Finish rolling machine strip steel threading between frames movable sleeve controlling method

A control method and inter-stand technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as lower surface scratches, reduce roll surface damage, improve strip surface quality, and reduce maintenance Effect of Repair and Spare Parts Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

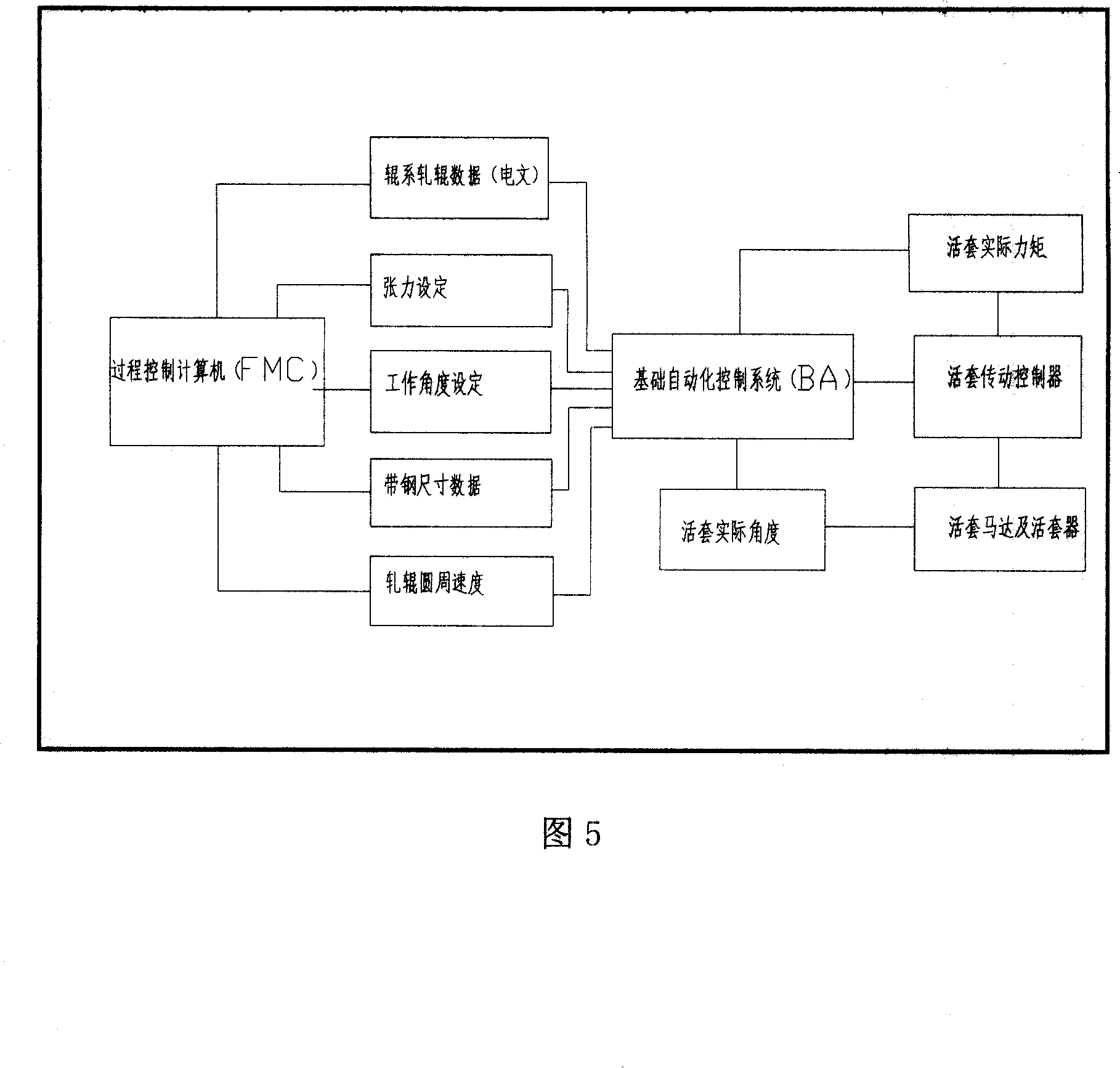

[0018] The electromechanical implementation conditions of the finishing rolling looper control method and the control method of the present invention:

