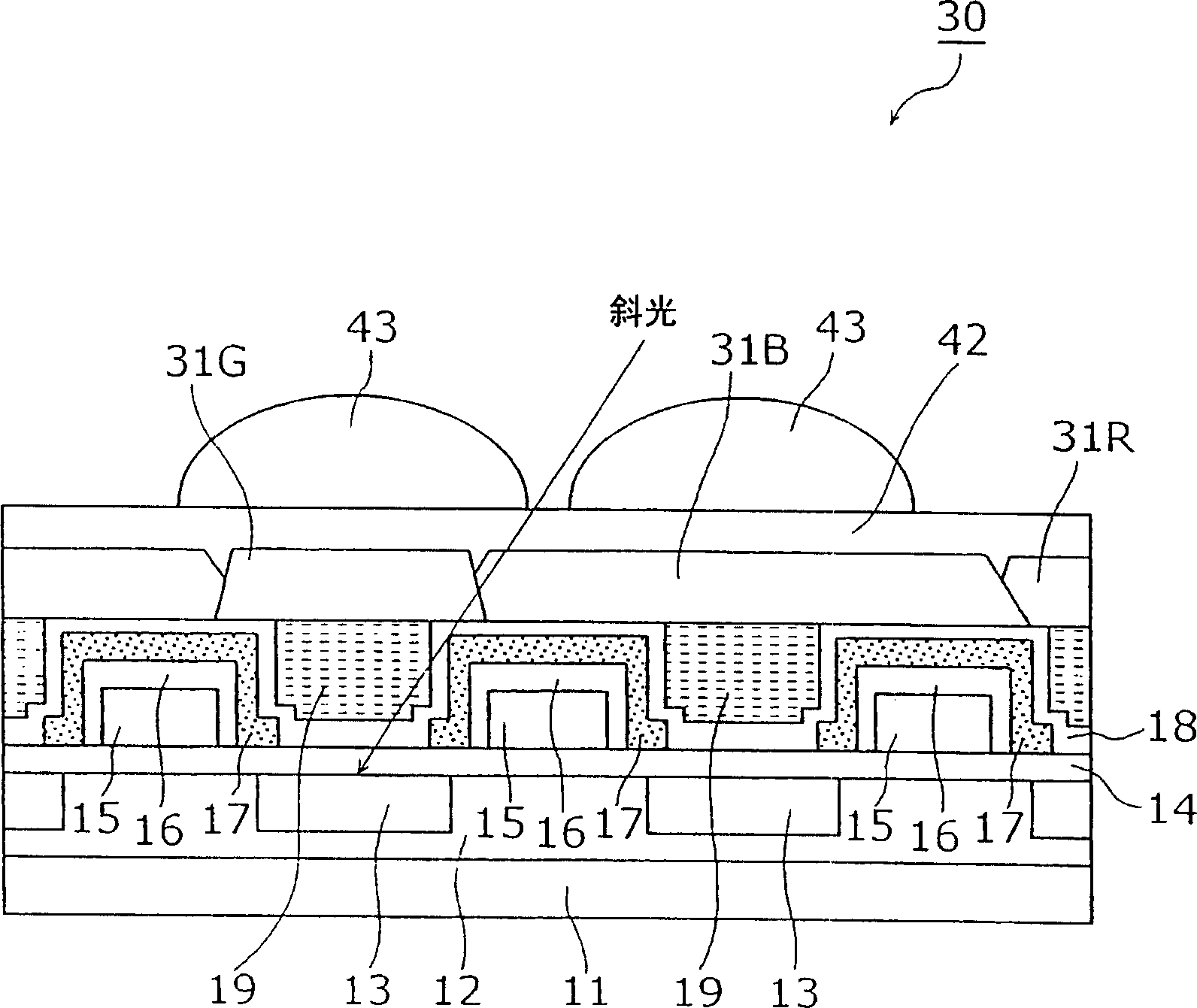

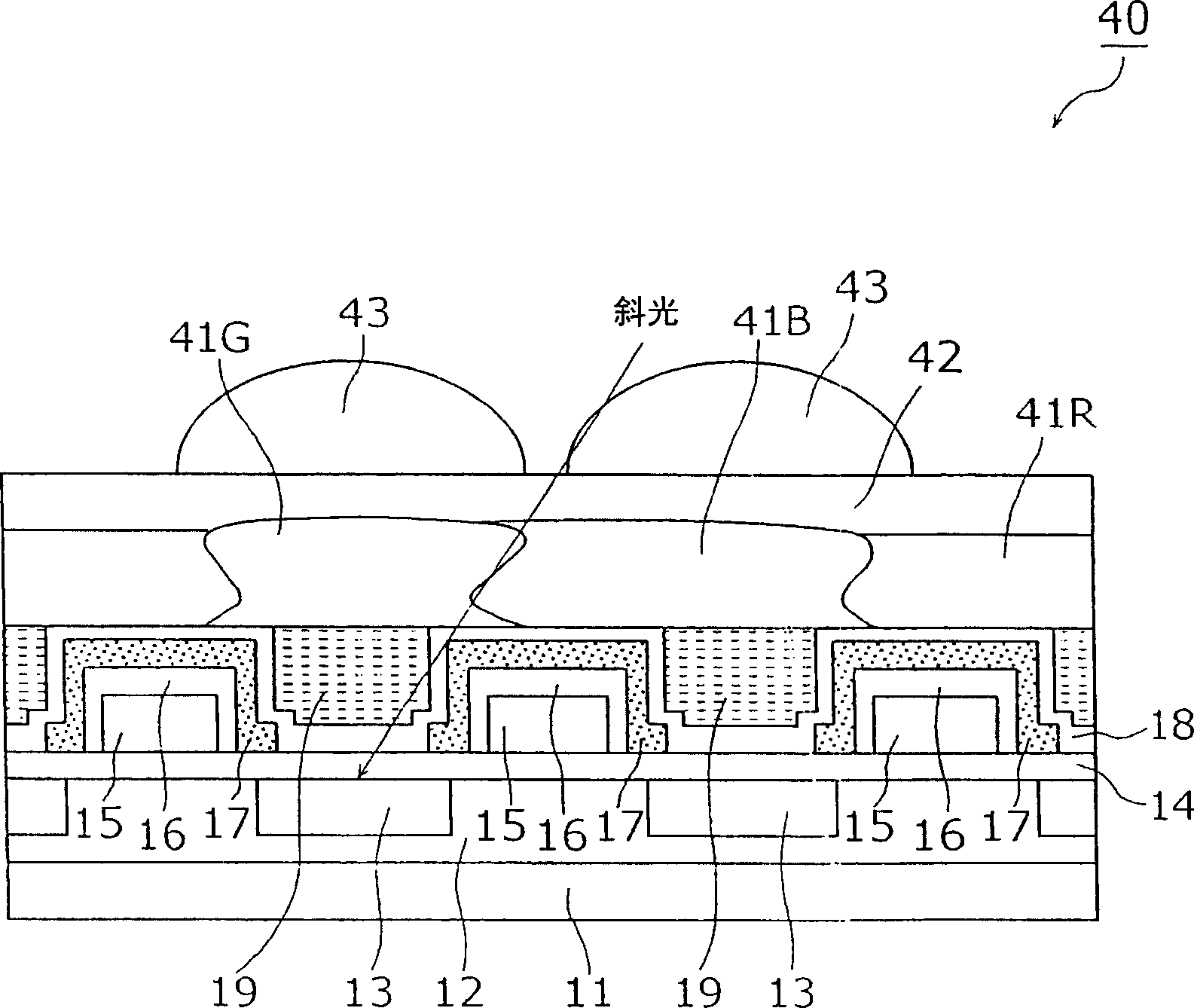

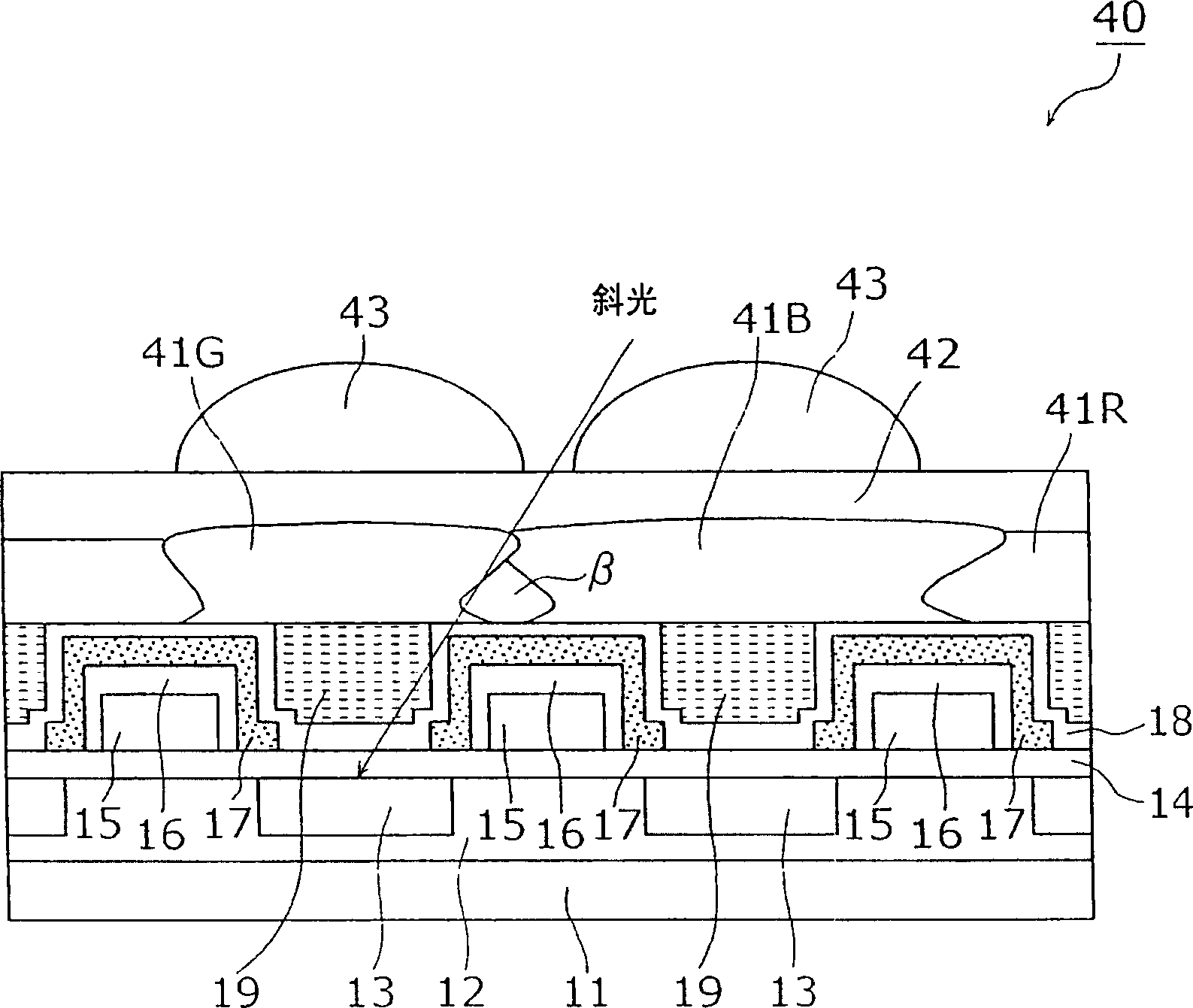

[0058] Figure 4 is a diagram showing a cross-sectional structure of a solid-state imaging device according to an embodiment of the present invention. In addition, this figure shows cross-sections of two photoelectric conversion elements.

[0059] The solid-state imaging device 1 such as Figure 4 As shown, it includes: a semiconductor substrate (N-type semiconductor substrate) 11 of the first conductivity type (for example, N type), a first semiconductor well (P well layer) 12 of the second conductivity type (P type), a plurality of Photoelectric conversion element 13, gate insulating film 14, transfer electrode 15, interlayer insulating film 16, light shielding film 17, surface protection film 18, first transparent planarizing film 19, resin portion 20, color filter layer 21, second transparent flattening film Chemical film 22 and micro lens 23 etc.

[0060] On the surface of the N-type semiconductor substrate 11, a P-well layer 12 having characteristics opposite to those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com