Method for solving problem of loop charging and drifting of production line of pickling-rolling coupled machine

A production line and filling technology, which is applied in the direction of rolling mill control devices, tail end control, metal rolling, etc., can solve the problems of equipment damage at the entrance section, inaccurate start time, and affecting production, so as to prevent equipment safety accidents and complete set filling Powerful functions and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described through embodiments in conjunction with the drawings.

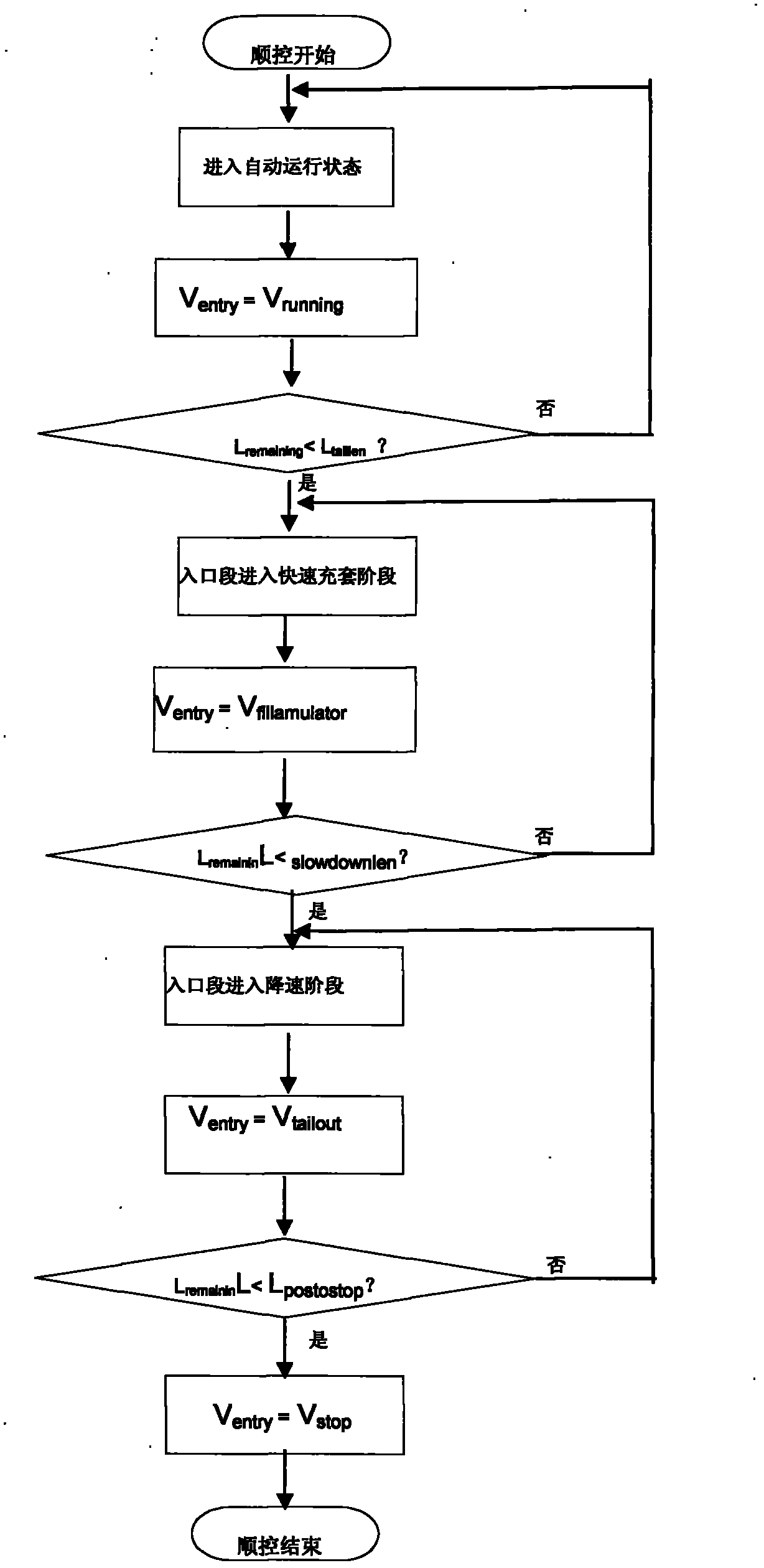

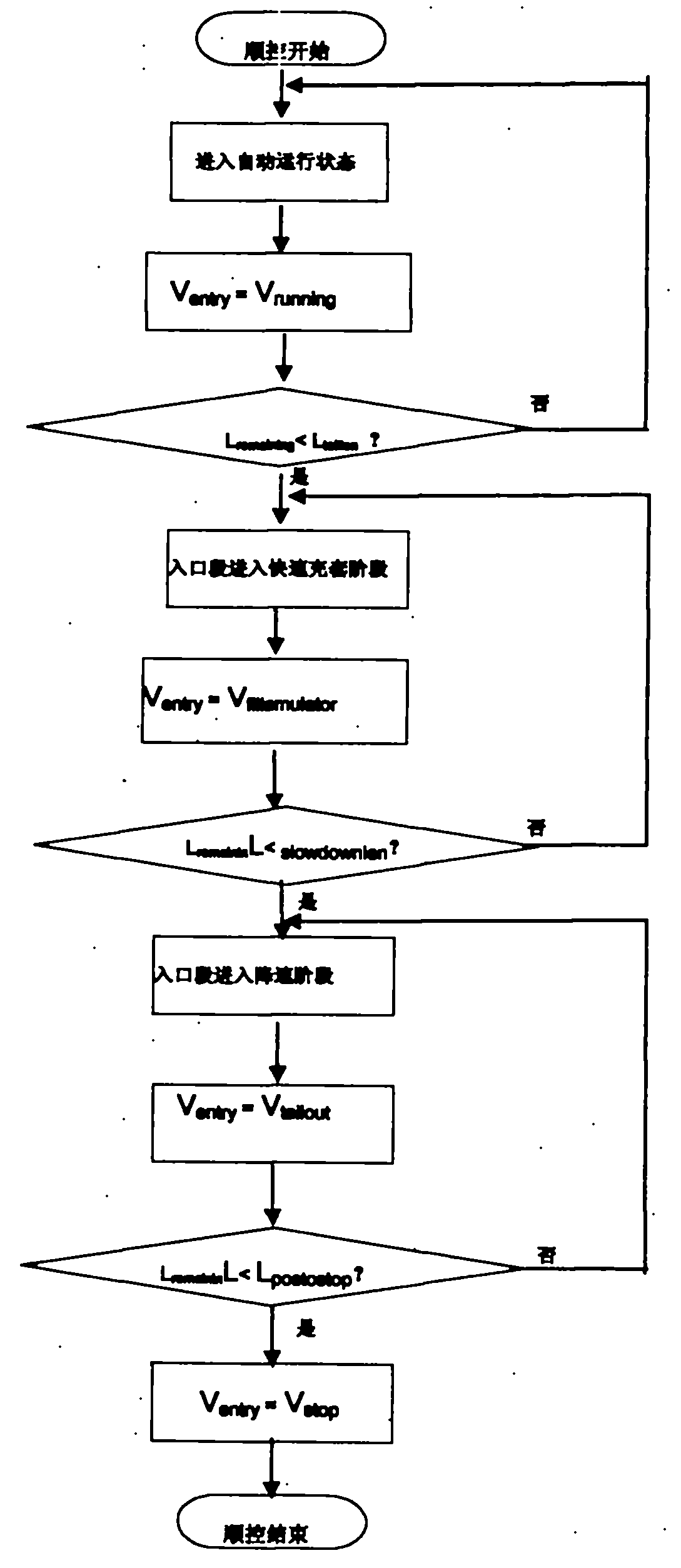

[0021] A method to solve the tail flick of the looper in the pickling rolling production line. When the inlet section enters the fast filling stage from the running stage, the control program calculates the strip length required to reduce the current speed to the tail flick speed. When the remaining strip length is less than the sum of the length required from the current speed to drop to the tail speed and the length required from the tail speed to stop, the tail speed is used as the speed setting value through the control program and the speed is controlled. The set value of the tail-flicking speed is input by the operator on the man-machine interface; after entering the tail-flicking phase, the control program uses the existing calculation method to calculate the strip length from the tail speed to the stop, when the remaining strip length on the decoiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com