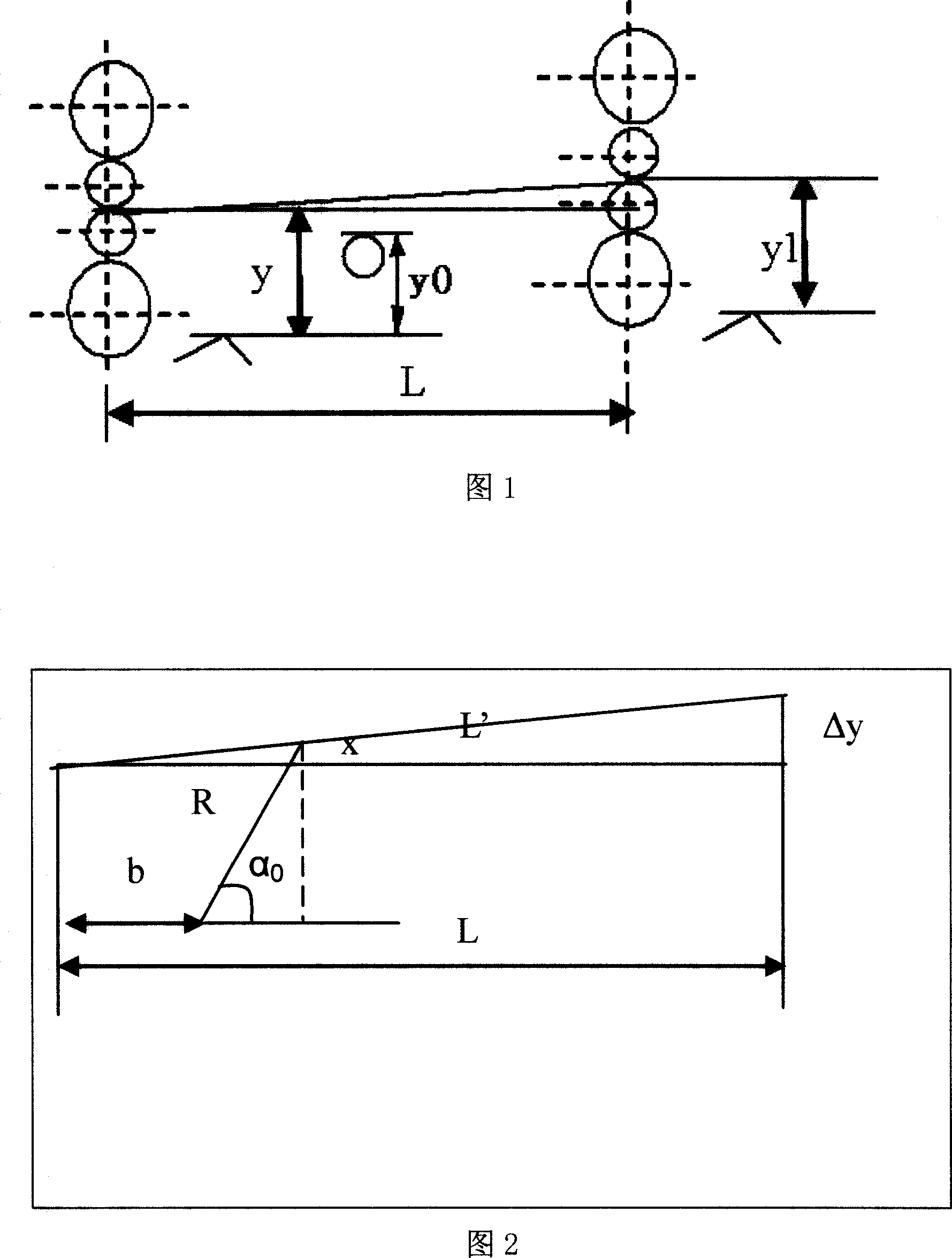

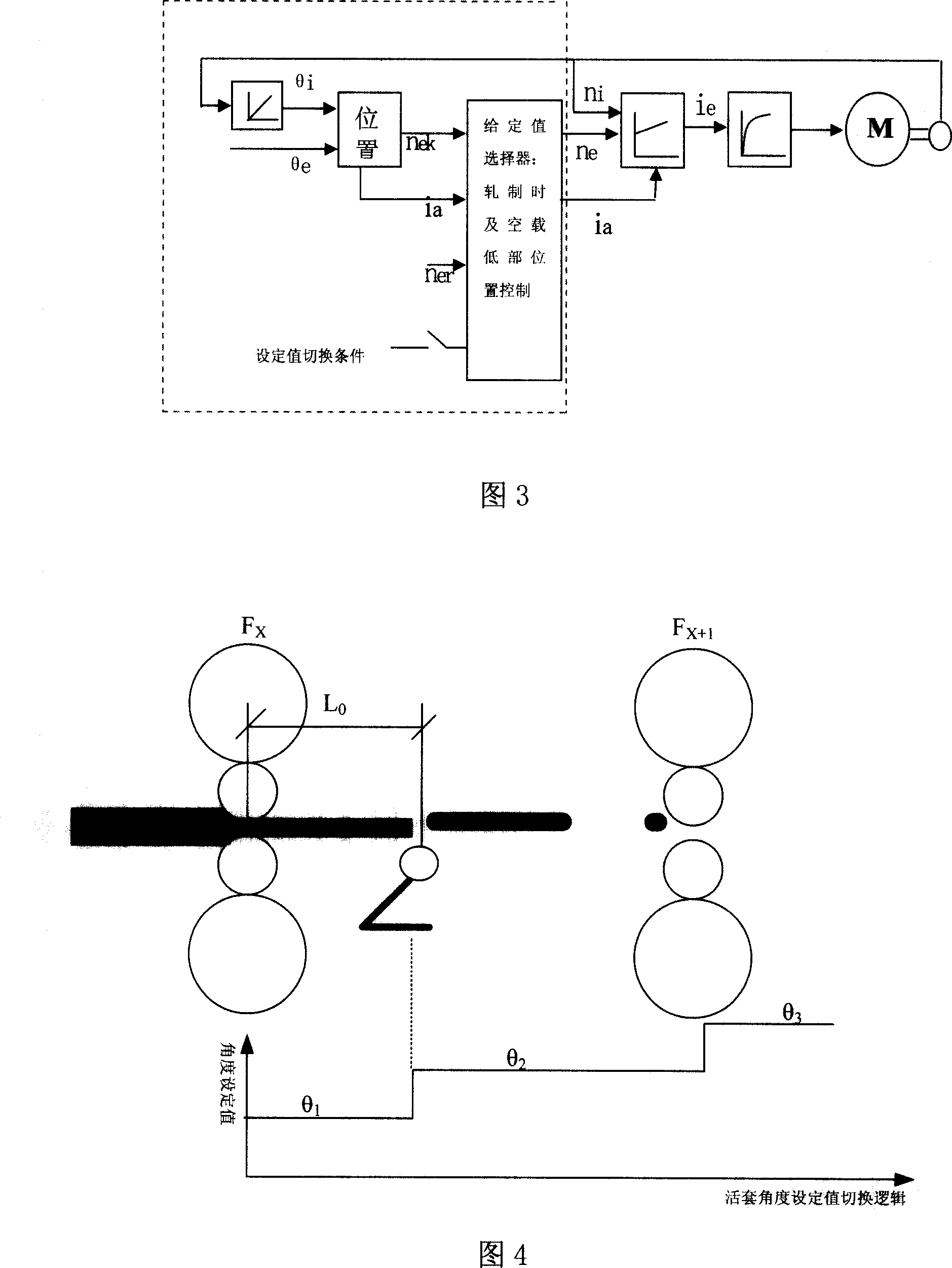

[0019] 1. Mechanical conditions: The prerequisite for the realization of the above technical scheme is to improve the lower end position on the relevant mechanical equipment, redesign the lower end position of the looper roll, and ensure that the upper busbar of the looper roll is always lower than the actual rolling line to ensure that the looper The position of the lower end of the support can be flexibly controlled according to different angle requirements.

[0020] The lower end of the looper holder of the prior art is the looper roller waiting position, and the general adjustment angle is 4°~11°. Because the lower end is subject to friction, the initial angle of the looper supporter is not easy to accurately calibrate, and the position of the lower end of the looper roll is the same as the initial angular position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com