Coil production method and production line thereof

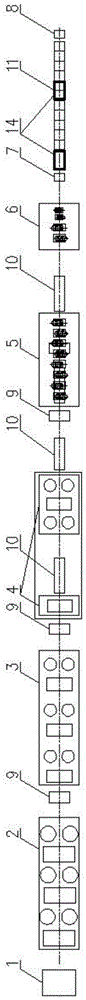

A production method and production line technology, applied in the field of coil production method and production line, can solve the problems of increased energy consumption in workshop production, increased production line length, increased construction engineering quantity, etc., so as to reduce production failure rate, reduce cooling line length, The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The production process of threaded steel bar is as follows:

[0052] (1) Heating: The billet is heated to 1000±50°C in a walking beam heating furnace.

[0053] (2) Rough rolling and intermediate rolling: The rough rolling temperature of the steel billet is controlled at 1000°C to 1100°C. During rolling, there are guides at the front and back of each rolling mill, and flying shears are installed behind the rough and intermediate rolling units. The billet is cut, and the elongation coefficient of each pass is controlled to be 1.25 to 1.3 during the rough rolling process; the temperature is controlled to ensure the reduction of the rough and medium rolling passes, and rolling within this temperature range can realize repeated recrystallization rolling , is conducive to the refinement of austenite grains, and can also reduce the loss of rolls in the rough and medium rolling units and improve the utilization rate.

[0054] (3) Pre-finishing and finishing rolling: after comp...

Embodiment 2

[0061] The production process of high-quality steel coils is as follows:

[0062] (1) Heating: The billet is heated to 1000°C to 1200°C in a walking beam heating furnace.

[0063] (2) Rough rolling and intermediate rolling: The rough rolling temperature of the steel billet is controlled at 950°C to 1150°C. During rolling, there are guides at the front and back of each rolling mill, and flying shears are installed behind the rough and intermediate rolling units. The billet is cut, and the elongation coefficient of each pass is controlled to be 1.2 to 1.35 during the rough rolling process, and the temperature is controlled to ensure the reduction in the rough and medium rolling passes. Rolling within this temperature range can realize repeated recrystallization rolling , is conducive to the refinement of austenite grains, and can also reduce the loss of rolls in the rough and medium rolling units and improve the utilization rate.

[0064] (3) Pre-finishing and finishing rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com